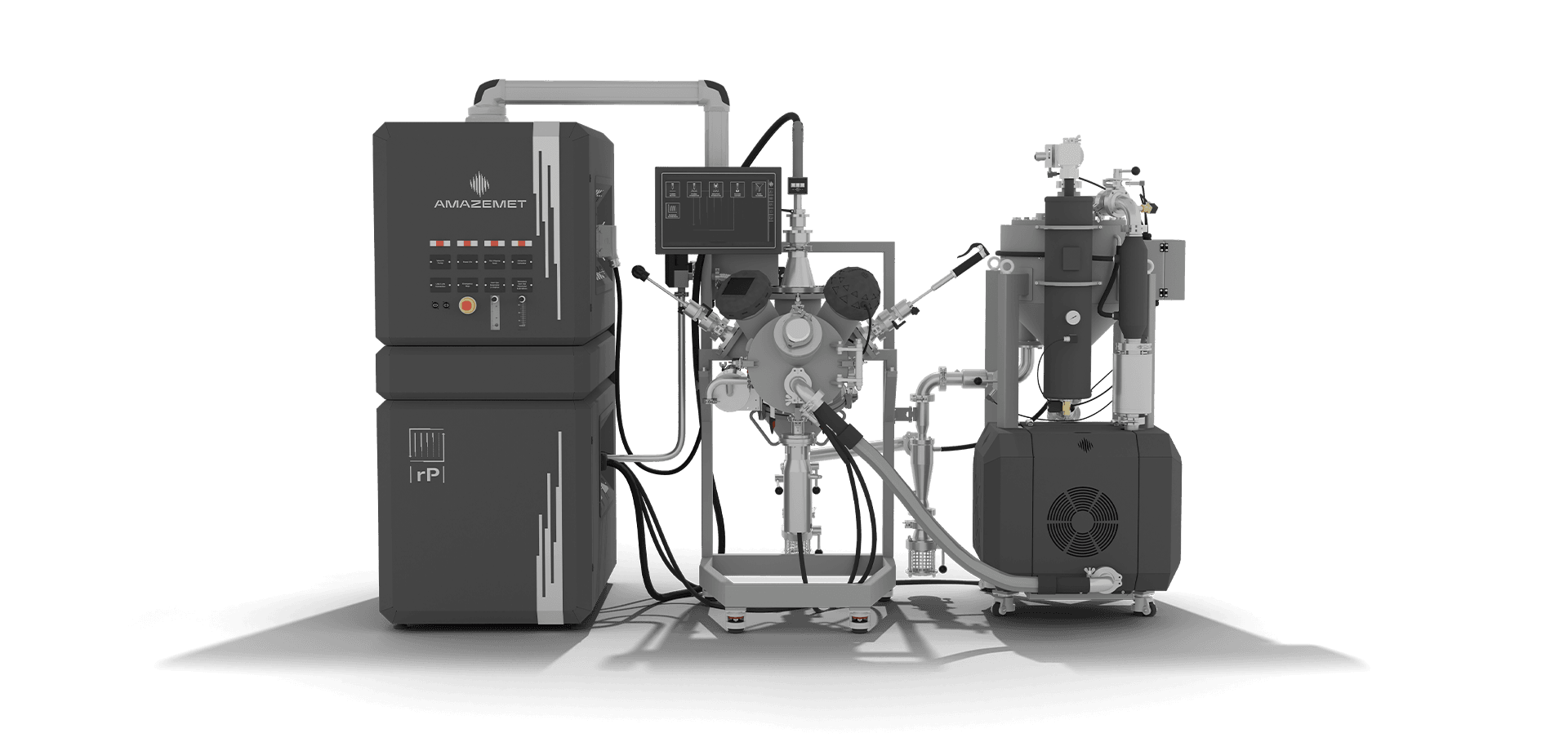

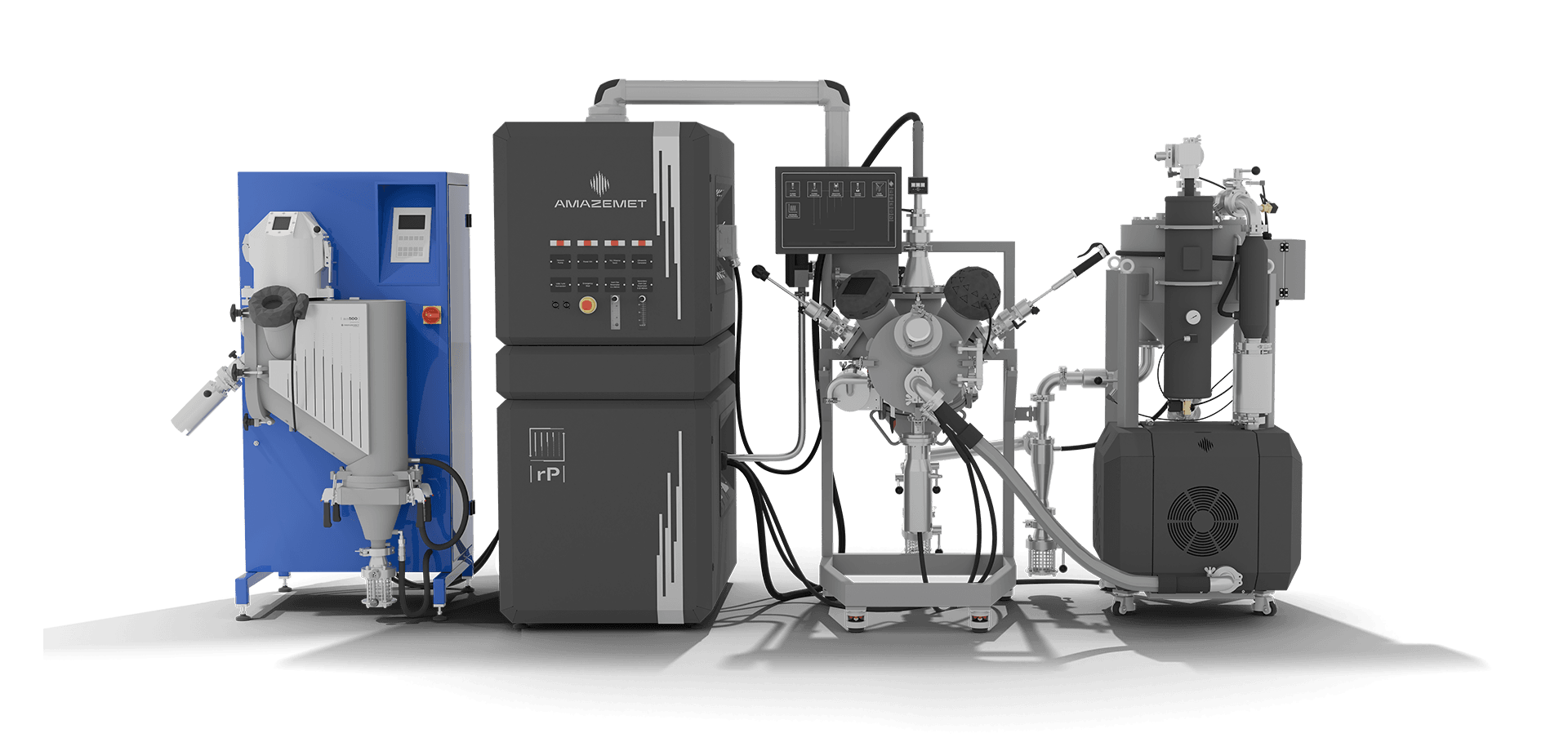

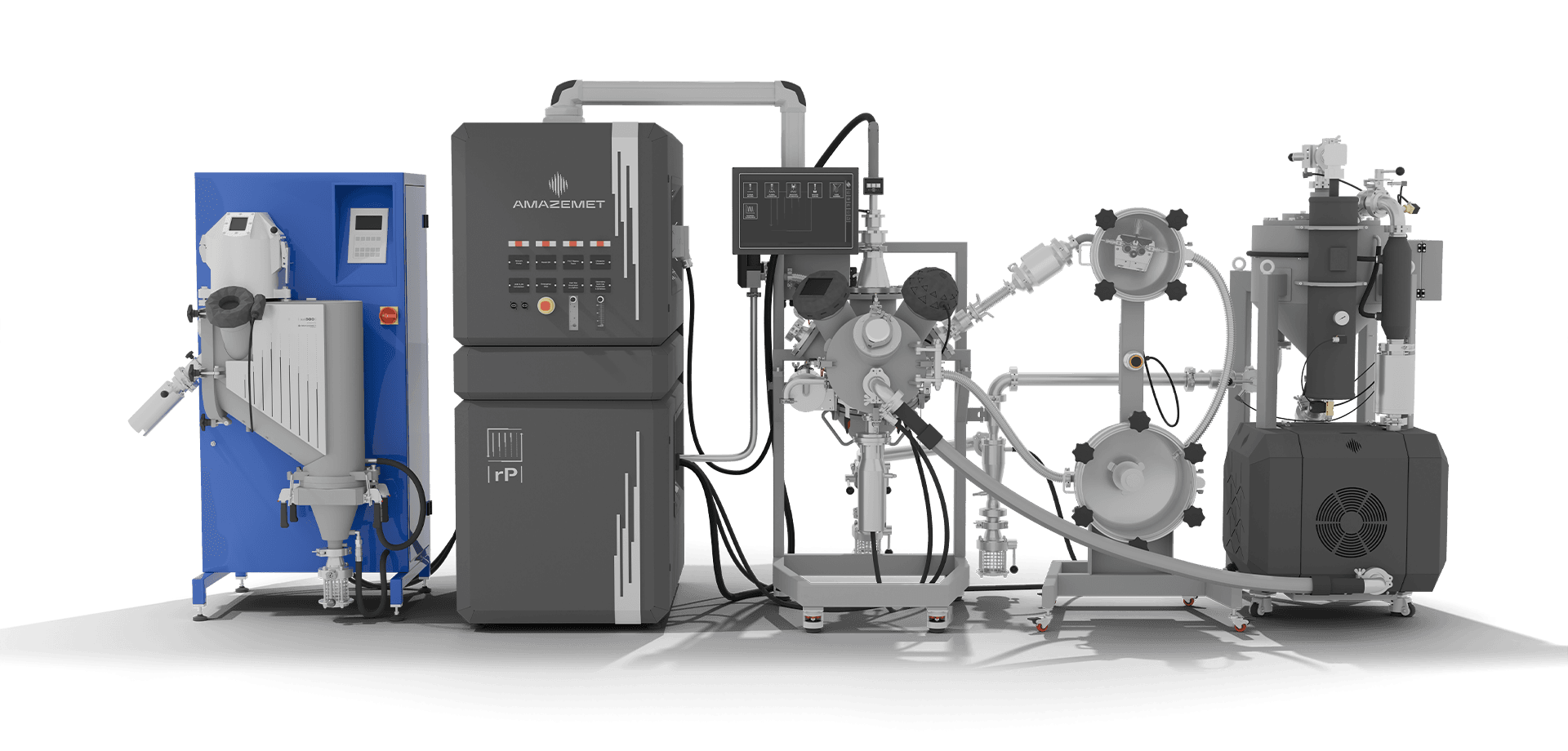

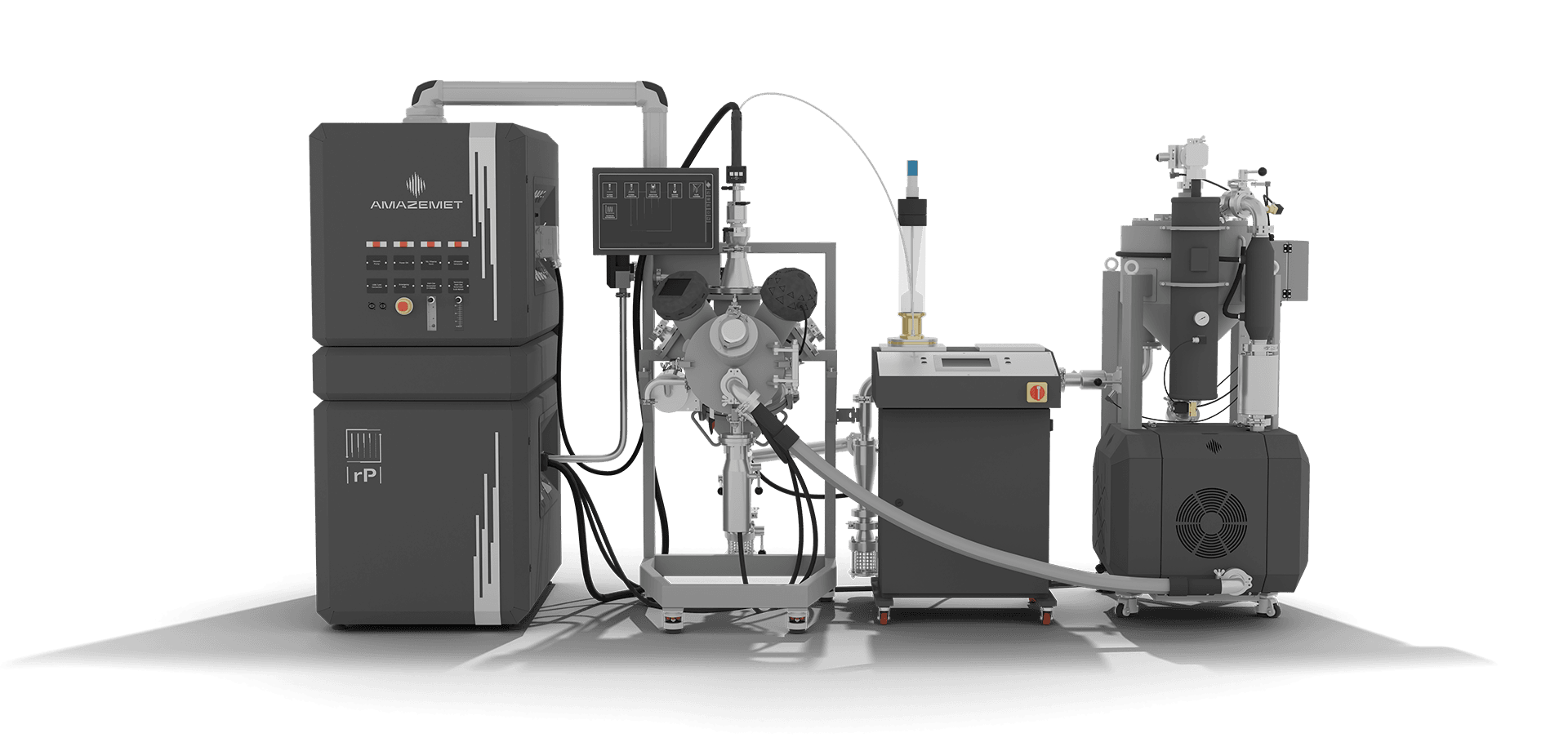

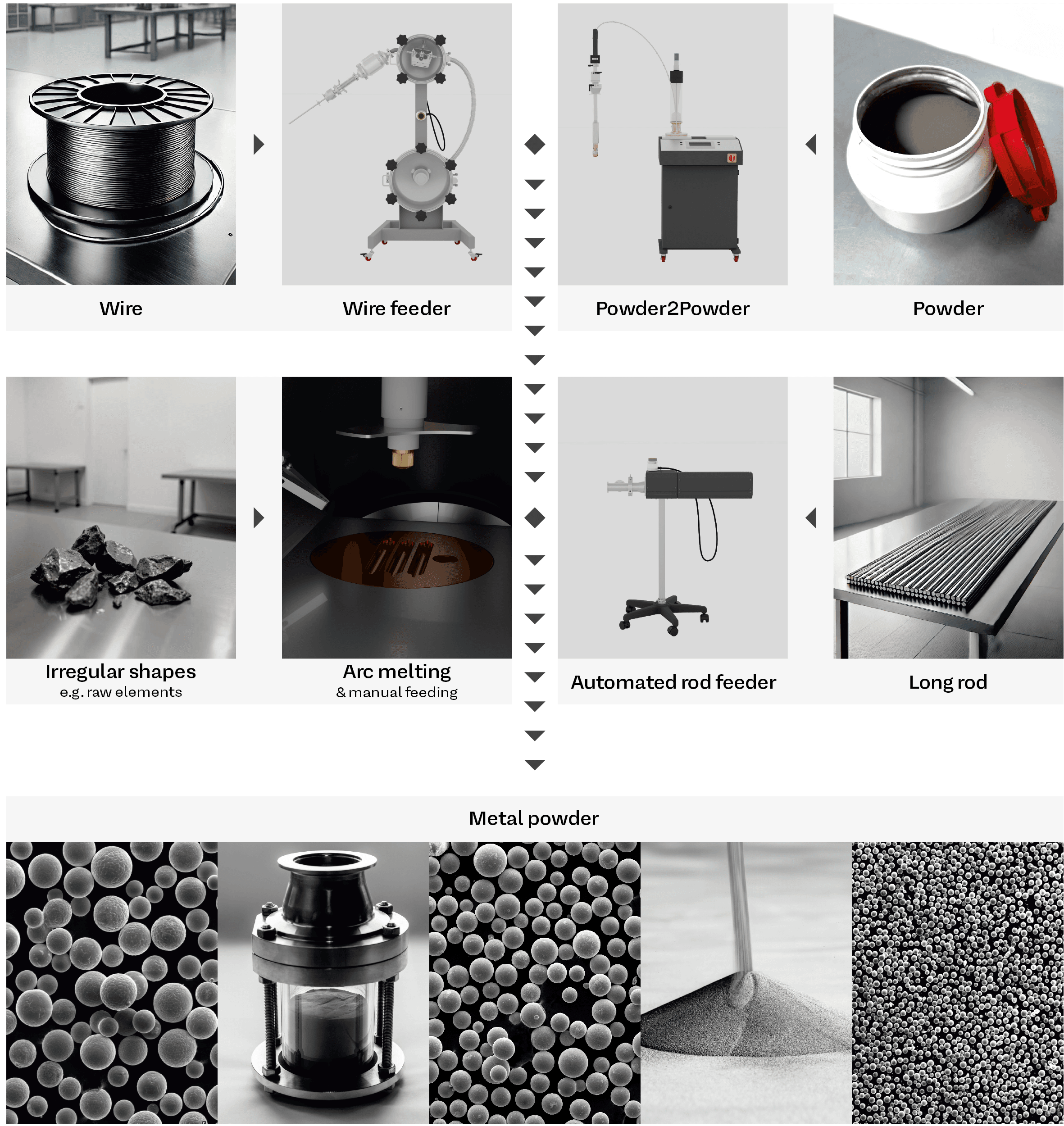

