Freedom in Metal AM Develompent & Production

Gallium Alloys: Functional Materials

Gallium Alloys: Functional Materials

Gallium alloys represent a unique class of functional metallic materials characterized by extremely low melting temperatures, high thermal conductivity, and unusual phase behavior.

GALLIUM ALLOYS

Gallium Alloys: Functional Materials for Advanced Thermal and Electronic Systems

Introduction

Unlike conventional structural metals, gallium alloys are primarily used where thermal management, soft interfaces, and controlled liquid metal behavior are required.

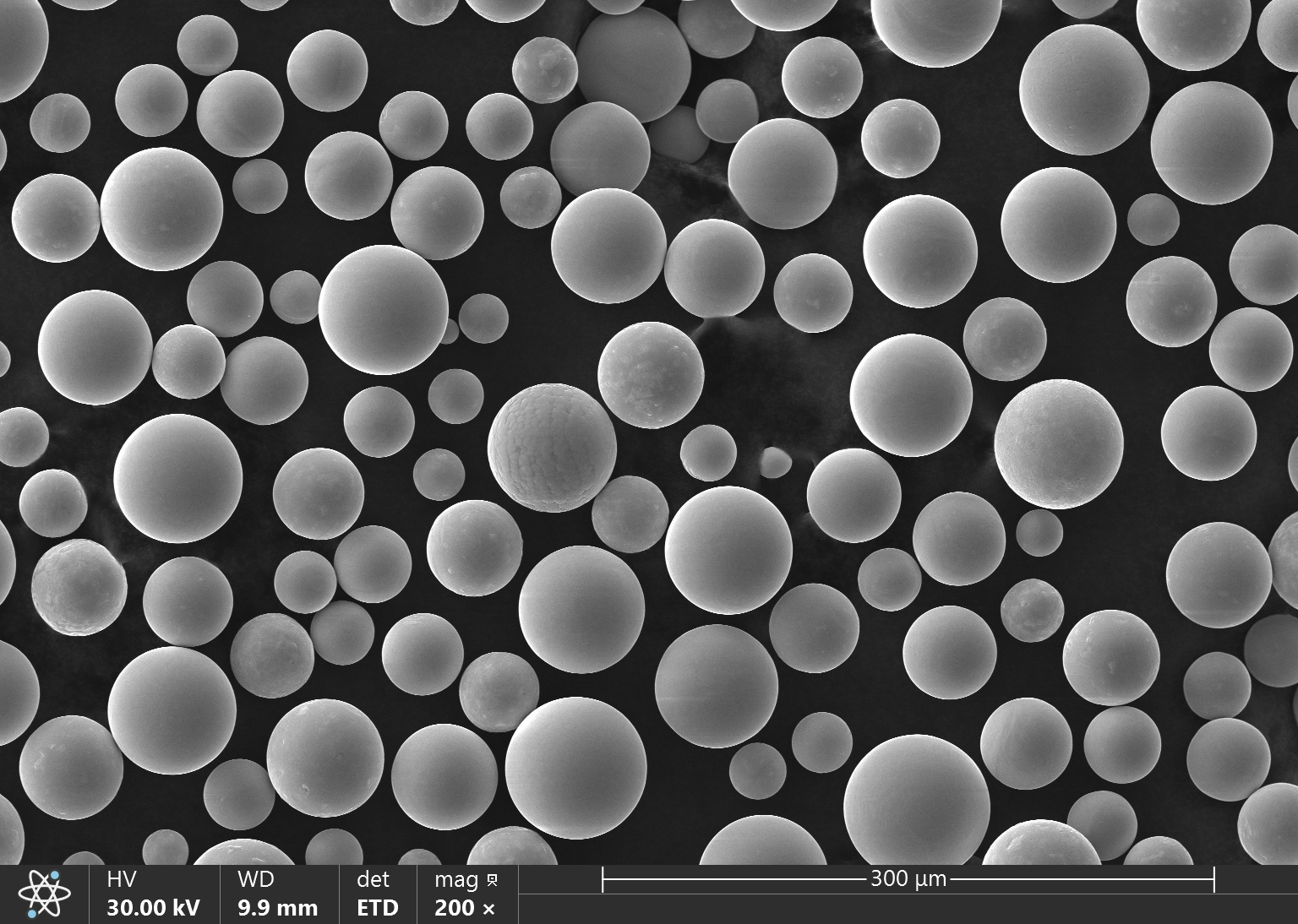

In powder form, gallium alloys enable research and development in electronics, flexible systems, thermal interface materials, and emerging liquid metal technologies. Although pure gallium is liquid near room temperature, specific gallium alloy systems can be engineered to modify melting behavior and mechanical response.

