Explore Our Patented Technologies

AMAZEMET Patents: Learn More About Our Breakthrough Solutions

AMAZEMET Patents: Learn More About Our Breakthrough Solutions

Explore AMAZEMET’s legally protected intellectual property. Our patents are proof of our commitment to innovation and form the foundation of our technological advantage in materials science, additive manufacturing and ultrasonic atomization.

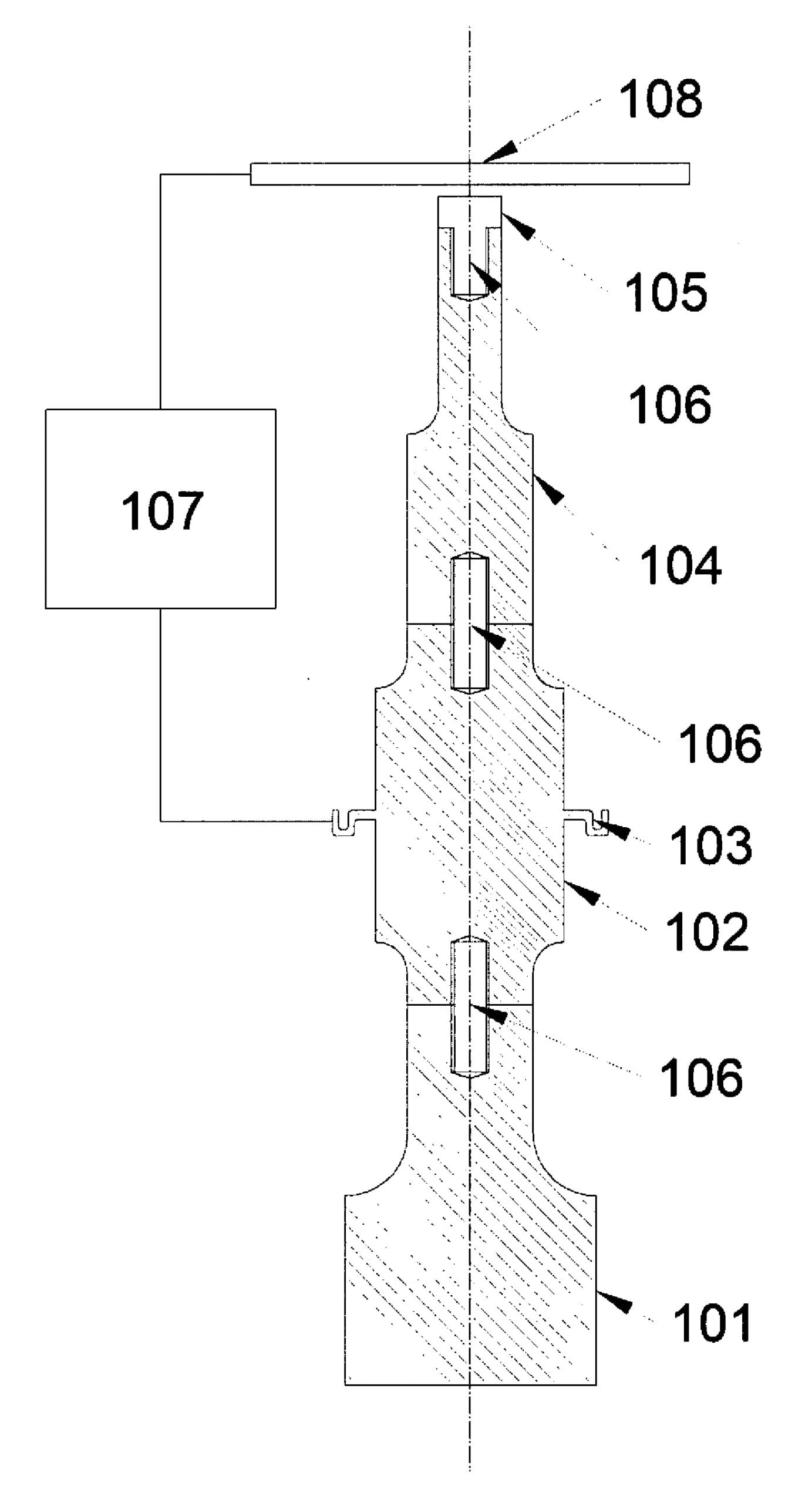

WO2020230027

CN113825583A; CN113825583B; EP3969190A1; JP2022533329A; JP7432949B2; KR20220006542A; PL429907A1; US11938557B2; US2022161353A1

