Freedom in Metal AM Development & Production

A Revolutionary Approach to Material Research & Powder Production

AMAZEMET’s technology is a game-changer for material research and metal additive manufacturing. We revived ultrasonic atomization to revolutionize the approach to powder production and material development, meeting the demands of modern researches and industries focused on innovation and efficiency.

HOW DOES IT WORK?

Our technology, unlike gas atomization systems, uses ultrasonic vibration for metal atomization. At its core, this technology utilizes high-frequency sound waves to create small particles from a liquid. It’s quite similar to the ultrasonic humidifiers, where a fine mist is produced from water. The same principle applies here, but instead of water, we use molten metals like steel, titanium, or other high-temperature alloys. Metal is poured or melted directly on the vibrating part resulting with tiny droplets being ejected from the surface. Droplets solidify in surrounding inert gas atmosphere forming powder particles.

The result are highly spherical metal powders with narrow particle size distribution – up to 80% is good to use in desired processes.

HISTORICAL BACKGROUND

Ultrasonic metal atomization is not a new technology—it was first developed in the 1960s to produce various metal powders. Initially, it found its use in creating powders for soldering, particularly of metals like lead and tin. However, the technology’s development slowed due to competition from gas atomization and a limited demand for ultra-spherical particles. At the time, the market did not require the small-scale production capabilities that have become essential today in industries such as additive manufacturing and academia. AMAZEMET has revitalized ultrasonic atomization, adapting and advancing it to meet the demands of modern applications.

rePOWDER – MORE THAN ULTRASONIC ATOMIZER

Our ultrasonic atomizer can be used to create metal powder from any alloy in any feedstock form, even in small quantities. What is more, raw elements or scrap materials can be used to prototype new alloying systems in form of cast or powder. Last but not least, failed printouts, unused powder, scrap or waste powder from other processes, thanks to rePOWDER, can be turned back into fine powder.

With this abilities, rePOWDER stands out as the most versatile atomizer available on the market.

STRONG FOUNDATION OF OUR SOLUTIONS

Strong Patents Behind AMAZEMET’s Technology

Our solutions, including the groundbreaking rePOWDER ultrasonic atomizer, are based on patented technology, which protects their uniqueness and reliability. Our portfolio of over 12 patents worldwide, continues to solidify our position at the forefront of technology. By securing intellectual property, we provide our clients with innovative and trusted technologies that drive progress in industries such as additive manufacturing, powder metallurgy, recycling and more.

