From custom powders to 3D printed metal part | Application note

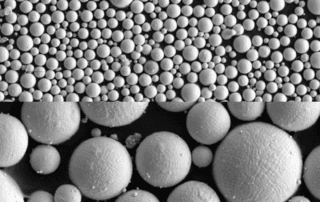

Ultrasonic atomization, featuring the rePOWDER system, addresses the challenge of high-cost precious metal powder production for additive manufacturing. This technology efficiently processes small batches of materials like silver, gold, and PGMs, yielding high-quality, spherical powders with excellent flowability and remarkable material recovery.

In-situ alloy homogenization from raw elements | Application note

Create custom FeCrAlY alloys from raw elements as spherical powder for research or CSP. Discover in-situ alloy homogenization with rePOWDER.

Low volume production of superalloy powders | Application note

Produce spherical superalloy powders from just 10g of feedstock. Explore low-volume, high-value Pt-based powder production with rePOWDER.

Bioresorbable metal powders for additive manufacturing | Application note

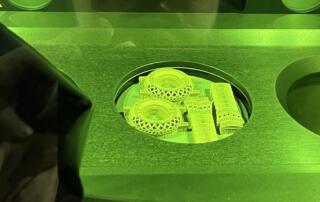

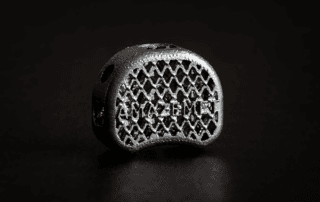

Bioresorbable metal powders enable implants that safely degrade in the body, offering major benefits for biomedical applications. In the 3D-BioMg project, AMAZEMET develops spherical magnesium-based powders to support next-generation implant design.

From custom powders to 3D printed metal part | Application note

Develop custom alloy powders for additive manufacturing to achieve better performance, lower waste, and enable new 3D-printed metal parts.