Freedom in Metal AM Develompent & Production

High-Temperature Materials

High-temperature materials are critical for applications that involve exposure to extreme heat, where metals need to maintain their strength, durability, and resistance to degradation. These materials, particularly nickel-based superalloys, cobalt alloys, and titanium alloys play a crucial role in high-stress environments, where high performance at elevated temperatures is essential. Their ability to resist heat-induced degradation, oxidation, and creep (slow deformation under stress) makes them indispensable in modern engineering applications.

HIGH-TEMPERATURE MATERIALS

Characterization & Properties

Characterization & Properties

High-temperature metals, especially those based on nickel, cobalt, and titanium, offer a range of properties that allow them to operate efficiently in extreme heat. Some key properties include:

High-temperature metals, especially those based on nickel, cobalt, and titanium, offer a range of properties that allow them to operate efficiently in extreme heat. Some key properties include:

High melting points

These metals maintain stability at temperatures far higher than many conventional materials. Nickel-based superalloys can withstand temperatures of over 1000°C.

Oxidation resistance

These alloys form protective oxide layers, preventing material degradation even in reactive, high-temperature environments.

Creep resistance

These metals resist deformation under constant stress and high temperatures, ensuring long-term durability.

Thermal fatigue resistance

Nickel and cobalt alloys, in particular, are engineered to withstand the repeated heating and cooling cycles found in engines and turbines.

CHOOSE YOUR COMPOSITION

Example High-Temperature Metal Compositions

These alloys provide optimal performance in high-stress, high-temperature environments where conventional materials would fail.

01

Nickel-based Superalloys (e.g., Inconel, Hastelloy)

