Freedom in Metal AM Develompent & Production

Refractory High-Entropy Alloys: Materials for Extreme Environments

Refractory High-Entropy Alloys: Materials for Extreme Environments

Combining multiple refractory elements into a single alloy system, Refractory High-Entropy Alloys (RHEAs) offer outstanding strength and stability at ultra-high temperatures, pushing the boundaries of aerospace and energy applications.

REFRACTORY HEAs

Refractory HEAs: Powder Production and Performance in Extreme Environments

Introduction

Refractory HEAs are an advanced class of alloys built from several refractory metals such as tantalum, niobium, molybdenum, titanium, rhenium, hafnium, or zirconium mixed in near-equiatomic ratios. Unlike conventional alloys, which rely on one primary element, RHEAs form solid solution phases that deliver a remarkable combination of high melting points, creep resistance, and oxidation stability.

This makes RHEAs especially attractive for aerospace propulsion, gas turbines, and nuclear energy systems, where traditional nickel or cobalt superalloys begin to fail. Their potential also extends to additive manufacturing (AM), where powders of RHEAs can be processed into complex geometries tailored for extreme performance.

Refractory HEAs are an advanced class of alloys built from several refractory metals such as tantalum, niobium, molybdenum, titanium, rhenium, hafnium, or zirconium mixed in near-equiatomic ratios. Unlike conventional alloys, which rely on one primary element, RHEAs form solid solution phases that deliver a remarkable combination of high melting points, creep resistance, and oxidation stability.

This makes RHEAs especially attractive for aerospace propulsion, gas turbines, and nuclear energy systems, where traditional nickel or cobalt superalloys begin to fail. Their potential also extends to additive manufacturing (AM), where powders of RHEAs can be processed into complex geometries tailored for extreme performance.

METAL AM

The Challenge of Developing RHEAs for Practical Use

Despite their promise, refractory HEAs remain difficult to source and produce in powder form.

As an emerging field of research, RHEAs face significant barriers that slow down their adoption:

01

Limited Availability

Few suppliers produce RHEA powders, and commercial offerings are nearly non-existent.

02

Complex Chemistry

Controlling the balance of multiple refractory elements is difficult, requiring precision in both composition and processing.

03

High Production Cost

Refractory metals such as hafnium, tantalum, or rhenium are expensive, making small-batch experimentation more feasible than bulk production.

04

Lack of Standards

Unlike nickel superalloys, RHEAs do not yet have established grades or widely accepted reference compositions, complicating collaboration and scaling.

These issues mean most RHEA research is limited to a small number of laboratories, despite their vast potential in hypersonics, energy, and aerospace propulsion.

These issues mean most RHEA research is limited to a small number of laboratories, despite their vast potential in hypersonics, energy, and aerospace propulsion.

AMAZEMET

Pathways to Unlocking RHEA Potential

Access to tailored powder production and in-house atomization is key to advancing RHEA research.

Two complementary approaches help overcome the bottlenecks in RHEA development:

- Custom Powder Production: Specialty suppliers can create small-batch RHEA powders with tailored ratios of refractory metals, enabling researchers to test new compositions without committing to bulk volumes.

- In-House Atomization: With systems such as rePOWDER, labs can design and manufacture their own RHEA powders, adjusting chemistries and particle size distribution on demand. This flexibility supports rapid iteration, confidential alloy development, and exploratory research that would be impossible with standard supply chains.

Together, these solutions allow researchers to explore the vast compositional space of refractory HEAs, accelerating the discovery of alloys optimized for extreme environments.

METAL POWDERS PRODUCTION

AMAZEMET: Supporting Innovation in RHEA Powders

AMAZEMET enables researchers and innovators to experiment with refractory HEAs by providing small-batch powders and in-house production capabilities.

Our approach is designed to help teams push the frontier of alloy design by:

Custom powder formulations

including Nb-Mo-Ta-Ti, Ti-Zr-Nb-Hf, or other experimental systems.

Flexible order volumes

from a few grams for laboratory trials to several kilograms for pilot-scale builds.

