Freedom in Metal AM Develompent & Production

Indium Alloys for Thermal, Electronic and Vacuum Applications

Indium Alloys for Thermal, Electronic and Vacuum Applications

Indium alloys occupy a unique position among soft metals due to their ductility, low melting point, high thermal conductivity, and exceptional wetting behavior.

INDIUM ALLOYS

Indium Alloys for Thermal, Electronic and Vacuum Applications

Introduction

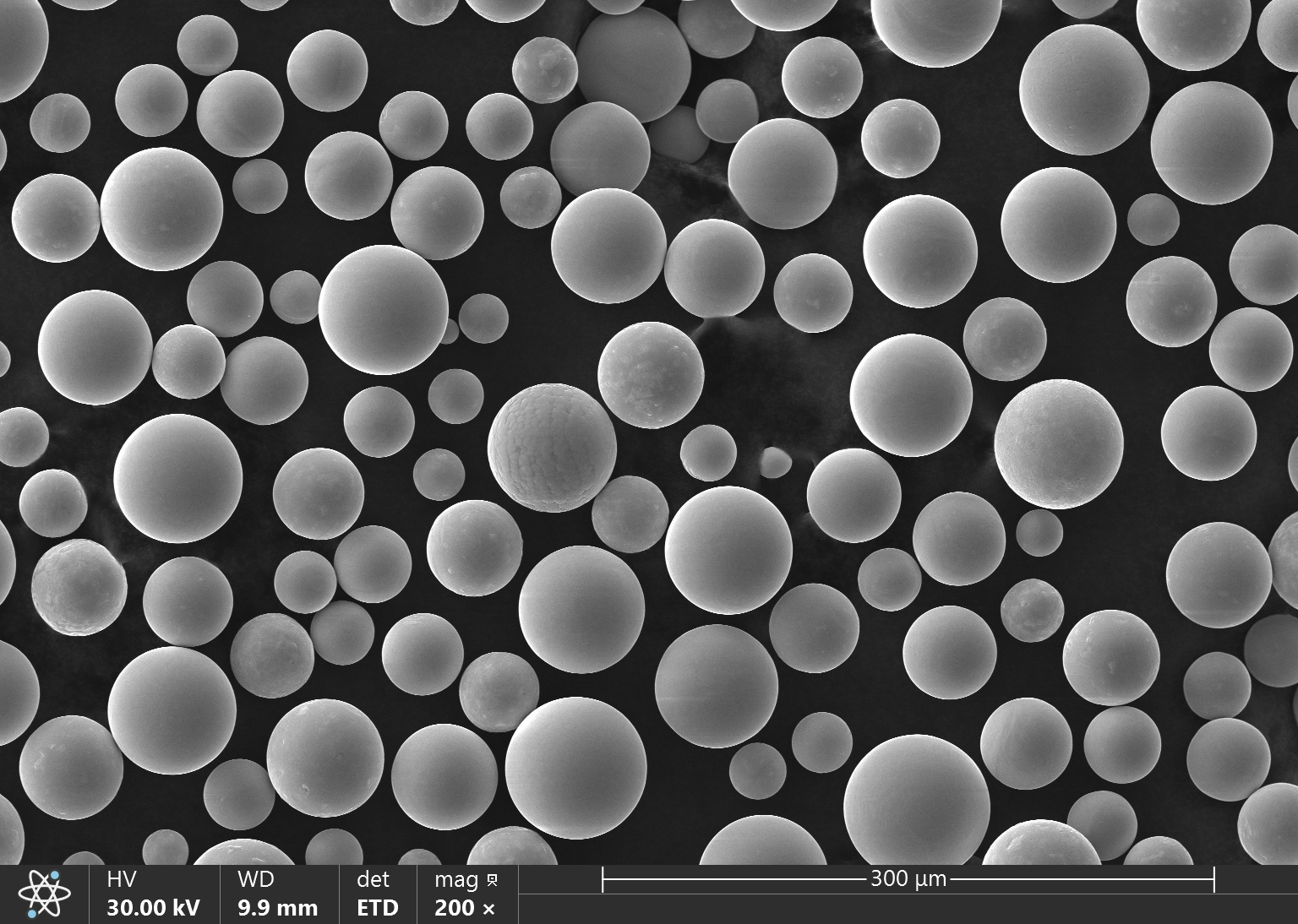

In powder form, indium alloys enable advanced joining, thermal interface solutions, and vacuum-sealed systems where precise material control is essential.

