Learn more about our technology, products & services

FREQUENTLY ASKED QUESTIONS

Find the answers to commonly asked questions regarding our technology, services, and products. If you don’t find the information you’re looking for, feel free to contact us directly for further assistance.

Choose the category:

or use the search tool:

Technology

Training typically takes three days. Operators will be equipped to handle operations, basic maintenance, and troubleshooting, with ongoing support available.

Modularity provides:

- Scalability for future upgrades

- Flexibility to adapt to various applications

- Reduced downtime during upgrades or maintenance

Recycling works for most ferrous and non-ferrous materials. Materials with severe contamination or chemical degradation may require additional preparation or may not be suitable for reatomization.

Ultrasonic atomization offers:

- Higher sphericity and flowability of powders

- A narrower range of particle sizes

- Flexibility for a wide range of alloys

- Cost savings due to reduced inert gas consumption.

A closed-loop design minimizes contamination and ensures uniform quality across batches. Real-time monitoring and control further enhance consistency.

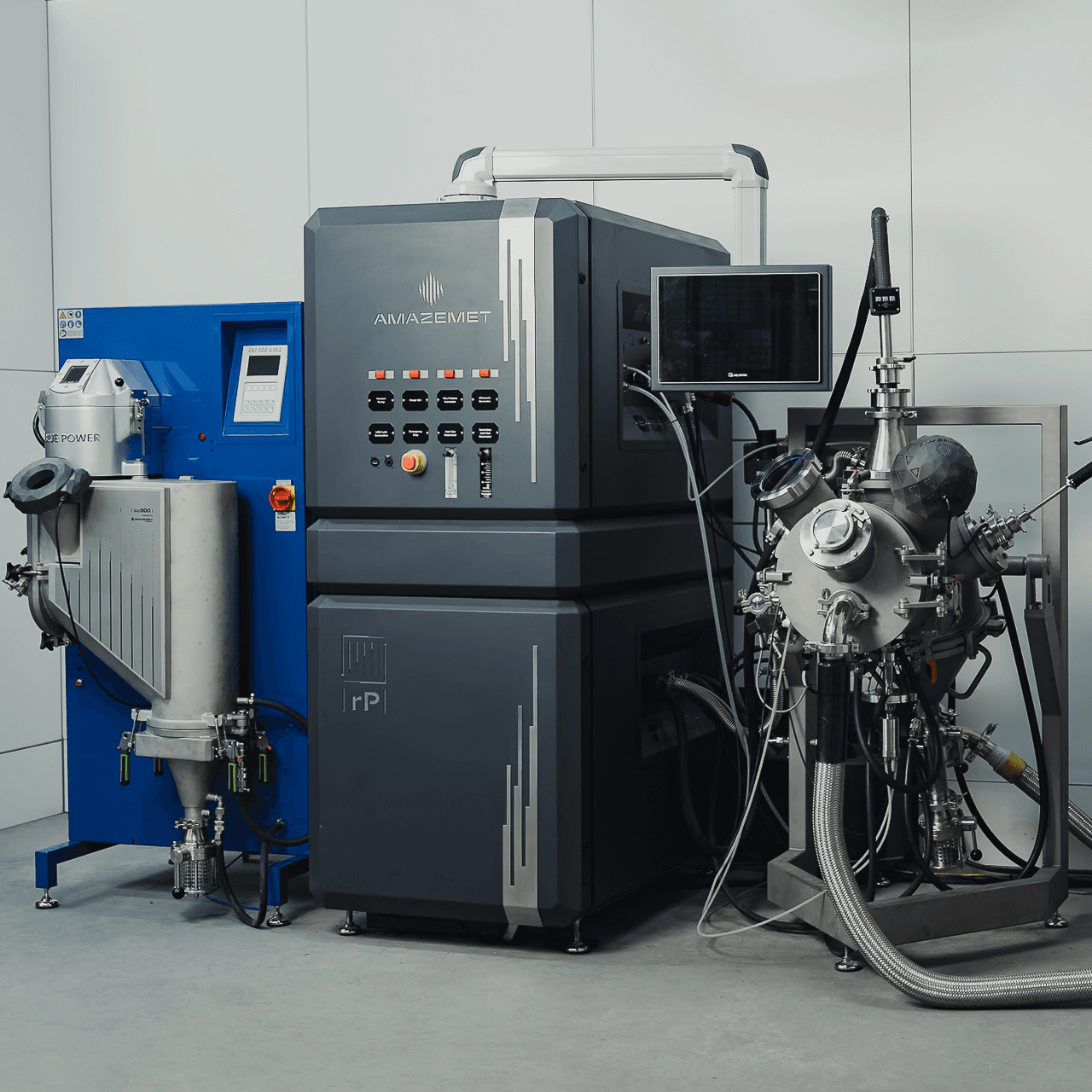

While upgrades can be added to the basic version, they may involve additional costs depending on the complexity and nature of the upgrade. However, the system is designed to be modular, so future upgrades can be integrated with minimal disruption and at any time. New modules that are being continuously developed by AMAZEMET are designed to be upgradable on every rePowder platform.

Training typically takes 3 days, depending on the operator’s experience with similar equipment. After this period, operators should be able to smoothly run the process and perform basic maintenance tasks. Ongoing support and training are also available to help operators improve their proficiency over time.

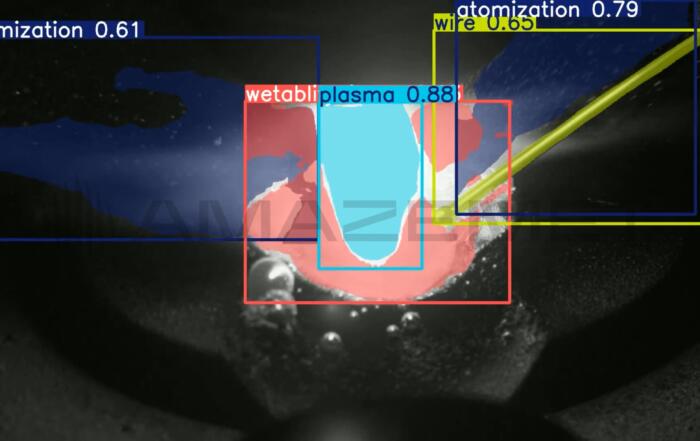

The process is controlled through a user-friendly interface that allows you to set and monitor various parameters such as temperature (induction) or arc current (plasma), ultrasonic frequency, overpressure, and feeding rate (in case of continuous wire feeder). Real-time data acquisition and feedback systems ensure precise control over the atomization process.

It is possible to run only one heat source at a time, both plasma and induction are stand-alone units and they share a control unit. While both cannot be used at the same time it is possible to perform processes on one of them while the other is being cleaned and prepared for the next processes.

