Freedom in Metal AM Develompent & Production

High Entropy Alloys

High Entropy Alloys (HEAs) are advanced materials that differ from traditional alloys by incorporating five or more principal elements in nearly equal proportions. This unique combination of elements leads to exceptional mechanical properties such as high strength, wear resistance, and thermal stability. HEAs’ ability to maintain performance in extreme conditions makes them suitable for high-stress applications, where traditional materials may fail.

HIGH-TEMPERATURE MATERIALS

Characterization & Properties

Characterization & Properties

HEAs have several properties that set them apart from conventional materials. Their multiple-element composition creates unique atomic structures, which contribute to their improved performance. Key properties include:

HEAs have several properties that set them apart from conventional materials. Their multiple-element composition creates unique atomic structures, which contribute to their improved performance. Key properties include:

High strength and hardness

These alloys can withstand heavy loads without deforming, even at high temperatures.

Corrosion and wear resistance

Ideal for applications in harsh environments where materials need to last longer.

Thermal stability

HEAs maintain their properties at elevated temperatures, which is important for energy and aerospace applications.

High fracture toughness

They resist cracking, making them durable in impact-prone environments.

CHOOSE YOUR COMPOSITION

Example HEA Compositions:

Each composition can be fine-tuned to balance various properties such as corrosion resistance, strength, and thermal performance, making HEAs highly versatile.

01

CoCrFeMnNi

A well-known “Cantor alloy,” this HEA is widely studied for its balance of mechanical properties, including strength and ductility. It’s ideal for cryogenic applications.

02

AlCoCrFeNi

Known for its excellent high-temperature stability, this composition is used in aerospace and energy applications where materials are exposed to high heat.

03

NbMoTaW

This refractory HEA is incredibly stable at high temperatures and is used in nuclear and space applications that demand high-temperature resistance.

