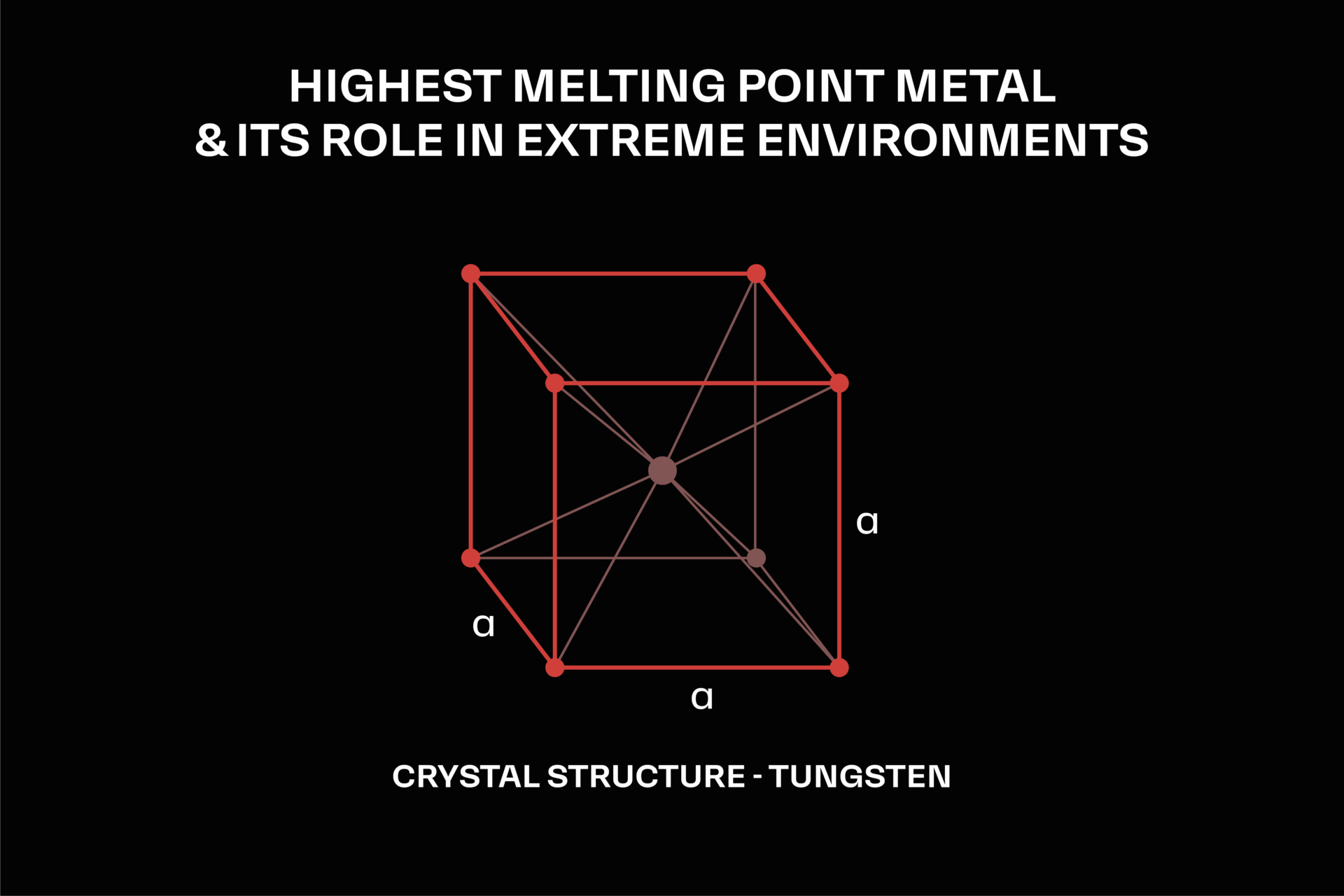

When it comes to operating under extreme temperatures, no ordinary metal will do. The highest melting point metal known is tungsten (W), which melts at an extraordinary 3,422 °C (6,192 °F). For comparison, steel melts around 1,500 °C and nickel-based superalloys around 1,350 °C. Understanding what metal has the highest melting point and the atomic-scale reasons for its thermal stability is critical to designing components for environments such as space re-entry, hypersonic flight, or fusion reactors.

Why Tungsten Has the Highest Melting Point

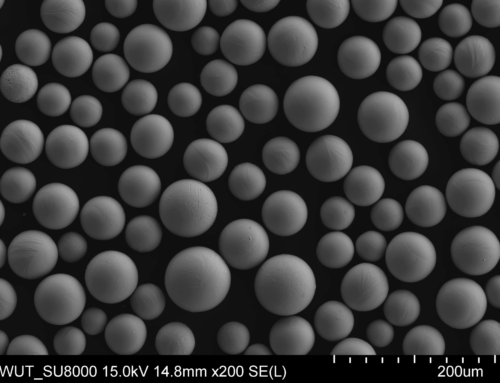

The key lies in atomic bonding and crystal structure. Tungsten crystallizes in a body-centered cubic (BCC) structure. Each tungsten atom forms extremely strong metallic bonds with its neighbors due to:

- High atomic number and dense electron cloud, which create powerful metallic bonding.

