Imagine an aircraft landing gear: it must endure thousands of high-impact landings without fracturing, resist wear from movement, and support tremendous loads. If the alloy is extremely hard but lacks toughness, it could crack on impact. If it is very strong but not sufficiently hard, it may deform or wear prematurely. This real-world example highlights why understanding hardness vs toughness, toughness vs strength, and strength vs hardness—and how they interact—is critical for engineering safe and reliable components.

Hardness: Resistance to Local Plastic Deformation

Hardness measures a material’s ability to resist local plastic deformation, such as indentation, scratching, or abrasion. Common tests include Vickers, Brinell, and Rockwell, which determine the size of an indentation left by a standardized indenter under a defined load.

Hardness correlates with yield strength and can be increased by:

- Solid solution strengthening (e.g., alloying Ti with Al or V)

- Precipitation hardening (e.g., Al–Cu or nickel-based superalloys)

- Work hardening (dislocation accumulation during cold deformation)

Higher hardness enhances wear resistance—vital for cutting tools, gears, or bearings—but excessive hardness may lower ductility and toughness. When comparing hardness vs strength, remember that a hard surface does not necessarily mean a component can resist bulk deformation or fracture.

Strength: Capacity to Withstand Applied Loads

Strength defines a material’s ability to withstand an applied stress without failure. It is expressed as:

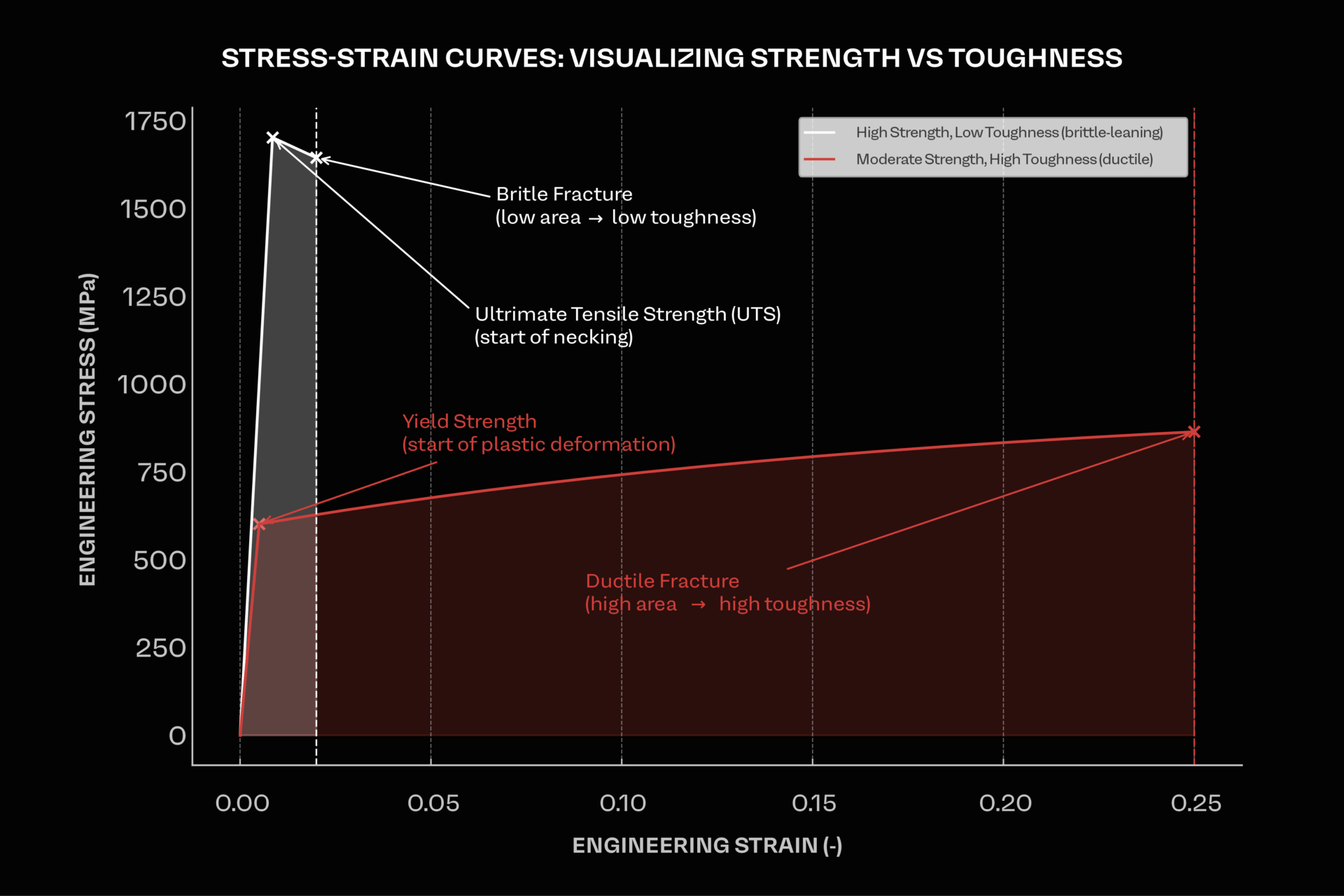

- Yield strength: stress at which plastic deformation begins

- Ultimate tensile strength (UTS): maximum stress the material can endure before necking and fracture

Strength is controlled by grain boundary strengthening (Hall–Petch effect), dislocation density, and phase transformation (e.g., martensitic steels). High strength is crucial in load-bearing structures like aerospace frames, pressure vessels, and structural beams. However, toughness vs strength comparisons show that a very strong but brittle material may fail catastrophically if it lacks toughness.

Toughness: Energy Absorption Before Fracture

The toughness, meaning in materials science, is the ability to absorb energy and plastically deform before fracturing. If someone asks what is toughness? or more specifically, what is toughness in materials?, it refers to a material’s combined strength and ductility. Toughness is typically measured in units of toughness such as J/m² or MPa√m, often through impact tests (Charpy, Izod) or fracture toughness (KIC) measurements.

Key mechanisms include:

- Crack tip blunting by plastic deformation

- Microvoid coalescence in ductile metals

- Transformation toughening, e.g., in zirconia ceramics YSZ

High metal toughness is indispensable for impact- and fatigue-resistant components such as aircraft landing gear, turbine blades, and automotive crash structures. Selecting a tough material ensures safety in applications subject to dynamic loading.

Comparison of Key Properties (Hardness vs Toughness vs Strength)

| Property | Definition | Typical Units | Key Mechanisms | Typical Applications |

|---|---|---|---|---|

| Hardness | Resistance to local plastic deformation (scratching/indentation) | HV, HRc, HB | Solid solution, precipitation hardening, work hardening |

Cutting tools, bearings, gears |

| Toughness | Energy absorption before fracture (units of toughness: J/m², MPa√m) | J/m², MPa√m | Crack tip blunting, microvoid coalescence, transformation toughening |

Aircraft landing gear, turbine blades, automotive crash structures |

| Strength | Resistance to permanent deformation or fracture under load | MPa, GPa | Grain refinement, dislocation strenthening, phase transformation |

Aerospace frames, pressure vessels, structural beams |

This table helps clarify frequent questions such as hardness vs toughness, toughness vs hardness, and hardness vs strength in a quick reference format.

Advanced Manufacturing Considerations

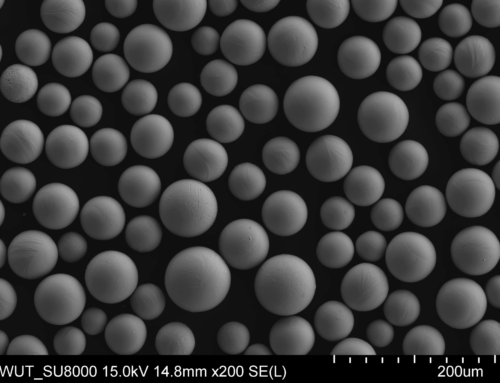

Additive manufacturing (AM) opens new opportunities for tailored materials. However, AM-produced alloys often achieve high strength but can lack toughness, especially in applications involving cyclic loading and fatigue, such as aerospace or energy systems.

Here, AMAZEMET’s ultrasonic atomization technology plays a critical role and supports researchers developing new materials with higher toughness while maintaining strength and hardness. This is vital for parts subjected to dynamic and fatigue-prone environments, from turbine engine components to conformally cooled tools.

Key Takeaways

- Hardness vs toughness: hardness resists surface deformation; toughness absorbs energy before fracturing.

- Strength vs hardness: strength resists overall deformation; hardness resists localized indentation.

- Toughness vs strength: toughness includes both strength and ductility, ensuring resistance to crack propagation.

By mastering the interplay of these properties, materials engineers can design safer, more durable components for demanding sectors.

Explore more: Metal powders | Ultrasonic atomizer