Freedom in Metal AM Develompent & Production

Lead Alloys in Powder Form

Lead Alloys in Powder Form

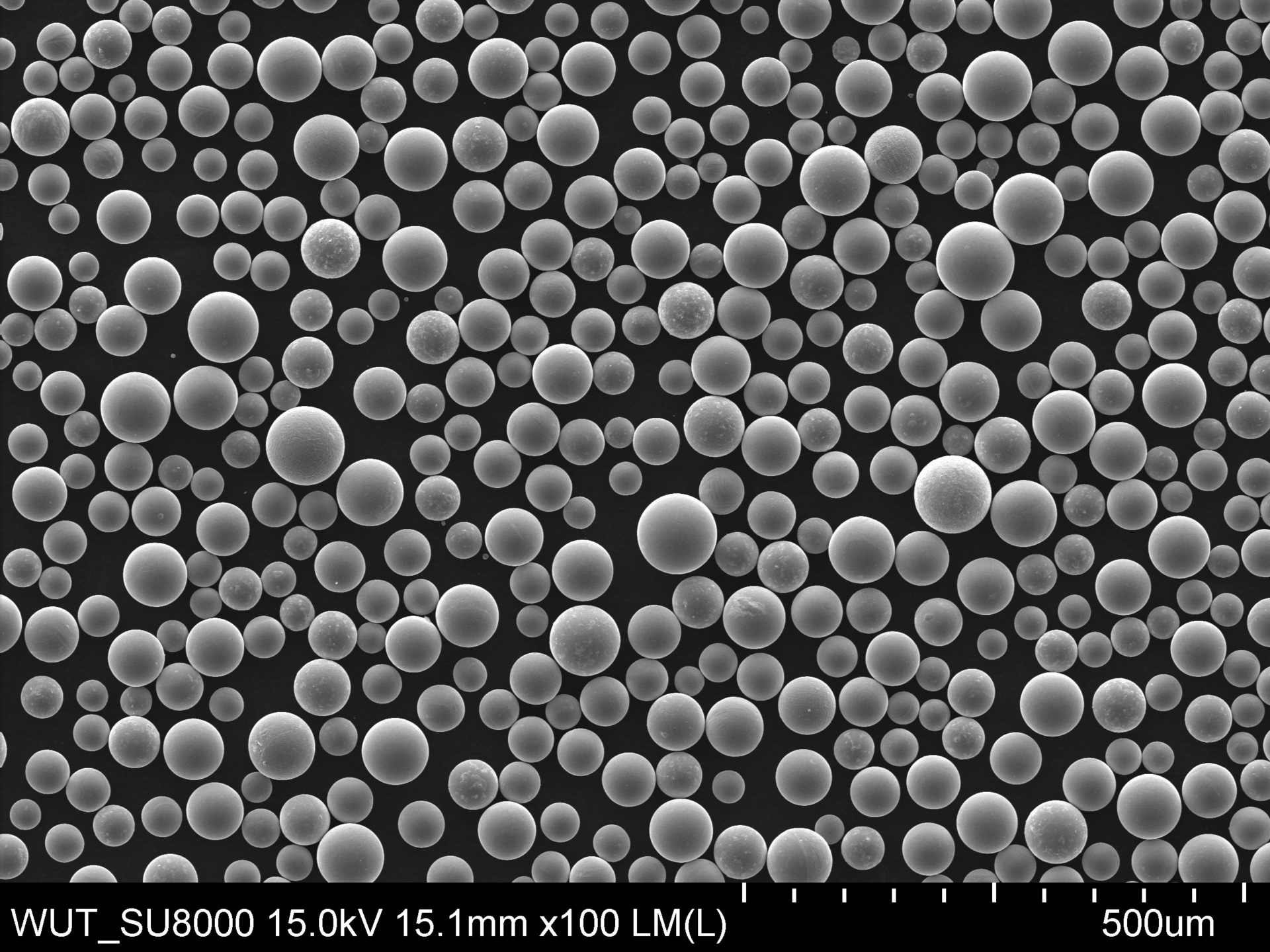

Lead alloy powders provide high-density solutions for radiation shielding, energy storage, and industrial damping. These materials allow for precise tailoring of electrochemical and mechanical properties through controlled alloying and powder metallurgy routes.

LEAD ALLOYS

Lead Alloys in Powder Form for Energy, Shielding and Industrial Applications

Introduction

Lead alloys remain essential in industries that require high density, corrosion resistance, vibration damping and controlled electrochemical behavior. In powder form, lead alloys enable advanced processing routes such as powder metallurgy, coatings, battery material manufacturing and specialized component production.