- Partially filled d-orbitals, enhancing bond strength by allowing more overlap of electron wave functions.

- High cohesive energy (around 8.9 eV/atom), making it exceptionally resistant to thermal vibrations.

Thermodynamically, melting occurs when thermal vibrations overcome the cohesive energy of the crystal lattice. In tungsten, this requires far higher temperatures than for most metals. This explains what has the highest melting point and why tungsten is the highest melting point metal among pure metals.

Refractory Properties in Extreme Applications

The thermal stability of tungsten translates into unique refractory properties, including:

- Resistance to creep and deformation at ultra-high temperatures.

- Low vapor pressure at high temperature, essential for vacuum or plasma environments.

- Retention of mechanical strength at temperatures where most metals fail.

These features make highest melting point material and other refractory alloys ideal for:

- Rocket nozzles and heat shields in space and hypersonic vehicles.

- Plasma-facing components in fusion reactors.

- High-temperature furnace parts and X-ray targets.

Refractory alloys like molybdenum-rhenium (MoRe) combine high melting point with improved ductility, enabling use in superconducting magnets and aerospace turbine components.

Challenges in Production of Refractory Metals

Producing highest melting point metal and other refractory materials is technically challenging:

- High sintering temperatures are required to densify powders.

- Tungsten is hard and brittle at room temperature, making conventional machining and forming difficult.

- Its high density and oxidation sensitivity complicate powder processing and handling.

These obstacles long limited the industrial use of refractory metals. However, additive manufacturing (AM) is renewing interest. Powder-based AM methods, such as laser powder bed fusion and directed energy deposition, can shape these metals without traditional casting or forging, allowing complex geometries and graded materials.

Toward Novel Refractory Alloys for Hypersonic Applications

The next frontier is the development of novel refractory alloys specifically optimized for additive manufacturing. These may combine tungsten with other high-melting-point elements such as molybdenum (Mo), niobium (Nb), rhenium (Re), hafnium (Hf), and tantalum to fine-tune thermal conductivity, oxidation resistance, and mechanical properties for hypersonic flight, space propulsion, and nuclear energy systems.

AMAZEMET also supports these efforts through the rePOWDER plasma module, which integrates arc melting furnace capabilities. This module employs a Focused Plasma Torch with exceptionally high arc energy density and controlled gas flow, enabling efficient melting, mixing, and homogenization of tungsten and other refractory alloys in a water‑cooled crucible. Such processing is vital for producing homogeneous ingots of ultra‑high‑melting‑point materials and their alloys for advanced research and demanding applications.

AMAZEMET’s ultrasonic atomizer technology plays an important role here. By enabling production of high-quality spherical metal powders of reftctory alloys including High Entropy Alloys – RHEAs, and other materials with the highest melting point, AMAZEMET accelerates research into advanced refractory alloys. Ultrasonic atomization ensures excellent powder flowability and precise chemical control—critical for stable AM processing of these challenging metals.

Comparison of Highest Melting Point Metals

| Material/Alloy | Approx. Melting Point (°C) | Crystal / Bonding Characteristics |

|---|---|---|

| Tungsten (W) | 3,422 | BCC structure, strong metallic bonds with high cohesive energy |

| Rhenium (Re) | 3,186 | Hexagonal close-packed (HCP) structure, strong metallic bonding and high cohesive energy |

| Tantalum (Ta) | 3,017 | BCC structure, strong metallic bonding, excellent corrosion resistance |

| Niobium (Nb) | 2,468 | BCC structure, good high-temperature stability, used in superconducting and high-temp applications |

| Molybdenum (Mo) | 2,623 | BCC structure, strong metallic bonds, lower cohesive energy than W and Re but high thermal stability |

| Molybdenum -Rhenium (MoRe) |

2,600–2,800 | Solid-solution alloying improves ductility and maintains high melting point |

| Hafnium Carbide (HfC) |

3,900 | Strong covalent Hf–C bonds in a rigid lattice |

| Hafnium Carbonitride (HfCN) |

4,110 | Mixed-anion cubic (rock-salt) structure with strong covalent Hf–C and Hf–N bonds; nitrogen inclusion increases melting point beyond HfC |

This table illustrates what material has the highest melting point and the bonding mechanisms behind these exceptional temperatures, supporting their use in extreme environments.

Key Takeaways

- Highest melting point metal: Tungsten (W), 3,422 °C, thanks to strong metallic bonding and BCC structure.

- Applications: Hypersonic vehicle parts, fusion reactor components, high-temperature furnaces.

- Production challenge: Extreme processing temperatures and brittleness overcome by powder metallurgy and AM.

- Future: Novel refractory alloys designed for additive manufacturing with the help of AMAZEMET ultrasonic atomization.

By undesratnig atomic mechanisms behind thermal stability, engineers can create next-generation components that survive where ordinary metals would simply vaporize. In this process, ultrasonic atomization plays a key role, enabling precise, high-quality refractory metal powders that accelerate research and industrial adoption of these extreme-performance alloys.