In this article you will learn:

-

What are the different materials used in 3D printing?

-

How do they impact the quality and functionality of the final product?

-

How have 3D printing methods evolved to accommodate a wider range of materials and enhance the quality of printed objects?

-

What are the typical applications of additively manufactured components from metals?

-

How do the advancements in additive manufacturing influence the development of new materials for additive manufacturing?

-

What are the printing materials cost?

-

What future trends do you foresee in the industry, especially concerning the cost and availability of printing materials?

Introduction

Printing materials play a fundamental role in the world of additive manufacturing. They shape the possibilities of what can be achieved with this technology. From simple binary alloys to new chemical compositions suited for additive manufacturing and advanced composite materials, each contributes to the wide array of applications of this technology. The selection of the appropriate material is a critical factor in determining the success of the printing process.

In the world of 3D printing, a wide array of material options applications exists, showcasing this technology’s immense versatility. The printing materials showcase a range of possibilities: from creating intricate jewelry to producing high-strength industrial parts and even medical implants.

(video: Jakub Tomaszewski)

3D Printing Materials: An Overview

3D printing, also known as additive manufacturing, has revolutionized the way we produce objects and parts across various industries. While 3D printing was initially associated with plastics and polymers, significant advancements have made it possible to print with metal materials. It opened up a world of possibilities for manufacturing, aerospace, healthcare, automotive, and more. The world of 3D printing offers an extensive range of printing materials, each with its own unique characteristics. For instance, it’s crucial to select composite materials when strength and lightweight characteristics are required. Using additive manufacturing you can develop new high-modulus lightweight alloys.

Moreover, the printing material cost should also be taken into account, as it varies significantly between different material types. For most of metallic alloys – a standard laser with 1070 nm wavelength can be used, but if you want to process high reflectivity materials like pure copper the usage of 515 nm laser – commonly known as “green laser”.

On the other hand, some materials are prone to cracking during high cooling rates or accumulating stresses which result in warping and delamination. In such cases usage of specific scanning strategies including the point scan strategy to surpass overheating, changing the laser intensity profile, or even heating up the material over 1000 °C can benefit the printability of developed materials.

Aconity MIDI LPBF System

Some of the capabilities are already feasible with our Aconity MIDI LPBF system. Others we can acquire from new joint research projects. Check our list of EU-funded projects which are already in progress. The next one might be with collaboration with you! Fill in the contact form here.

(source: Aconity)

The selection of materials depends heavily on the desired properties of the final product. Strong materials are often selected for high-temperature applications such as aerospace and automotive components. On the other hand properties such as biocompatibility, heat conductivity, and magnetic properties are needed.

Overall, the rich variety of common material options and their specific applications make 3D printing such a powerful and transformative technology.

Metal Materials in 3D Printing

Utilizing a range of metals, from magnesium alloy, steels, titanium alloys to precious metals like gold and platinum up to refractory high entropy alloys the printing material types in this category significantly expand the possibilities of 3D printing. The process often involves the use of metal filaments but mostly metal powders are needed.

(photo: Jakub Tomaszewski)

In recent years, metal additive manufacturing has emerged as a powerful and versatile tool in the world of 3D printing. Materials are particularly valued in industries like aerospace, automotive, and medical technology, where high-performance parts with high tolerance levels are required. Moreover, in the jewelry industry, the ability to print inspired by nature designs with precious metals is revolutionizing traditional manufacturing – investment casting.

Technologies of obtaining metal powders

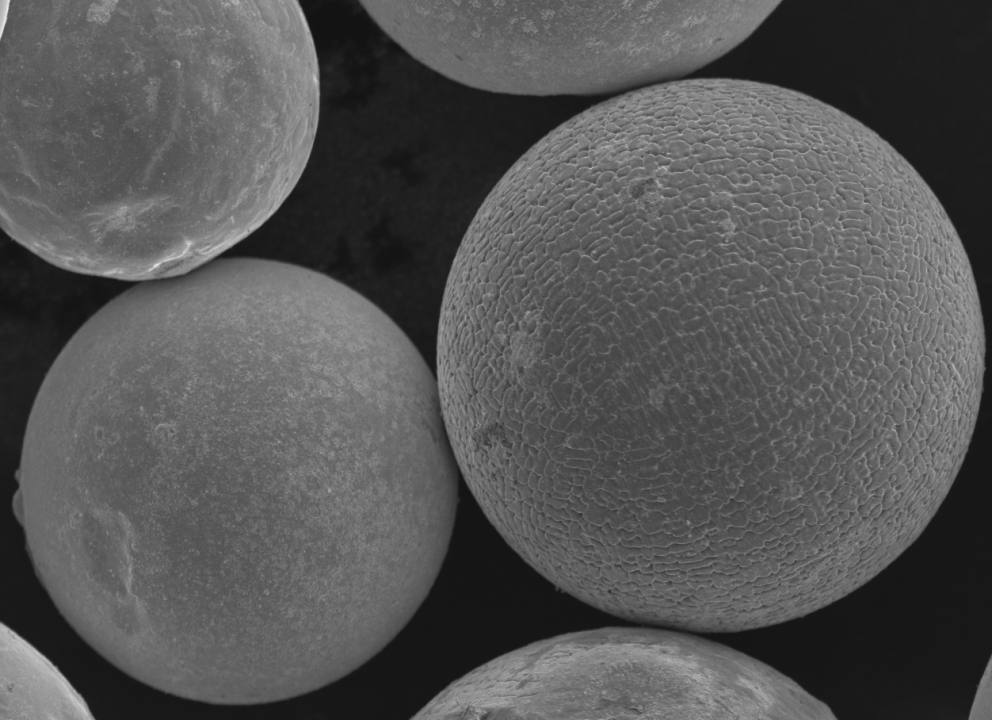

Obtaining metal powders for additive manufacturing involves several methods, each with its unique approach. Gas atomization, the most common technique, sprays high-pressure gas onto molten metal. This process breaks the metal into tiny droplets, which then solidify into spherical particles. Plasma atomization follows a similar path, but it employs a plasma torch to melt the metal. It’s especially useful for metals with high melting points, producing extremely fine particles. Electrolysis, on the other hand, is useful for metals that are hard to reduce. It involves dissolving the metal in a solution and using an electric current to reduce it out, resulting in fine metal particles.

