GROWING LIST OF OUR PUBLICATIONS

In AMAZEMET we are committed to the dissemination of groundbreaking research in advanced materials, metallurgical engineering and additive manufacturing. Our publications include scholarly articles that delve deep into a range of topics and offers unique insights into cutting-edge methodologies. We take pride in fueling the curiosity of researchers and practitioners alike, fostering an environment conducive to learning, discovery, and the broadening of intellectual horizons.

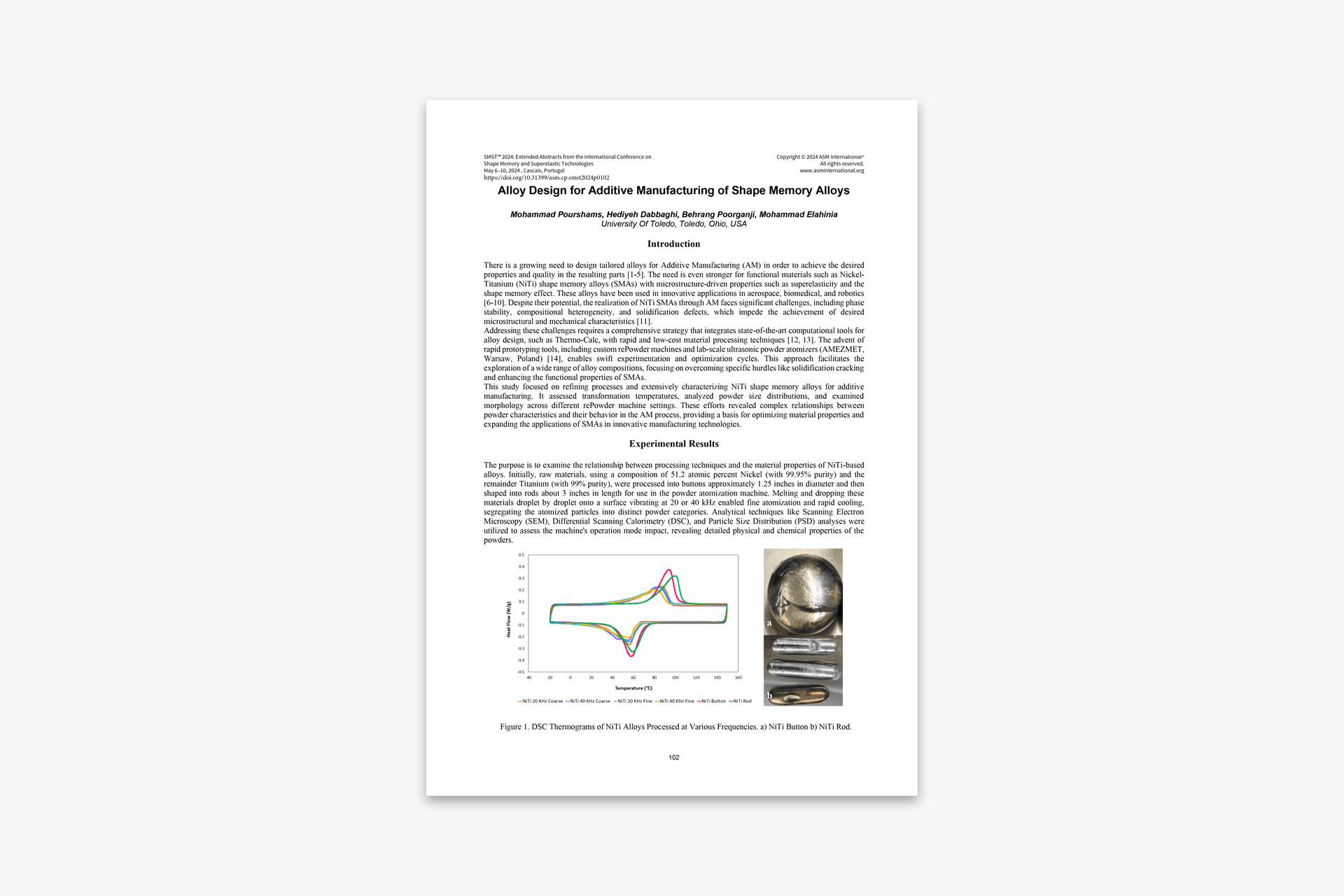

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

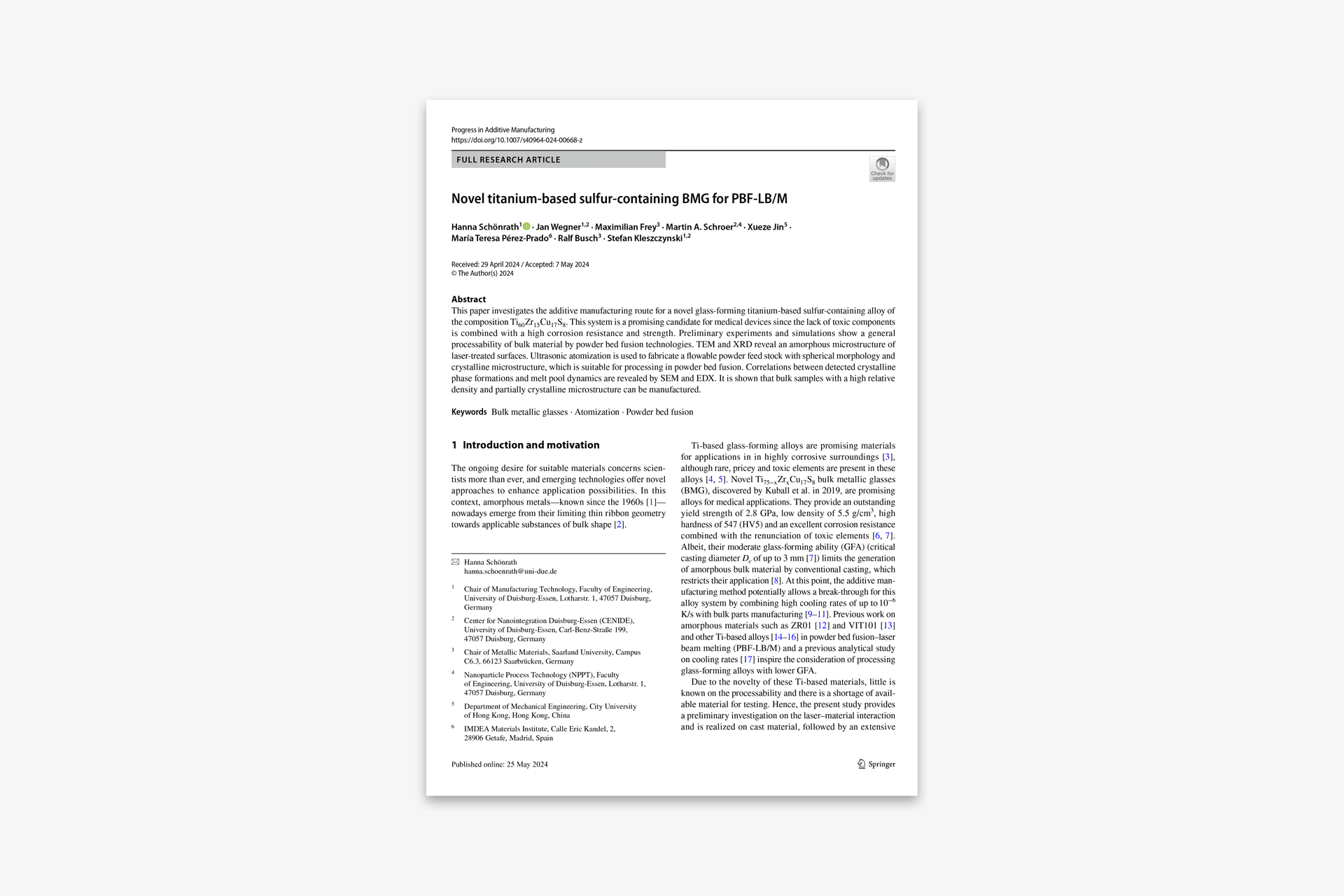

Authors: Hanna Schönrath, Jan Wegner, Maximilian Frey, Martin A. Schroer, Xueze Jin, María Teresa Pérez-Prado, Ralf Busch & Stefan Kleszczynski

