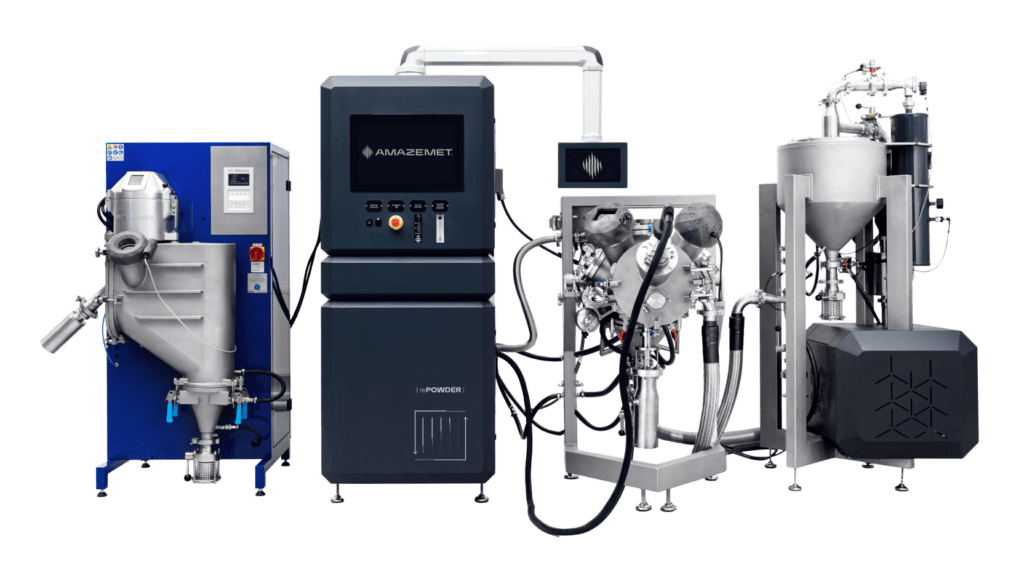

Ultrasonic powder atomizer

and alloy prototyping platform

What is rePowder used for?

Powder production

Our powder atomizer can be used to create metal powder from any alloy in any feedstock form, even in small quantities.

Read more

Alloy prototyping

Recycling

How does it work?

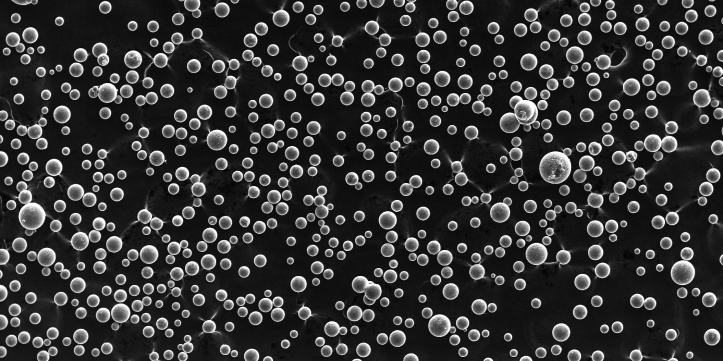

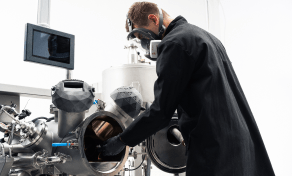

rePowder, unlike gas atomization systems, uses ultrasonic vibration for metal atomization.

Metal is poured or melted directly on the vibrating part resulting with tiny droplets being ejected from the surface.

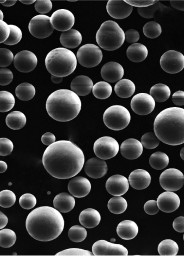

Droplets solidify in surrounding inert gas atmosphere forming powder particles.

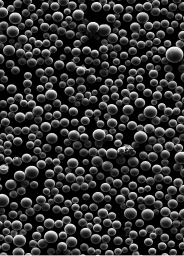

The result are highly spherical metal powders with narrow particle size distribution – up to 80% is good to use in desired processes.

Want to learn more about ultrasonic atomization?

Feedstock can be melted using either induction or arc/plasma melting.

Induction melting

ARC / PLASMA MELTING

Up to 3500 °C

Induction melting

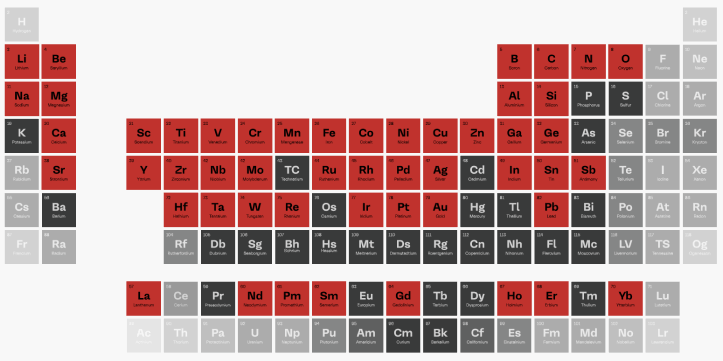

Induction melting is used to process alloys with melting points up to 1300 °C, for example:

– relatively low melting point and volatile materials that tend to evaporate in the plasma, such as Sn, Zn, Mg, Pb, and Al alloys,

– materials with high thermal capacities and conductivities, including precious metals like Cu, Ag, and Au alloys.

