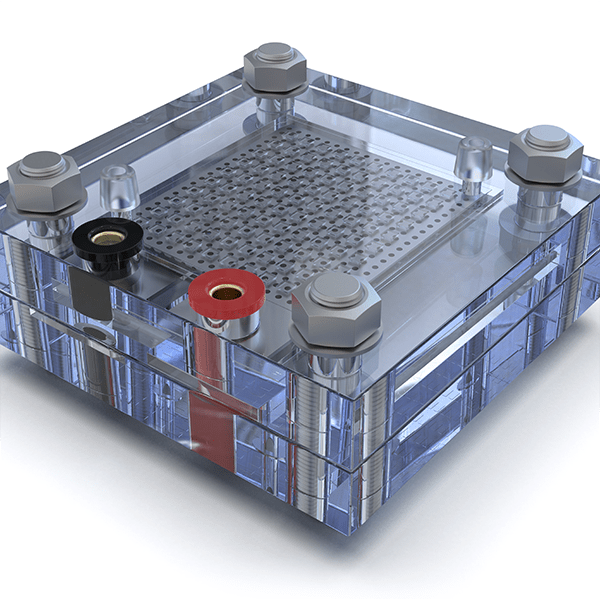

Compact high vacuum

furnace

Compact high vacuum

furnace

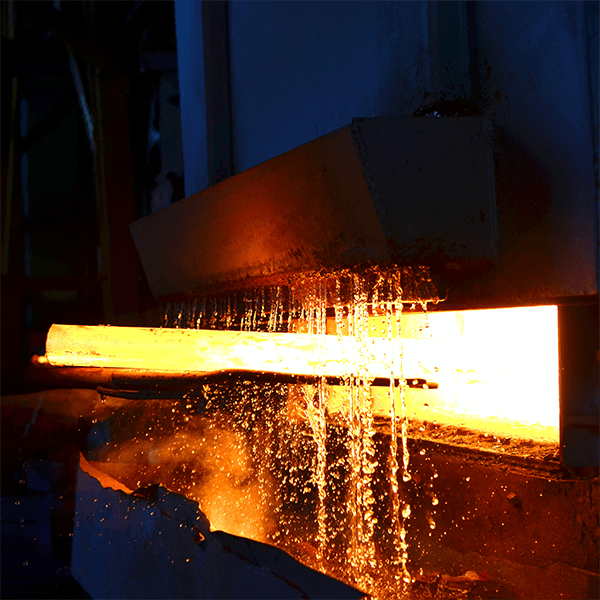

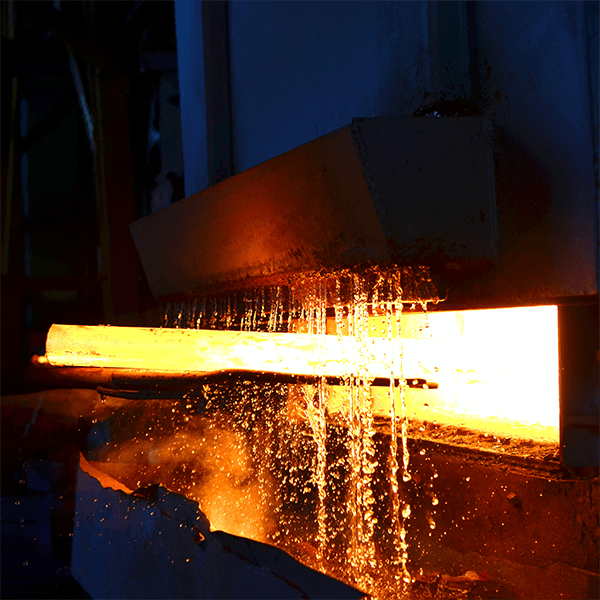

Distortion is one of the main problems encountered in AM processes. Proper heat treatment is, therefore, crucial for obtaining high-quality products. High-vacuum furnaces provides reliable heat treatment conditions in every process.