Authors: Álvaro Díaz-García, Jia Yan Law, Łukasz Żrodowski, Bartosz Morończyk, Rafał Wróblewski, Victorino Franco

Authors: Łukasz Żrodowski, Rafał Wróblewski, Tomasz Choma, Bartosz Morończyk, Mateusz Ostrysz, Marcin Leonowicz, Wojciech Łacisz, Piotr Błyskun, Jan S. Wróbel, Grzegorz Cieślak, Bartłomiej Wysocki, Cezary Żrodowski and Karolina Pomian

Authors: Abhinav Priyadarshi, Shazamin Bin Shahrani, Tomasz Choma, Lukasz Zrodowski, Ling Qin, Chu Lun Alex Leung, Samuel J. Clark, Kamel Fezzaa, Jiawei Mi, Peter D. Lee, Dmitry Eskin, Iakovos Tzanakis

Authors: Heinrich Möller, V. Mostweni, Łukasz Zrodowski, Tomasz Choma

Authors: Ngwakoana Phala, Claudia Polese, Tomasz Choma, Hein Möller, Łukasz Żrodowski and Lesley Cornish

Authors: Vinzenz Müller, Janek Maria Fasselt, Tobias Kruse, Christian Klötzer, Rafael Kleba-Ehrhardt, Tomasz Choma, Max Biegler, Michael Rethmeier

Authors: Tijan Mede, Andraž Kocjan, Irena Paulin, Matjaž Godec

Authors: Michael Zach, Dane Brashear, Jonah Duran, Łukasz Żrodowski, Bartosz Kalicki, Tomasz Choma, Marcin Sołowiow, Steven Adler

Authors: Anatoliy Zavdoveev, Łukasz Zrodowski, Dmytro Vedel, Pedro Cortes, Tomasz Choma, Mateusz Ostrysz, Oleksandr Stasiuk, Thierry Baudin, Andrey Klapatyuk, Aleksandr Gaivoronskiy, Vitaliy Bevz, Elena Pashinska, Mykola Skoryk

Authors: Anna Dobkowska, Łukasz Żrodowski, Monika Chlewicka, Milena Koralnik, Bogusława Adamczyk-Cieślak, Jakub Ciftci, Bartosz Morończyk, Mirosław Kruszewski, Jakub Jaroszewicz, Dariusz Kuc, Wojciech Święszkowski, Jarosław Mizera

Authors: Matjaž Godec, Jakob Kraner, Danijela Skobir Balantič, Irena Paulin, Damjana Drobne, Veno Kononenko c, Aleksandra Kocijan, Paul McGuiness, Črtomir Donik

Authors: Clement N. Ekaputra, Jovid U. Rakhmonov, Christian Leinenbach, David C. Dunand

Authors: Y. Rao, C. Baruffi, A. De Luca, C. Leinenbach, W.A. Curtin

Authors: Tomasz Borowski, Katarzyna Zielińska, Maciej Spychalski, Bogusława Adamczyk-Cieślak, Łukasz Żrodowski

Authors: Tomasz Borowski, Katarzyna Zielińska, Maciej Spychalski, Bogusława Adamczyk-Cieślak, Łukasz Żrodowski

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

OUR SCIENTIFIC PARTNERS

OUR CUSTOMERS

STRONG FOUNDATION OF OUR SOLUTIONS

Strong Patents Behind AMAZEMET’s Technology

Our solutions, including the groundbreaking rePOWDER ultrasonic atomizer, are based on patented technology, which protects their uniqueness and reliability. Our portfolio of over 12 patents worldwide, continues to solidify our position at the forefront of technology. By securing intellectual property, we provide our clients with innovative and trusted technologies that drive progress in industries such as additive manufacturing, powder metallurgy, recycling and more.

CASE STUDIES & APPLICATION NOTES

At AMAZEMET, we believe in showcasing the real-world impact of our technologies. Our case studies and application notes provide detailed insights into the successful implementation of our solutions. These resources highlight specific projects, challenges addressed, and the measurable benefits achieved through our innovative approaches. By sharing these examples, we aim to inspire and support our clients in discovering new possibilities for their own applications.

