Since our foundation in 2019 as a dynamic spin-off from the prestigious Warsaw University of Technology, we at AMAZEMET have rapidly established ourselves as key innovators in the additive manufacturing (AM) and advanced materials sector. In just six dynamic years (as of May 16, 2025), we have demonstrated remarkable growth and technological prowess, driven by our mission to empower scientists and engineers worldwide with cutting-edge solutions for material development and processing. We are proud that despite numerous market perturbations, our company has remained profitable and is committed to sustainable development. This case study highlights our journey, impactful innovations, and the significant milestones we’ve achieved.

Streamlining Advanced Material Development

The realm of advanced materials and additive manufacturing presents complex hurdles. Developing novel materials, producing specialized powders with precise characteristics, and efficiently post-processing printed parts often involve high costs, intricate procedures, and technological limitations. Scientists and industries globally seek more accessible, cost-effective, and versatile tools to accelerate research, innovation, and the broader adoption of ultrasonic and AM technologies. Recognizing these critical gaps, we embarked on a mission to redefine this landscape.

AMAZEMET’s Three Core Business Lines

To comprehensively address the multifaceted needs of the material science and additive manufacturing sectors, we at AMAZEMET have built our operations upon three synergistic business lines. These business lines not only showcase our core competencies but also highlight our commitment to providing end-to-end solutions, from fundamental research to specialized production.

