BISMUTH ALLOYS

Bismuth Alloys in Powder Form for Low Melting and Precision Applications

Introduction

In powder form, bismuth alloys enable advanced manufacturing processes including powder metallurgy, thermal spraying, additive manufacturing of low temperature systems, and precision joining technologies.

Pure bismuth powder is valued for its low toxicity compared to lead and its unique volumetric expansion during solidification. When alloyed with tin, indium, cadmium, or lead substitutes, a tailored bismuth alloy can achieve highly controlled melting ranges and mechanical properties. These characteristics make bismuth alloys essential in fusible alloys, safety devices, tooling inserts, damping systems, and radiation shielding components.

As part of our advanced Metal powders portfolio, AMAZEMET supports the development of custom bismuth alloy powder for research, joining technologies, and specialized industrial applications.

In powder form, bismuth alloys enable advanced manufacturing processes including powder metallurgy, thermal spraying, additive manufacturing of low temperature systems, and precision joining technologies.

Pure bismuth powder is valued for its low toxicity compared to lead and its unique volumetric expansion during solidification. When alloyed with tin, indium, cadmium, or lead substitutes, a tailored bismuth alloy can achieve highly controlled melting ranges and mechanical properties. These characteristics make bismuth alloys essential in fusible alloys, safety devices, tooling inserts, damping systems, and radiation shielding components.

As part of our advanced Metal powders portfolio, AMAZEMET supports the development of custom bismuth alloy powder for research, joining technologies, and specialized industrial applications.

IMPORTANCE

Why Bismuth Alloys Matter in Modern Manufacturing

Bismuth alloys are widely used where controlled melting behavior and environmental considerations are critical.

Low Melting Point Systems

Many bismuth based alloy compositions are engineered to melt below 200 °C. These systems are used in safety mechanisms, fire suppression links, casting molds, and temperature-sensitive assemblies.

Lead Replacement Applications

Due to environmental regulations, bismuth alloys are often used as substitutes for traditional lead systems. A properly engineered bismuth alloy can deliver comparable density and processing characteristics with improved environmental compliance.

Brazing and Soldering Technologies

Certain bismuth alloys are applied in low temperature joining. In powder form, these materials support advanced joining processes and specialized brazing alloys used in electronics and precision assemblies.

Radiation Shielding and Damping

High density bismuth based alloy systems are applied in medical and nuclear shielding components, as well as vibration damping solutions.

METAL AM

Challenges in Sourcing Custom Bismuth Alloy Powder

Although demand for bismuth alloys is growing, obtaining tailored bismuth powder for R&D and specialized production presents clear limitations.