Universities and research institutes today face the challenge of quickly changing research directions and the need to adapt their equipment to new projects, often within tight budget constraints. AMAZEMET’s rePOWDER ultrasonic atomization system addresses this by providing an open platform designed for modular expansion. This allows institutions to start with a core system and expand their capabilities as research needs evolve and funding becomes available. The journey of the Technical University of Munich (TUM) with rePOWDER is a prime example of this principle, showing how upgradability supports innovation and protects the long-term value of research investments.

Since our foundation in 2019 as a dynamic spin-off from the prestigious Warsaw University of Technology, we at AMAZEMET have rapidly established ourselves as key innovators in the additive manufacturing (AM) and advanced materials sector. In just six dynamic years (as of May 16, 2025), we have demonstrated remarkable growth and technological prowess, driven by our mission to empower scientists and engineers worldwide with cutting-edge solutions for material development and processing. We are proud that despite numerous market perturbations, our company has remained profitable and is committed to sustainable development. This case study highlights our journey, impactful innovations, and the significant milestones we've achieved.

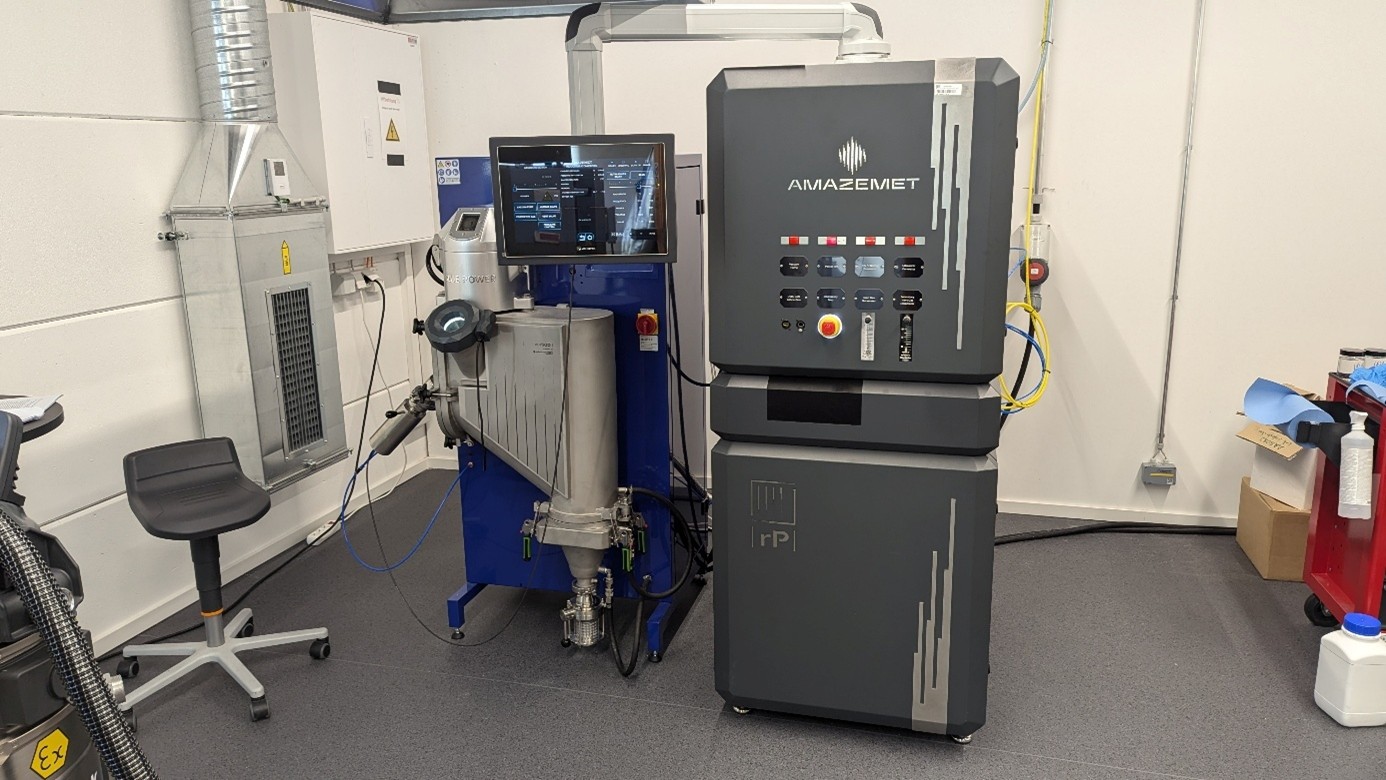

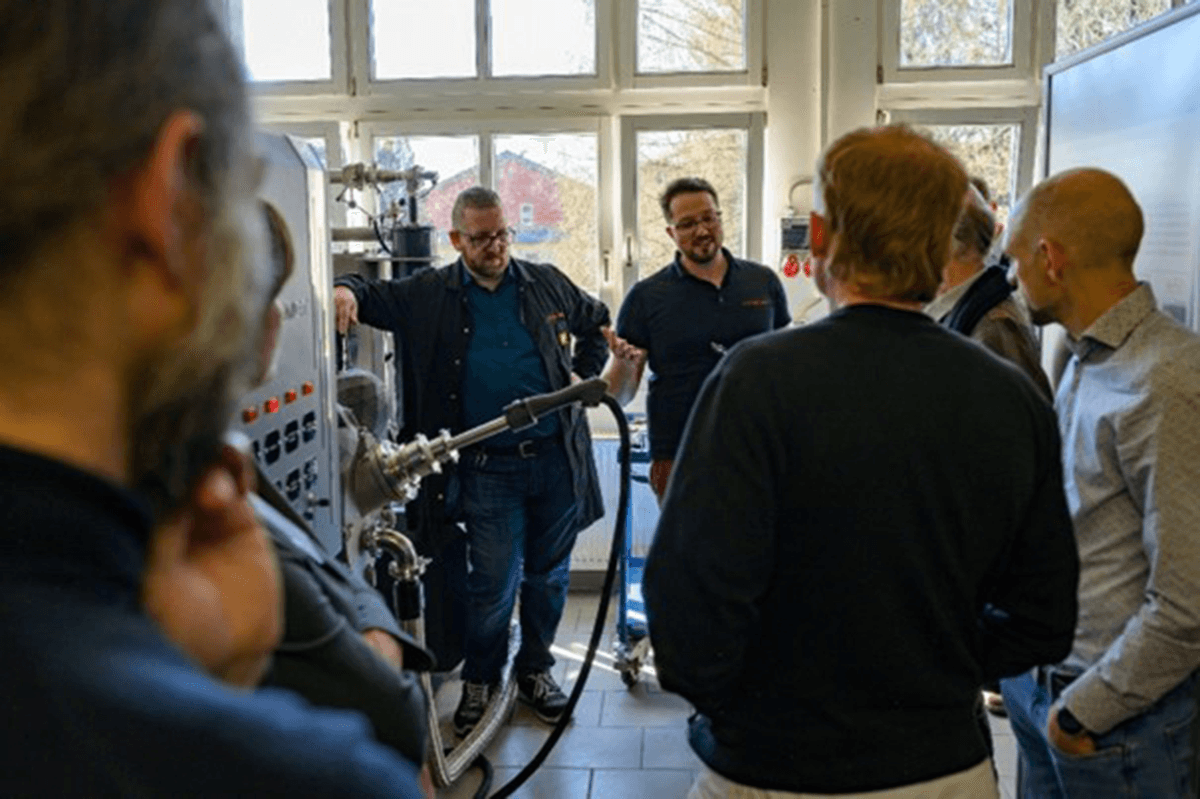

At AMAZEMET, we understand that the path to groundbreaking scientific discoveries often involves a lengthy and demanding process of securing funding. Our mission extends beyond providing innovative technological solutions; we strive to be a supportive partner for scientists at every stage of their journey. The case study of our collaboration with Chemnitz University of Technology (CUT) and the implementation of the rePOWDER system perfectly illustrates this approach.