ARC / PLASMA MELTING

Suitable for working with all medium and high-melting materials including:

– ferrous alloys,

– Ti, Ni, Pt, Ir based alloys,

– refractory metals such as W, Ta, V, Mo, Nb, Re, etc. including High Entropy Alloys,

– metal matrix composite powders and amorphous metals.

Core benefits & features

Have any questions about our products?

Customization with possibilities of later expansion

Thanks to modular design you can choose the options that fit the needs of you and your team.

Customization with possibilities of later expansion

Thanks to modular design you can choose the options that fit the needs of you and your team.

Go to the device configurator, create your setup and ask for quotation.

Contact our specialist who will help you choose the right modules

METAL Powder production

The PSD can be modulated by using different

frequencies:

20 kHz is most suitable for electron beam melting (EBM) and direct energy deposition (DED), leading to a d50 between 60-100 pm, depending on the atomized material,

40 kHz is most suitable for LPBF technologies, leading to a d50 between 45-60 pm,

60 kHz is most suitable for binder jetting (BJ) and LPBF technologies that require PSDs narrower than those obtained with 40 kHz. AMAZEMET’s latest trials using silver alloys provided a d50 of 32-38 pm.

The elements already processed with rePowder:

Availability of both induction and arc/plasma melting allows to cover the whole range of melting temperatures from 200 °C to 3500 °C. Such feature allows to produce powder from almost any alloy composition.

Example powders created with rePowder:

AMZ4 Metalic glass

WTaVTi HEA

Ag

MgLi

PtRh

Powder production capacity of rePowder - Exact values always depend on material processed

For arc/plasma melting

For induction melting

Modules that allow to extend powder atomizer functionality

and atomization possibilities:

rePowder allows to create new alloys in several ways

Alloying in cold crucible with arc melting

Alloying on the top of the sonotrode with immediate atomization (arc melting)

Alloying in graphite crucible in induction furnace with immediate atomization

Alloying in graphite crucible in induction furnace with immediate atomization

Arc melting and suction casting (with, or without ultrasonics)

Modules useful in alloying:

Suction casting

Manipulator

Each technique can be used for various materials and allows to obtain prototype alloys in different forms, depending on further research needs.

What alloys can be created with rePowder? Basically any alloy – many materials that were atomized with

the device were first alloyed with it.

See more powders made with rePowder

recycling

rePowder uses ultrasonic vibration to create metal powder. Metal is poured or melted directly on the vibrating part resulting with tiny droplets being ejected from the surface. Droplets solidify in surrounding inert gas atmosphere forming powder particles.

Failed printouts from precious or rare materials can be turned back into powder for reuse.

Thanks to staridzed KF connections custom feeders for various forms of feedstock, e.g. chips, can be created for more efficient recycling.

POWDER ATOMIZER

& RESEARCH PLATFORM

by AMAZEMET

MORE THAN ULTRASONIC POWDER ATOMIZER

rePowder is the most flexible materials design system on the market. It allows for materials alloying, casting and powders atomization in a single setup.

The basic setup can be easily upgraded with customized options such as various feeding units or casting methods – making any material and feedstock possible to process.

INDUCTION AND PLASMA: ALLOY & ATOMIZE ANY MATERIAL

In metallurgy there are rarely methods of alloys processing that fit both Sn-based solders and refractory alloys. Arc-melting is a great method for Ta, Ti-based alloys but in contact with a plasma arc severe evaporation of volatile elements happens. The same issue is visible for ultrasonic atomization when particles fly through DC plasma arc.

With an induction based system it is easy to control chemical composition of processed alloy regardless of melting point. Our systems use both processing methods for highest R&D flexibility and the best powder quality. Feedstock for atomization can be prepared in the rePowder system without any auxiliary equipment.

RAISE YOUR POWDER QUALITY

Using rePowder you produce fine powder with excellent flowability – perfect for Additive Manufacturing and other Powder Metallurgy processes. Depending on frequency chosen d50 of the powder ranges:

– 40-60 μm for 40 kHz system,

– 80-100 μm for 20 kHz,

so no matter what the process is involved – powder suitable for AM can be produced quickly and efficiently.

For both induction and plasma-based atomisation, the process is carried out in inert gas – usually argon. Depending on research purpose reactive gases can be also used to obtain shell-core particles. With use of induction melting, processes can be carried out in vacuum as well.