01

Bulk Production Focus

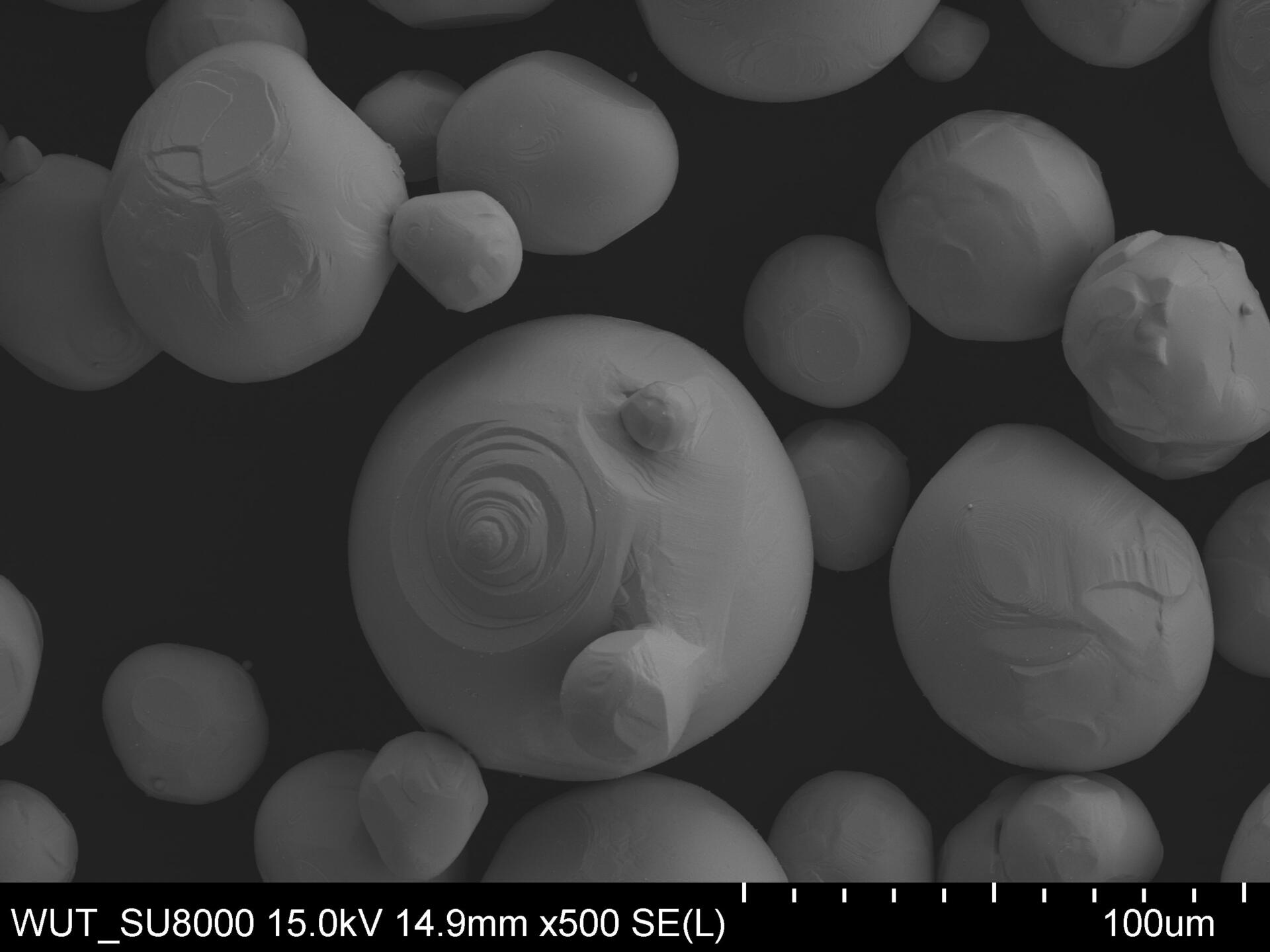

Most suppliers provide ingots or standard casting grades. Fine, spherical bismuth alloy powder is less commonly available in research-scale quantities.

02

Limited Alloy Flexibility

Standard fusible alloys dominate catalogs. Modified bismuth alloy compositions with optimized mechanical or melting characteristics often require custom production.

03

Minimum Order Quantities

Industrial suppliers typically require large purchase volumes, which restricts access for laboratories and pilot production.

04

Particle Size Control

In powder metallurgy and thermal processes, particle size distribution directly affects flowability, packing density and final performance. Off-the-shelf bismuth powder may not meet strict technical requirements.

05

Price Volatility

Bismuth powder price fluctuations can impact project budgeting. Small-batch atomization helps optimize material usage and reduce waste.

These constraints slow innovation in environmentally compliant alloy systems and advanced low melting point materials.

These constraints slow innovation in environmentally compliant alloy systems and advanced low melting point materials.

AMAZEMET

Custom Bismuth Alloy Powder Production and Atomization

Flexible atomization solutions provide an effective path forward for specialized bismuth alloys.

Small-Batch Atomization

Custom bismuth alloy powder can be produced with:

- Precise control over alloy chemistry

- Adjustable melting range

- Defined particle size distribution

- Research-scale volumes from grams to kilograms

This approach enables rapid development of new bismuth based alloy systems for joining, shielding, or damping technologies.

In-House Atomization with rePOWDER

For organizations that frequently iterate alloy compositions, laboratory-scale atomization offers strategic advantages.

With rePOWDER systems, teams can:

- Develop proprietary bismuth alloy compositions

- Control process parameters influencing particle morphology

- Produce only the required quantity of bismuth powder

- Reduce dependency on fluctuating bismuth powder price dynamics

- Secure confidential formulations for competitive applications

While external supply meets immediate needs, in-house atomization ensures long-term autonomy in bi alloy development.

METAL POWDERS PRODUCTION

AMAZEMET: Bismuth Alloys and Powder Development

AMAZEMET specializes in custom metal powder atomization for research and industrial innovation. Our expertise in bismuth alloys includes:

Development of tailored bismuth alloy powder systems

Controlled atomization parameters

Flexible production volumes

Rapid prototyping support

AMAZEMET SERVICES & REPOWDER

Custom Powder Services and rePOWDER for Bismuth Alloys

From tailored powders to in-house powder production, AMAZEMET supports the entire tin alloys development process.

1. Custom Powder Production

- Non-standard bismuth alloy chemistries

- Controlled particle size distribution

- Optimized melting characteristics

- Fast turnaround compared to traditional bulk suppliers

2. rePOWDER Atomizer for In-House Bismuth Powder Production

- Suitable for low melting point systems including bismuth alloys

- Adjustable atomization parameters

- R&D and pilot scale capability

- Secure processing for proprietary bi alloy systems

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch Bismuth alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore brazing alloys at the highest level.