The system operates in a vacuum or controlled inert atmosphere to minimize oxygen levels during the atomization process. By purging the chamber with inert gases like argon or helium, we can reduce oxygen levels to below 50 ppm, depending on the system configuration and the required material specifications. If further reduction of oxygen is needed the getter heating and closed loop recirculation allows to reduce the oxygen level below 10 ppm.

Our expertise in atomization spans a wide range of materials including magnesium, aluminum, titanium, steels, nickel, platinum group metals, refractory alloys and various HEAs. We’ve successfully atomized materials with complex compositions, achieving high sphericity and quality of the powder. Some challenges include handling materials with high reactivity or low vapor pressure, which require careful process control.

The maximum feedstock input quantity depends on the system’s capacity, typically ranging from a few to a few hundred grams. The feedstock is usually fed through a feeder that allows precise input into the melting zone, ensuring consistent atomization.

- Induction melting: Best suited for non-ferrous materials with melting points up to 1300°C. It’s efficient for materials that require precise temperature control and are sensitive to contamination.

- Plasma torch: Ideal for ferrous materials and those with high melting points up to 3000°C. It provides a broader range of material compatibility, including refractory metals.

You might need both heat sources to handle a wide range of materials with different melting points and physical properties, allowing for more versatile production capabilities.

The system can atomize a wide range of metals and alloys, including ferrous and non-ferrous materials. Using either induction or plasma systems nearly all alloying systems can be processed.

Different sonotrodes are designed to handle various materials and frequency ranges. Some are optimized for atomization of high-melting-point metals, while others are suited for lower-melting-point alloys. The design and material of the sonotrode can significantly affect the atomization efficiency of certain alloys.

The closed-loop cycle is designed to minimize contamination and maintain high powder quality during recycling. The failed printouts, samples after mechanical testing or leftover powder can be atomized again. This is especially beneficial for expensive and exotic materials.

