Scientific collaboration is in our DNA

OUR STORY

MISSION

VISION

AMAZEMET as an international company being an executive partner for many scientific organizations and technological companies in technology development and prototyping.

World-class leader in ultrasonic technologies.

AMAZEMET BACKGROUND

AMAZEMET, a 2019 spin-off from Warsaw University of Technology, specializes in providing and developing advanced ultrasonic atomization devices for tailored powder manufacturing and compact high-vacuum furnaces for post-processing and heat-treatment applications. Laboratory-scale solutions like rePOWDER and inFURNER support leading researchers worldwide in Additive Manufacturing and beyond.

Building on its expertise in materials science, AMAZEMET has expanded its operations to include the production of custom metal powders tailored to specific requirements.

Additionally, it offers production and engineering services such as welding, CNC machining, metal 3D printing, for demanding small and medium production runs.

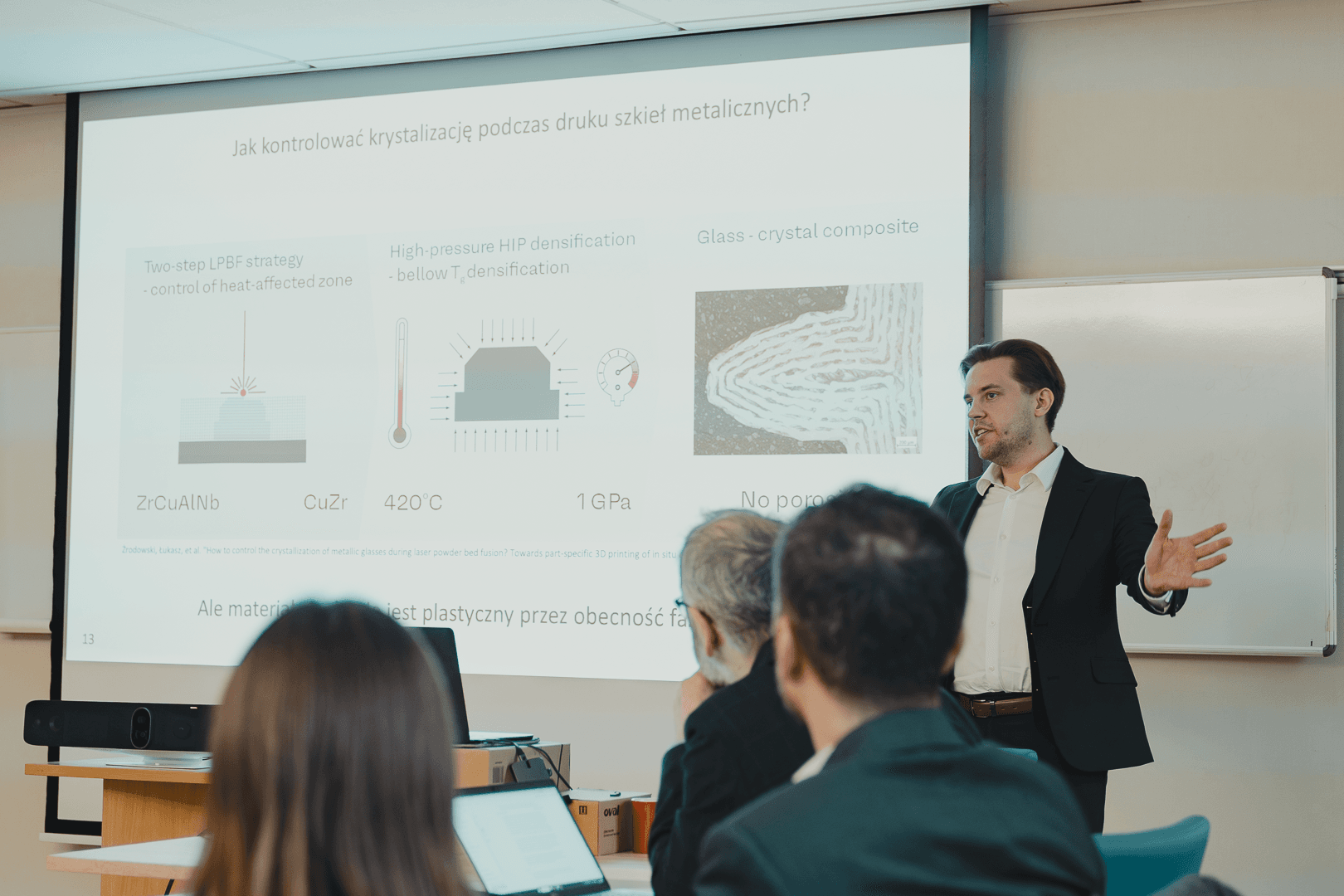

Rooted in academia, AMAZEMET actively collaborates on research projects to develop innovative materials for AM, mantaining a strong ties with scientists and academic institutions all around the globe.

