Freedom in Metal AM Develompent & Production

A Closer Look at Cobalt Alloys

A Closer Look at Cobalt Alloys

Cobalt alloys are rapidly emerging as essential materials for applications that demand durability under extreme conditions, combining excellent wear resistance with high-temperature stability.

COBALT SUPERALLOYS

Cobalt-Based Alloys: High-Performance Materials for Wear and Thermal Stability

Introduction

Cobalt alloys, often referred to as cobalt superalloys, are engineered from cobalt with carefully chosen alloying elements to enhance performance in critical applications. These cobalt-based alloys excel in environments where high strength and corrosion resistance are paramount, such as in turbine components, cutting tools, and medical implants. Widely used commercial cobalt-based superalloys include Stellite® (e.g., Stellite 6, Stellite 21), Haynes® (e.g., Haynes 25 / L-605, Haynes 188), Ultimet®, and FSX-414.

These alloys typically contain controlled amounts of chromium, tungsten, molybdenum, nickel, and carbon to achieve excellent wear resistance, oxidation and corrosion resistance, and mechanical strength at elevated temperatures.

For example, Stellite alloys are common in cutting and wear parts, Haynes alloys serve in turbine blades and combustion hardware, and Co-Cr-Mo biomedical grades are used for orthopedic and dental implants.

Their established performance makes them a natural starting point for R&D projects aiming to modify microstructure, particle size distribution, or minor alloying additions for specialized applications.

While established industrial players supply standard grades in bulk, advanced R&D and niche projects often call for innovative formulations or small-quantity orders. In these cases, securing high-quality cobalt powder becomes vital for developing next-generation materials.

Cobalt alloys, often referred to as cobalt superalloys, are engineered from cobalt with carefully chosen alloying elements to enhance performance in critical applications. These cobalt-based alloys excel in environments where high strength and corrosion resistance are paramount, such as in turbine components, cutting tools, and medical implants. Widely used commercial cobalt-based superalloys include Stellite® (e.g., Stellite 6, Stellite 21), Haynes® (e.g., Haynes 25 / L-605, Haynes 188), Ultimet®, and FSX-414.

These alloys typically contain controlled amounts of chromium, tungsten, molybdenum, nickel, and carbon to achieve excellent wear resistance, oxidation and corrosion resistance, and mechanical strength at elevated temperatures.

For example, Stellite alloys are common in cutting and wear parts, Haynes alloys serve in turbine blades and combustion hardware, and Co-Cr-Mo biomedical grades are used for orthopedic and dental implants.

Their established performance makes them a natural starting point for R&D projects aiming to modify microstructure, particle size distribution, or minor alloying additions for specialized applications.

While established industrial players supply standard grades in bulk, advanced R&D and niche projects often call for innovative formulations or small-quantity orders. In these cases, securing high-quality cobalt powder becomes vital for developing next-generation materials.

METAL AM

Challenges in Obtaining Custom Cobalt Alloy Materials

Standard offerings may serve general markets well, but specific performance goals in high-stress, high-temperature applications often require tailored modifications.

Conventional suppliers of cobalt alloys typically focus on large-volume production, leaving researchers and specialized manufacturers with limited options for custom formulations. Often, the subtle balance of alloying elements that defines a superior cobalt alloy is not achievable through off-the-shelf products. This creates several key challenges:

01

Bulk Supply Limitations

Many cobalt alloy suppliers cater primarily to high-volume orders, making it difficult to access small batches for experimentation.

02

Rigid Compositions

Standard cobalt based alloys may not offer the precise adjustments—such as targeted doping or microstructural control—needed to achieve optimal performance.

03

Extended Production Times

Custom orders for modified alloys or specialized cobalt powder formulations can entail long lead times, delaying critical development cycles.

These obstacles can hinder innovation, restrict design flexibility, and ultimately slow down the pace of new product development.

These obstacles can hinder innovation, restrict design flexibility, and ultimately slow down the pace of new product development.

AMAZEMET

Innovative Pathways for Custom Cobalt Alloy Solutions

To overcome these limitations, engineers and researchers can explore specialty powder providers or implement in-house production techniques tailored to their unique requirements.

For applications demanding non-standard material properties, two primary strategies offer a solution:

- Specialty Powder Providers: Advanced materials vendors can produce custom batches of cobalt powder in smaller volumes. These suppliers can fine-tune the alloy composition and processing conditions, resulting in a bespoke cobalt alloy that meets precise performance criteria.

- In-House Production Systems: By investing in an in-house atomization system, you gain direct control over the production of cobalt metal powder. This approach allows for rapid iteration, fine adjustments to alloy chemistry, and the ability to produce exactly the quantity you need—enhancing both research flexibility and intellectual property security.

Both options empower you to bypass the restrictions of mass-produced materials and achieve the specialized properties necessary for breakthrough applications.

METAL POWDERS PRODUCTION

AMAZEMET: Your Specialist in Custom Cobalt Alloy Solutions

AMAZEMET supports advanced research projects and specialized development initiatives with custom, small-batch solutions in the field of cobalt alloys.

At AMAZEMET, we recognize that many projects require materials that extend beyond conventional supply. Rather than offering only standard compositions, our focus is on developing tailor-made cobalt alloys that match defined requirements. Whether the need involves specific alloying strategies, refined microstructural control, or access to custom cobalt powder formulations, our team works closely with you to create solutions that support research and development objectives. We provide flexible, high-quality products designed to meet demanding engineering specifications.