Lead powder is widely used in battery technologies, radiation shielding systems, counterweights and damping components. By modifying composition through alloying additions such as antimony, tin, calcium, silver or bismuth, a specific lead alloy can be tailored to improve strength, creep resistance or electrochemical stability.

Compared to bulk ingots, lead alloy powder offers greater flexibility in forming, blending and controlled consolidation processes. As part of our broader expertise in Metal powders, AMAZEMET supports the development of custom lead alloys for research and specialized manufacturing.

Lead alloys remain essential in industries that require high density, corrosion resistance, vibration damping and controlled electrochemical behavior. In powder form, lead alloys enable advanced processing routes such as powder metallurgy, coatings, battery material manufacturing and specialized component production.

Lead powder is widely used in battery technologies, radiation shielding systems, counterweights and damping components. By modifying composition through alloying additions such as antimony, tin, calcium, silver or bismuth, a specific lead alloy can be tailored to improve strength, creep resistance or electrochemical stability.

Compared to bulk ingots, lead alloy powder offers greater flexibility in forming, blending and controlled consolidation processes. As part of our broader expertise in Metal powders, AMAZEMET supports the development of custom lead alloys for research and specialized manufacturing.

METAL AM

Challenges in Sourcing Custom Lead Alloy Powder

Although lead alloys are well established in industry, obtaining customized lead powder in controlled quantities presents several challenges.

01

Bulk-Oriented Production

Most manufacturers focus on large-scale casting and battery-grade materials. Small-batch lead alloy powder production is rarely available.

02

Limited Alloy Flexibility

Standard compositions dominate the market. Modified lead alloys with specific microstructural or electrochemical targets often require special production runs.

03

High Minimum Order Quantities

Suppliers typically operate on industrial volumes, which limits access for R&D laboratories and pilot-scale projects.

04

Particle Size Control

For powder metallurgy or shielding applications, particle size distribution directly influences density, compaction and performance. Off-the-shelf lead powder may not meet defined specifications.

These constraints slow innovation in battery development, shielding systems and advanced low melting point alloys, including those used in Brazing alloys and soldering technologies.

These constraints slow innovation in battery development, shielding systems and advanced low melting point alloys, including those used in Brazing alloys and soldering technologies.

AMAZEMET

Custom Lead Alloy Powder Production and Atomization

To overcome supply limitations, tailored atomization of lead alloys provides a flexible alternative.

- Specialty Powder Providers:

Custom lead alloy powder can be produced in research-scale volumes, allowing precise control over:- Alloy chemistry such as Pb-Sb, Pb-Ca or Pb-Sn, Pb-Ag, Pb-Bi systems

- Particle size distribution

- Powder homogeneity

- Batch volume from grams to kilogramsThis enables rapid testing and development of optimized lead alloys for energy storage, shielding and joining applications.

- In-House Atomization:

For organizations requiring repeated iteration, lab-scale atomization offers long-term strategic control. With rePOWDER technology, teams can:- Develop proprietary lead alloy compositions

- Produce controlled lead powder quantities on demand

- Adjust process parameters to refine particle characteristics

- Protect confidential battery or shielding formulations

While external supply addresses immediate material needs, in-house atomization provides autonomy in developing specialized lead alloys and Pb alloy systems.

METAL POWDERS PRODUCTION

AMAZEMET: Lead Alloys and Powder Expertise

As part of our broader metal powder development platform, we support both custom lead powder supply and laboratory-scale atomization equipment for advanced material development.

AMAZEMET specializes in custom metal powder production with a strong focus on flexibility and research scalability. Our capabilities in lead alloy powder development include:

Tailored lead alloys for battery, shielding and damping applications

Controlled atomization parameters

Research-scale production

Rapid iteration for new alloy concepts

AMAZEMET SERVICES & REPOWDER

Custom Powder Services and rePOWDER for Lead Alloys

From tailored powders to in-house powder production, AMAZEMET supports the entire lead alloys development process.

1. Custom Powder Production:

- Development of non-standard lead alloy chemistries

- Flexible order volumes

- Controlled particle size distribution

- Shorter turnaround compared to bulk industrial suppliers

2. rePOWDER Atomizer for In-House Lead Powder Production:

- Suitable for low melting point metals including lead alloys

- Full control over alloying additions and atomization parameters

- Adapted for R&D and pilot production

- Secure processing for proprietary formulations

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch lead alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore brazing alloys at the highest level.