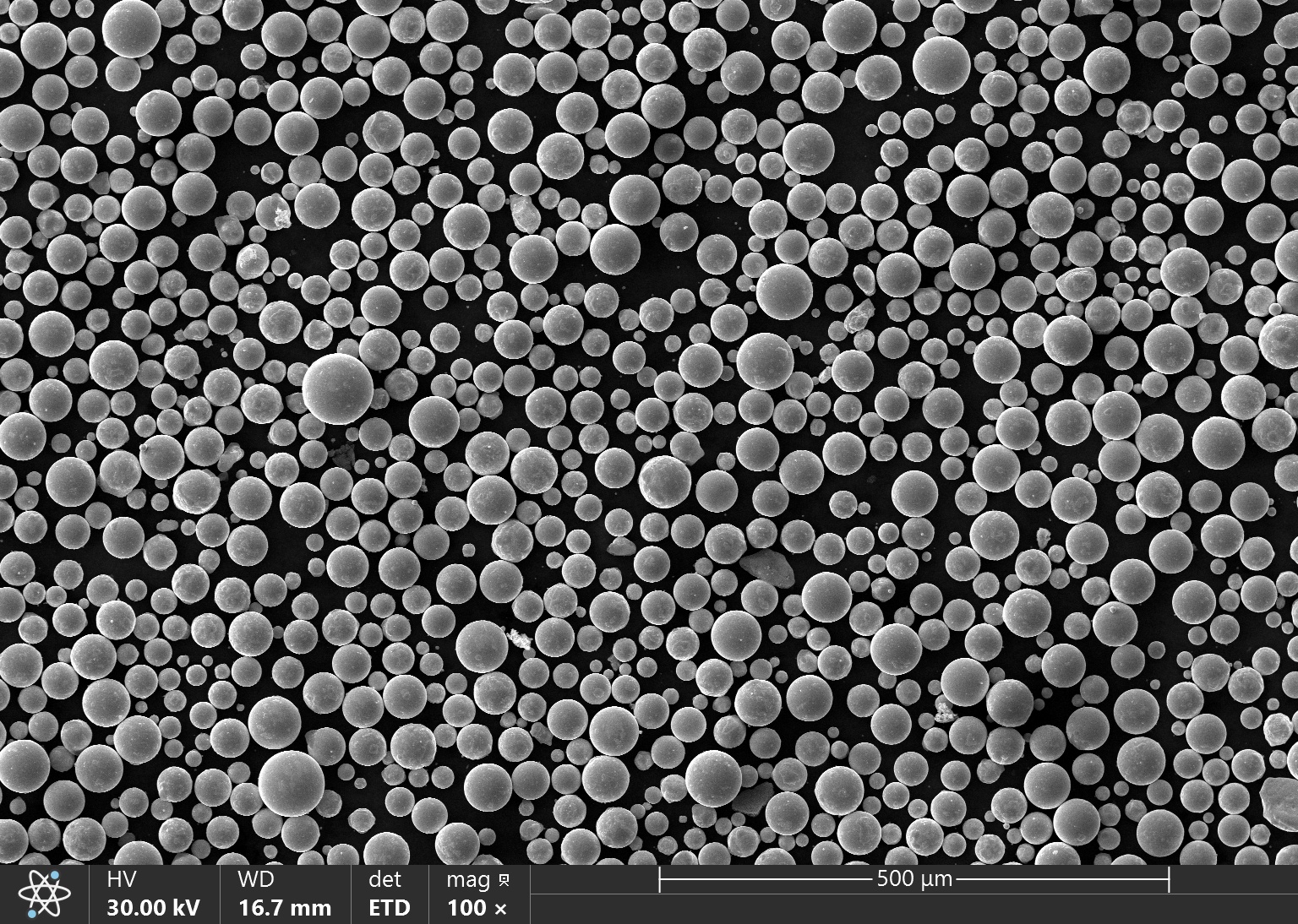

Consistent powder quality

with spherical morphology and controlled composition suitable for additive manufacturing. By bridging the gap between conceptual alloy design and practical powder production, AMAZEMET supports progress in one of the most exciting frontiers of metallurgy.

AMAZEMET SERVICES & REPOWDER

AMAZEMET Services & rePOWDER: Refractory HEA Development

AMAZEMET Services & rePOWDER: Refractory HEA Development

1. Custom Powder Production (Small Batches):

- Tailored multi-element compositions designed for specific high-temperature performance targets.

- Scalable quantities ideal for early-stage discovery and prototyping.

- Faster delivery than conventional refractory supply chains.

2.In-House Atomization

- Adapted for refractory systems, enabling the processing of complex HEA chemistries.

- Parameter control particle sizes and alloy chemistry.

- Confidential development, securing proprietary alloy research in-house.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch refractory HEA alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore lightweight materials at the highest level.