Discover some of the predefined versions of the device:

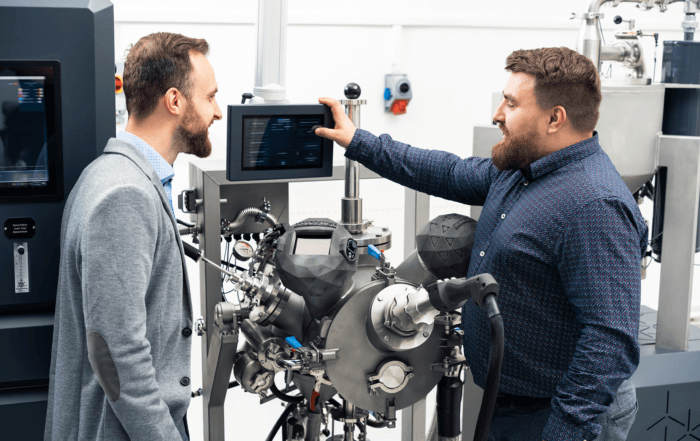

rePOWDER – MORE THAN ULTRASONIC ATOMIZER

Our ultrasonic atomizer can be used to create metal powder from any alloy in any feedstock form, even in small quantities. What is more, raw elements or scrap materials can be used to prototype new alloying systems in form of cast or powder. Last but not least, failed printouts, unused powder, scrap or waste powder from other processes, thanks to rePOWDER, can be turned back into fine powder.

With this abilities, rePOWDER stands out as the most versatile atomizer available on the market.

HOW IT WORKS?