For the development of metal additive manufacturing

Being both a production company and the Warsaw University of Technology spin-off AMAZEMET combines the understanding of relevant fundamental science and academic environments with industrial processes and needs. These qualities make the company a perfect partner for scientific collaboration.

As a part of different consortia, AMAZEMET provides know-how in the area of materials science, 3D printing process, metal powder materials, ultrasonic technology, postprocessing, and other methods and technologies connected with metal 3D printing and materials development.

PARTNERSHIP

Years of Close Collaboration with Industry Leaders

At AMAZEMET, we value long-term relationships founded on trust and shared expertise. Through the years AMAZEMET partnered up with several world-recognized companies. Together, we’ve developed innovative solutions, tackled complex challenges, and driven advancements in many fields:

From 2023 AMAZEMET is also a Sales Representative in Poland for Colibrium Additive (former GE Additive) – the leading company in metal 3D printing technology. AMAZEMET’s role is the distribution of Arcam and Concept Laser devices in the Polish additive manufacturing market.

Aconity3D – the producer of modular metal 3D printers aimed mostly at R&D of additive manufacturing technologies.

Blue Power Casting Systems – German company that develops gas atomization technologies and casting systems while specializing in induction melting technology. Together Blue Power and AMAZEMET work on compact induction-based ultrasonic powder atomizer AUS500.

COLLABORATION

OUR SCIENTIFIC PARTNERS

Our collaborations drive innovation and push the boundaries of materials science. Meet AMAZEMET’s trusted academic partners who play a key role in advancing our research and technological developments. Together, we shape the future of additive manufacturing and beyond.

Freemelt ONE & AMAZEMET’s rePOWDER Ultrasonic Atomizer

Colibrium Additive at Formnext 2024 | Jose Greses Exclusively For AMAZEMET

TU Darmstadt & AMAZEMET Magnetocalorics Research

AMAZEMET & f3nice | Matteo Vanazzi | Sustainable Innovation with rePOWDER

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. Explore some of our key partnerships with industry leaders and innovators driving progress in additive manufacturing and materials science.

Scientific cooperation

One of the most important challenges facing the development of science and industry is the formation of partnerships that foster interdisciplinary and international cooperation – for example, research project collaborations between companies and universities.

The greatest value for partners who collaborate with AMAZEMET is the scientific support of the Warsaw University of Technology. The specialists involved in these projects have extensive experience in materials engineering, and they understand the need for research and development. Applying these skills while using innovative technologies, such as ultrasonic atomization, makes AMAZEMET a unique contributor to the consortium.

STRONG FOUNDATION OF OUR SOLUTIONS

Strong Patents Behind AMAZEMET’s Technology

Our solutions, including the groundbreaking rePOWDER ultrasonic atomizer, are based on patented technology, which protects their uniqueness and reliability. Our portfolio of over 12 patents worldwide, continues to solidify our position at the forefront of technology. By securing intellectual property, we provide our clients with innovative and trusted technologies that drive progress in industries such as additive manufacturing, powder metallurgy, recycling and more.

