Technical University of Munich: Future-Proof Equipment for Advanced Research | Case Study

Universities and research institutes today face the challenge of quickly changing research directions and the need to adapt their equipment to new projects, often within tight budget constraints. AMAZEMET’s rePOWDER ultrasonic atomization system addresses this by providing an open platform designed for modular expansion. This allows institutions to start with a core system and expand their capabilities as research needs evolve and funding becomes available. The journey of the Technical University of Munich (TUM) with rePOWDER is a prime example of this principle, showing how upgradability supports innovation and protects the long-term value of research investments.

Chemnitz University of Technology: Partnership and Persistence in Securing Funding | Case Study

At AMAZEMET, we understand that the path to groundbreaking scientific discoveries often involves a lengthy and demanding process of securing funding. Our mission extends beyond providing innovative technological solutions; we strive to be a supportive partner for scientists at every stage of their journey. The case study of our collaboration with Chemnitz University of Technology (CUT) and the implementation of the rePOWDER system perfectly illustrates this approach.

Join AMAZEMET at ITSC 2025 & AeroMat 2025 in Canada

We'd be delighted to meet with you during our time in Vancouver! Whether you're interested in the advantages of our ultrasonically atomized powders for Cold Spray or exploring the possibilities for alloy prototyping in Additive Manufacturing, please feel free to reach out and schedule a meeting with Bartosz Morończyk via LinkedIn.

Don’t Miss AMAZEMET at Plasma Tech 2025 in Portugal!

We'd love to meet with you during Plasma Tech 2025! Whether you're interested in learning more about our ultrasonic atomization technology for metal powder recycling or exploring collaboration opportunities, we're here to help. Feel free to reach out and schedule a meeting with Tomasz Choma via LinkedIn.

Meet AMAZEMET at HIP International Conference 2025

We are excited to announce AMAZEMET’s participation in the 14th International Conference on Hot Isostatic Pressing (HIP 2025), taking place from April 6 to 10, 2025, in Aachen, Germany.

Meet AMAZEMET at EMAM Symposium 2025

We are pleased to announce our participation in the European Military Additive Manufacturing Symposium (EMAM) 2025, taking place on April 8–9, 2025, at the Maritim Hotel in Bonn, Germany. This event brings together key players from defense, academia, and industry to discuss the role of additive manufacturing in strategic and security-critical applications.

Meet AMAZEMET at AMUG 2025

At AMUG 2025, AMAZEMET will showcase the potential of its innovative Powder2Powder (P2P) technology. Visit us at Booth 74 to learn more about AMAZEMET's innovative technologies and explore how we’re advancing the field of metal additive manufacturing (AM).

Meet AMAZEMET at TMS 2025 Annual Meeting & Exhibition

Meet AMAZEMET at TMS 2025 Annual Meeting & Exhibition. Our experts will be on hand to showcase AMAZEMET's cutting-edge solutions, like Powder2Powder - ultrasonic re-atomization device, and answer any questions you may have.

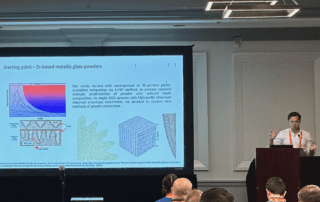

Alloy Design for Additive Manufacturing of Shape Memory Alloys

Authors: Mohammad Pourshams; Hediyeh Dabbaghi; Behrang Poorganji; Mohammad Elahinia

Novel titanium-based sulfur-containing BMG for PBF-LB/M

Authors: Hanna Schönrath, Jan Wegner, Maximilian Frey, Martin A. Schroer, Xueze Jin, María Teresa Pérez-Prado, Ralf Busch & Stefan Kleszczynski