(photo: Jakub Tomaszewski)

Another notable technique in this domain is ultrasonic atomization developed by AMAZEMET. This process utilizes high-frequency sound waves to generate a fine mist from a liquid metal source. The ultrasonic vibrations create capillary waves on the metal’s surface. When the amplitude of these waves reaches a critical point, small droplets are released, forming a fine powder. The particle size in this method primarily depends on the ultrasonic frequency used, allowing for precise control over the powder characteristics. This technique is advantageous for its ability to produce very fine, spherical particles, and it’s highly effective for a wide range of metals and alloys.

Together, these techniques provide a broad spectrum of options for generating metal powders for use in 3D printing and additive manufacturing.

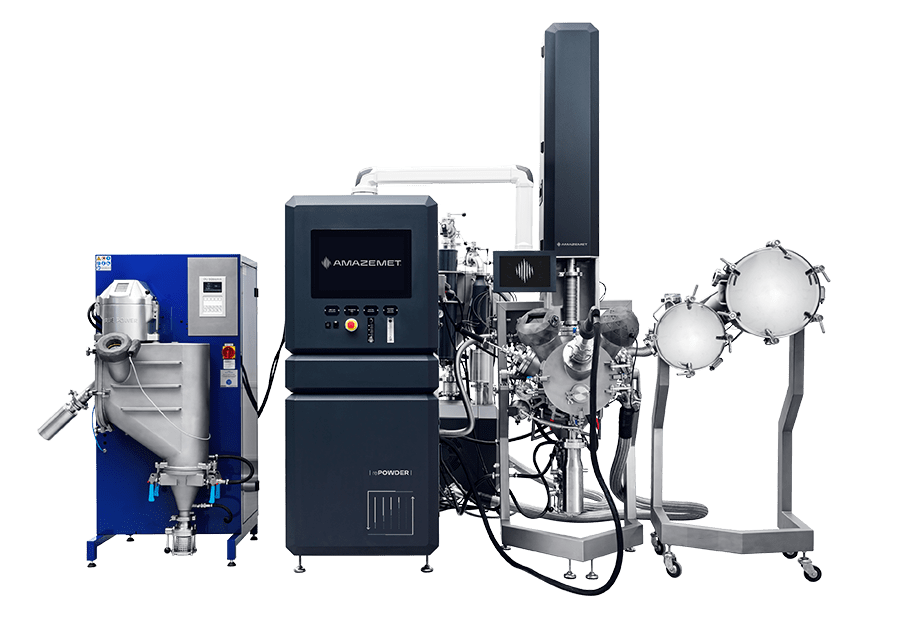

AMAZEMET Technology

rePOWDER – ultrasonic powder atomizer is a liquid-to-solid type of process whereby ultrasonic vibrations are used to create powders. The size of the produced particles depends primarily on the ultrasonic frequency, although it is also influenced by the physical properties of the liquid material. The PSD (Particle Size Distribution) can be modulated by using different frequencies. The choice depends on the type of heat source and atomized material, but in general, the higher the frequency, the smaller the powder particles.

(source: AMAZEMET)

Ultrasonic atomization can be carried out on a wide range of pure elements (e.g., Li, Zn, Mg to Pt, Mo, Ta, W) as well as any alloy composition (e.g., Mg-Li, CuSn6, WTaVTi, MoR). Apparatus is able to atomize chips, failed AM prints, damaged samples, rods, wire, powder from almost any type of metallic material. The rePOWDER platform was designed to enable many different types of processes to be performed using a single device. It includes the preparation of a new composition (arc melting), alloy homogenization, ultrasonic atomization, and additional options for further R&D. Our R&D department is always ready to help develop new materials with tailored chemical compositions.

The Cost of 3D Printing Materials

The cost of 3D printing materials plays a substantial role in determining the overall cost of a project. Material costs can fluctuate greatly based on their type, quality, and the source of procurement. It’s essential to strike a balance between cost-effectiveness and the required quality and performance of the final product. Strategies such as buying materials in bulk, recycling used materials where possible, and careful selection of materials to match the specific project requirements can aid in cost optimization without sacrificing quality.

Future Trends and Conclusion

The materials for additive manufacturing are continuously optimized, introducing numerous new chemical compositions developed by rePOWDER ultrasonic atomizers. Click here to check the list of articles in which we are co-authors. With the ongoing advancements in 3D printing materials, we can expect further breakthroughs. They will push the boundaries of additive manufacturing and redefine its capabilities and applications. Industry must include the environmental concerns that are becoming increasingly important in manufacturing. Future trends in metal additive manufacturing will emphasize sustainability by promoting the use of recycled materials and more efficient energy consumption. The industry will also explore ways to reduce waste and emissions associated with the production processes.

(photo: Jakub Tomaszewski)

In view of the development of artificial intelligence, the machine learning technologies will play a significant role in optimizing metal AM processes. These technologies can help in predicting and preventing defects, automating quality control, and optimizing design for manufacturing (DfAM). This integration will make 3D printing in metals more accessible and reliable.

Whether you’re a hobbyist, a designer, or an industry professional, understanding these materials is key to fully use the potential of metal additive manufacturing.