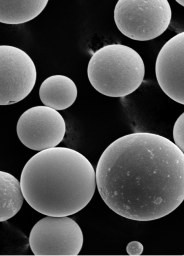

– PERFECTLY SPHERICAL PARTICLES

NO OTHER ATOMIZATION METHOD OFFERS SPHERICITY AS HIGH AS UP TO 0,98

– FREE FROM CONTAMINATION

AND CONTROLLABLE OXIDATION CONDITIONS THANKS TO AIRLOCK EQUIPPED POWDER CONTAINERS

– PRECISE ALLOYING

WITH FULL MELTING CONTROL BY SPOT-ON MELTING TIG TORCH

– PARTICLE SIZE CONTROL

THE HIGHER ULTRASONIC FREQUENCY, THE SMALLER PARTICLES

– CLEAN ENVIROMENT

10-2 MBAR or 10-5 MBAR VACUUM IN THE CHAMBER

FEEDSTOCKIN ANY SHAPE OR FORM

Failed printouts, chips, wire, rod, granulate and more – any material can be melted and atomized without prior preparation. Turn a full turbine blade from proprietary Ni-based alloy or golden earrings? We did that without any hesitation to obtain nice powder. If feedstock is in non regular shape or it is hard to control – simply cast it in rePowder and atomize it later. Special cased, automated feeder can be applied eg. for continus atomization with wire, rod or even non-spherical powder!

HOW DOES POWDER ATOMIZER WORK?

Instead of using high-velocity gas as in VIGA/EIGA equipment, rePowder uses high-intensity ultrasonic vibration to eject tiny droplets of molten metal which solidify from spherical powder. At high generality level rePowder works in the same way as ultrasonic humidifier although at way higher temperature. Velocity of the particle is very low between 100 mm/s and 250 mm/s thus it is possible to miniaturize atomization equipment without risk of spraying powder on the chamber walls. Material is molten either with induction and dips at the vibration surface or it is molten directly with plasma arc at ultrasonic unit.

CLOSED LOOP CYCLE

With the rePowder system any material is a suitable feedstock for atomization. Used together with metal 3D-printing devices it provides a closed-loop system for material processing. Oversized particles and failed prints can be atomized again, significantly reducing waste and demand for new material.

Imagine an infinite platinum or beryllium processing loop without any external supplier or subcontractor. Full material recycling can be realized in-house until all of the material is turned into a product.

THE MOST USER-FRIENDLY COMPACT POWDER ATOMIZER

– SPACE SAVER

FOOTPRINT OF JUST A FEW SQUARE METERS INCLUDING INFRASTRUCTURE

– NO CALIBRATION NEEDED

PROGRAMS FOR BASIC MATERIALS / ALLOYS ARE ALREADY INSTALLED

– EASY TO CLEAN DESIGN

SURFACES PREVENTING POWDER ADHESION TO REDUCE METAL LOSS AND CROSS-CONTAMINATION

PERFECT POWDER IN 4 EASY STEPS

– PREPARE YOUR MATERIAL

IN ANY SHAPE OR FORM – IT ONLY NEEDS TO FIT INTO CRUCIBLE

– HEAT IT

UP TO 1800ºC ALLOWING TO WORK WITH MOST NON-FERROUS METALS

– ATOMIZE

WITH PRODUCTION CAPACITY UP TO SEVERAL KG/H FOR BRONZE

– ENJOY

YOUR OWN EXTREMELY SPHERICAL POWDER WITHOUT ANY SATELLITES

ENDLESS POSSIBILITIES OF ALLOYING AND ATOMIZING

– POSSIBLE USE FOR NON-METALLIC MATERIALS WITH CERTAIN FLUIDITY

– CUSTOM ALLOY CREATION POSSIBILITY

– ALLOYING WITH GOOD STIRRING AND MIXING EFFECT

– BATCHES DOWN TO 100G FINANCIALLY VIABLE

– CONTROLLABLE ATMOSPHERE AND MELTING UNDER VACUUM

– YIELD-INCREASING ULTRASONIC TECHNOLOGY

OTHER FEATURES

– PREVENTION OF MATERIAL LOSS

and inaccuracy of alloy chemistry due to precise control of melting temperature via crucible based induction heating system, while evaporation of alloy ingredients like Zn or Cr is a common issue during plasma-assisted atomization.

– MAXIMUM VERSATILITY

by using the machine for granulating or ingot casting as an option.

– ANTI-OXIDATION FEATURES

As all AU series machines offer the possibility of oxidation-free processing in the closed-chamber machine by means of de-gassing, vacuum and protective gas features. Oxygen sensor values below 0.5 ppm can be achieved reproducibly.

– NO SOPHISTICATED AND EXPENSIVE FILTER REQUIRED

for evaporated alloy ingredients otherwise caused by plasma melting.

– A DESIGN FOR EASY HANDLING & CLEANING, QUICK ALLOY CHANGE WITH MINIMUM CROSS CONTAMINATION

The user-oriented and modular structure of the systems ensures optimum accessibility for all work as well as for inspection and maintenance. This construction principle also ensures short installation and training periods.

– LARGER VERSION OFFERING A CRUCIBLE VOLUME OF 1.5 L IN DEVELOPMENT!

Get your own special

metal powders

Find out about the possibility of powder samples of your own composition.

Leave a message and our application engineer will contact you within 3 working days.