From custom powders to 3D printed metal part

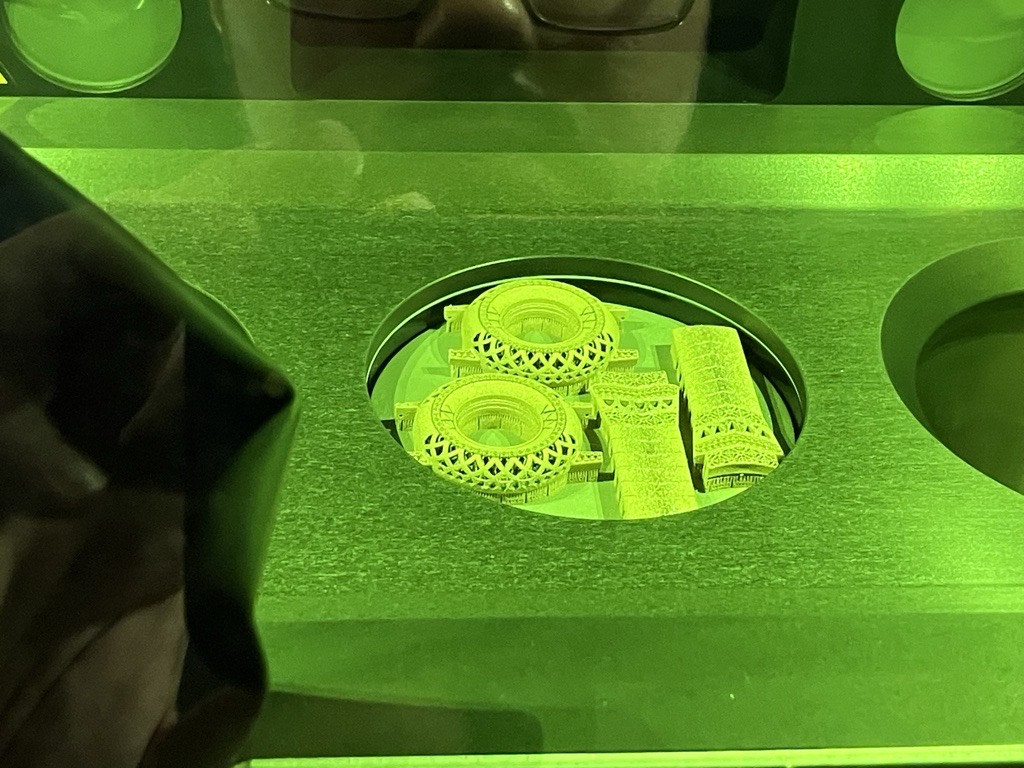

The rise of metal additive manufacturing (AM) has transformed how intricate components are designed and produced, significantly reducing material waste and production time. Central to the efficiency of powder-based AM processes is the availability of high-quality, spherical metal powders with excellent flowability and consistent particle size distribution. Precious metals such as silver, gold, and platinum group metals (PGMs)—including platinum, iridium, palladium, rhodium, and others like rhenium—are highly valued for their unique properties and are extensively used across various industries. Their applications span from jewelry and luxury goods to catalysts, aerospace components, electronics, and medical devices.

However, these precious metals’ high cost and scarcity pose substantial challenges in powder production, especially when dealing with small volumes. Traditional atomization techniques often require large quantities of material, resulting in considerable losses due to inefficiencies and contamination. Therefore, there is a critical need for innovative production methods that can efficiently process small batches of precious metals while ensuring minimal material loss and high powder quality.

Application

Producing high-quality precious metal powders in low volumes is essential for several advanced applications:

- Jewelry and Luxury Goods: Crafting intricate designs with precious metals requires powders that can produce detailed features with superior surface finish.

- Aerospace and Defense: Manufacturing components capable of withstanding extreme temperatures and corrosive environments, where the exceptional properties of PGMs are invaluable.

- Electronics: Developing conductive inks and pastes for high-performance circuitry in electronic devices, where silver and gold powders are particularly important.

- Catalysis: Creating efficient catalysts for chemical reactions in automotive and industrial processes, leveraging the catalytic properties of PGMs.

- Medical Devices: Fabricating biocompatible implants and surgical instruments with complex geometries, utilizing the unique properties of precious metals.