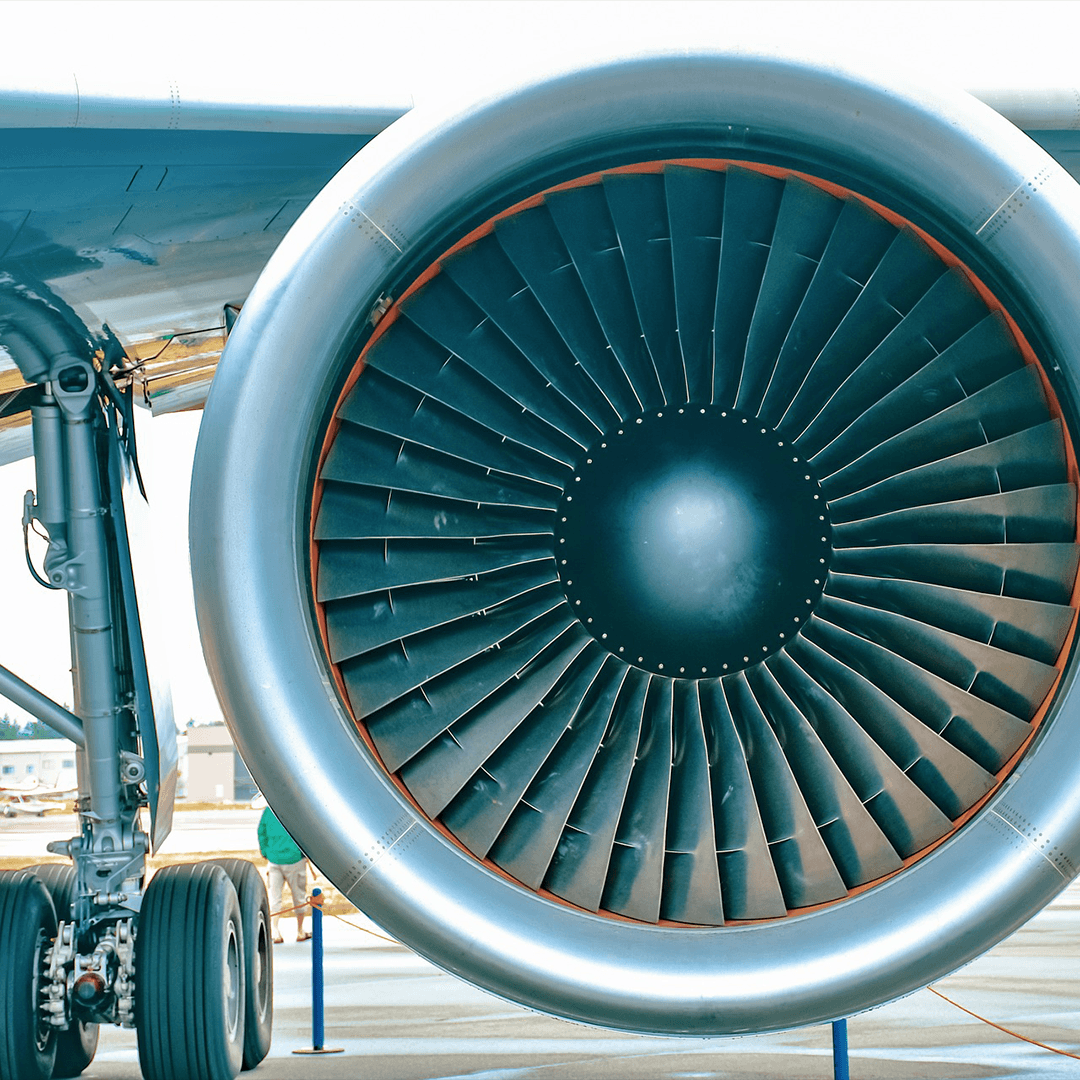

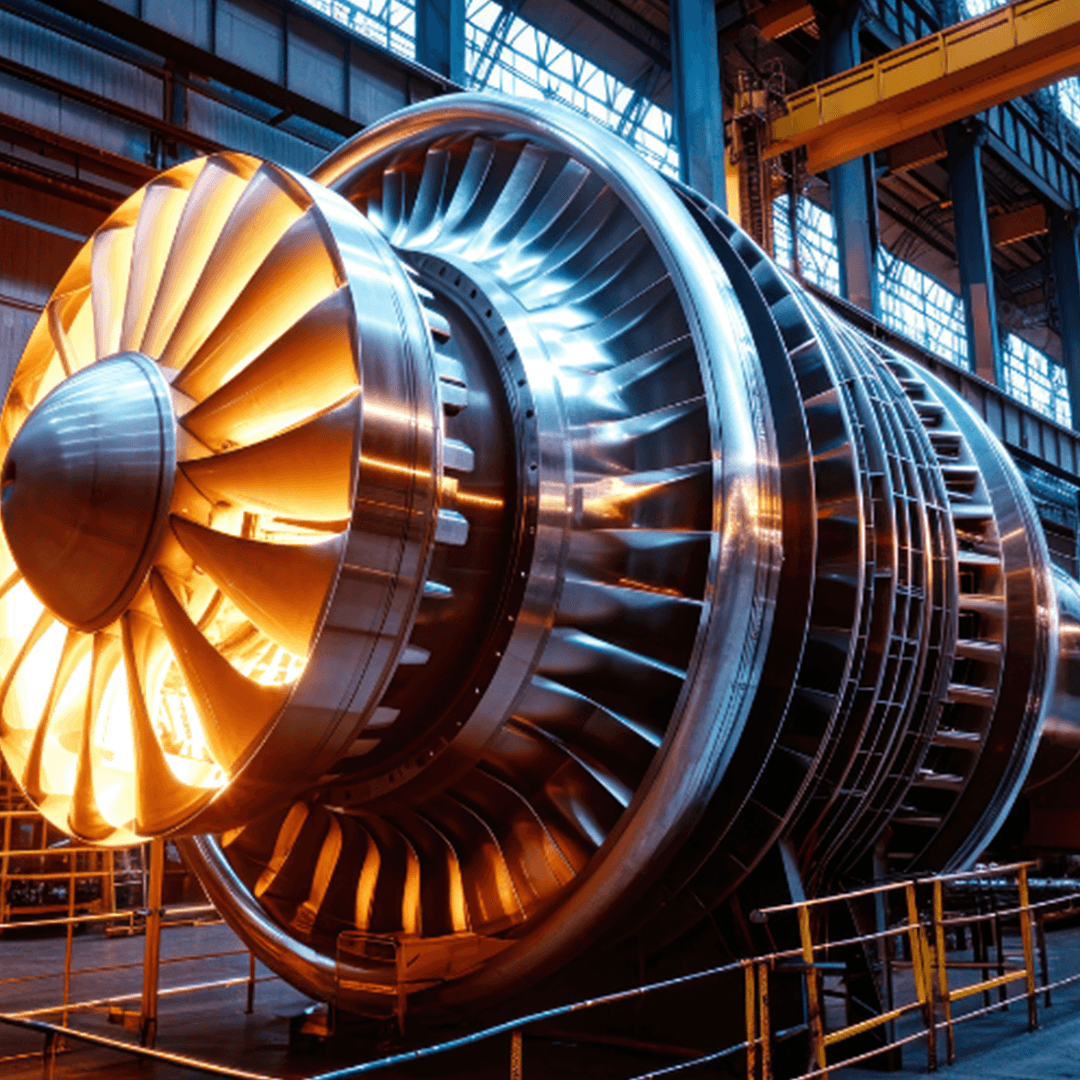

These superalloys are designed to maintain mechanical strength at high temperatures. They are often used in jet engines, gas turbines, and power plants.

02

Cobalt-based Alloys (e.g., Haynes, Stellite)