Feedstock materials should be as pure as possible to avoid contamination during atomization. Special preparation might include degassing, preheating, or surface cleaning to remove oxides and other contaminants. The system is designed to handle minor impurities, but the quality of the feedstock directly affects the final powder quality.

Sales

The closed-loop design enables reatomization of leftover powder, failed prints, or mechanically tested samples, reducing waste and saving costs.

The system supports a wide range of materials, including:

- Tin, lead, bismuth, magnesium, aluminum, copper, titanium, nickel, and cobalt

- Refractory alloys (e.g., molybdenum, niobium, zirconium).

- High-entropy alloys (HEAs).

Yes, ultrasonic atomization produces powders with high sphericity and flowability, making them ideal for additive manufacturing processes such as LPBF, DED, and EBM.

Yes, AMAZEMET offers free consultations with their application engineers. Customers are encouraged to schedule a meeting to discuss their requirements and ensure the device is tailored to their specific applications.

Depending on the level of customization, lead times range from 12 to 18 weeks.

Yes, AMAZEMET can assist with funding options such as Siemens leasing programs, national grants, and European funding opportunities.

Pricing varies depending on customization, including heat sources, ultrasonic frequency, and additional features like feeders and instruments. Visit AMAZEMET’s website or contact the sales team for a detailed quotation. You can also use our device configurator.

The device is designed to fit most laboratory spaces. Space requirements depend on the system’s configuration and optional modules. Contact AMAZEMET for detailed facility guidelines.

Yes, AMAZEMET provides full training and ongoing support for operators to ensure smooth device operation. The standard training program lasts three days but can be extended depending on operator experience or specific customer needs. Training is available either on-site or at AMAZEMET’s facilities.

Custom upgrades can be developed in two ways:

- Collaborative Development: AMAZEMET brings its experience and knowledge to design and manufacture tailored upgrades that meet your specific requirements.

- Open System (Sandbox): The rePowder platform is designed as an open system, allowing customers to develop and integrate their own solutions or modifications independently. This flexibility ensures that the system adapts to your evolving needs. Such upgrades however should be discussed with AMAZEMET for safety and warranty reasons.

Yes, the modular design of AMAZEMET’s devices allows for upgrades to be added later. Upgrades may involve additional costs depending on complexity but are designed for seamless integration with the existing system. All new modules are compatible with the rePOWDER platform.

Equipment

Yes, the platform supports additional sensors and instruments, such as oxygen sensors and cameras. Customers can integrate their own instruments after consulting AMAZEMET.

Powder is collected in airlock containers or directly in the chamber using antistatic brushes. For reactive powders, fireproof vacuum cleaners or specialized containers are recommended.

Yes, continuous atomization is possible with appropriate feeding systems, such as automatic bar feeders (up to 2 meters) and continuous wire atomization for diameters of 1.2–2.4 mm.

The sonotrode and other components are highly durable, with lifespans dependent on material properties and operational parameters. Proper use ensures over 30 hours of continuous operation for the sonotrode.

Yes, the system supports various feedstock forms, including powders, ingots, wires, and scrap, provided they fit the feed mechanism and melting zone. Automatic feeders are available for wire and bars.

Cleaning involves vacuuming residual powder, wiping down surfaces with isopropyl alcohol, and using dust-free paper. Specialized equipment like fireproof vacuum cleaners is recommended for reactive materials.

- Sonotrode: 20–30 minutes.

- Material: 2–4 hours for full material change, including purging and cleaning.

rePowder platform is an open system thus additional measurement instruments can be installed. The system is designed to be flexible, allowing integration with various sensors and measurement devices to meet specific process requirements.

- In means of changing used sonotrode while working on the same material: The changeover time for the sonotrode or gasket typically takes around 20-30 minutes, depending on the operator’s familiarity with the system and the complexity of the setup.

- In means of changing material changeover: Changing materials may take longer, around 2-4 hours, as it involves purging the system of the previous material, cleaning the equipment, and setting up for the new material.

Cleaning the device and recirculation system typically involves using the vacuum cleaner dedicated to metallic powders, followed up with isopropyl alcohol cleaning using dust free paper. The cleaning process can take anywhere from 2 to 4 hours, depending on the level of residue.