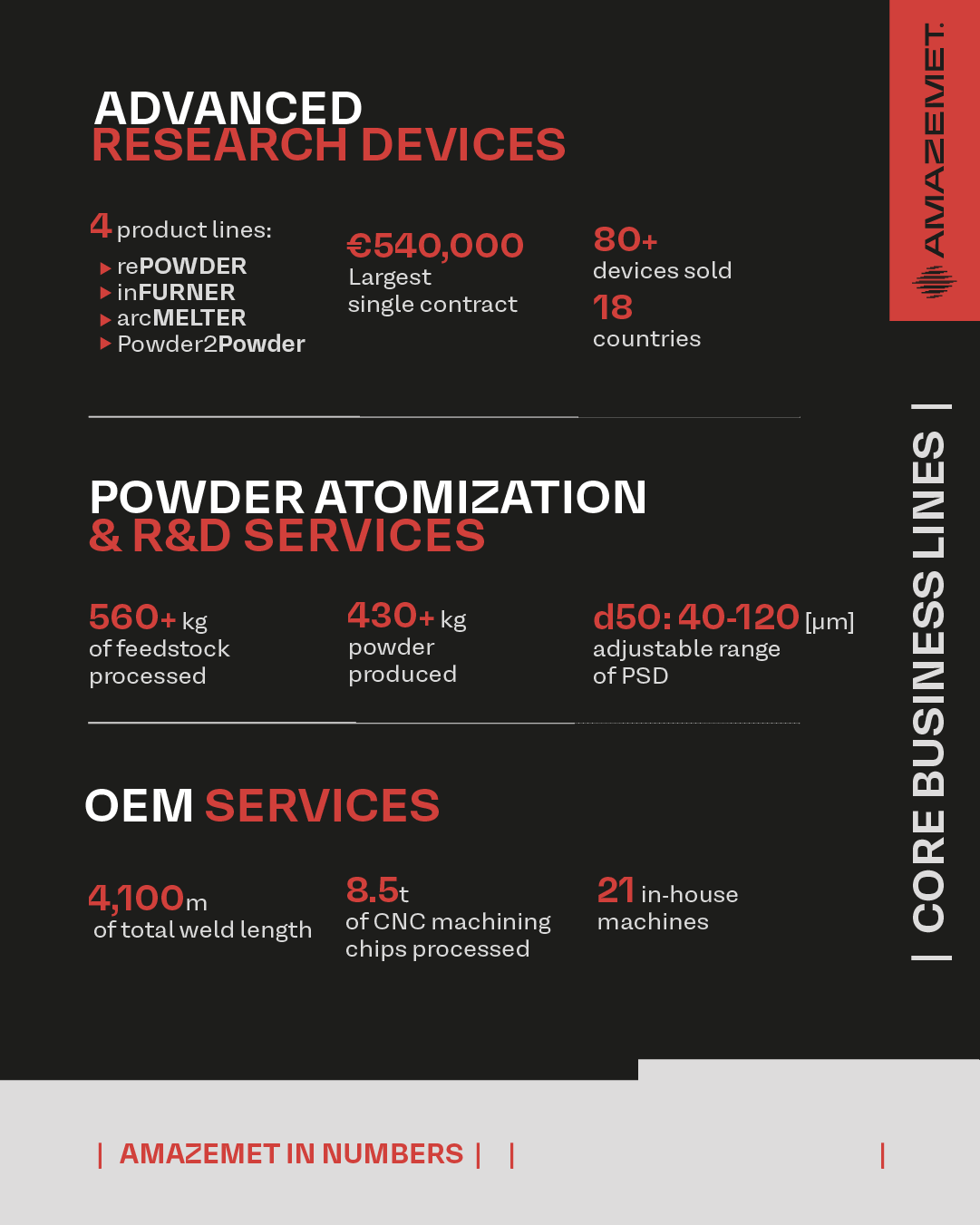

- Advanced Research Devices Manufacturing: This is the cornerstone of our company. We design, develop, and produce four primary product lines of cutting-edge laboratory equipment: rePowder (ultrasonic powder atomization), inFurner (compact high-vacuum heat treatment furnace), arcMELTER (laboratory arc melter), and Powder2Powder (advanced powder processing and modification). These systems empower researchers and industrial clients globally, with over 80 devices sold worldwide, reaching customers in 18 countries. This global adoption enables the exploration and processing of an extensive range of materials. The success of this business line is further underscored by significant projects, including our largest single contract valued at up to €540,000 net. The precision and efficiency embedded in our equipment are hallmarks of this business line.

- Powder Atomization & R&D Services: Leveraging our profound expertise in material processing, we offer bespoke powder atomization services. To date, our R&D and trial processes have yielded over 400 kg of specialized metal powder, with an adjustable particle size distribution (PSD) range of 40–120 microns to meet diverse application needs. We also actively engage in collaborative R&D projects, providing our partners with access to our advanced technology and deep know-how. This collaborative approach accelerates material discovery, optimizes application development, and provides a framework for scientific advancement.

- OEM Services: Complementing our equipment and R&D services, we extend our manufacturing capabilities to offer comprehensive OEM Services for demanding small and medium series. Utilizing our internal machine park—which includes 21 key devices for specialized production—we deliver solutions such as high-precision welding, CNC machining, and metal 3D printing. To date, our team has achieved an impressive 4,100 meters of total weld length and processed over 8.5 tonnes of CNC machining chips, showcasing the scale and precision of our operations. This robust in-house capability allows us to support clients from initial material development through to the delivery of finished, high-quality components and sub-assemblies.

OUR CUSTOMERS

Trusted by Innovators Worldwide

AMAZEMET is proud to collaborate with a diverse range of clients who trust our cutting-edge solutions to advance their projects. Explore some of our key partnerships with industry leaders and innovators driving progress in additive manufacturing and materials science.

Our Philosophy: Open, Modular, and Innovative Solutions for Researchers Worldwide