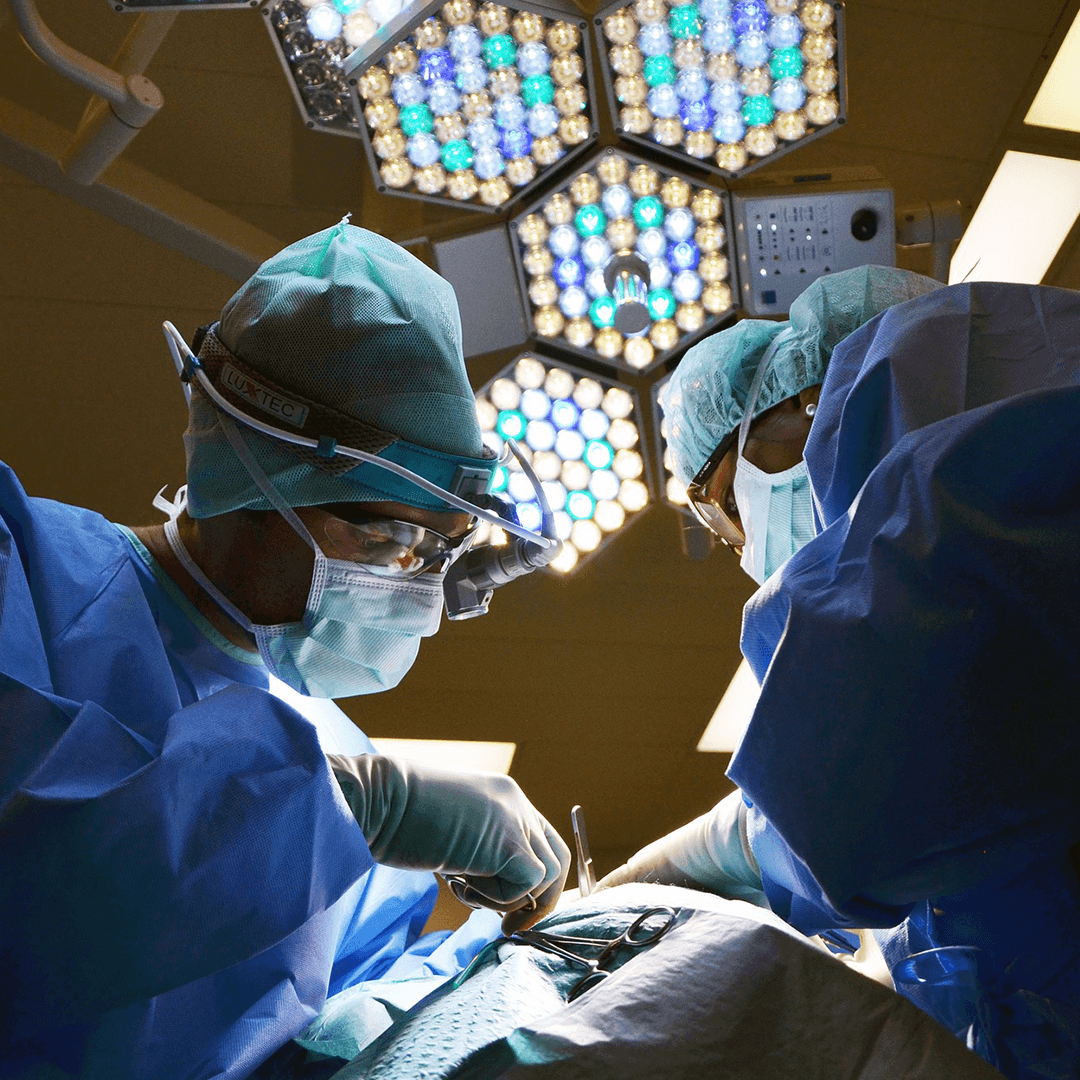

Known for their excellent thermal and oxidation resistance, cobalt alloys are used in critical components like turbine blades and medical implants where high temperature and wear resistance are essential.

03

Titanium Alloys (e.g., Ti-6Al-4V)