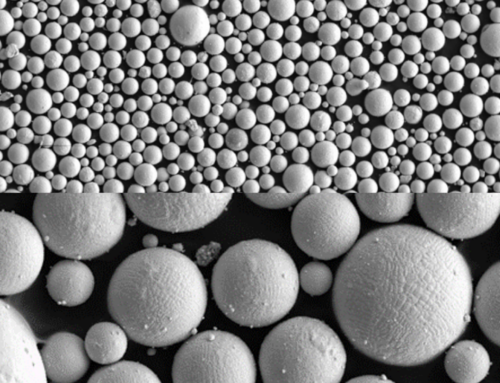

These applications demand metal powders with specific characteristics, such as exceptional flowability, lack of satellites (small particles adhering to larger ones), and high sphericity, to ensure optimal performance in AM processes and the final products.

Technology

Ultrasonic Atomization for Precious Metals

Ultrasonic atomization has emerged as a highly effective technique for producing precious metal powders in low volumes. This technology employs high-frequency ultrasonic vibrations to disintegrate a molten metal stream into fine droplets, solidifying into spherical powder particles. The process offers several significant advantages:

- Exceptional Flowability and Powder Quality: Ultrasonic atomization produces powders with smooth surfaces and high sphericity, leading to excellent flowability. The absence of satellites enhances the powder’s performance in AM processes, ensuring uniform layer deposition and consistent mechanical properties in the printed parts.

- High Material Recovery: The design of the ultrasonic atomization system allows for the recovery of up to 99.95% of the input material. This high recovery rate is crucial when working with expensive precious metals, as it minimizes waste and reduces overall production costs.

- Narrow Particle Size Distribution: The process yields powders with a consistent and narrow particle size range. This uniformity is essential for achieving high-quality results in AM, affecting powder packing density and layer uniformity during printing.

- Efficiency with Small Quantities: Ultrasonic atomization is well-suited for processing small batches, making it ideal for precious metals where material availability and cost are significant concerns. Manufacturers can produce the exact amount of powder needed for specific applications without excess.

- Versatility through rePOWDER Modularity: The rePOWDER system’s modularity allows for producing low and high melting point materials. This flexibility enables processing a wide range of precious metals and their alloys.

Processing Low and High Melting Point Materials

The rePOWDER system adapts to the specific melting requirements of different precious metals:

- Low Melting Point Materials (Silver, Gold, and Master Alloys): These metals can be atomized using an induction module coupled with crucible melting. Induction melting provides precise temperature control and rapid heating, which is essential for metals like silver and gold that have relatively low melting points and are sensitive to oxidation. The crucible melting approach ensures a controlled environment, preserving the purity and properties of the metals.

Example in Jewelry Industry: Jewelers can produce custom alloys and powders of silver and gold for specialized designs, creating intricate and high-quality jewelry pieces with exceptional detail and finish.

- High Melting Point Materials (Platinum Group Metals): Metals such as platinum, iridium, palladium, and rhodium require higher temperatures for melting. These can be atomized using plasma melting in a crucible-free process. Plasma melting generates the extreme temperatures needed to melt PGMs without the risk of contamination from crucible materials. The crucible-free approach further ensures the purity of the metal powders.

Example in Jewelry Industry: High-end jewelry pieces made from platinum and other PGMs benefit from powders produced via plasma melting, creating complex designs that are otherwise difficult to achieve with traditional manufacturing methods.

Conclusion

Producing precious metal powders in low volumes is challenging due to the high cost and specialized properties of these materials. Ultrasonic atomization, enhanced by the modularity of the rePOWDER system, offers a powerful solution to these challenges. By enabling efficient processing of small quantities with minimal material loss and producing powders with exceptional flowability and quality, this technology opens new possibilities for utilizing precious metals in advanced applications.

Industries can now harness the unique properties of silver, gold, platinum, and other precious metals while maintaining economic viability and sustainability. The ability to produce powders without satellites and with superior flowability significantly enhances the performance of AM processes, leading to higher-quality end products.

As additive manufacturing technologies continue to advance and find new applications, the role of ultrasonic atomization in producing high-quality precious metal powders is set to become increasingly significant. This technology not only drives innovation across aerospace, electronics, catalysis, and medical devices but also revitalizes the jewelry industry by enabling the creation of intricate designs that were previously unattainable.