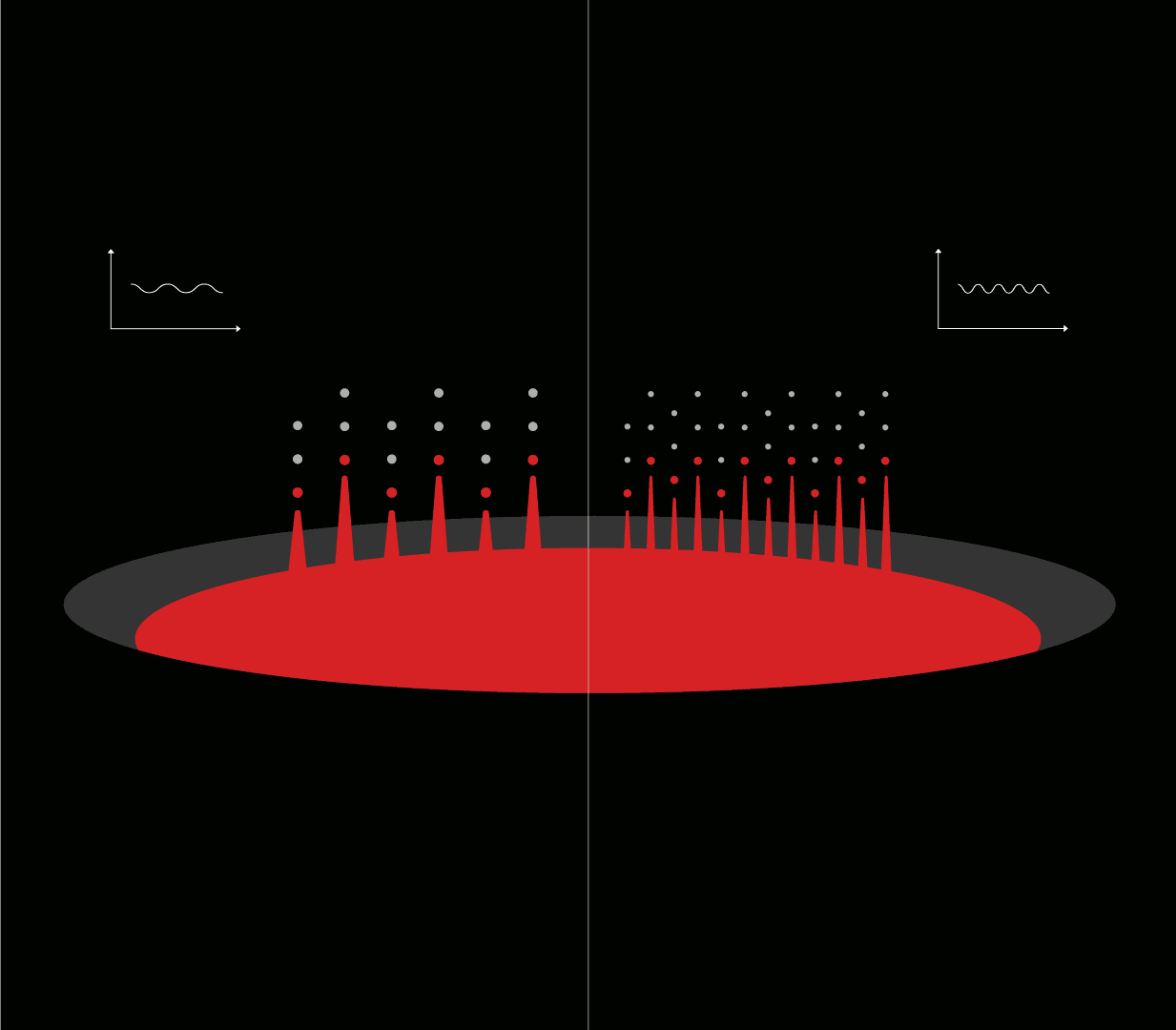

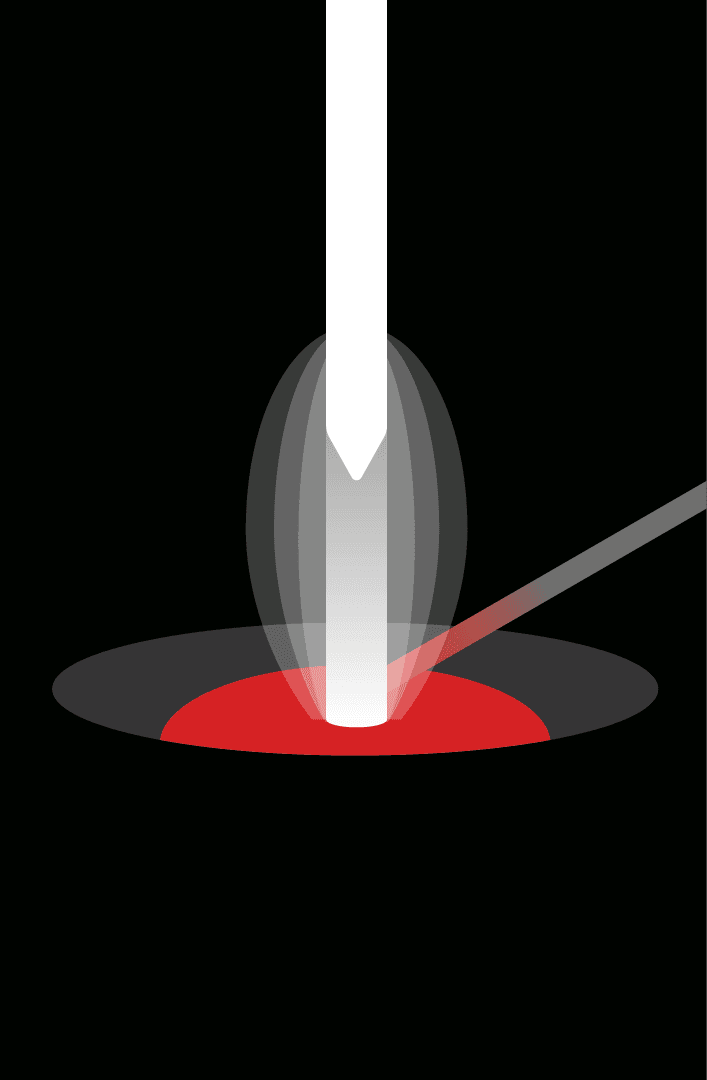

Ultrasonic atomization is a liquid-to-solid type of process, where ultrasonic vibrations are used to create powders. The main principles of this technology are based on amplitude and surface wettability. When the threshold vibrational amplitude in the liquid layer wetted to the sonotrode is exceeded, standing capillary waves are generated (Lierke et al., 1967). Further increasing the amplitude disrupts the internal forces of the liquid, thereby ejecting small droplets from the melt.

