AMAZEMET and Siemens: Building a Digital Foundation for Additive Manufacturing Hardware Innovation

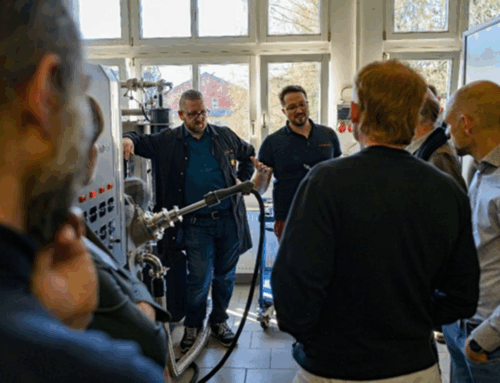

At AMAZEMET, our identity is rooted in solving real-world research challenges because that's how we began. As a spin-off from the Warsaw University of Technology, our company was born from a Ph.D. project that required access to affordable, small-batch metal powders—a need the market couldn't meet. This experience shaped our mission: to develop practical, accessible tools for materials science. Our collaboration with Siemens and the implementation of the Siemens Xcelerator portfolio is a key part of our story, demonstrating how we built the necessary digital infrastructure to scale from an academic project to a global hardware provider.

From Research Initiative to a Global Company: The Inevitable Need for a Unified Digital Workflow