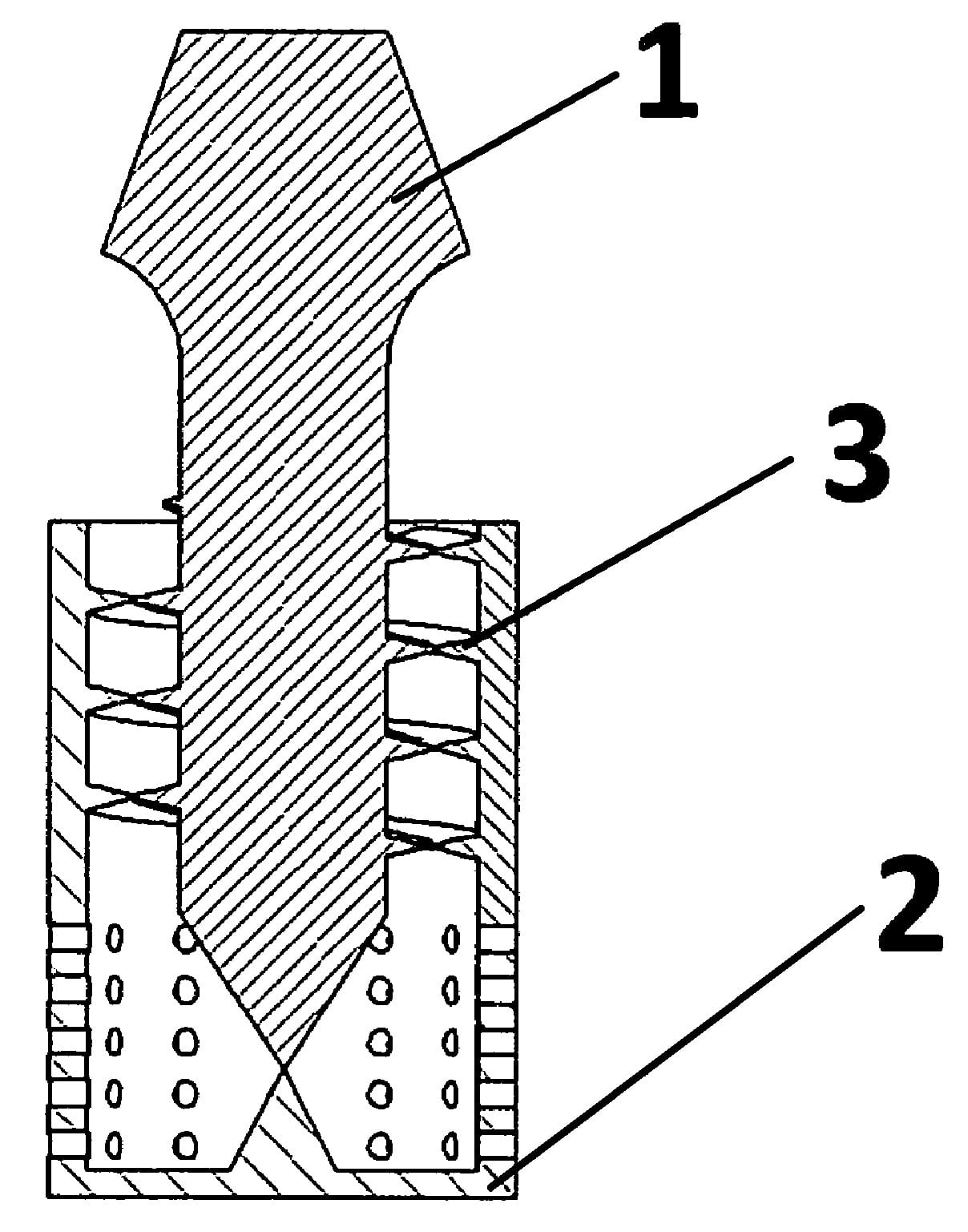

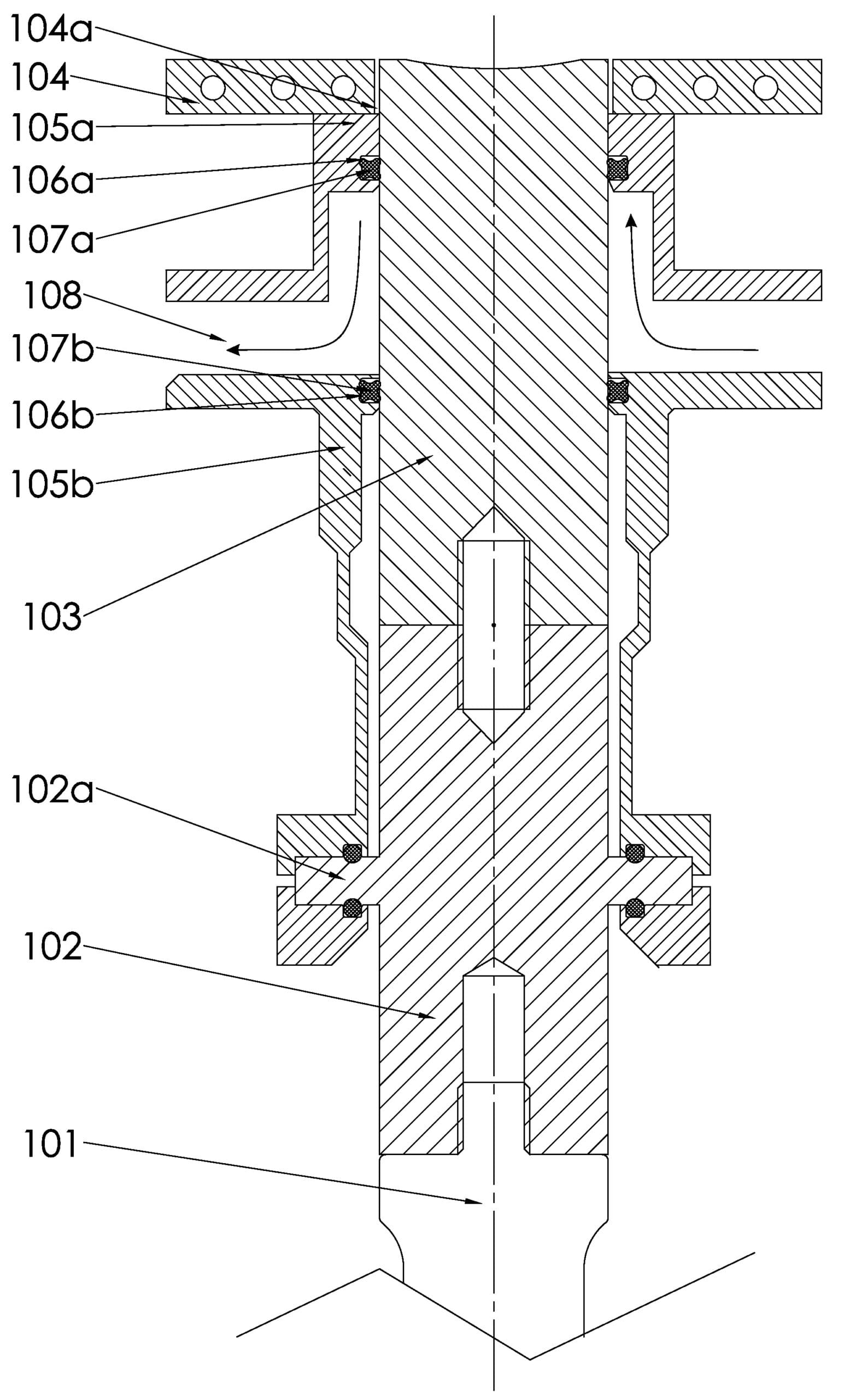

Sonotrode with Smart Cooling

This invention improves the performance of a tool called a sonotrode, which sends ultrasonic waves into molten metal. Normally, these tools are hard to cool because the most stressed area (the “node”) also happens to be the hardest to seal. The new design cools the tip—right where it gets hottest—using a clever water-jacket system. This boosts efficiency by up to 8x and helps make finer powder, especially for titanium alloys like Ti64.