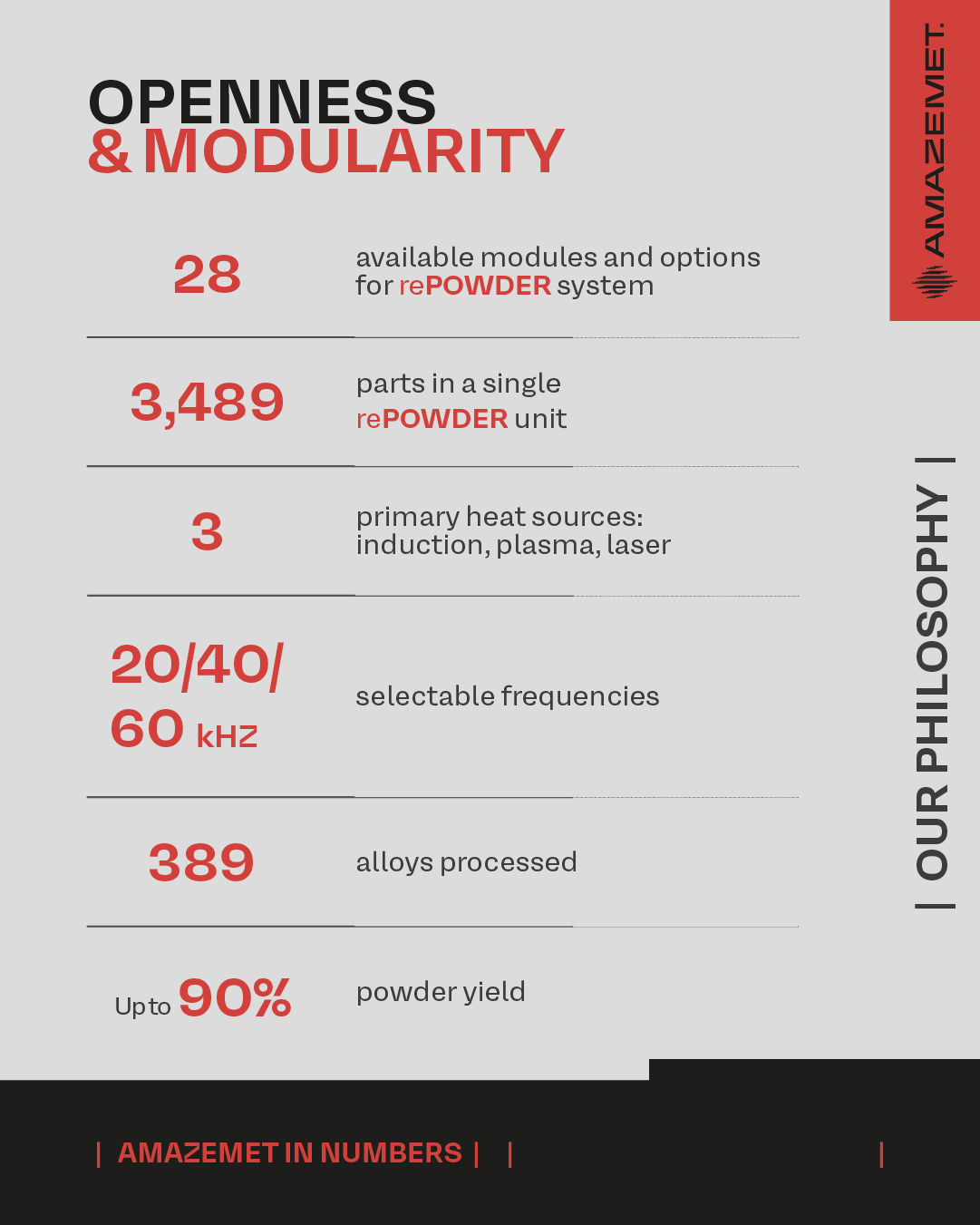

Our core strength at AMAZEMET lies in translating complex scientific concepts into practical, high-performance equipment. We emphasize creating compact, lab-scale devices ideally suited for R&D purposes, with a special focus on equipping university laboratories and research institutions. This philosophy allows us to continually expand our offerings with new solutions and modules, and to propose products tailored to specific client expectations and needs, building upon our four primary product lines. This design approach enables our systems to be highly versatile, for instance, by being capable of integrating with or utilizing a range of three primary heat sources – induction, plasma, and laser technologies – to effectively process a wide spectrum of materials. Our systems, developed under this philosophy, have demonstrated capability in processing an impressive 389 unique alloys.

A representative rePOWDER unit, for example, consists of approximately 3,500 precision parts and offers 28 available modules and options, underscoring its sophisticated engineering. It is designed for creating specialized, small-batch powders, achieving material yields of up to 90%. For rePOWDER specifically, characteristics such as particle size distribution (PSD), sphericity, and flowability – parameters we meticulously control, including the ability to utilize selectable ultrasonic frequencies (e.g., 20 kHz, 40 kHz, 60 kHz) to fine-tune the atomization process – are critical for advanced AM applications.

Furthermore, our philosophy, which includes a proprietary framework for new material development, directly confronts AM industry challenges like powder costs, waste, and sustainability. Technologies like our Powder2Powder (P2P) system, leveraging plasma and ultrasonic atomization, exemplify this. P2P enables efficient powder recycling and reuse for comprehensive lifecycle management, significantly cutting costs and waste while fostering a circular, closed-loop production for sustainable AM.

