Freedom in Metal AM Develompent & Production

Navigating the World of Nickel Superalloys

Navigating the World of Nickel Superalloys

Nickel superalloys are the cornerstone of high-temperature, high-stress applications. Widely used in aerospace, power generation, and chemical processing, these alloys combine superior mechanical strength, corrosion resistance, and thermal stability that few other metals can match.

NICKEL SUPERALLOYS

How to Source and Customize Nickel Superalloys for Specialized Needs

Introduction

The industry recognizes major commercial nickel alloys such as Inconel, Hastelloy, Rene, Haynes, and Waspaloy—each tailored for specific extreme environments. Trademarks of large-scale producers (e.g., Special Metals, Haynes International, Allegheny Technologies) confirm the importance and specialized nature of nickel superalloys in critical applications.

Yet, in-depth research or niche projects often require powders in small quantities or custom modifications (e.g., slight tweaks to chemistry, doping with specific elements). Large producers typically focus on mass supply, which can pose challenges for engineers, research teams, or smaller manufacturers who need specialized batches in limited volumes. Understanding your alloy options and how to source or produce them is essential to overcoming these hurdles.

The industry recognizes major commercial nickel alloys such as Inconel, Hastelloy, Rene, Haynes, and Waspaloy—each tailored for specific extreme environments. Trademarks of large-scale producers (e.g., Special Metals, Haynes International, Allegheny Technologies) confirm the importance and specialized nature of nickel superalloys in critical applications.

Yet, in-depth research or niche projects often require powders in small quantities or custom modifications (e.g., slight tweaks to chemistry, doping with specific elements). Large producers typically focus on mass supply, which can pose challenges for engineers, research teams, or smaller manufacturers who need specialized batches in limited volumes. Understanding your alloy options and how to source or produce them is essential to overcoming these hurdles.

METAL AM

The Difficulty of Securing the Right Nickel Powder

Off-the-shelf superalloys excel in many scenarios, but complex design parameters sometimes demand deeper customization beyond what mainstream alloys can offer.

Despite their high performance, many standard nickel superalloys don’t fully align with cutting-edge design requirements. You might need an alloy that balances strength, oxidation resistance, and thermal conductivity in ways not achieved by baseline compositions. Slight adjustments to chemistry, grain structure, or precipitation phases can yield significant improvements in performance—yet are rarely available in pre-made powders.

Such modifications involve specialized metallurgical expertise and production capabilities that go beyond typical catalog offerings. Researchers, small-scale manufacturers, and R&D teams may find themselves at a crossroads: they know exactly how to enhance an alloy, but sourcing or creating that precise composition in powder form becomes a daunting step.

01

Large-Volume Focus

Major superalloy manufacturers prioritize bulk orders. This can lead to high MOQs (minimum order quantities) and inflated costs if you only need a few kilograms for prototyping or testing.

02

Long Lead Times & Limited Flexibility

Even if you find the right powder, the path from request to delivery of custom powder can be slow. Meanwhile, you might have unique deadlines for projects, especially in R&D environments.

03

Niche & Research Requirements

For cutting-edge work, like novel chemical compositions or doping elements, mainstream suppliers may not accommodate experimental variations. Researchers and smaller engineering teams often struggle to access the best-fit powder—whether it’s a modified Ni alloy or a specific grade of nickel alloy.

These pain points can stall innovation, drive up costs, and hinder project timelines across industries relying on advanced materials.

These pain points can stall innovation, drive up costs, and hinder project timelines across industries relying on advanced materials.

AMAZEMET

Speciality Powder Suppliers and In-House Production Pathways

To bridge the gap between standard superalloys and uniquely optimized compositions, two primary routes emerge: partnering with specialty powder providers or adopting in-house atomization technologies.

Advanced materials laboratories and specialty powder suppliers can produce custom batches of nickel superalloy powders, often in limited quantities for R&D or pilot production. This approach saves you from large minimum orders and generic compositions, although lead times and costs can vary.

A more direct method involves in-house powder production, where you adapt the alloy chemistry, doping elements, or microstructure on your own terms. Modern metal atomization systems allow for small-batch experiments, enabling you to:

- Rapidly iterate and fine-tune new alloy concepts

- Produce only the amount of powder required for testing or prototyping

- Maintain control over every step of the process, safeguarding proprietary formulations

Both paths can ultimately help you overcome the rigidity of mainstream alloys, giving your project the exact material properties needed for success, whether you’re exploring nickel based superalloys or special Ni alloys that aren’t widely distributed.

METAL POWDERS PRODUCTION

Tailoring Nickel Superalloy Powders for Research & Specialized needs

While large producers excel at high-volume orders, AMAZEMET focuses on small-batch or custom alloy powders—and provides solutions for in-house metal powder production.

We understand that trademark restrictions might limit the direct replication of big-brand superalloys, but for innovative new nickel based alloys or academic experimentation, the possibilities are virtually endless.

At AMAZEMET, we appreciate the pivotal role nickel superalloys play in both established industries and innovative research. Rather than duplicating trademarked compositions, we specialize in custom or experimental alloys. Our team can help you:

Formulate Rare

or Novel Compositions

Adjust standard chemistries (within legal and patent constraints) or develop entirely new blends for specific performance characteristics.