WO2022034517A1

CN116075680A; CN116075680B; EP4192985A1; EP4192985B1; EP4192985B8; EP4192985C0; ES2968617T3; PL4192985T3; PL434866A1; US2023304131A1

High-Temperature Composite Sonotrode

GRANTED

Here, the focus is on a new kind of sonotrode made from strong composite materials (like ceramic reinforced with fibers). These can handle extreme heat and vibration better than traditional ones. This design is especially useful for recycling non-ferrous metals and allows for powerful ultrasonic processing, such as breaking down molten metals, removing gas bubbles, or creating powders. It’s a key part of the induction version of the rePowder system.

WO2020225711

CN113825579A; CN113825579B; EP3962682A1; JP2022534547A; PL429832A1; US2022111442A1

Smart 3D Printing Support Removal

GRANTED

PENDING

Support structures are often needed in 3D printing to keep metal parts stable during printing. But removing them afterward is tricky. This method uses thin, porous supports that can be dissolved with specially designed chemical or electrochemical baths, often with ultrasound to speed things up. This means less risk of damaging the printed part, shorter processing times, and better results—especially useful for delicate or complex designs.

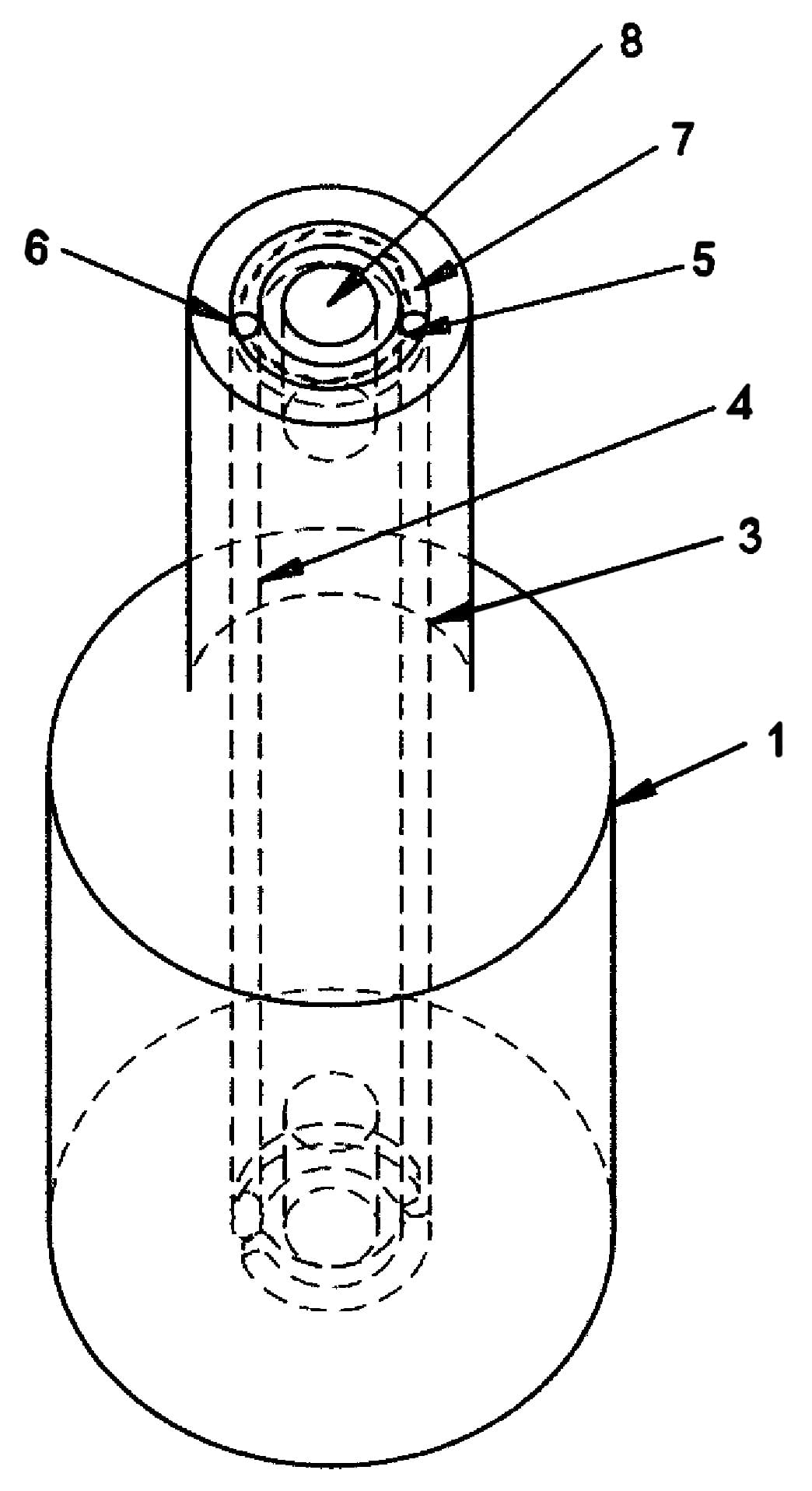