04

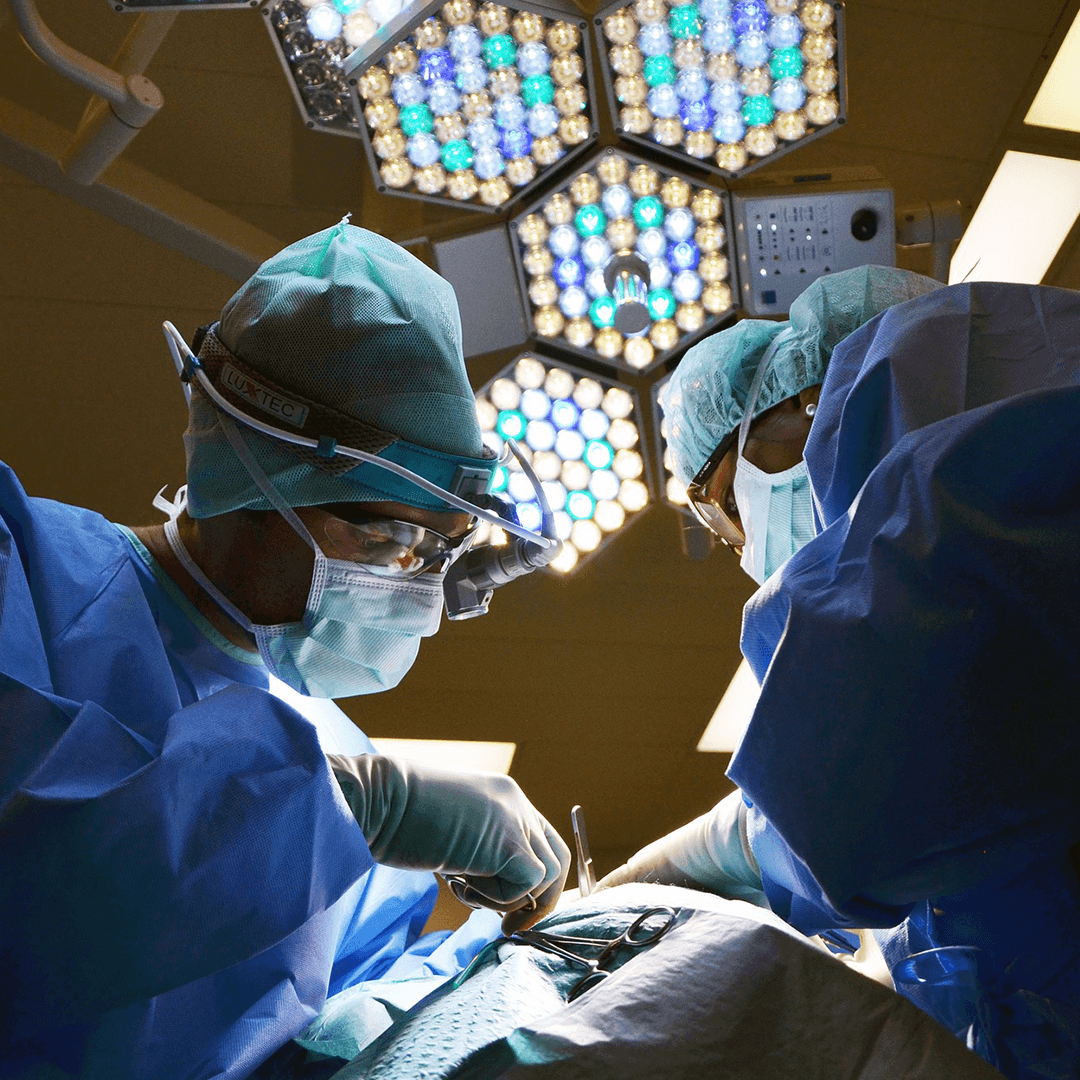

TiZrHfNbTa

A composition that exhibits excellent corrosion resistance and mechanical strength, often explored for biomedical implants and energy applications.

