Freedom in Metal AM Develompent & Production

Brazing AND Soldering Alloys

Brazing and soldering alloys form a specialized category of metals engineered for joining other materials at temperatures significantly lower than those used for structural metals. Key representatives include tin, lead, bismuth, and their alloys, all valued for enabling strong, conductive, and reliable joints with minimal heat input. These alloys are crucial in applications such as electronics assembly, safety devices, and precision manufacturing where controlled joining is required.

BRAZING VS. SOLDERING ALLOYS

Characterization & Comparison

Characterization & Properties

While both brazing and soldering alloys serve as joining materials, they differ notably in their working temperatures, chemical composition, and application areas:

Brazing / Soldering alloys possess several distinct properties that make them essential in various industries. Key characteristics include:

Soldering Alloys

Typically melt below 450°C and are primarily tin-based, sometimes alloyed with lead, silver, or bismuth. They are used in electronics, electrical work, and plumbing, forming conductive but lower-strength joints ideal for delicate or heat-sensitive assemblies.

Brazing alloys

Have melting or flow points above 450°C yet remain below the melting temperature of the base metals. Common base elements include copper, silver, aluminum, and nickel. Brazing produces stronger joints suitable for structural, automotive, and aerospace applications, where greater strength and temperature resistance are required.

BRAZING AND SOLDERING ALLOYS

KEY PROPERTIES

Brazing and soldering alloys are essential in industry thanks to their:

01

Low Melting or Flow Temperature

Sufficiently low to protect sensitive components, but high enough for secure bonding.

02

Excellent Conductivity

Many alloys exhibit outstanding electrical and thermal conductivity—vital for electronic applications.

03

Castability and Wetting

Formulated for excellent wetting and bonding to base metals, crucial for strong, durable joints. Their optimized compositions also allow for efficient powder atomization.

BRAZING / SOLDERING ALLOYS

Applications

These alloys are used across many demanding sectors:

METAL POWDES PRODUCTION

Purchasing Brazing

and Soldering Alloy Powders

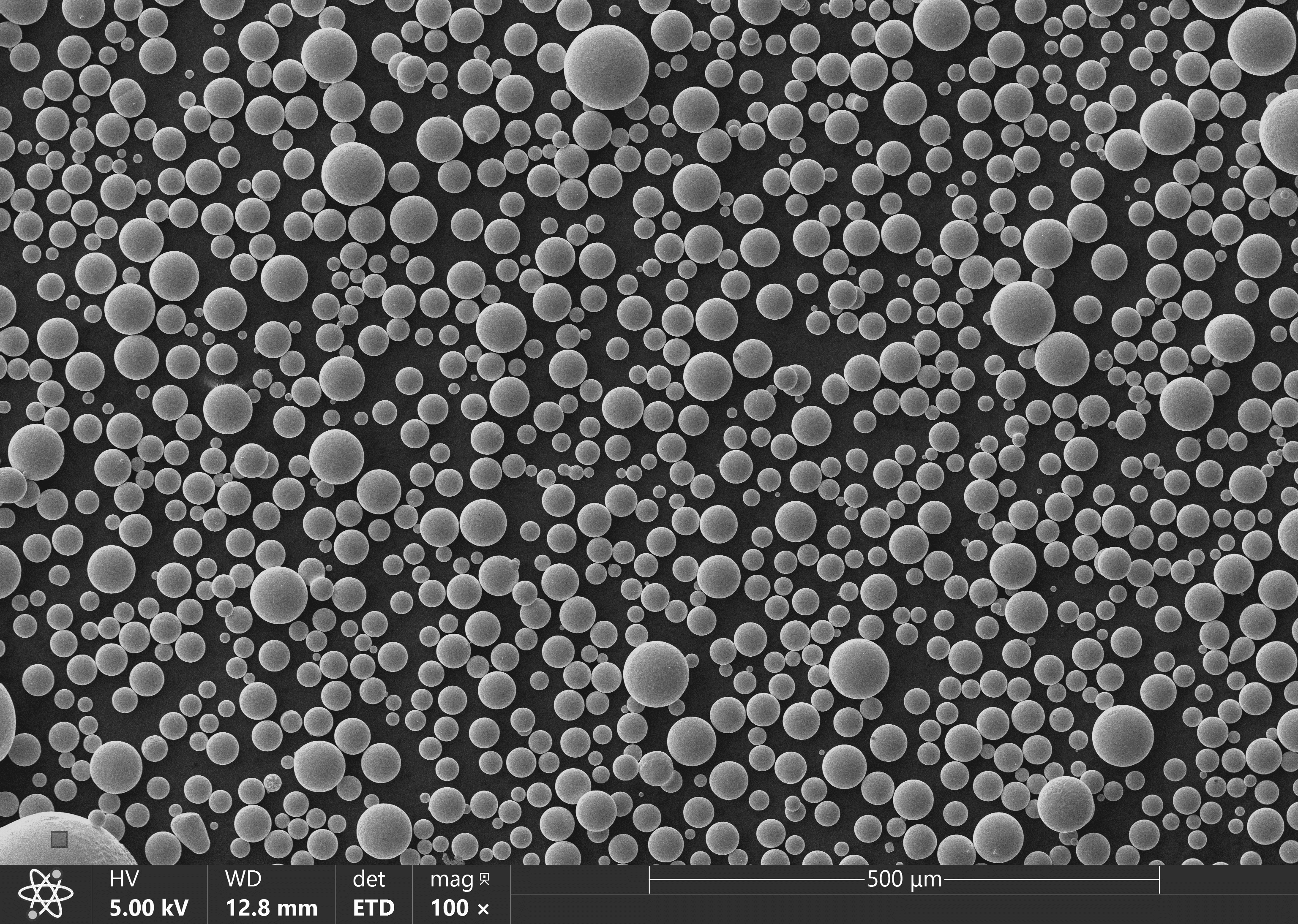

Brazing and soldering alloy powders are available from leading suppliers focused on quality and consistency for joining, electronics, and safety-related applications. AMAZEMET manufactures a wide range of brazing and soldering alloy powders—including bismuth-, tin-, and indium-based systems—using advanced ultrasonic atomization. This process ensures uniform particle size, high purity, and customizable compositions for tailored joining and repair solutions.

WHY AMAZEMET

Why Choose AMAZEMET Powders?

AMAZEMET’s brazing and soldering alloy powders are distinguished by:

High purity

Stringent quality control ensures consistent results in critical applications.

Uniform Particle Size

Advanced atomization creates fine, uniform powders for precision and reproducibility.

Custom compositions

Tailored alloys available, from master alloys to pure elements, meeting unique project specifications.

ORDER POWDERS

AMAZEMET Alloy Processing Capabilities

Our production portfolio covers:

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

HIGH QUALITY METAL POWDERS

Production Process: How Brazing and Soldering Alloy Powders Are Made

Our powders are produced by transforming ingots or pellets into small, uniform particles tailored to joining technologies. Induction-based ultrasonic atomization is used:

In-House Custom Alloy Production with rePOWDER

For organizations requiring bespoke brazing or soldering alloy powders, AMAZEMET offers the rePOWDER metal powder atomizer. This system allows full in-house control over alloy chemistry and powder characteristics.

Benefits include:

- Flexibility: Produce custom alloy powders on demand for specific joining or repair projects.

- Cost Efficiency: Reduce reliance on external suppliers and gain rapid access to needed materials.

- Versatility: The system handles a broad spectrum of brazing and soldering alloys, supporting both R&D and small-scale production environments.

With rePOWDER, you gain flexibility, quality assurance, and independence in producing advanced joining alloy powders for your most critical applications.