As part of our broader Metal powders platform, AMAZEMET supports the development of custom gallium alloys for specialized industrial and research applications.

Unlike conventional structural metals, gallium alloys are primarily used where thermal management, soft interfaces, and controlled liquid metal behavior are required.

In powder form, gallium alloys enable research and development in electronics, flexible systems, thermal interface materials, and emerging liquid metal technologies. Although pure gallium is liquid near room temperature, specific gallium alloy systems can be engineered to modify melting behavior and mechanical response.

As part of our broader Metal powders platform, AMAZEMET supports the development of custom gallium alloys for specialized industrial and research applications.

IMPORTANCE

What Makes Gallium Alloys Technically Distinct

Gallium alloys differ fundamentally from most metallic systems.

Low Melting Behavior

Many gallium alloy compositions melt near or below room temperature. This makes them suitable for soft thermal interfaces, reconfigurable electronics, and temperature-sensitive joining systems.

High Thermal Conductivity

Compared to polymer-based thermal materials, gallium alloys provide significantly higher thermal conductivity. This makes them attractive for high-performance heat transfer systems.

Compatibility with Other Low-Melting Metals

Alloys with gallium often include indium, tin, or bismuth to fine-tune melting range and viscosity. These systems are widely studied for advanced functional applications.

Emerging Applications

Gallium alloys are used in:

- Flexible and stretchable electronics

- Thermal interface materials

- Microfluidic conductive systems

- Research in soft robotics and adaptive materials

In these areas, gallium powder production enables controlled formulation and blending in laboratory environments.

METAL AM

Supply Considerations for Gallium Alloy Powder

Gallium alloys are not commodity materials. Their production and distribution are highly specialized.

01

Limited Powder Availability

Most gallium is traded in bulk metallic form. Fine gallium powder or gallium alloy powder suitable for advanced processing is less commonly available.

02

Specialized Application Base

The majority of gallium alloy usage is concentrated in electronics and semiconductor-related industries. Research-scale quantities may not align with industrial supply chains.

03

Alloy Development Requirements

Because melting behavior is extremely sensitive to composition, small variations in gallium alloy chemistry can significantly affect performance. This demands precise control over atomization and mixing processes.

04

Technical Barriers

Producing stable gallium powder requires controlled processing conditions to avoid oxidation and ensure consistency.

For these reasons, customized atomization is often necessary for advanced gallium alloy development.

For these reasons, customized atomization is often necessary for advanced gallium alloy development.

AMAZEMET

Custom Gallium Alloy Powder Development

Tailored gallium alloys can be produced through controlled small-batch atomization.

Custom gallium alloy powder enables:

- Precise control of melting temperature

- Adjustment of viscosity and flow characteristics

- Controlled particle size distribution

- Research-scale production volumes

This is particularly relevant for experimental joining systems and low-temperature Brazing alloys, where thermal behavior must be predictable and repeatable.

Rather than relying on fixed industrial grades, laboratories can refine gallium alloy systems iteratively to meet exact functional requirements.

METAL POWDERS PRODUCTION

AMAZEMET: Advanced Gallium Alloy Powder and Atomization Expertise

AMAZEMET specializes in custom metal powder development for research and innovation-driven industries.

In the context of gallium alloys, we provide:

Custom gallium alloy powder formulations

Controlled atomization parameters

Research-scale production

Rapid iteration capabilities

AMAZEMET SERVICES & REPOWDER

In-House Gallium Alloy Production with rePOWDER

From tailored powders to in-house powder production, AMAZEMET supports the entire tin alloys development process.

For organizations developing proprietary systems based on gallium alloys, in-house atomization offers strategic benefits.

Laboratory-scale production enables:

- Exploration of new gallium alloy systems

- Adjustment of composition in alloys with gallium

- Controlled production of gallium powder batches

- Protection of intellectual property

- Independence from specialized external supply chains

This approach transforms gallium alloy development into a fully controlled engineering process rather than a procurement limitation.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch Gallium alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore brazing alloys at the highest level.