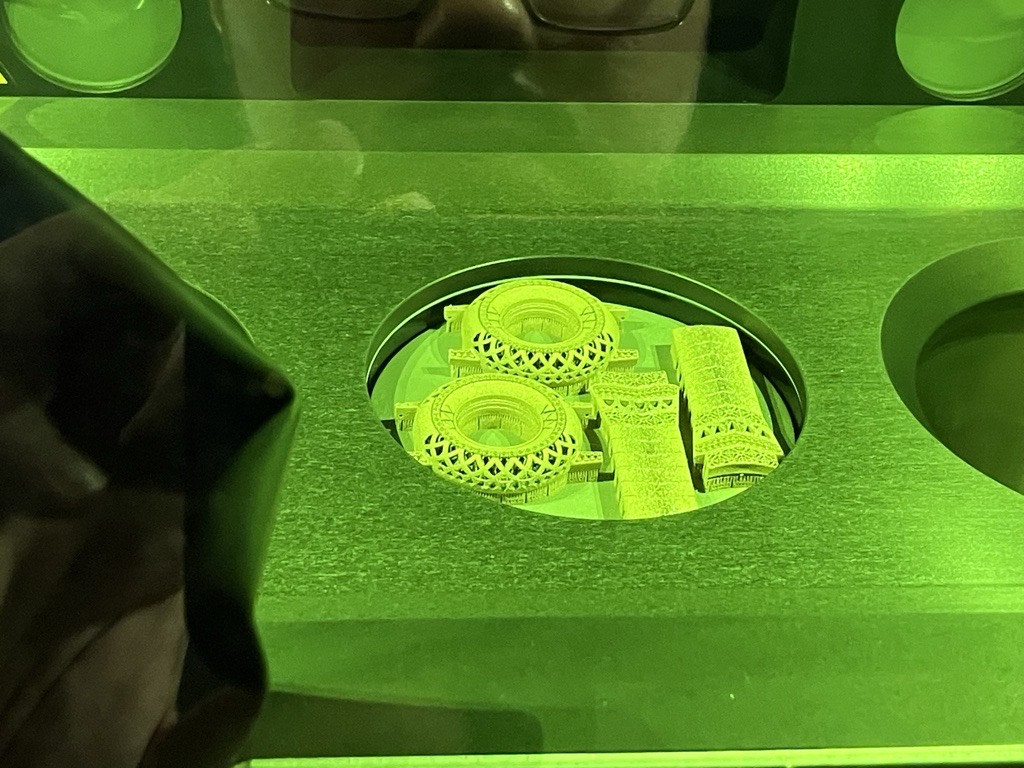

Ultrasonic atomization, featuring the rePOWDER system, addresses the challenge of high-cost precious metal powder production for additive manufacturing. This technology efficiently processes small batches of materials like silver, gold, and PGMs, yielding high-quality, spherical powders with excellent flowability and remarkable material recovery.

Create custom FeCrAlY alloys from raw elements as spherical powder for research or CSP. Discover in-situ alloy homogenization with rePOWDER.