Indium powder is widely used in electronics, semiconductor packaging, cryogenic systems, and optical assemblies. Unlike many structural metals, indium remains soft and malleable even at low temperatures, which makes an indium alloy particularly suitable for hermetic sealing and high-reliability interfaces.

As part of our advanced Metal powders portfolio, AMAZEMET develops customized indium alloys for research institutions and high-precision industries.

In powder form, indium alloys enable advanced joining, thermal interface solutions, and vacuum-sealed systems where precise material control is essential.

Indium powder is widely used in electronics, semiconductor packaging, cryogenic systems, and optical assemblies. Unlike many structural metals, indium remains soft and malleable even at low temperatures, which makes an indium alloy particularly suitable for hermetic sealing and high-reliability interfaces.

As part of our advanced Metal powders portfolio, AMAZEMET develops customized indium alloys for research institutions and high-precision industries.

IMPORTANCE

Why Indium Alloys Are Technically Distinct

Indium alloys are not primarily structural materials. Their importance lies in functional performance.

Exceptional Wettability

Indium metal powder demonstrates outstanding wetting on glass, ceramics, and metals. This makes indium alloys ideal for sealing and joining applications where conventional solders fail.

Low Temperature Joining

Many indium alloy systems melt at relatively low temperatures, enabling bonding of temperature-sensitive components. These properties are critical in optical devices, sensors, and semiconductor assemblies.

Cryogenic Performance

Unlike brittle solders, indium alloys retain ductility at cryogenic temperatures. This makes them essential in aerospace instrumentation and superconducting systems.

Vacuum and Hermetic Sealing

Indium powder and indium alloy formulations are widely used for vacuum seals in research equipment, detectors, and analytical instruments.

Because of these properties, the quality of indium metal powder directly affects joint reliability and long-term system stability.

METAL AM

Market Realities: Indium Powder Supply Constraints

Despite its technical importance, indium powder is not a mass-market material.

01

Limited Powder Availability

Indium is primarily produced as a by-product of zinc refining. As a result, the number of indium powder suppliers globally is limited.

02

Specialized Demand

Most indium powder suppliers focus on electronics-grade materials or specific solder systems. Custom indium alloy compositions are rarely available off-the-shelf.

03

Small-Scale R&D Challenges

Research teams often require only grams or kilograms of indium alloy powder. Many indium powder suppliers operate at industrial volume thresholds, limiting flexibility.

04

Price Sensitivity

Indium powder supplier pricing is strongly influenced by global indium availability. Efficient batch production and precise alloy development help reduce waste and optimize material usage.

These constraints make it difficult to source experimental indium alloys without a specialized atomization partner.

These constraints make it difficult to source experimental indium alloys without a specialized atomization partner.

AMAZEMET

Custom Indium Alloy Powder Development

Instead of relying solely on standard electronics-grade materials, controlled atomization allows the development of tailored indium alloys.

Custom indium alloy powder can be engineered to:

- Adjust melting range

- Optimize mechanical compliance

- Modify thermal conductivity

- Improve bonding characteristics

- Refine particle size distribution for powder-based processing

This approach is particularly valuable in advanced Brazing alloys and soldering technologies where melting behavior and flow are tightly controlled.

By combining material design with laboratory-scale production, indium alloy development becomes iterative rather than supply constrained.

METAL POWDERS PRODUCTION

AMAZEMET as an Indium Powder Supplier for Advanced Applications

AMAZEMET operates at the intersection of material science and powder atomization technology. Rather than acting as a commodity distributor, we function as a technical indium powder supplier for:

- Research laboratories

- Semiconductor developers

- Aerospace instrumentation projects

- High-reliability joining systems

Our capabilities include:

Custom indium alloy powder formulations

Controlled particle size distribution

Research-scale production

Rapid alloy iteration

AMAZEMET SERVICES & REPOWDER

In-House Gallium Alloy Production with rePOWDER

From tailored powders to in-house powder production, AMAZEMET supports the entire tin alloys development process.

For institutions developing proprietary sealing or joining systems, internal production of indium metal powder can provide strategic advantages.

With laboratory-scale atomization systems, teams can:

- Experiment with new indium alloy compositions

- Control powder morphology

- Produce minimal required volumes

- Maintain full confidentiality

- Reduce dependency on fluctuating external indium powder suppliers

This approach transforms indium alloy development from a procurement issue into a controlled engineering process.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch Indium alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore brazing alloys at the highest level.