Alloy Development from Sustainable Materials – Close-Loop of Materials Using Ultrasonic Atomization

Authors

Abstract

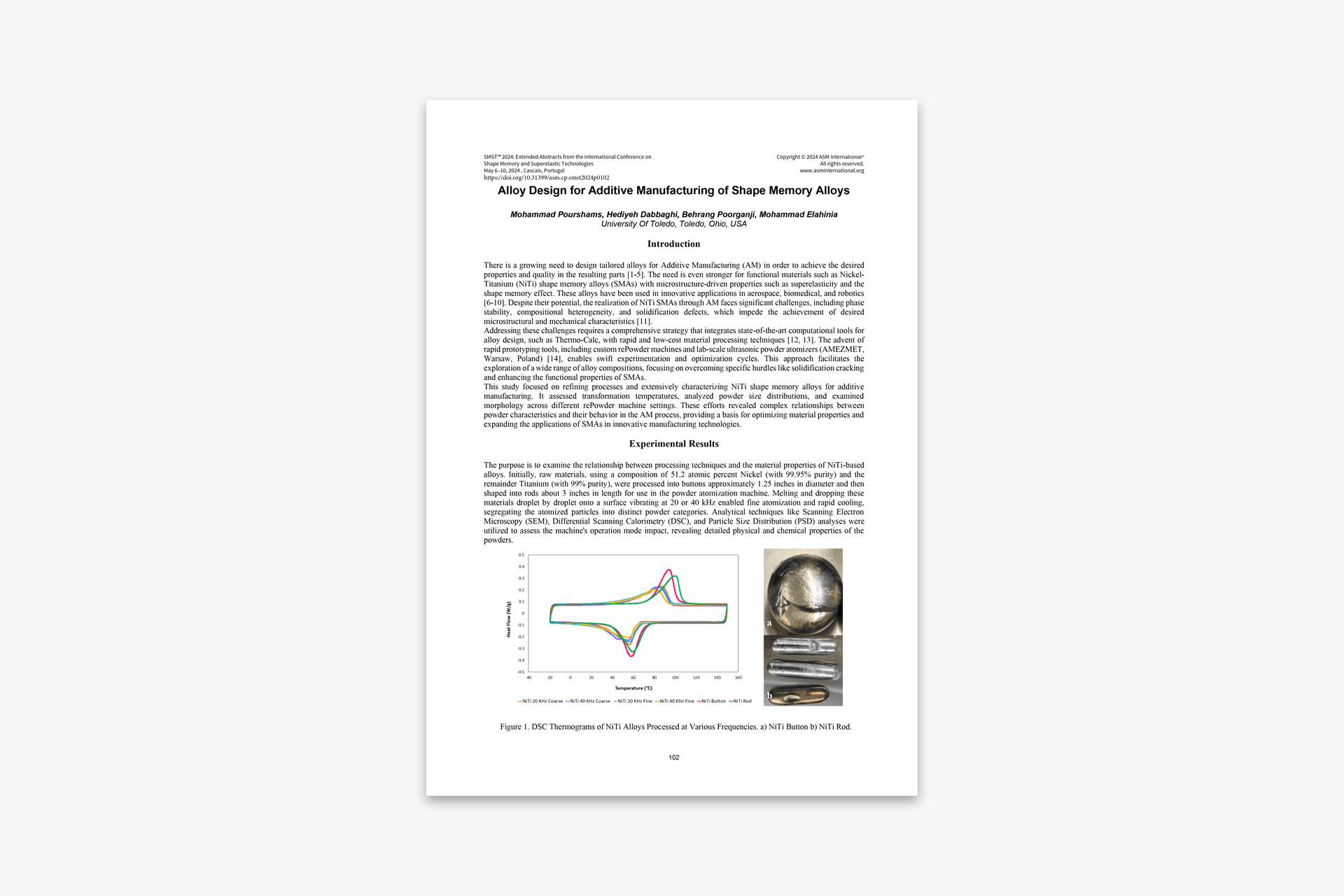

Current methods for the production of spherical powders restrict the development of new chemical compositions dedicated to the additive manufacturing industry. This novel ultrasonic atomization process enables in-house powder production from even one gram up to a few kilograms to verify new alloys. The technology uses vibrations to break the surface tension of liquid metal to allow atomization. To melt the material plasma torch or induction heating can be used allowing to process wide range of metals. Plasma-based ultrasonic atomization was used to manufacture spherical powder of a high-temperature alloy, while induction-based ultrasonic atomization was used to develop a low-melting alloy. Additional case study of recycling titanium alloy maching chips into the powder by arc melting and ultrasonic atomization is presented.