Driving Innovation Through Research and Development

At the heart of AMAZEMET’s pioneering spirit is a relentless commitment to research and development. We actively push the boundaries of material science and additive manufacturing, underscored by our significant achievements in innovation. Our R&D efforts are evidenced by 49 patent applications filed, with 16 patents already granted, protecting our unique technological breakthroughs. We are deeply involved in the scientific community, currently managing 9 active research projects and having successfully completed 5 co-funded projects. Our proactive approach to seeking out new avenues for discovery is highlighted by over 40 funding applications submitted, and we have secured over €5 million in total funding to fuel these vital activities. Furthermore, our team contributes significantly to the global scientific discourse, with 32 scientific publications, sharing our findings and advancements with the broader research community.

Scientific collaboration is in our DNA

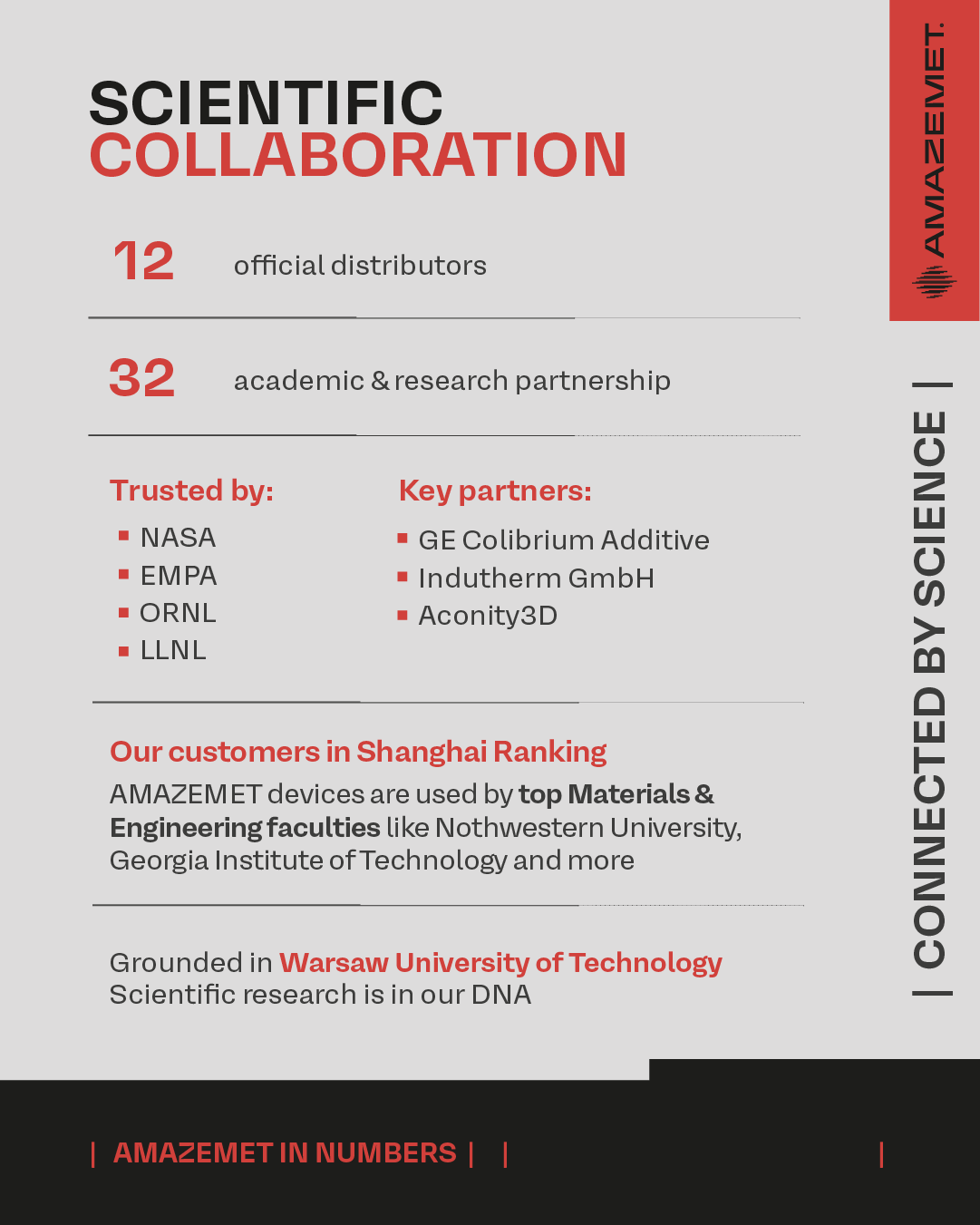

Our heritage as a Warsaw University of Technology spin-off profoundly influences our approach, empowering our team to develop groundbreaking solutions. This foundation, combined with our R&D approach, allows us to provide scientists worldwide with essential tools and technologies. Crucially, this capacity is amplified through extensive collaboration, which is central to our strategy and a testament to the trust placed in our technology and expertise. This is demonstrated through our partnerships with industry leaders like GE (Colibrium Additive), Indutherm GmbH, and Aconity3D, our 12 official distributors who support our extensive global reach, and our 34 academic and research partnerships globally.