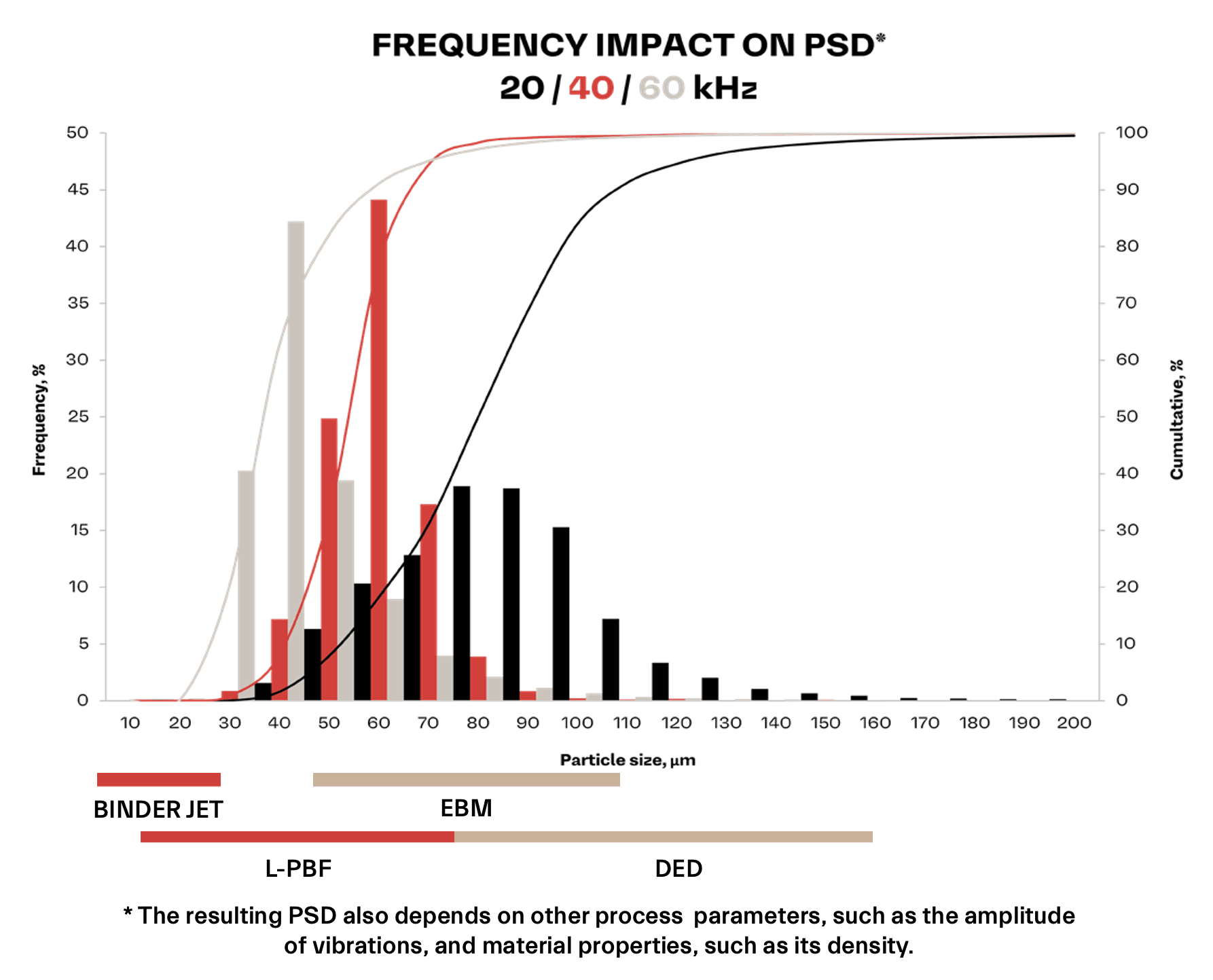

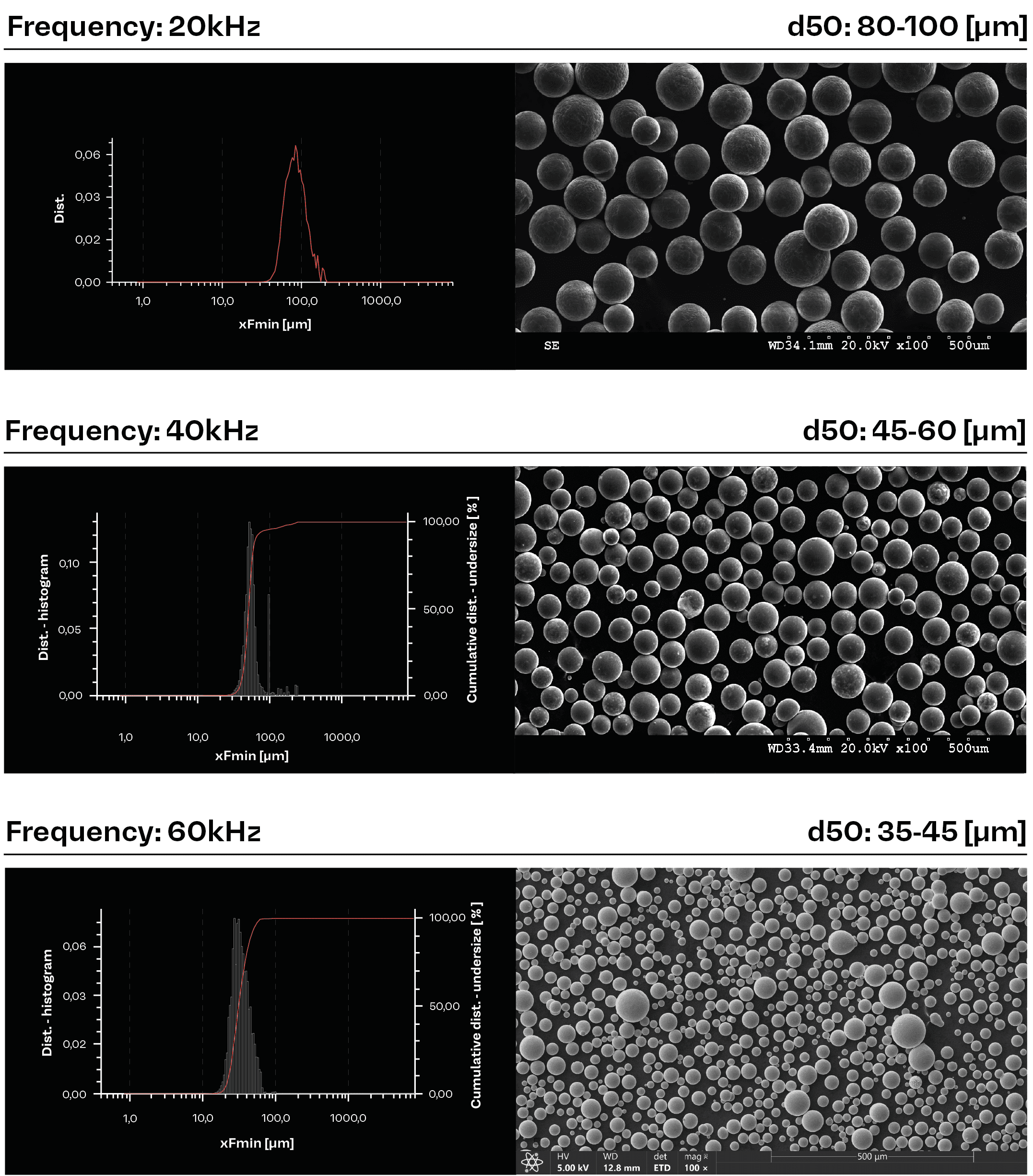

FREQEUNCY VS PARTICLE SIZE

The size of the produced particles depends primarily on the ultrasonic frequency, although it is also influenced by the physical properties of the liquid material like density.

The resulting narrow particle size distribution (PSD) allows up to 80% of the manufactured powder to be used for dedicated technology.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