PL246719

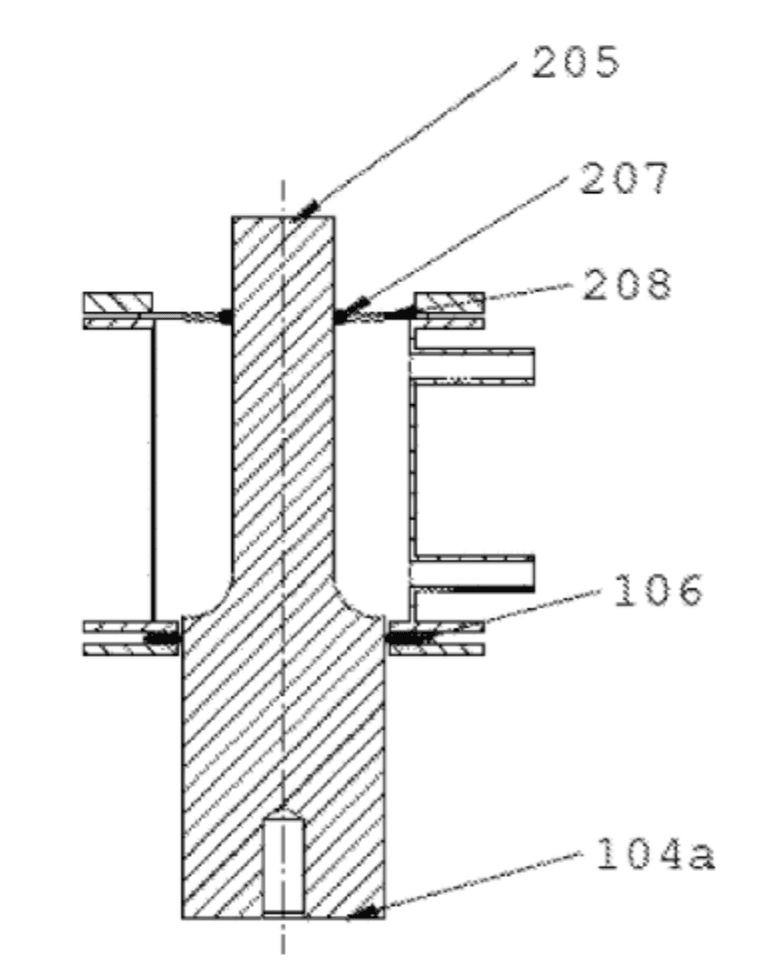

Ultrasonic Atomizer for High-Temps

PENDING

Ultrasonic atomization turns molten metal into fine powder—but doing this at very high temperatures is challenging. This invention solves the cooling problem by placing the sonotrode in a specially cooled base. It keeps the tool working smoothly even with metals that melt above 700°C, ensuring longer life and better performance in high-heat environments like metal 3D printing or welding.

PL237650

Liquid-cooled Sonotrode

GRANTED

This sonotrode has built-in water channels that keep the tip cool even under intense ultrasonic vibration and high temperatures. It’s ideal for high-frequency systems where overheating is a risk. The design ensures stable operation and extends the tool’s life, solving problems that older air- or gas-cooled systems couldn’t handle well.

PL237650

Better Wettability for Metal Processing

GRANTED

In processes like welding or ultrasonic casting, it’s essential for the sonotrode to “bond” well with the liquid metal. This invention creates a special diffusion layer on the sonotrode’s surface, so molten metals stick better without damaging the tool. It balances two tricky goals: strong bonding and durability at high temperatures.