Yes, continuous atomization is possible with the appropriate feedstock delivery system. By incorporating a continuous feeder and maintaining a steady state of molten material, the process can run continuously, improving efficiency and throughput. AMAZEMET has currently to perform continuous wire atomization which can employ wires between 1,2 to 2,4 mm in diameter.

Yes, custom upgrades are possible. We offer a modular platform that allows for the addition of new features and capabilities as your needs evolve. This might include enhanced control systems, additional sensors, or even new atomization technologies. We work closely with customers to develop these upgrades to ensure they meet specific operational requirements.

Powders

For the most extreme temperature conditions, refractory metals and their alloys are the top choice. Metals like Tungsten, Rhenium, and Tantalum have the highest melting points. However, for most industrial applications, engineered high temperature alloys, especially nickel based alloys (superalloys), offer the best balance of superior strength, oxidation resistance, and processability, making them essential for the aerospace and power generation industries. While standard stainless steel provides good heat resistance for many common uses, specific stainless steel alloys are required to handle more severe heat.

In many high temperature applications, corrosion resistance is as important as heat resistance itself. At high temperatures, metals react more quickly with oxygen and other elements, leading to high temperature oxidation. A stable, protective oxide layer is essential for preventing the degradation of the base metal. This is why materials like stainless steel and nickel-based superalloys are valued for their combined heat resistant properties and corrosion control.

The high temperature strength of an alloy is not determined by a single factor, but by a combination of key properties. The primary factors include a high melting point, strong atomic bonds, and stable mechanical properties at elevated temperatures. The ability to resist creep (slow deformation) and maintain structural integrity under heat stress is crucial for performance in any operating environment.

Molybdenum is known for its chemical versatility and can exhibit several oxidation states, with +4 and +6 being the most common and stable in chemical compounds like molybdenum disulfide (MoS₂) and molybdenum trioxide (MoO₃). This property is key to its use in catalysts and chemical processes.

The amount of molybdenum needed depends entirely on the application. For example, some high-strength structural steel may contain less than 1% molybdenum, while specialized superalloys for aerospace can contain significantly more to achieve desired properties at extreme temperatures.

Reactive powders like magnesium or titanium are processed in an inert atmosphere to prevent oxidation. Airlock containers and fireproof vacuum cleaners are available for safe powder collection.

Reactive materials are processed in an inert atmosphere to prevent oxidation or contamination. The system minimizes exposure to air, ensuring safe and efficient handling during atomization.

Powders are produced in a controlled inert atmosphere, ensuring high purity. Oxygen levels are typically below 50 ppm, which can be reduced further using getter heating and a closed-loop recirculation system.

Particle size depends on ultrasonic frequency and material properties. For example:

- 20 kHz: 40–150 μm

- 40 kHz: 20–90 μm

For specific materials, contact AMAZEMET for detailed size distribution data.

Finer powders are achieved by using higher ultrasonic frequencies and adjusting process parameters like material density, viscosity, and surface tension. However, powders below 10–20 microns cannot be produced with ultrasonic atomization due to physical limitations.

The particle size distribution can vary depending on the material and the ultrasonic frequency used. For example, using frequencies around 20 kHz typically produces particle sizes in the range of 40-150 micrometers, while higher frequencies such as 40 kHz can produce particles as fine as 20-90 micrometers. Specific distributions for different materials and frequencies can be provided upon request, as these vary based on the material properties and system configurations used.

The key factor to obtain finer powder during ultrasonic atomization is the frequency of the ultrasonic waves used. Higher frequencies generally produce finer particle sizes due to the increased energy imparted to the molten material, which breaks it into smaller droplets. Other factors include the density, viscosity and surface tension of the molten material, as well as the power level and design of the sonotrode. Although there are certain ways to reduce the size of produced powder, there is no possibility to manufacture very fine powders below 10 microns.

Learn more from our blog

10 Advantages of Additive Manufacturing for Sustainable Metal Production

Tomasz Choma2025-11-27T13:39:56+01:0026/11/2025|

AMAZEMET at MRS Fall Meeting 2025: Advancing Materials Research

Jan Marchewicz2025-11-27T11:07:18+01:0025/11/2025|

AMAZEMET at Formnext 2025: Announcing AI-Driven Atomization Process

Jan Marchewicz2025-11-15T06:56:16+01:0031/10/2025|