Securing Funding Challenge

At AMAZEMET, we understand that the path to groundbreaking scientific discoveries often involves a lengthy and demanding process of securing funding. Our mission extends beyond providing innovative technological solutions; we strive to be a supportive partner for scientists at every stage of their journey. The case study of our collaboration with Chemnitz University of Technology (CUT) and the implementation of the rePOWDER system perfectly illustrates this approach. It showcases how sustained collaboration and shared dedication to research can drive technological advancement and open new avenues for exploration.

Chemnitz University of Technology & AMAZEMET – Addressing the Custom Powder Challenge

At the Chair of Materials and Surface Engineering at Chemnitz University of Technology (CUT), led by Prof. Thomas Lampke, Dr. Thomas Lindner and his research team are advancing the development of novel alloys for use in thermal coating technologies. A key challenge in this work has been the production of high-quality powders in small, customizable batches to match the flexible alloy designs under investigation. This flexibility allows the team not only to adapt conventional alloys but also to explore entirely new compositions, such as high-entropy alloys (HEAs).

Producing sintered samples allows for a direct comparison between cast and powder-metallurgical materials, providing a solid basis for analyzing structure–property relationships. This significantly advances the research and development of novel alloy systems.

The collaboration with AMAZEMET and the implementation of the rePOWDER system has played a pivotal role in overcoming these challenges. The ability to rapidly produce custom powders has opened new opportunities for alloy design and evaluation, allowing the team to explore promising material systems tailored for demanding applications.

Building on its international research network, the department has initiated a strong consortium for a proposed M-ERA.NET project. In collaboration with the University of Wroclaw and AMAZEMET in Poland, HS-Technik in Austria, and the University of Iskenderun in Turkey, Chemnitz University of Technology is focusing on the further development of high-manganese, iron-based alloys with improved work-hardening capabilities for surface protection applications. Central to these efforts is the use of the rePOWDER system as a core research tool.

AMAZEMET’s Support on the Road to M-ERA.NET Funding

At AMAZEMET, we actively supported Chemnitz University of Technology throughout the grant application process. Our involvement included:

- Collaboration in proposal development: The participation of an innovative SME like AMAZEMET in the consortium strengthened the application.

- Providing expert knowledge and technical information: We explained how the unique capabilities of rePOWDER, such as independent material prototyping (arc-melting, ultrasonic atomization of reactive materials), could significantly enhance the project. We emphasized how rePOWDER would provide long-term support for research on HEA materials and steels for thermal spraying.

- Necessity of rePOWDER for the project’s scientific goals: We clarified that the lack of an in-house atomizer prevented CUT from achieving key objectives of the M-ERA.NET project.

- Participation in key events: The joint presentation at the 24th Materials Engineering Colloquium (WTK) strengthened the project’s credibility and facilitated knowledge exchange with other scientists.

As Tomasz Choma from AMAZEMET recalled:

“We maintained collaboration by persistently reiterating the opportunities within M-ERA.NET. We shared our own experiences of applying for funding in academia, demonstrating that perseverance pays off.”

rePOWDER – Grantmaking Ultrasonic Atomization Platform

In 2024, the rePOWDER system was installed and commissioned at Chemnitz University of Technology. However, this was not the end of our collaboration, but rather an exciting new phase.