PL239793

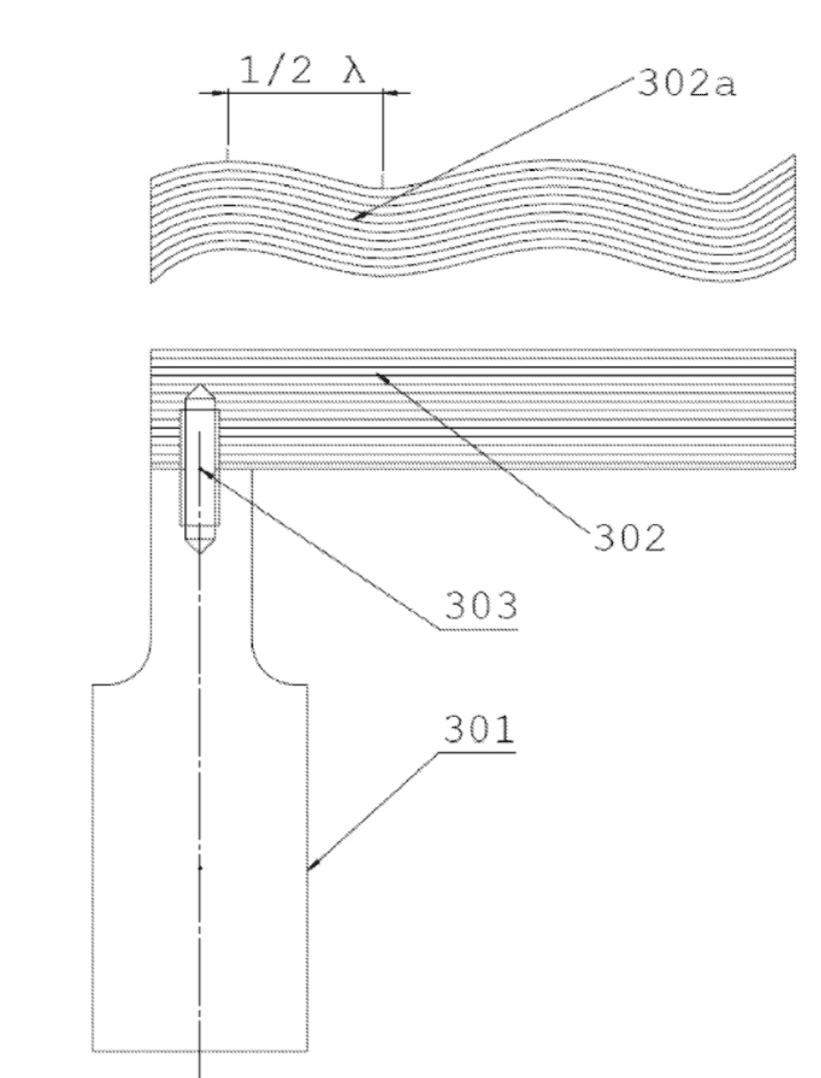

Efficient Power Connection for Ultrasonics

GRANTED

To power an ultrasonic system used for metal processing, a steady, high-current electrical connection is needed—without affecting the tool’s vibration. This patent introduces a smart connector made of a conductive, flexible diaphragm that transmits both electricity and ultrasonic waves. It enables efficient operation, better material quality, and even supports automation for larger-scale powder production.