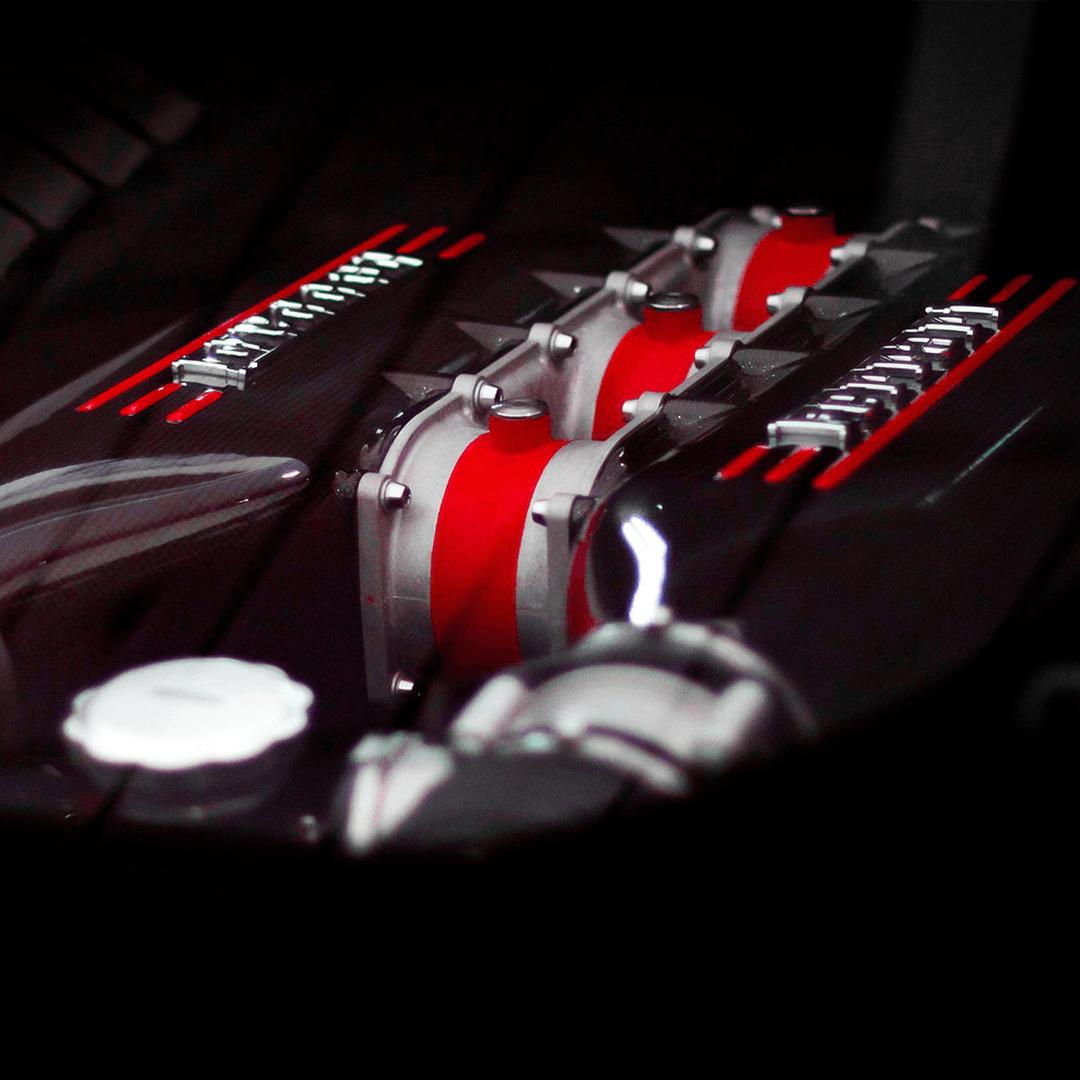

Titanium alloys offer an excellent balance of strength, low weight, and high-temperature resistance. They are frequently used in aerospace applications such as airframes, jet engines, and exhaust systems.

SPECIFICATIONS OF OUR MACHINES

Applications of High-Temperature Metals

High-temperature metals are used in a wide range of industries that rely on materials capable of enduring extreme conditions. These applications illustrate the widespread use of high-temperature metals in sectors where durability and performance are paramount.

METAL POWDES PRODUCTION

Where to Buy High-Temperature Metal Powders?