Produce Small Quantities

Perfect for prototyping or academic research where 100 kg is impractical, but 1 kg or even 100 g is sufficient.

Ensure Consistent Quality

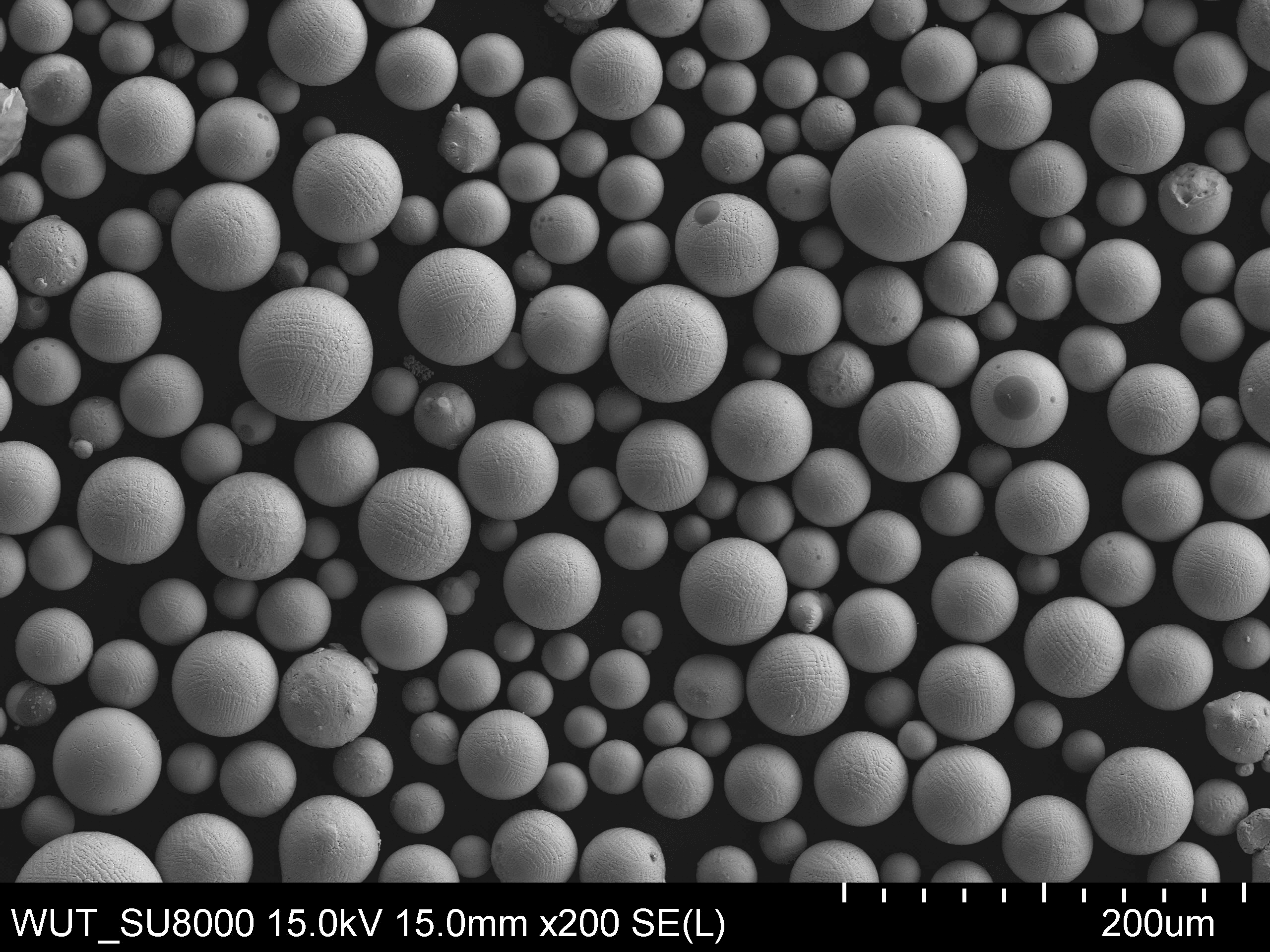

Our atomization process yields uniform, high-purity powders critical for high-stress applications.

AMAZEMET SERVICES & REPOWDER

Elevating Your Nickel Superalloy Journey

With specialized services or lab-friendly equipment, AMAZEMET helps you secure precisely the nickel superalloy powders you need without unnecessary complexity.

1. Custom Powder Production Services (Small Batches):

- Focus on Non-Standard Compositions: We work with you to craft new alloys that are not commercially available.

- R&D Quantities: Efficiently order just enough powder to validate designs or run experiments.

- Agile Turnaround: Avoid the lengthy queues of large foundries—get faster feedback loops.

2. rePOWDER Atomizer for In-House Development:

- Plasma Module: Adapted to handle tough materials like nickel superalloys.

- Intellectual Property Security: Keep novel formulations confidential by conducting atomization within your facility..

- Research Scalability: Produce minimal to moderate quantities, a game-changer for lab-based or pilot-scale experimentation.

- Iterative Innovations: Fine-tune compositions on-site, from doping elements to microstructure control.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need custom small-batch powders or seek to produce them yourself, AMAZEMET can help you navigate beyond standard commercial alloys.