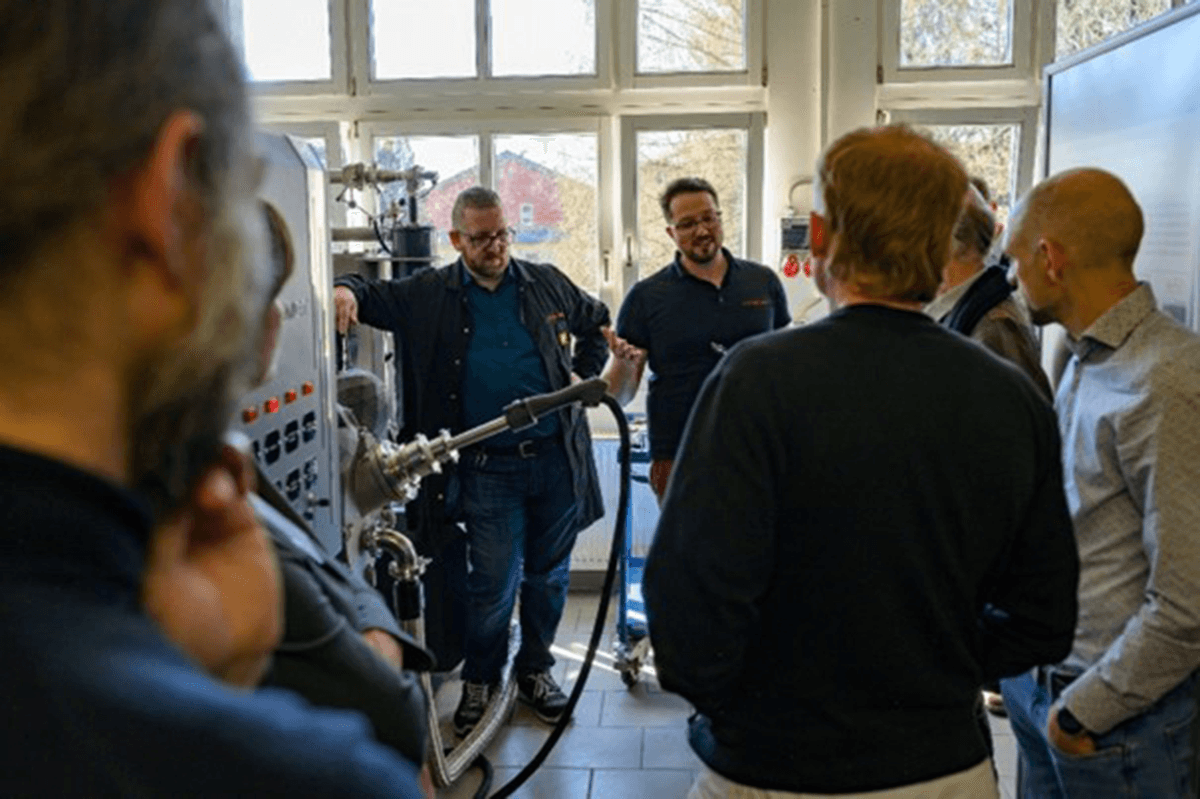

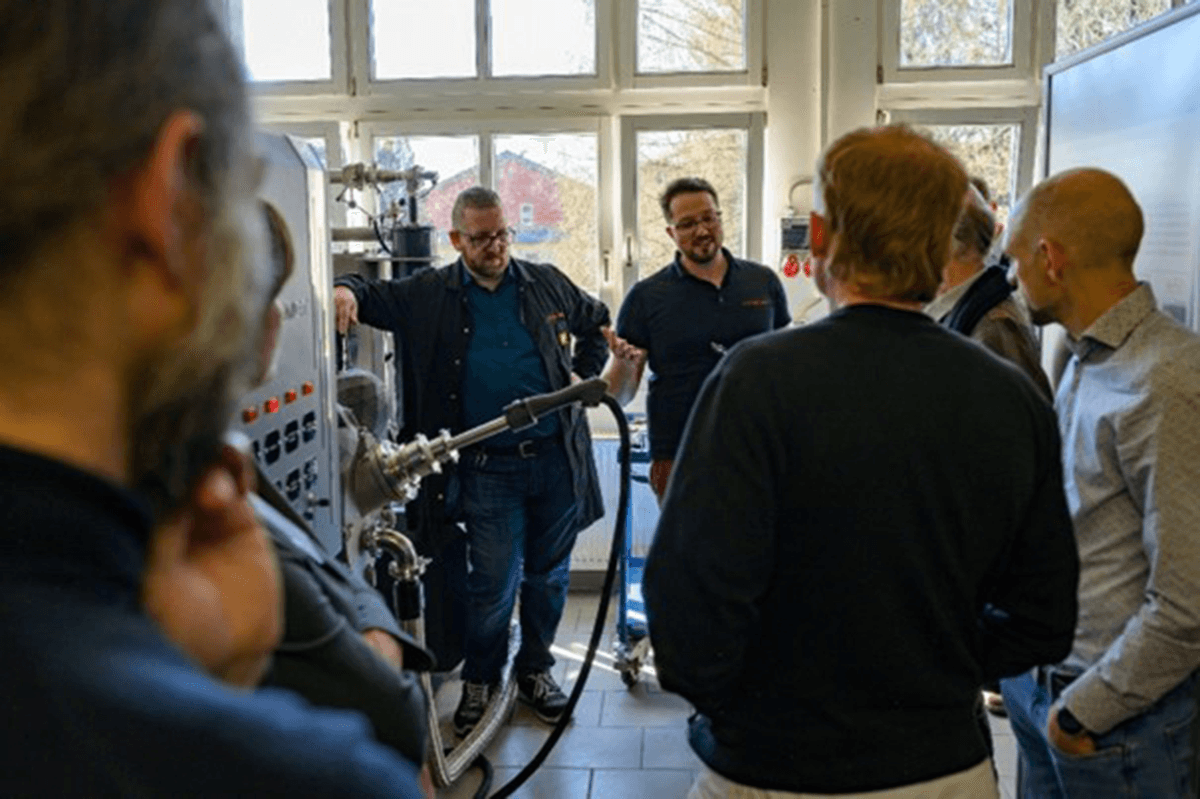

Figure 2: Participants of the WTK conference during a Lab Tour, observing a demonstration of AMAZEMET’s rePOWDER ultrasonic atomizer. Pictured (from left to right): device operator from Chemnitz, Bartosz Morończyk (AMAZEMET); Thomas Lindner (Chemnitz University of Technology). (Image courtesy of Chemnitz University of Technology).

At AMAZEMET, we believe that innovative equipment like rePOWDER plays a crucial role in helping scientists secure funding for ambitious research projects. rePOWDER offers:

- Independence and control: Scientists are no longer limited to collaborating with industry or external atomization services. They have complete control over powder production.

- Versatility: The ability to work with various materials and technologies means that rePOWDER can be utilized in multiple projects, increasing the chances of securing future grants.

- Reduced costs and time: In-house powder production is often more economical and faster than ordering from external suppliers.

- Potential to generate new projects: The unique capabilities of rePOWDER open new research avenues and inspire the submission of further funding applications.

As Łukasz Żrodowski, CEO of AMAZEMET, emphasizes:

“Thanks to the remarkable openness and versatility of rePOWDER, scientists have the opportunity to independently produce powder for their research and have full control over both materials and processes. This makes it much easier to plan ambitious research without being constrained by the limitations imposed by industrial powder suppliers.”

Figure 3: Bartosz Morończyk delivering his pitch at the beginning of the WTK conference

