In this article you will learn

-

What is the nature of the partnership between AMAZEMET and WUT Racing?

-

How does AMAZEMET contribute to WUT Racing’s efforts?

-

What happened during Formula Student Poland competition?

-

What are the future plans for this collaboration?

Empowering WUT Racing’s Aspirations

In the realm of engineering, collaborations can significantly enhance learning and application. This is evident in the partnership between AMAZEMET, known for its focus on additive manufacturing, and WUT Racing, a team of engineering students from Warsaw. This collaboration is a practical exploration of how 3D metal printing can be innovatively used in building competitive racing vehicles for Formula Student events.

WUT Racing Evolution

Since its formation in 2011 by students from the Warsaw University of Technology, WUT Racing has grown, including members from other Warsaw-based universities. The team’s primary goal is the design and construction of vehicles for Formula Student competitions. Over time, they’ve developed various models of their race car, each reflecting their increasing knowledge and evolving skills.

AMAZEMET’s Contribution and Core Values

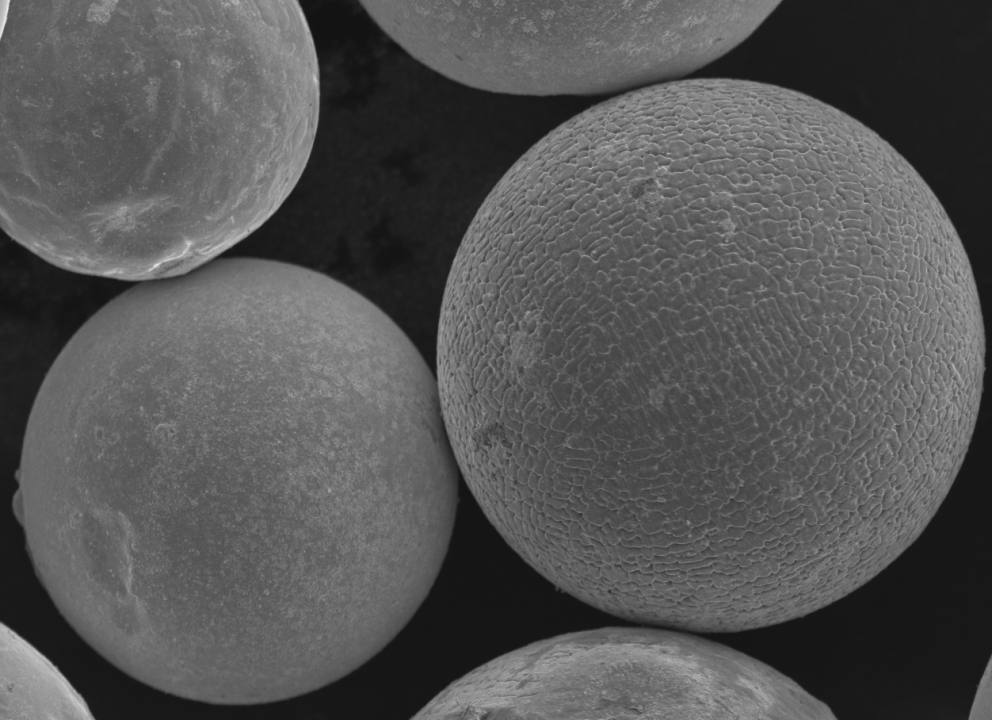

AMAZEMET’s role in this partnership extends to the domain of 3D metal printing, which has enabled WUT Racing to produce customized, lightweight, and strong vehicle parts. At the core of AMAZEMET’s ethos is a strong commitment to research and development. With a strong academic background, the company takes pride in supporting the student community at the Warsaw University of Technology. That is one of the ways of aiding students in realizing their dreams through practical applications of advanced technologies.

Recent Achievements and Experiences: Formula Student Poland

A recent highlight for WUT Racing was participating in the Formula Student Poland competition, a platform where they tested their vehicle in rigorous, wet conditions and interacted with other student teams. It was an opportunity to apply the knowledge and resources provided by AMAZEMET, demonstrating the practical benefits of the partnership. During this event, representatives from AMAZEMET were present at the racetrack, providing support to the WUT Racing team. This hands-on involvement exemplifies the collaborative spirit of the partnership. We encourage you to watch the video from this event, which captures the exciting atmosphere of the competition.

Looking Ahead: Collaboration between AMAZEMET and WUT Racing

Both AMAZEMET and WUT Racing are keen on maintaining their collaborative efforts. WUT Racing is actively working on its next vehicle, utilizing the insights and experience gained from its partnership with AMAZEMET and past competitions.

For those interested in more detailed aspects of this collaboration, information is available through WUT Racing’s online presence. They show how 3D metal printing technology is being applied in racing contexts. It is worth to follow their LinkedIn profile, where they share experiences from the Formula Student circuit.

This partnership exemplifies the effective collaboration between industry and academia. It showcases how student teams can apply new technologies in real-world scenarios, supported by a company that values research, development, and the empowerment of future engineers.