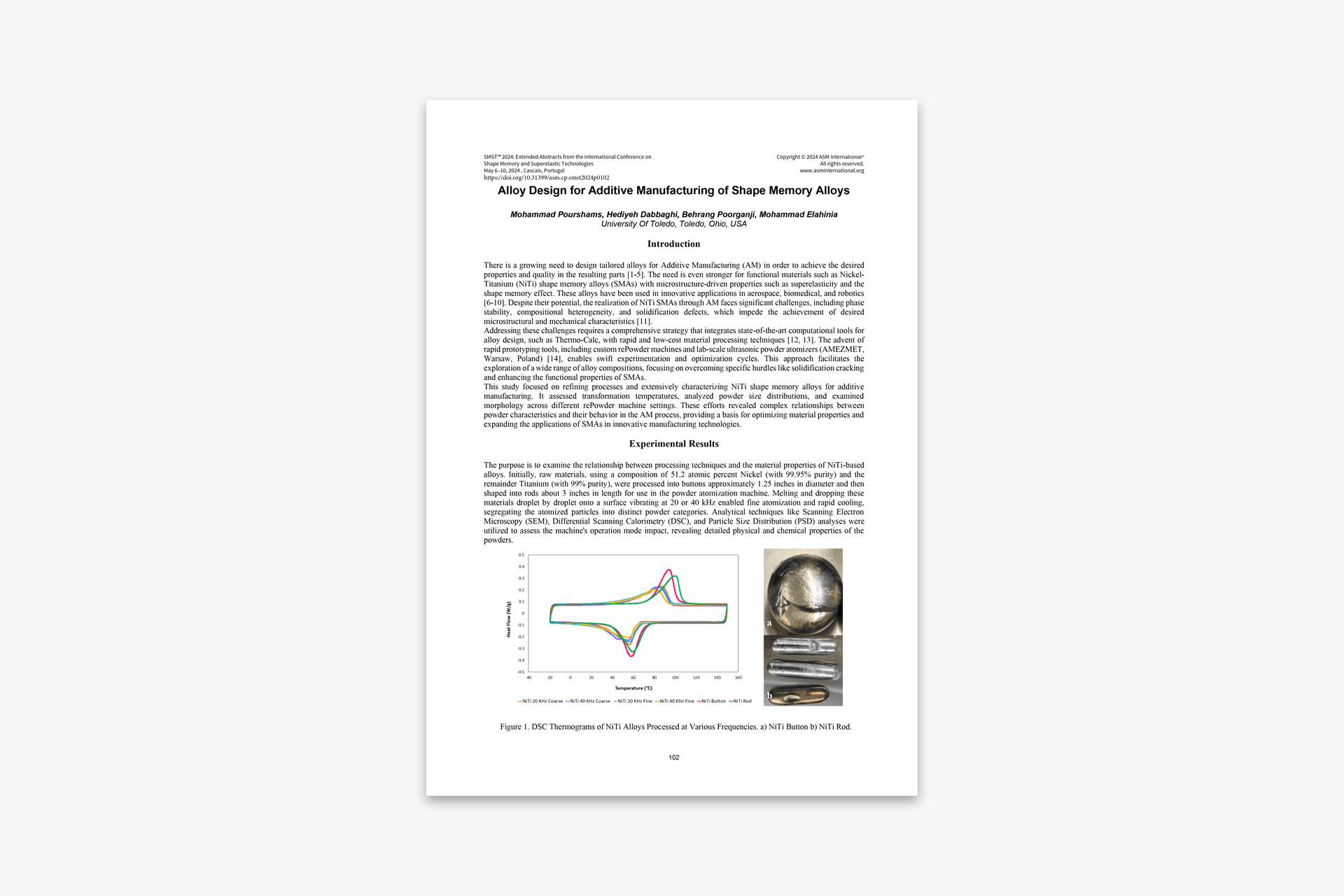

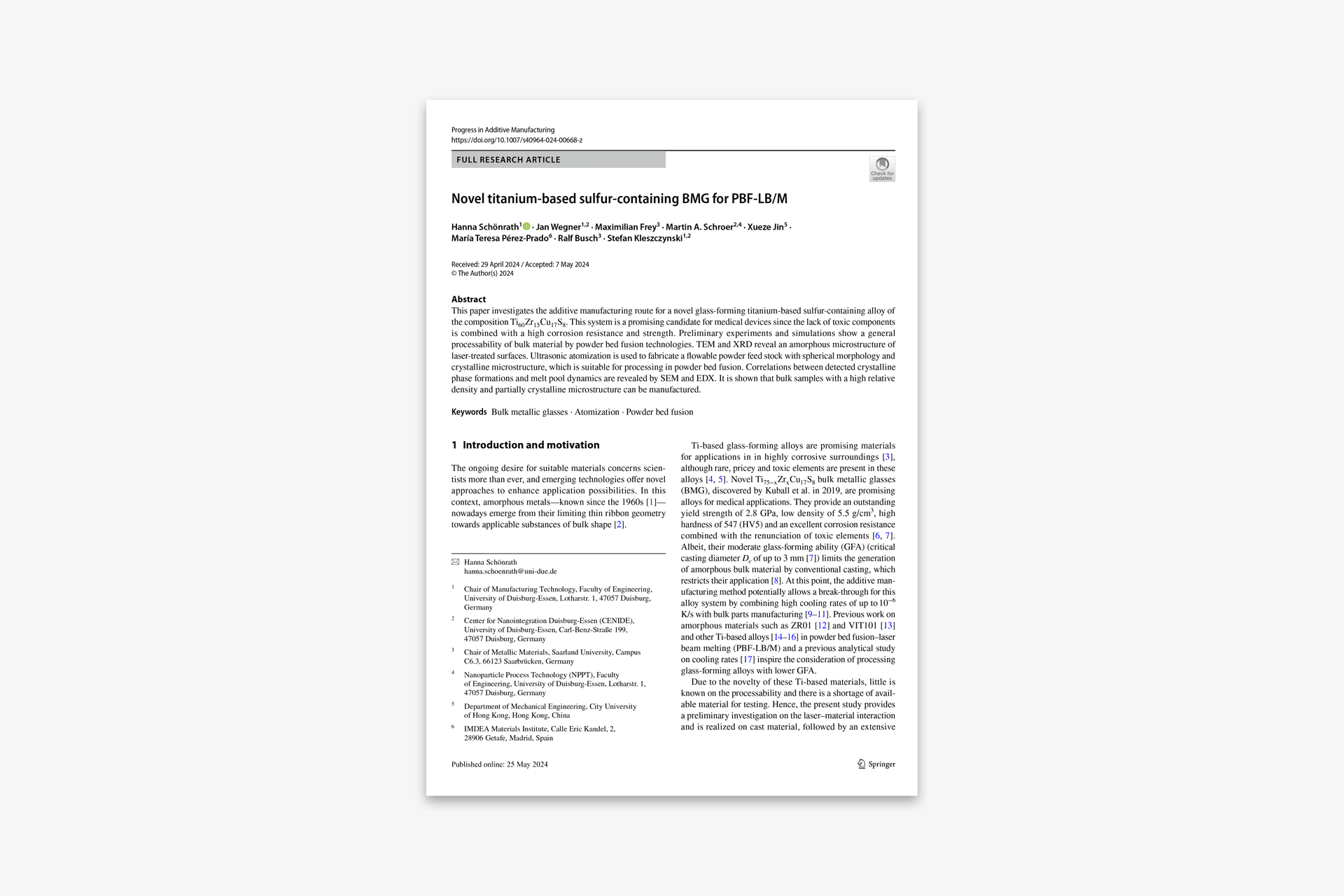

GROWING LIST OF PUBLICATIONS

In AMAZEMET we are committed to the dissemination of groundbreaking research in advanced materials, metallurgical engineering and additive manufacturing. Our publications include scholarly articles that delve deep into a range of topics and offers unique insights into cutting-edge methodologies. We take pride in fueling the curiosity of researchers and practitioners alike, fostering an environment conducive to learning, discovery, and the broadening of intellectual horizons.

CASE STUDIES & APPLICATION NOTES

At AMAZEMET, we believe in showcasing the real-world impact of our technologies. Our case studies and application notes provide detailed insights into the successful implementation of our solutions. These resources highlight specific projects, challenges addressed, and the measurable benefits achieved through our innovative approaches. By sharing these examples, we aim to inspire and support our clients in discovering new possibilities for their own applications.