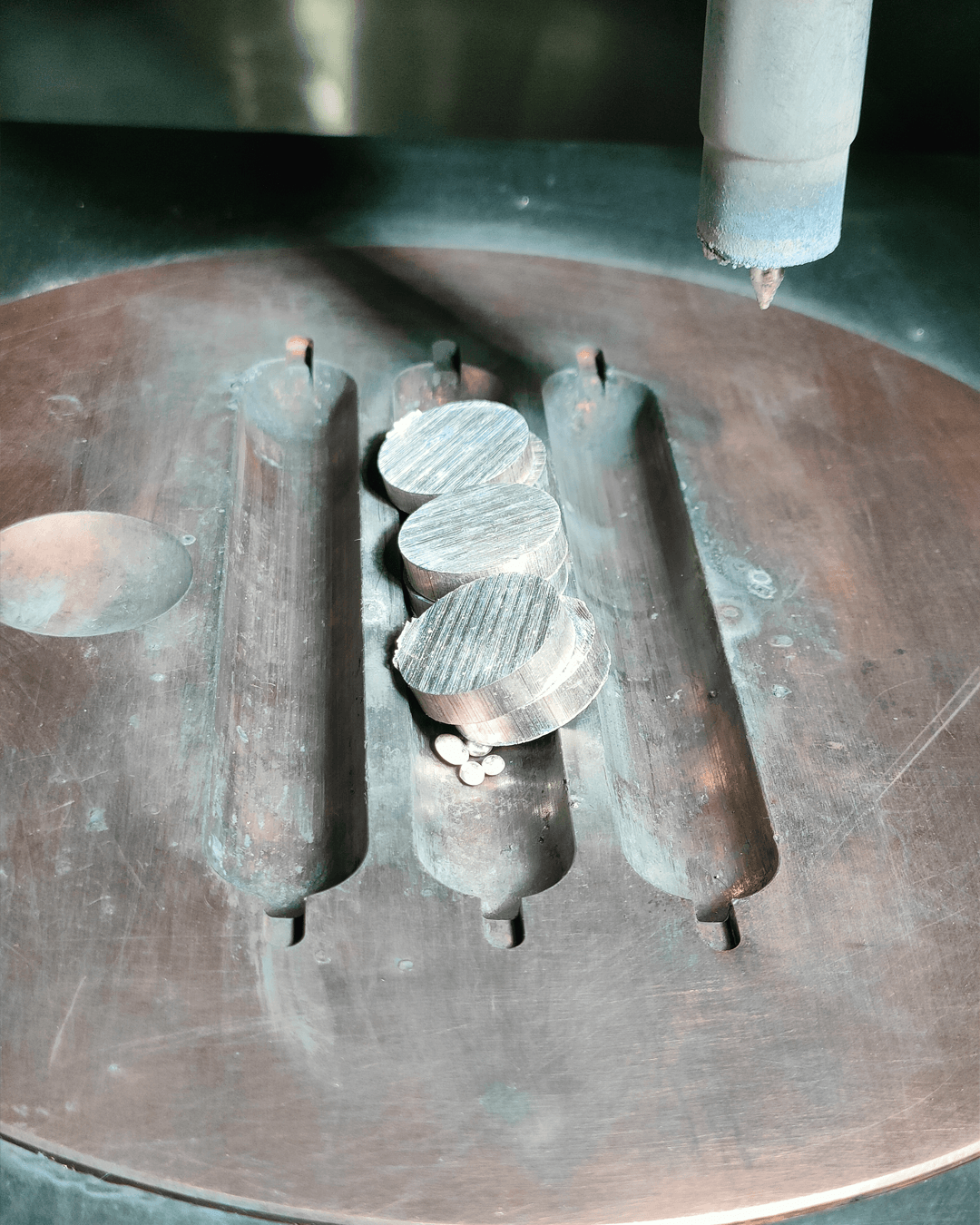

Discover how arcMELTER efficiently transforms CNC machining chips into high-quality ingots for severe plastic deformation (SPD). This case study highlights the use of a getter for inert atmosphere purification before homogenization. Learn about this sustainable, cost-effective closed-loop approach to metal production and material valorization.

Learn how arcMELTER transformed poorly flowing irregular powder into spherical feedstock suitable for Direct Energy Deposition. This case study details how the process also enabled alloy homogenization with an additional element, improving thermal stability and precipitation hardening, unlocking new possibilities for advanced component manufacturing.

Explore how arcMELTER facilitated the creation of a custom Mg-25%Ag master alloy, bypassing temperature limitations and evaporation issues of induction melting. This case study demonstrates a novel approach to precise alloying with pure elements, offering greater control and flexibility for material property tailoring without relying on commercially available master alloys. Discover the benefits for mechanical, corrosion, and thermal properties.

Discover how we utilized arc melting (arcMELTER) for in-situ phase transformation in TiB2/Ti MMCs, achieving unique dendritic structures and avoiding additive manufacturing challenges. This case study highlights the potential of this technology for advanced materials in aerospace and automotive applications. Explore the property testing results and future research directions.

High entropy alloys are hard to obtain due to often usage of refractory elements. Thanks to the fact that arcMELTER can be equipped with focus plasma torch working with such elements is much smoother than just standard TIG torch. Additionally with the use of inFURNER you can perform the test of anneling time influence and thermal stability of HEA microstructure in casted state, powder form obtained by rePOWDER of after your powder-based manufacturing process.