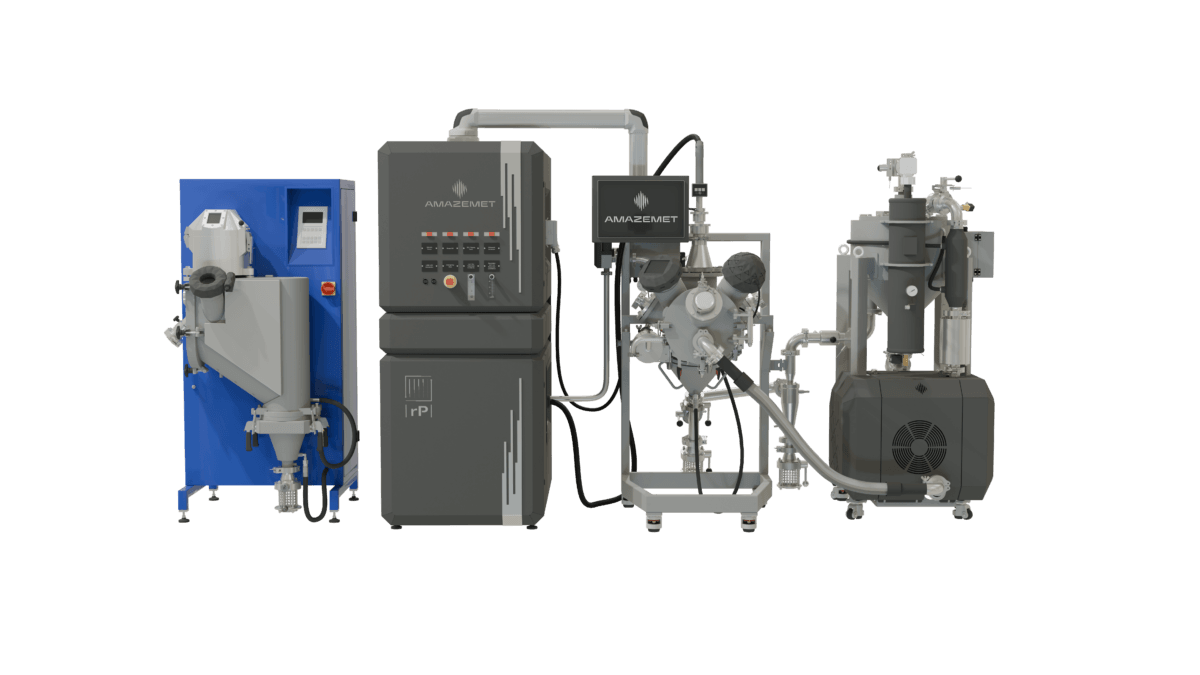

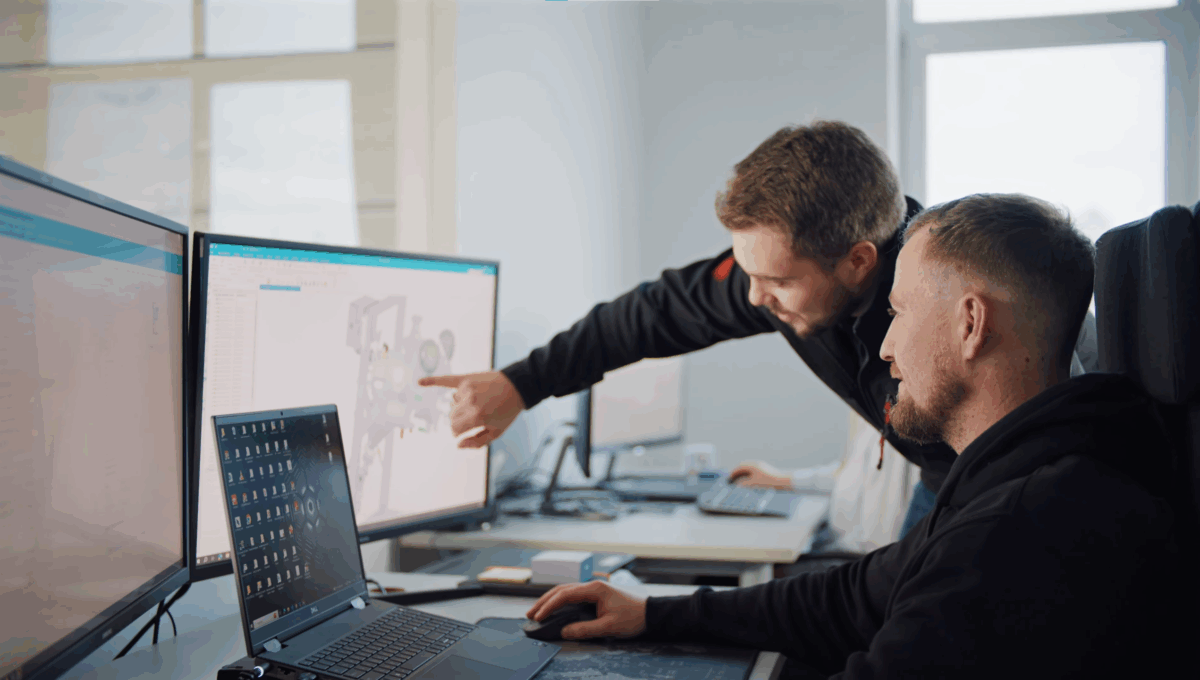

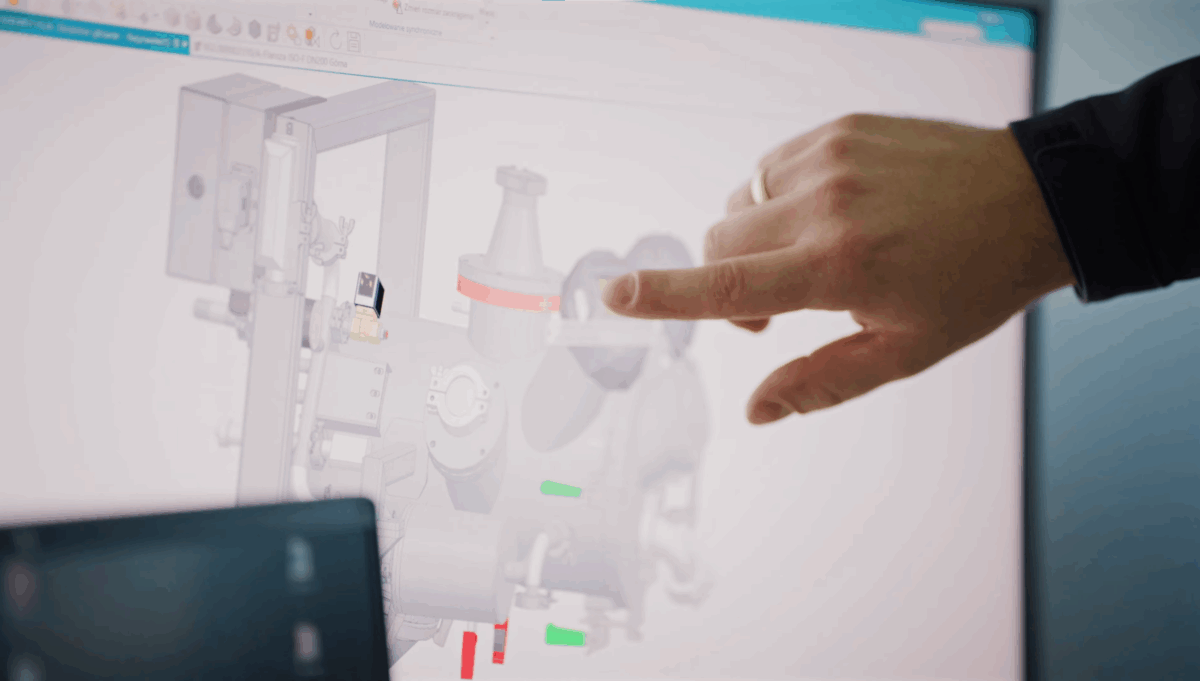

AMAZEMET started when our founding team engineered an ultrasonic atomizer to affordably produce experimental powders for their research. This solution grew into a 60-person international company that now provides a suite of tools, including the rePOWDER ultrasonic atomizer and the inFURNER high-vacuum furnace. As our team and product complexity grew, so did our operational challenges. Engineering data, from design files and Bills of Materials (BOMs) to service documentation, was siloed across different systems. This created a high risk of sending incorrect designs to production—a costly error we could not afford as we scaled. A centralized, digital approach was no longer optional; it was critical.