From any feedstock

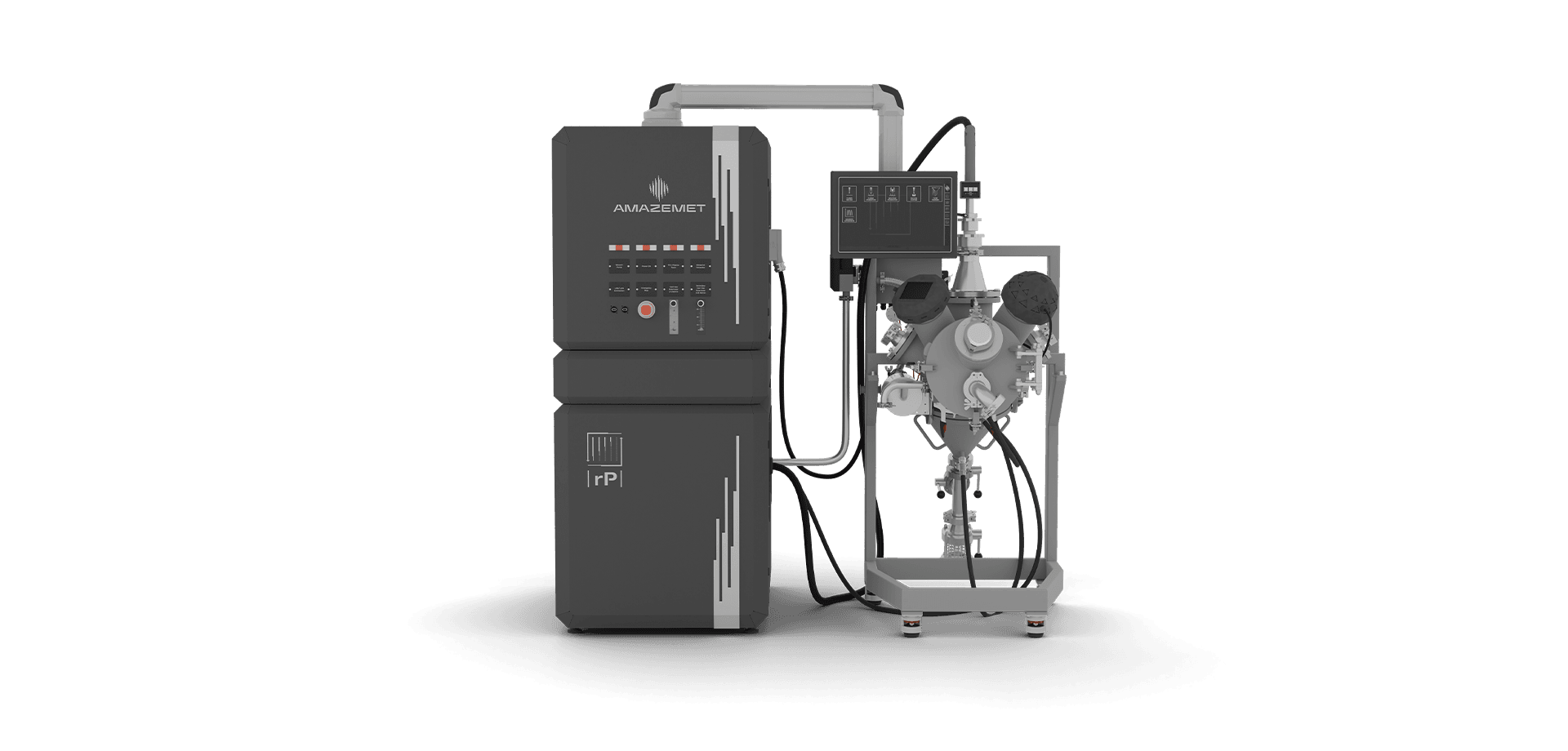

rePOWDER

ultrasonic atomizer

To desired powder

Powder quality: Flowability (hall flow): 4-5 g/s

Morphology: Sphericity (aspect ratio): d50 > 0.90

2 types of heat source

| Induction Melting |

Induction Melting is usually used to process alloys with melting points up to 1300 °C, for example:

The material in any shape and form can be placed into the crucible, including final alloy, master alloys, or pure elements.

All materials are easily alloyed thanks to the magnetic stirring effect.

| Arc / Plasma melting |

Heating can be carried under an inert or reactive gas atmosphere using an electric arc (TIG generator) or focused plasma. Material is fed and melted directly to the top of the sonotrode. It is crucial to have an appropriate sonotrode material with good wettability to the melted material to achieve an efficient atomization process and minimize the possibility of contamination.

Suitable for working with all medium and high-melting materials including:

Availability of both induction and arc/plasma melting allows to cover the whole range of melting temperatures from 200 °C to 3500 °C. Such feature allows to produce powder from almost any alloy composition. This periodic tables shows the elements already processed with rePowder.

The rePowder ultrasonic metal atomizer and alloy prototyping platform combines versatility, efficiency, and innovation, offering a seamless solution for material research and production. Discover some of the most beneficial features of our device.

Processing of any elements or alloys

Ultrasonic atomization can be carried out on a wide range of pure elements (e.g., Zn, Mg to Pt, Mo, Ta), as well as any alloy composition (e.g., Mg-Li, CuSn6, TiTaZrRuCu, MoRe).

Any form of feedstock

The ability to atomize chips, failed AM prints, damaged samples, rods, wire, powder, and more.

Automated operation

A variety of automated feeders (e.g. powder, rod, wire) and automated plasma torch to make the operation as easy as possible.

Modularity and openness

The rePowder platform has a modular design. New modules can be added at any time. All connections in the device follow current standards (e.g., ISO-KF), so each customer can create and connect their modules as needed.

One device – many possibilities

The rePowder platform was designed to enable many different types of processes to be performed using a single device, including the preparation of a new composition, alloy homogenization, ultrasonic atomization, suction casting, and further options in development.

Multiple alloys in one day

The device is laboratory-scale, easy to clean, and allows for rapid material changeover. Several atomization processes can be carried out for different alloys on different ultrasonic systems in the course of one day.

Multiple applications

The obtained powder can be used in a variety of technologies, including additive manufacturing, sintering, thermal spraying, catalysis etc.

Recycling

The device allows reprocessing of printed parts or scraps material into powder for further use in the desired application.

Low maintenance costs

The device uses minimal amounts of noble gases (~10 L/min). The cost of a single atomization process is minuscule.

Various capacities depending on specific needs

The ability to produce powder from a few grams (e.g. for small amounts of an alloy or rare and expensive elements) up to several kg per day (when processing wire material or using induction module).

STRONG FOUNDATION OF OUR SOLUTIONS

Strong Patents Behind AMAZEMET’s Technology

Our solutions, including the groundbreaking rePOWDER ultrasonic atomizer, are based on patented technology, which protects their uniqueness and reliability. Our portfolio of over 12 patents worldwide, continues to solidify our position at the forefront of technology. By securing intellectual property, we provide our clients with innovative and trusted technologies that drive progress in industries such as additive manufacturing, powder metallurgy, recycling and more.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. Explore some of our key partnerships with industry leaders and innovators driving progress in additive manufacturing and materials science.

Freemelt ONE & AMAZEMET’s rePOWDER Ultrasonic Atomizer

Colibrium Additive at Formnext 2024 | Jose Greses Exclusively For AMAZEMET

TU Darmstadt & AMAZEMET Magnetocalorics Research

AMAZEMET & f3nice | Matteo Vanazzi | Sustainable Innovation with rePOWDER

COLLABORATION

OUR SCIENTIFIC PARTNERS

Our collaborations drive innovation and push the boundaries of materials science. Meet AMAZEMET’s trusted academic partners who play a key role in advancing our research and technological developments. Together, we shape the future of additive manufacturing and beyond.

Frequently asked questions

Find answers to the most commonly asked questions about rePOWDER. If you can’t find the information you’re looking for, feel free to contact us directly.