Apart from metal 3D printing post-processing, vacuum furnace is an obligatory equipment in many scientific and industrial laboratories. Vacuum furnace applications include:

Learn more about vacuum furnace technology and applications

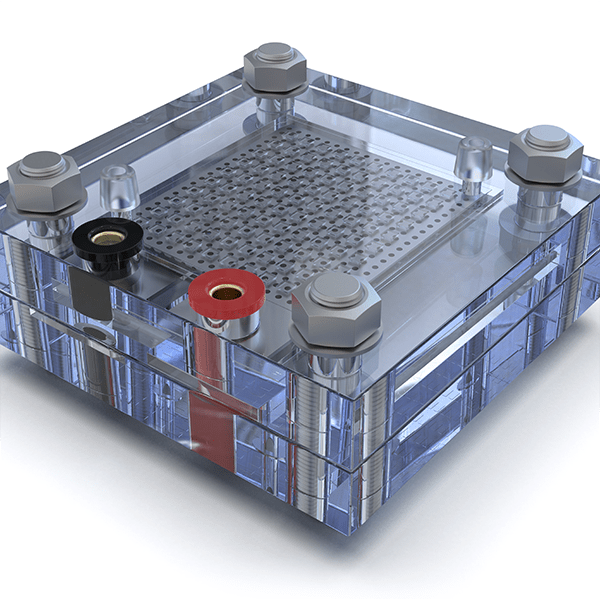

Core benefits & features

Hot zone specification

Hot zone materials – heaters and thermal screens – vary depending on the maximum furnace temperature requirements:

1200 °C: molybdenum heaters and thermal screens. Processing example: stress relief in Ti-based alloys

1600 °C: tantalum heaters and tungsten thermal screens. Processing example: sintering of refractory alloys

For both temperature options there are two hot zone sizes available:

Φ120 mm x 100 mm height – compatible with small build plate 3D printers,

Φ200 mm x 200 mm height – compatible with popular medium-sized build plate 3D printers.

In all setups, hot zone vacuum down to 10-2 mbar is reached with the preliminary pump. Then, the high-vacuum pump takes over to reach vacuum levels of 2×10−7 mbar (with a turbomolecular pump) or 3×10−9 mbar (with an ionization pump).

Choose the setup for your needs

inFurner features various hot zone dimensions compatible with popular printers, and options that allow to expand furnace possibilities.

Learn more about our projects and collaborations

Contact our specialist who will help you choose the right options with respect to your needs

impact of vacuum heat

treatment on your parts

Contact us to find out about possibility of sample heat treatment of your part.

Leave a message and our application engineer will contact you within 3 working days.

HIGH VACUUM FURNACE

by AMAZEMET

COMPACT SOLUTION FOR EVERY LABORATORY

ALL PERIPHERALDEVICES ENCLOSED IN ONE, DESK-SIZED CASING

FURNACE EXACTLY AS YOU NEED IT

– HOT ZONE DIMENSIONS MAY VARY FROM 120 TO 200 mm IN DIAMETER AND FROM 100 TO 200 mm IN HEIGHT

– YOU CAN CHOOSE BETWEEN HEATING PARTS MADE OF MOLYBDENUM, TANTALUM OR TUNGSTEN, ALLOWING TEMPERATURE TO REACH 1600 ºC WITH ΔT<2 ºC

– FURNACE IS READY TO FEATURE EITHER DIFFUSION, TURBOMOLECULAR OR ION VACUUM PUMP PROVIDING PRESSURES RANGING FROM 3×10-5 to 3×10-9 mbar

EVERYTHING UNDER CONTROL ANYWHERE YOU ARE

– PROGRAMMABLE CUSTOM HEAT TREATMENT CYCLES

– FURNACE CONTROL VIA TOUCH PANEL

– PROCESS PARAMETERS SELF-MONITORING FOR SAFETY PURPOSES

– ON-LINE DATA TRANSFER

– PROCESS RECORDING

AVAILABLE SETUPS AND FEATURES

HEATING SYSTEM

– Molybdenum (Max. temp. 1200 °C)

– Tantalum (Max. temp. 1600 °C)

PROCESS GAS SYSTEM

– High Pressure Gas Quenching (HPGQ) up to 100 [°C/min]

– Available gases: Ar; He

– Mass flow controller (Ar)

– Gas flow maintenance in the working chamber

FURNACE INSTRUMENTATION

– Electronic display of furnace parameters:

– Pressure

– Temperature

– Valves’ position status

– Furnace devices’ status

– Residual oxygen sensor

VACUUM

Low

– Oil rotary vane pump – 3×10-3 [mbar]

– Dry scroll pump – 7×10-3 [mbar] – e.g. for treatment of semiconductors

High

– Diffusion pump – 3×10-6 [mbar] with LN2 cooling up to 8×10-8 [mbar]

– Turbomolecular pump – 9×10-8 [mbar]

– Ion pump – 3×10-9 [mbar] – for treatment of semiconductors

COOLING

– Water cooler – 4,6 kW

– Water chiller – 3 / 10,4 / 28 kW

– Liquid nitrogen for diffusion pump

PROCESS MANAGEMENT

– Control panel

– Process recording

– Remote access to the furnace parameters