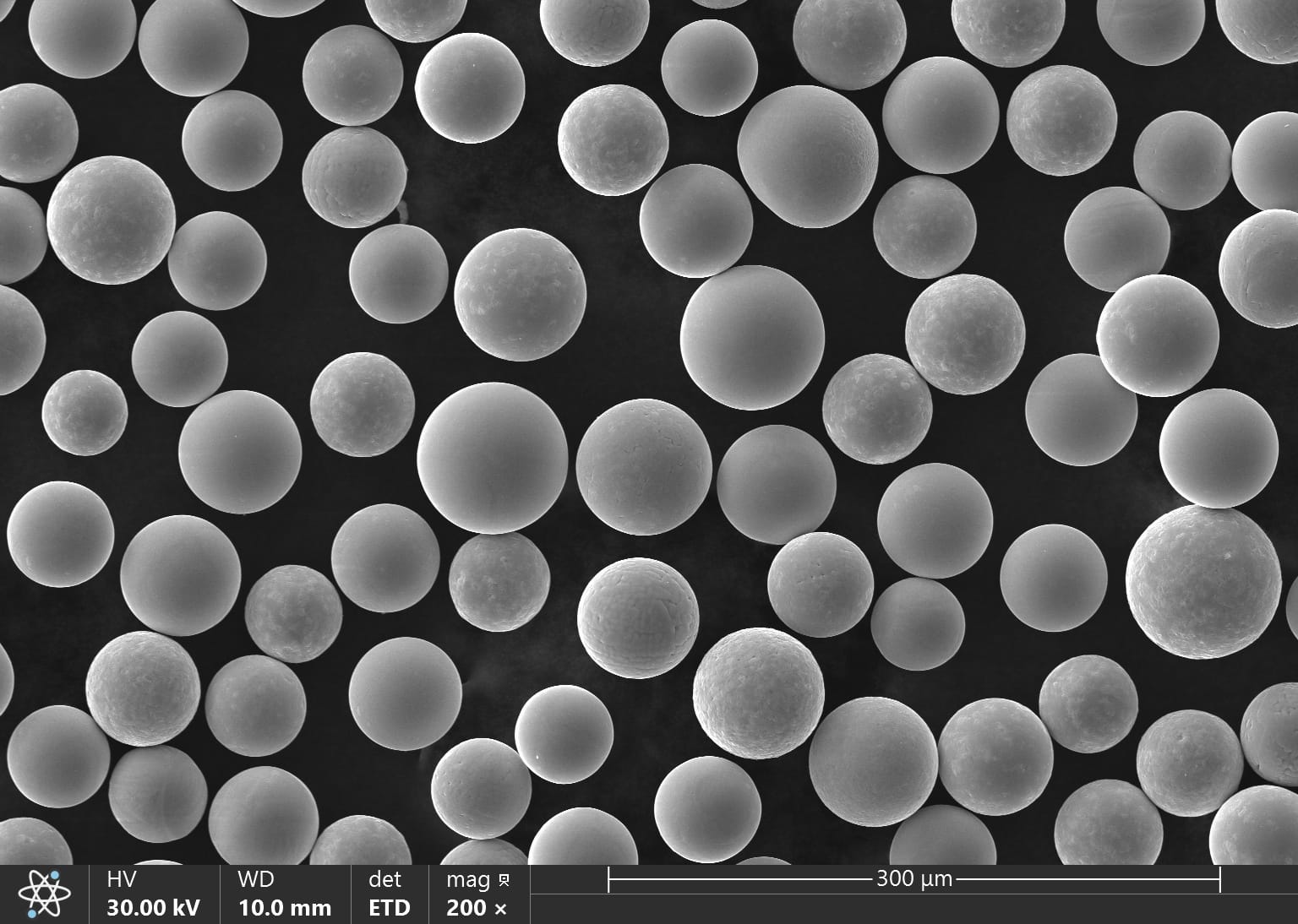

Specialized suppliers offer high-temperature metal powders for advanced manufacturing processes. AMAZEMET provides possibility to manufacture variety of nickel, cobalt, and titanium-based powders, optimized for additive manufacturing and other high-performance applications. Our powders are produced using plasma ultrasonic atomization, ensuring high purity and uniformity in particle size.

WHY AMAZEMET

Why Choose our High-Temperature Metal Powders?

At AMAZEMET, we offer high-quality powders designed to perform in the most demanding environments. Our high-temperature metal powders are trusted by industries that require materials capable of maintaining their integrity in extreme heat conditions. Here’s why our high-temperature metal powders stand out:

High purity

Our powders are produced with strict quality control, ensuring reliable performance in high-stress environments.

Fine, spherical particles

The plasma ultrasonic atomization process guarantees uniform particle size and shape, optimizing them for use in additive manufacturing and powder metallurgy.

Excellent flowability

Our powders handle easily in industrial processes, ensuring precise distribution and consistent performance.

Custom compositions

We offer tailored powders to meet specific needs, ensuring optimal material performance for specialized applications.

ORDER POWDERS

High-Temperature Metal Powders for Sale

AMAZEMET offers a possibiliety to manufacture range of high-temperature metal powders, including nickel-based, cobalt-based, and titanium alloys. Produced through plasma ultrasonic atomization, our powders are designed to meet the demanding needs of high-temperature manufacturing processes like 3D printing, metal injection molding, and powder metallurgy. Our product offerings include:

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

HIGH QUALITY METAL POWDERS

How to Make High-Temperature Metal Powders?

The production of high-temperature metal powders requires specialized techniques to ensure uniformity and reliability. Our approach ensures that the powders are of high quality, with the properties required for advanced manufacturing techniques like 3D printing and metal injection molding. AMAZEMET uses plasma ultrasonic atomization, a method that involves:

Custom Powders In-House

For those seeking to produce custom high-temperature metal powders in-house, AMAZEMET offers the rePOWDER metal powder atomizer. This system enables you to create small batches of metal powders on demand, giving you control over the composition and quality of your materials. The rePOWDER atomizer provides several benefits:

- Customization: Tailor the composition of your powders to meet specific needs.

- Efficiency: Produce powders in-house, reducing lead times and dependence on external suppliers.

- Versatility: The atomizer can handle various high-temperature metals, including nickel, cobalt, and titanium alloys.

- Ease of use: Compact and easy to operate, making it ideal for research institutions and small-scale production environments.

With the rePOWDER system, you can produce custom high-temperature metal powders, giving you flexibility and control over your material needs.