We are proud to work with and support some of the world’s most prestigious institutions, including NASA, Empa, Oak Ridge National Laboratory, and Lawrence Livermore National Laboratory. Notably, AMAZEMET devices are used by top-ranked universities featured in the Shanghai Ranking for Materials Science & Engineering, such as Northeastern University and Georgia Institute of Technology, among others. Furthermore, our spirit of collaboration and achievement is illustrated through joint case studies developed with various other leading research institutions and technology companies. These extensive collaborations provide us with access to current knowledge and know-how, create opportunities for joint technological advancement, and allow us to make a broader market impact and popularize our technologies among researchers.

Our Driving Force: Dedication and Expertise of AMAZEMET Team

At AMAZEMET, we cultivate a flat organizational structure and strive for a high standard of organizational culture, drawing inspiration from turquoise principles. We believe that teamwork, self-organization, individual innovativeness, creative problem-solving, efficient project management, and process automation are paramount. This empowering environment is where our talented team thrives.

Our achievements are powered by our dynamic team of 58 highly skilled professionals, including a dedicated core of 19 R&D personnel. The presence of 6 PhDs and PhD students within our ranks ensures a robust connection to cutting-edge research and scientific excellence, constantly pushing the boundaries of material science. We are also committed to nurturing future talent, having hosted 14 interns and trainees, providing them with invaluable experience in a high-tech environment and benefiting from their fresh perspectives. This collective deep expertise is crucial for developing sophisticated, modular equipment and providing our clients with unparalleled support. The team’s dedication and vibrant energy – perhaps best illustrated by the approximately 60 kg of coffee consumed monthly! – are the true engine behind our innovations and client successes.