SPECYFIKACJA NASZYCH MASZYN

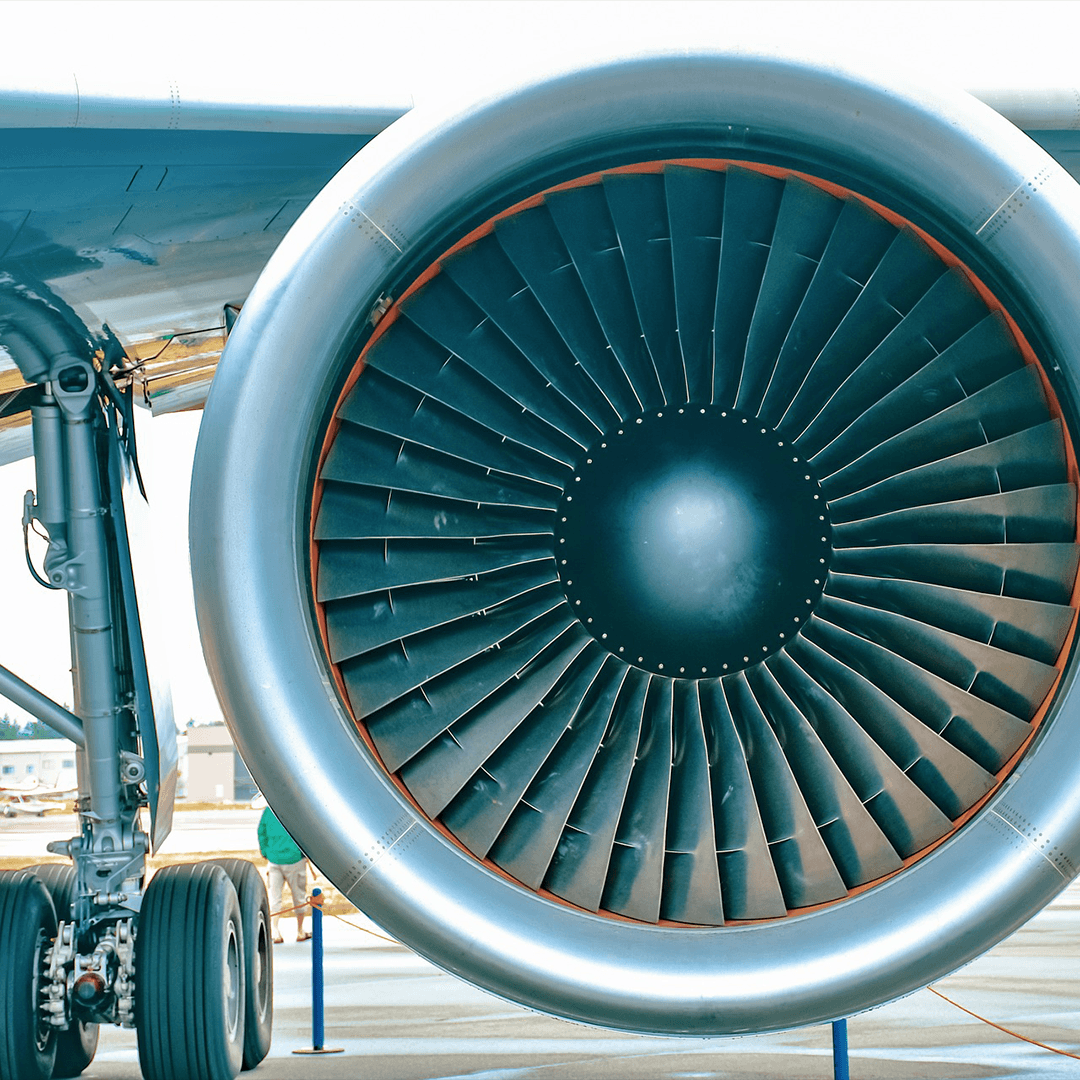

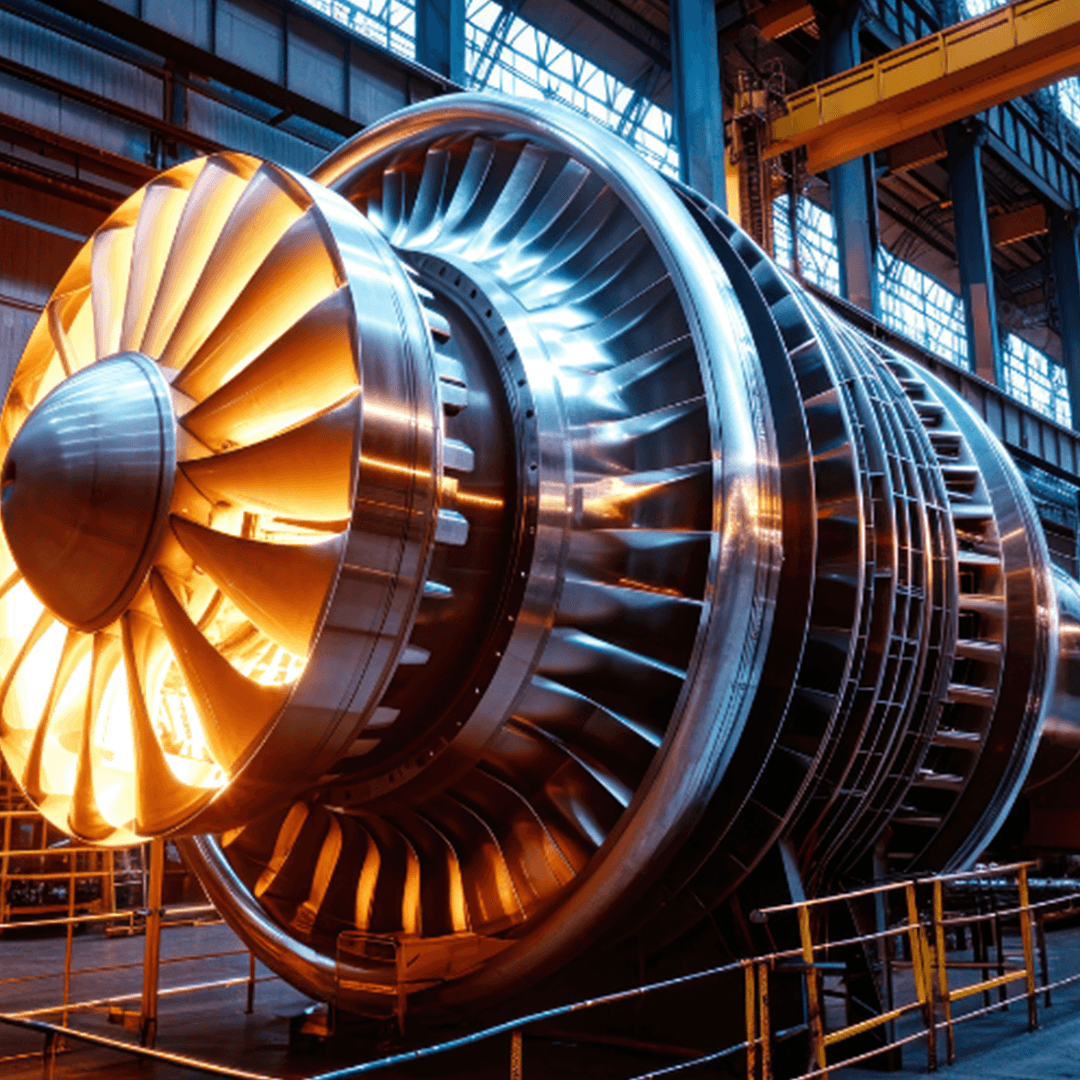

Applications of High-Temperature Metals

HEAs are being used in a variety of cutting-edge applications due to their superior mechanical properties. With these applications, HEAs offer solutions for industries that need materials capable of performing in the most demanding conditions.

METAL POWDES PRODUCTION

Where to Buy High Entropy Alloy Powders?