Implementing Siemens Xcelerator for Specific Engineering and Data Management Challenges

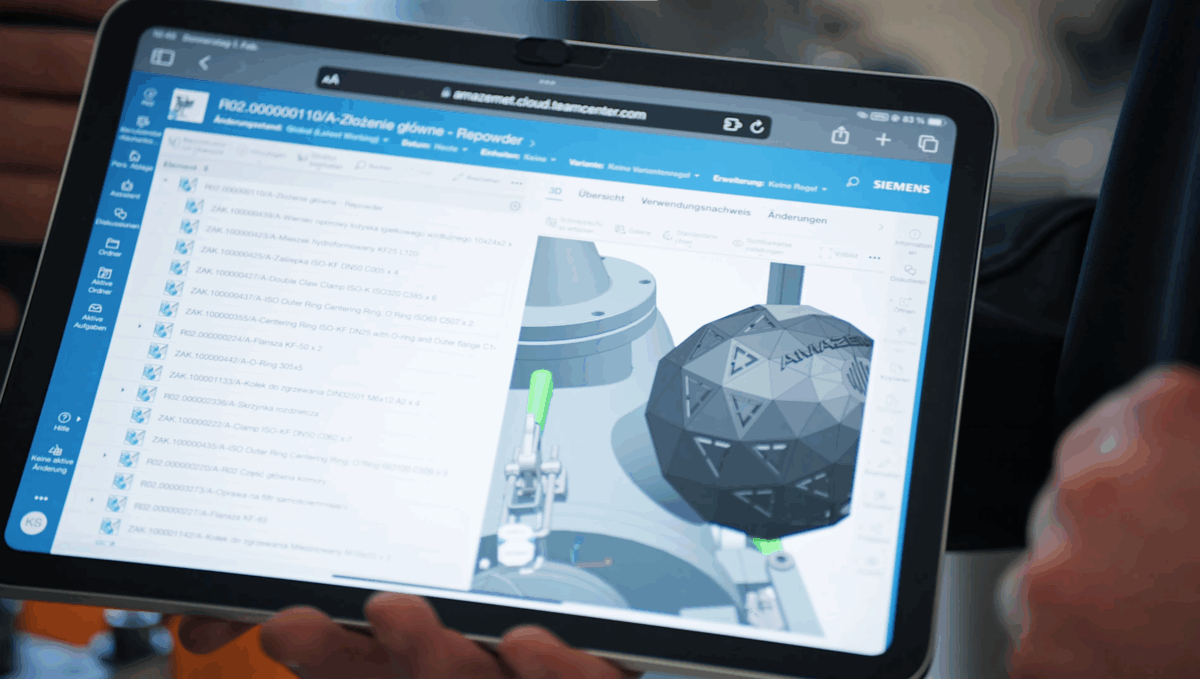

To resolve these issues, we adopted key solutions from the Siemens Xcelerator portfolio: Siemens NX™ for product engineering and Teamcenter® X for cloud-based Product Lifecycle Management (PLM). The new platform directly addressed our primary pain points by unifying product development, manufacturing processes, and documentation.

The benefits of each component became clear. As our CEO, Łukasz Żrodowski, notes:

"With our team expanding, centralizing data became crucial to prevent costly errors like sending incorrect designs for production. That's why we went digital with Siemens Xcelerator."

A Customer Success Plan for Strategic Implementation

Siemens worked with us as a strategic partner to develop a Customer Success Plan tailored to our needs. This plan outlined a clear path for adoption, onboarding, and continuous improvement, ensuring we could extract the full value from the software. This collaborative guidance helped us navigate the complexities of scaling, shorten our development timelines, and establish a digital framework prepared for our future objectives.

As Mariusz Zabielski, Vice President at Siemens Digital Industries Software, observed:

"AMAZEMET is a perfect example of how innovators across industries are adopting Siemens Xcelerator to digitally transform and fulfill the promise of widespread additive manufacturing adoption."

Measurable Outcomes of the Digital Transformation

Our implementation of Siemens Xcelerator has yielded direct, measurable improvements in our operational efficiency:

- Accelerated Product Development: The stability of Siemens NX allows our engineers to work on complex assemblies without system crashes or data loss, speeding up design iterations.

- Centralized Data Integrity: Teamcenter X acts as our single source of truth, eliminating errors that arise from outdated or fragmented documentation.

- Enhanced Team Collaboration: The cloud-based platform ensures our growing international team has secure, on-demand access to the correct data and files.

- Infrastructure for Growth: We now have a scalable digital backbone that can support our planned expansion.

A Stronger Foundation for Our Customers' Success

Our goal at AMAZEMET remains to create innovative hardware that empowers scientists and engineers. Investing in our digital infrastructure with Siemens was a strategic move to reinforce this commitment. This transformation ensures our internal processes can keep pace with our innovation. For our customers in research, energy, and aerospace, this means we can deliver better products with greater reliability.

As we look ahead to extend our reach into industrial additive manufacturing and explore new markets, we do so with the confidence that our operations are built on a solid foundation, ready to support the next generation of materials development.