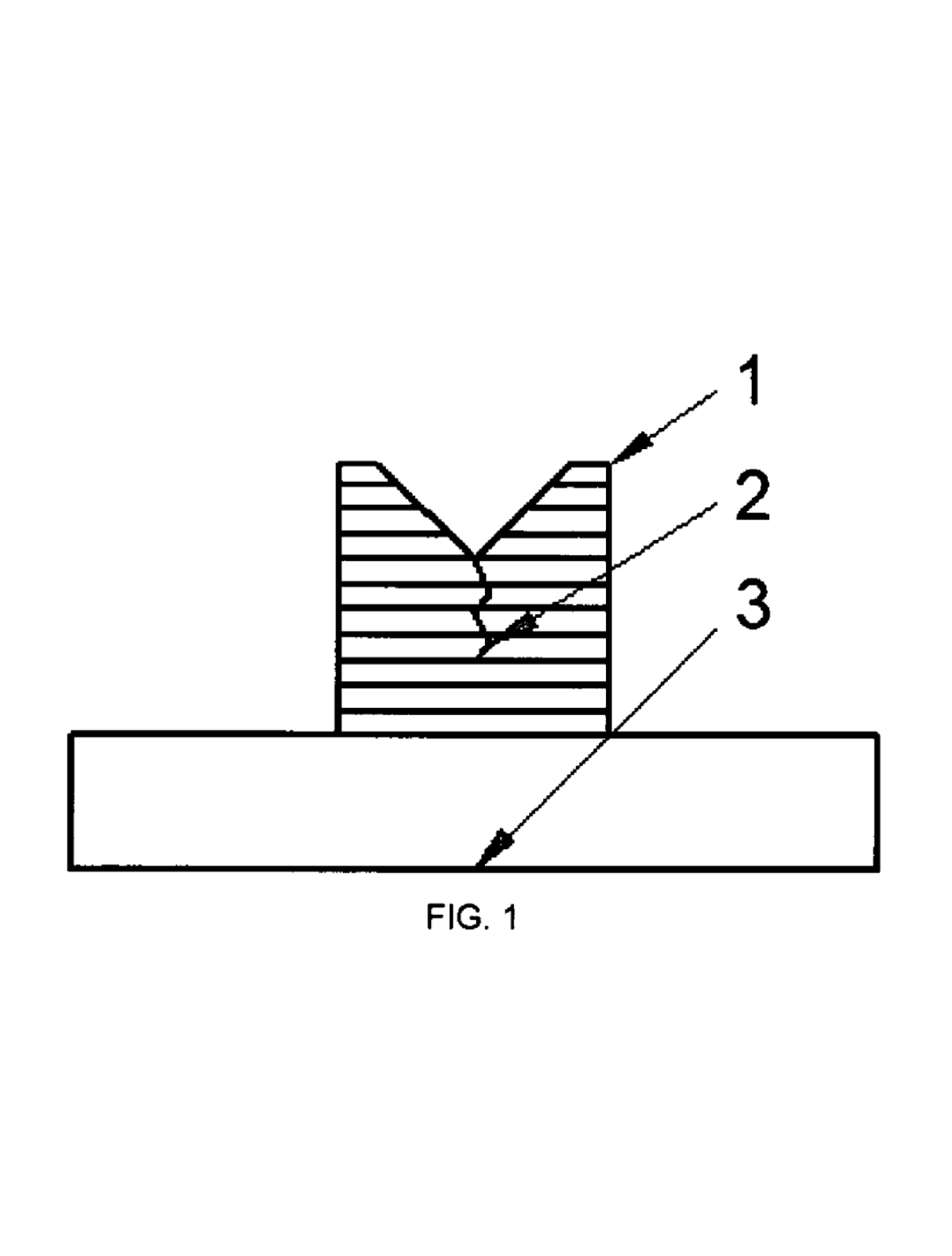

Pat.238391

Method of manufacturing structural components from metallic glass-based composites by selective powder remelting

GRANTED

Metallic glasses (amorphous metal alloys) exhibit unique properties—high hardness, strength, elasticity, corrosion resistance, and minimal magnetic coercivity—compared to their crystalline counterparts. However, their low ductility (brittleness) can lead to catastrophic fracture because there are no microstructural features to blunt or deflect cracks. One approach to improve plasticity and crack resistance is to create composites that include a crystalline phase capable of enhancing ductility or absorbing energy via a phase transformation. Such composites can be produced either ex situ (e.g., laminating a crystalline material onto the metallic glass) or in situ (partial crystallization during solidification), but maintaining uniform distribution of the crystalline phase can be challenging. Typical production methods—casting into copper molds, powder metallurgy (hot pressing, extrusion), partial crystallization during cooling—struggle to ensure uniform properties throughout the material due to uneven cooling or phase distribution.

PL243123

High-Precision Bone Implants

GRANTED

This invention improves the way metal bone implants are made using 3D printing. By placing removable supports on the thread edges and dissolving them chemically, the implants end up with sharp, clean threads. This makes them easier and more effective to screw into bone—no need for extra machining. The process is especially useful for creating custom implants quickly and precisely.