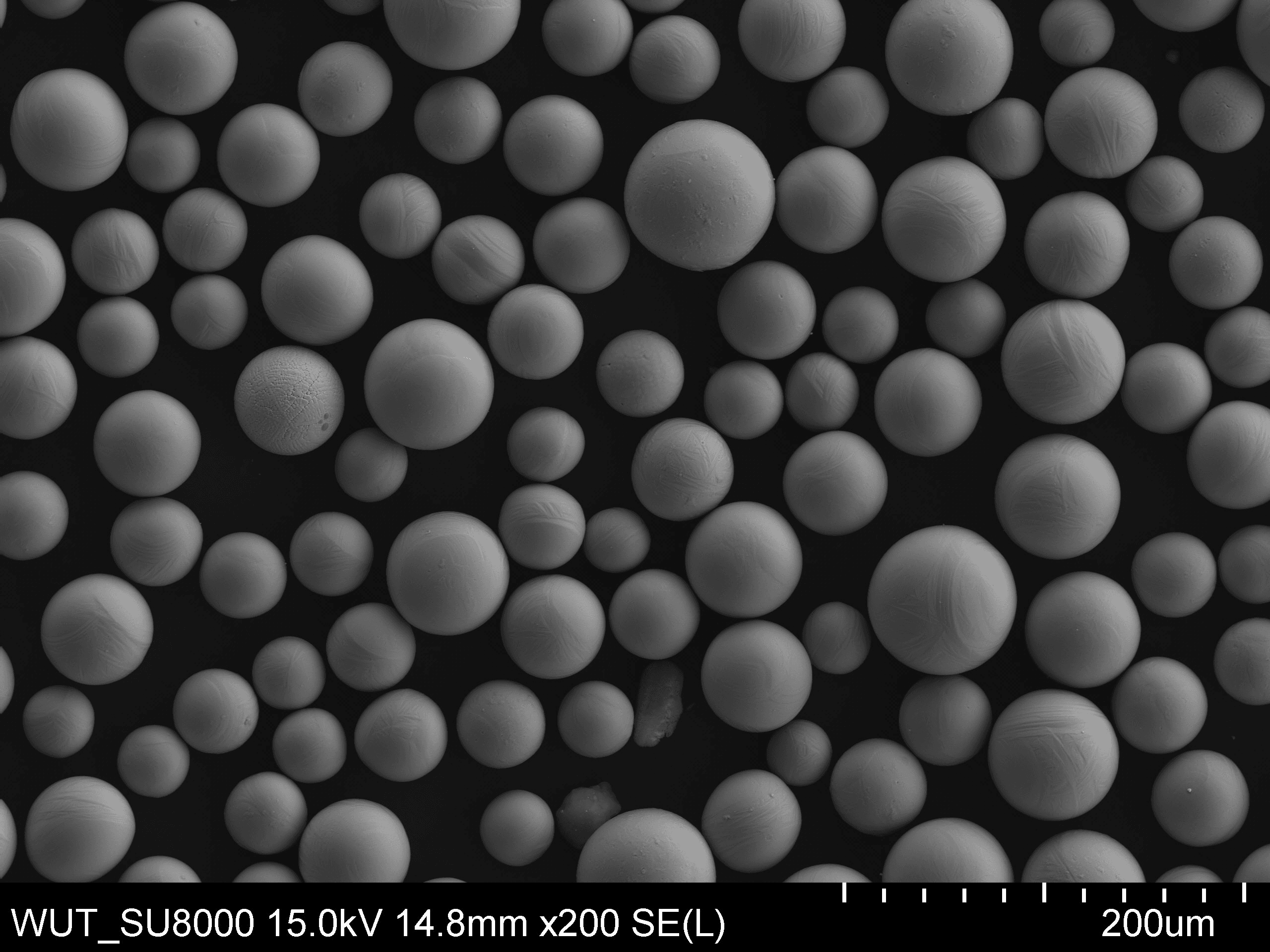

High Entropy Alloy powders are available from specialized suppliers that focus on producing high-quality powders for advanced manufacturing techniques like 3D printing and powder metallurgy. AMAZEMET offers a service to manufacture wide range of HEA powders, produced using plasma ultrasonic atomization. Our powders are ideal for industries requiring high-performance materials with consistent quality.

WHY AMAZEMET

Why Choose AMAZEMET High Entropy Alloy Powders?

At AMAZEMET, we are capable to manufacture high-quality HEA powders with our novel ultrasonic atomization technology. Our HEA powders are trusted by industries that need materials capable of withstanding extreme conditions while maintaining performance. Here’s what makes our products stand out:

High purity

Ensures consistent performance in demanding applications.

Fine, spherical particles

The plasma ultrasonic atomization process produces powders with uniform size and shape, making them ideal for additive manufacturing.

Excellent flowability

Our powders are easy to handle and distribute in manufacturing processes.

Custom compositions

We can create powders that meet specific requirements for research or industrial applications.

ORDER POWDERS

High Entropy Alloy Powders for Sale

AMAZEMET provides a range of HEA powders created through plasma ultrasonic atomization, a method that ensures fine, spherical particles, ideal for additive manufacturing and advanced production processes. Our HEA powders are produced to the highest standards, ensuring that they meet the demands of modern industrial applications. Some of the compositions we offer include:

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

HIGH QUALITY METAL POWDERS

How to Make High-Temperature Metal Powders?

HEA powders are made using advanced atomization techniques to ensure uniformity and quality. This process ensures that the HEA powders are of consistent size and quality, ready for use in demanding applications. At AMAZEMET, we use plasma ultrasonic atomization, that involves:

Custom Powders In-House

For customers interested in creating custom HEA powders, AMAZEMET offers the rePOWDER metal powder atomizer. This system enables you to atomize small batches of metal powders on-site, giving you control over the material’s composition and quality. Benefits of the rePOWDER system include:

- Customizability: You can create HEA powders with specific compositions tailored to your needs.

- Efficiency: Produce powders in-house and on-demand, reducing the need for external suppliers.

- Versatility: The rePOWDER atomizer allows you to atomize a variety of metals, including High Entropy Alloys.

- Ease of use: The compact design is ideal for research institutions and small-scale production environments.

With rePOWDER, you can experiment with different HEA compositions and develop custom powders for your unique applications.