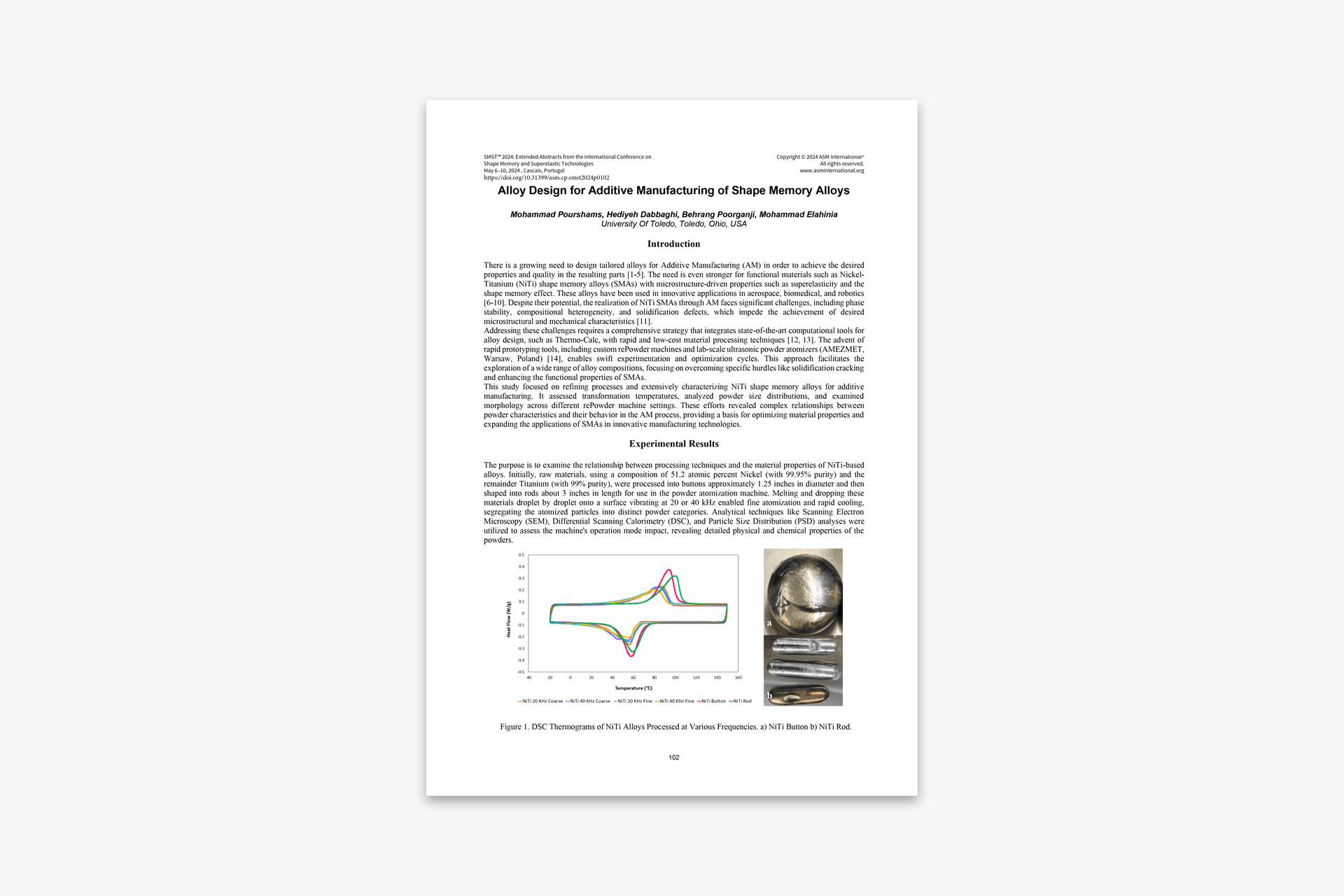

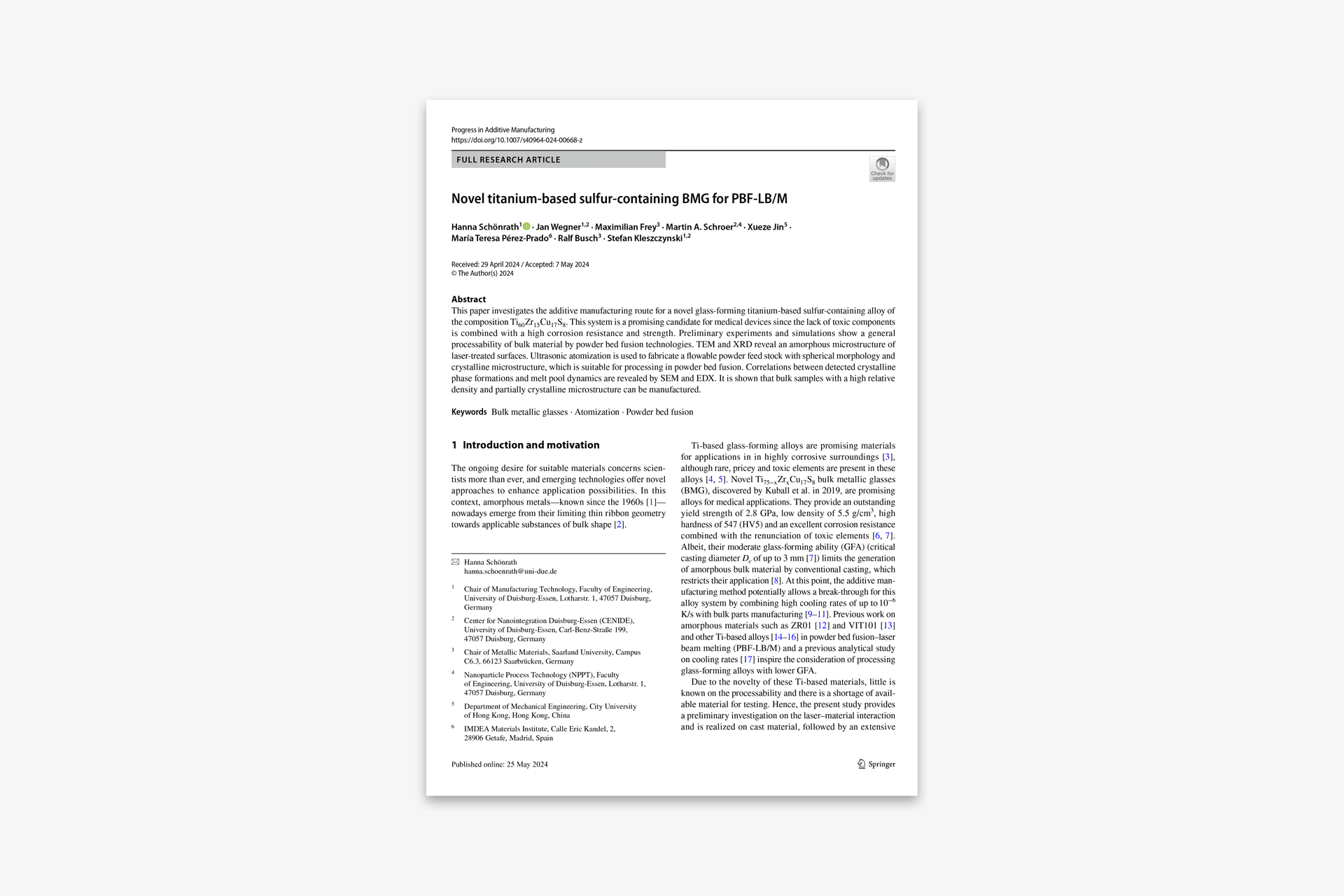

GROWING LIST OF PUBLICATIONS

In AMAZEMET we are committed to the dissemination of groundbreaking research in advanced materials, metallurgical engineering and additive manufacturing. Our publications include scholarly articles that delve deep into a range of topics and offers unique insights into cutting-edge methodologies. We take pride in fueling the curiosity of researchers and practitioners alike, fostering an environment conducive to learning, discovery, and the broadening of intellectual horizons.

FREEDOM IN METAL ADDITIVE MANUFACTURING DEVELOPMENT & PRODUCTION

FREEDOM IN METAL ADDITIVE MANUFACTURING DEVELOPMENT & PRODUCTION

MEET OUR EXPERTS

Meet the people who stand behind AMAZEMET and learn more about our team members, their areas of expertise, and how they contribute to our mission and vision as a company. Explore our website and discover what makes our team truly exceptional.

Łukasz Żrodowski

CEO, co-founder

Adrian Truszkowski

Sales Director

Bogdan Dąbrowski

Sales Manager

Jakub Ciftci

Application Engineer

Tomasz Choma

Application Engineer

Bartosz Morończyk

Application Engineer

AMAZEMET – ADDITIVE MANUFACTURING COMPANY

The company is the people. It’s the team that is the backbone of AMAZEMET’s success – being a metal additive manufacturing solutions market leader.

As the company provides various devices and technologies for additive processes, the team is made up of talented individuals with expertise in different fields: from additive technologies, printing process, and the materials market, to production process, project management, and material science. These people share a passion for pushing the boundaries of what is possible with technology in the advanced metal additive manufacturing sector.