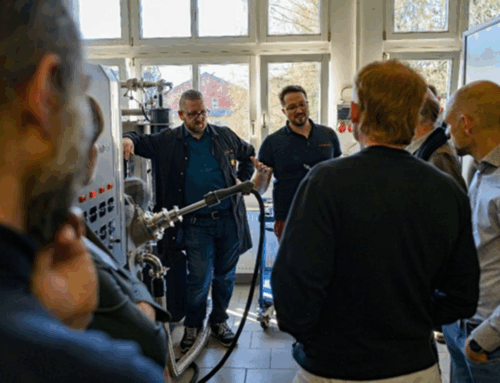

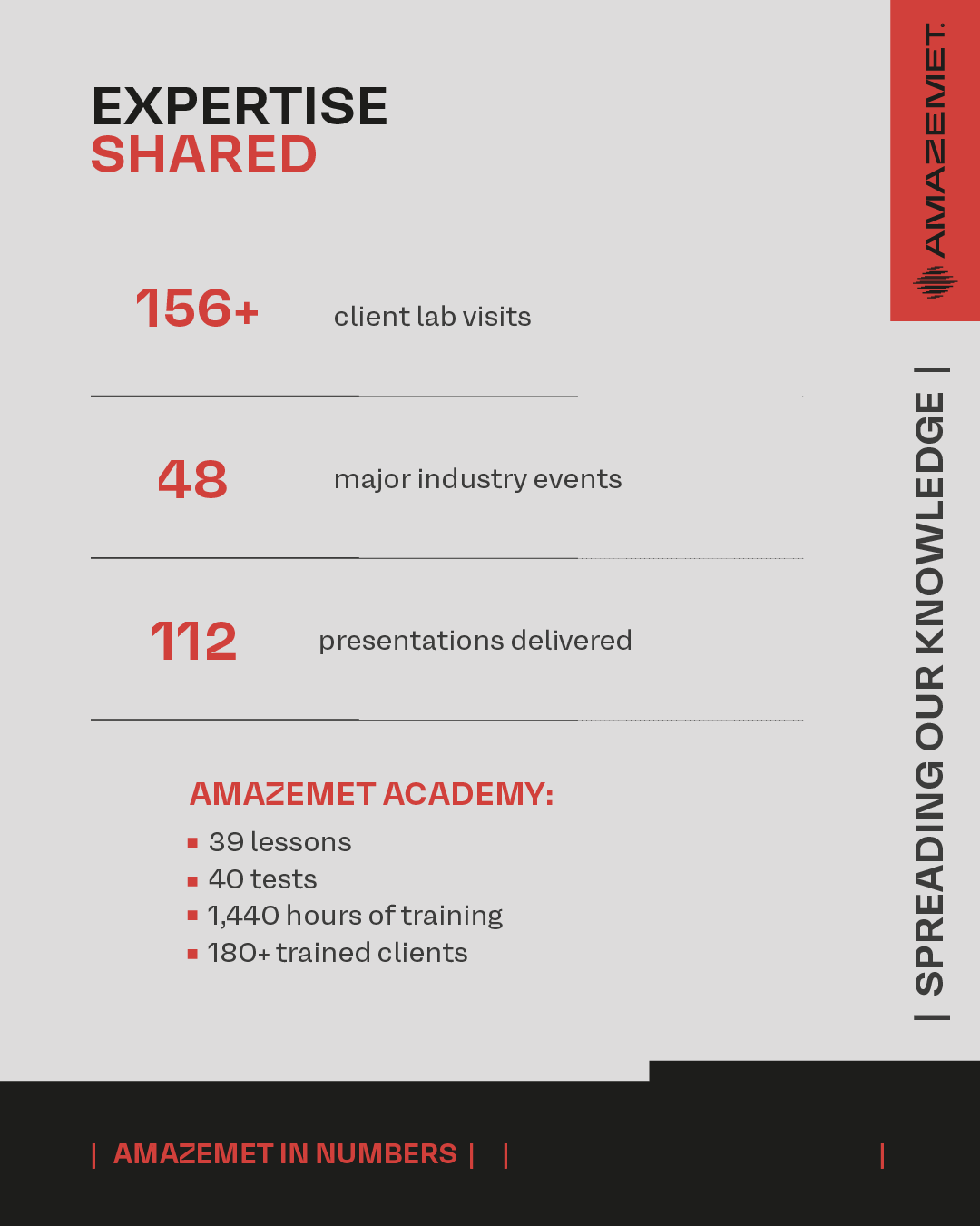

Sharing our expertise with scientific community

We actively engage with the scientific and industrial communities. With over 156 client visits to our R&D lab in Majdan, Poland, we foster direct interaction and valuable feedback. Our presence at 48 major industry events and delivery of 112 presentations worldwide further solidify our position as thought leaders. As part of our commitment to customer success, we offer comprehensive training through our AMAZEMET ACADEMY. This platform provides 39 lessons and 40 tests, covering everything from detailed rePOWDER operation to foundational knowledge related to our core expertise. To date, this has resulted in approximately 1,440 hours of specialized training delivered to around 180 client personnel, ensuring they can maximize the potential of our equipment.

Let’s Shape the Future of Material Science Together

As we continue to share our expertise and engage deeply with the global scientific community, our journey since 2019 has solidified AMAZEMET’s role as a catalyst for innovation in material science. Our three core business lines, from advanced device manufacturing to specialized R&D and OEM services, are all geared towards one central aim: empowering researchers and industry pioneers. By providing versatile tools, fostering collaboration, and relentlessly pursuing new technological frontiers, we are not just participants in the advancement of materials – we are dedicated partners in engineering a future defined by discovery and groundbreaking applications.

Contact AMAZEMET today and discover how we can boost your research and development. Let’s engineer the future of material science, together.