Long-Term Partnership and Shared Success

Our collaboration with Chemnitz University of Technology is an excellent example of a long-term partnership that extends beyond the mere sale of equipment. We actively support our clients or partners at various stages of their scientific work, especially during the long process of securing funding, by offering:

- Support during the securing funding process: We provide assistance in applying for research grants and funding opportunities.

- Partnership in research and development: We share our expertise and collaboratively seek new research opportunities.

- Atomization services: Even before the purchase of equipment, we offer the possibility of research collaboration and powder atomization service.

- Joint scientific publications: We actively engage in joint publications, contributing to the advancement of scientific knowledge.

- Extensive network of contacts: We help in establishing collaborations with other universities and companies worldwide.

As Bartosz Morończyk, Application Engineer at AMAZEMET, concludes:

“At AMAZEMET, we understand the dynamics of scientific projects. We ourselves actively apply for grants. Our goal is to build lasting relationships and support scientists in their pursuit of innovation.”

Figure 4: International Thermal Spray Conference in Milan/ITALY, 2024. Paweł Sokołowski (PWr) networking with Thomas Linder (Chemnitz University of Technology), a representative of HS Technik, and Bartosz Morończyk from AMAZEMET.

Let’s innovate together

If you are a scientist seeking innovative solutions in metal powder atomization and a partner who understands the challenges of securing funding, contact us. At AMAZEMET, we believe that together we can achieve much more.