AMAZEMET SERVICES & REPOWDER

AMAZEMET Services & rePOWDER: Your Custom Cobalt Alloys

From bespoke powder production to in-house atomization, AMAZEMET offers comprehensive solutions for custom cobalt alloy development aligned with defined specifications.

By combining these services, AMAZEMET equips you with the tools and expertise to pioneer new frontiers in high-performance cobalt based alloys.

1. Custom Powder Production Services (Small Batches):

- Tailored Compositions: Work with our experts to design and manufacture unique cobalt alloy powders that are not available in standard catalogs.

- Optimized Volumes: Order precisely the amount you need for your R&D or pilot projects, avoiding excess inventory.

- Rapid Production: Lead times can be shorter than those typically associated with large-volume industrial suppliers, facilitating timely prototyping and testing.

2. rePOWDER Atomizer for In-House Development:

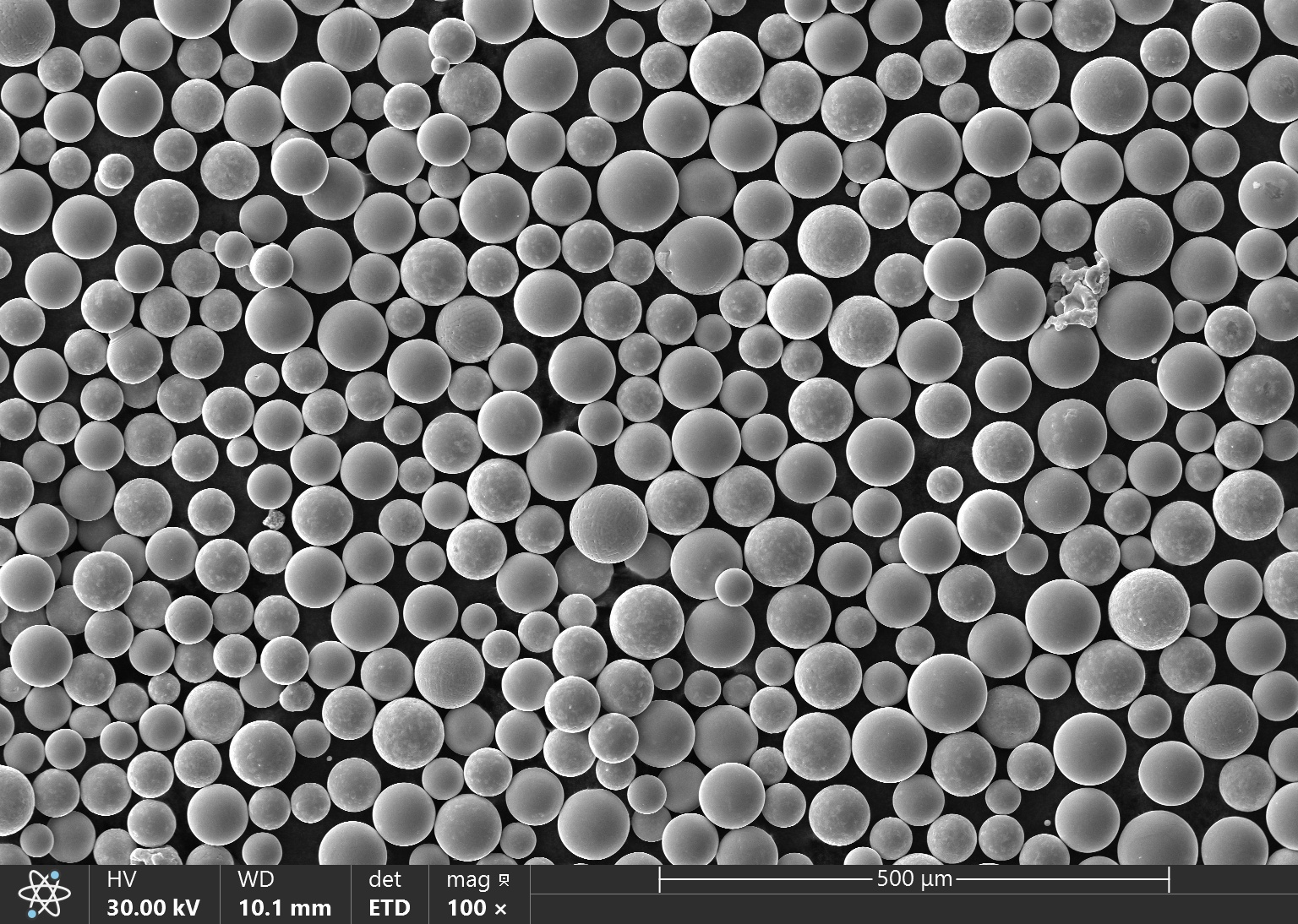

- Advanced Processing Capability: The rePOWDER system is designed to handle cobalt alloys and produce high-quality powders.

- Customizable Process Parameters: Fine-tune variables such as Particle Size Distribution and alloying additions to create the exact cobalt alloy powder you require.

- Enhanced Security: Produce materials on-site, protecting your proprietary formulations and reducing reliance on external suppliers.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need custom small-batch powders or seek to produce them yourself, AMAZEMET can help you navigate beyond standard commercial alloys.