Freedom in Metal AM Develompent & Production

Why Titanium Aluminides Are Revolutionizing High-Temperature Applications

Why Titanium Aluminides Are Revolutionizing High-Temperature Applications

Renowned for their exceptional performance in extreme environments, titanium aluminides (TiAl) are transforming the aerospace, automotive, and energy industries.

TITANIUM ALUMINIDES

Why Titanium Aluminides Are Gaining Ground in Demanding Environments

Introduction

Titanium aluminides, a unique class of intermetallic compounds, offer an attractive combination of low density, high strength, and excellent thermal stability. These titanium aluminide alloys are engineered to function in high-temperature, high-stress applications where traditional materials often fail. By carefully controlling the alloying elements, manufacturers can optimize the microstructure—balancing ordered intermetallic phases with ductile metallic regions—to achieve performance characteristics unattainable with conventional alloys.

Major industrial sectors recognize the value of titanium aluminides for components like turbine blades, automotive parts, and aerospace structures. However, while large-scale titanium aluminide manufacturing produces standard grades in bulk, specialized research and niche projects often demand powders in small quantities or custom modifications. In such cases, understanding your options—from off-the-shelf materials to bespoke titanium aluminide powder formulations—is critical to advancing your design objectives.

Titanium aluminides, a unique class of intermetallic compounds, offer an attractive combination of low density, high strength, and excellent thermal stability. These titanium aluminide alloys are engineered to function in high-temperature, high-stress applications where traditional materials often fail. By carefully controlling the alloying elements, manufacturers can optimize the microstructure—balancing ordered intermetallic phases with ductile metallic regions—to achieve performance characteristics unattainable with conventional alloys.

Major industrial sectors recognize the value of titanium aluminides for components like turbine blades, automotive parts, and aerospace structures. However, while large-scale titanium aluminide manufacturing produces standard grades in bulk, specialized research and niche projects often demand powders in small quantities or custom modifications. In such cases, understanding your options—from off-the-shelf materials to bespoke titanium aluminide powder formulations—is critical to advancing your design objectives.

METAL AM

Why Titanium Aluminides Are Gaining Ground in Demanding Environments

While standard titanium aluminide alloys meet many industrial needs, advanced projects sometimes require tailored powders that can’t be found in conventional catalogs.

Even though commercial titanium aluminide alloys excel in many applications, cutting-edge designs often call for modifications—such as minor adjustments in chemistry or specific heat treatments—to fine-tune the phase balance and mechanical properties. These refinements can be crucial when aiming for enhanced high-temperature performance or improved ductility.

The primary challenges include:

01

Limited Small-Batch Options

Traditional catalogs center on a handful of major α+β alloys, such as Ti-6Al-4V, leaving limited room to fine-tune heat treatment windows or doping agents for unique α, β, or α+β microstructures.

02

Inflexible Composiotions

Certain applications—like high-fatigue aerospace components or next-generation implants—may benefit from near-β or fully β alloys, aiming for specific elasticity or formability not covered by standard offerings.

03

Extended Lead Times

Big producers focus on established grades and bulk orders, delaying or inflating costs for projects that only require modest quantities of specialized powder.

These obstacles force engineering teams to either settle for suboptimal materials or invest in developing custom solutions—both of which can impede innovation.

These obstacles force engineering teams to either settle for suboptimal materials or invest in developing custom solutions—both of which can impede innovation.

AMAZEMET

BRIDGING THE GAP: TAILORED TiAl POWDER AND POWDER PRODUCTION

Specialty suppliers and in-house production methods offer the flexibility needed to overcome the limitations of standard titanium aluminide alloys.

To meet the specific requirements of advanced research and niche manufacturing, two primary solutions emerge:

- Specialized Powder Providers: Certain vendors focus on producing small-batch, custom titanium aluminide powders with precise compositional control. These providers can adjust alloying elements and heat treatment protocols to fine-tune microstructure and performance, giving you access to non-standard formulations that might include unique TiAl variants.

- In-House Atomization: Investing in an in-house powder production system enables you to produce your own custom titanium aluminide alloy powders. With modern atomization technology, you can experiment with varied processing parameters, such as cooling rates and doping levels, to achieve the exact balance of phases and properties you need. This approach not only reduces dependency on external suppliers but also offers rapid iteration and full control over your proprietary formulations.

Both paths empower you to bypass the constraints of mass-market titanium aluminide manufacturing, allowing you to create materials specifically tailored for your application.

METAL POWDERS PRODUCTION

Titanium Aluminide Powder Solutions

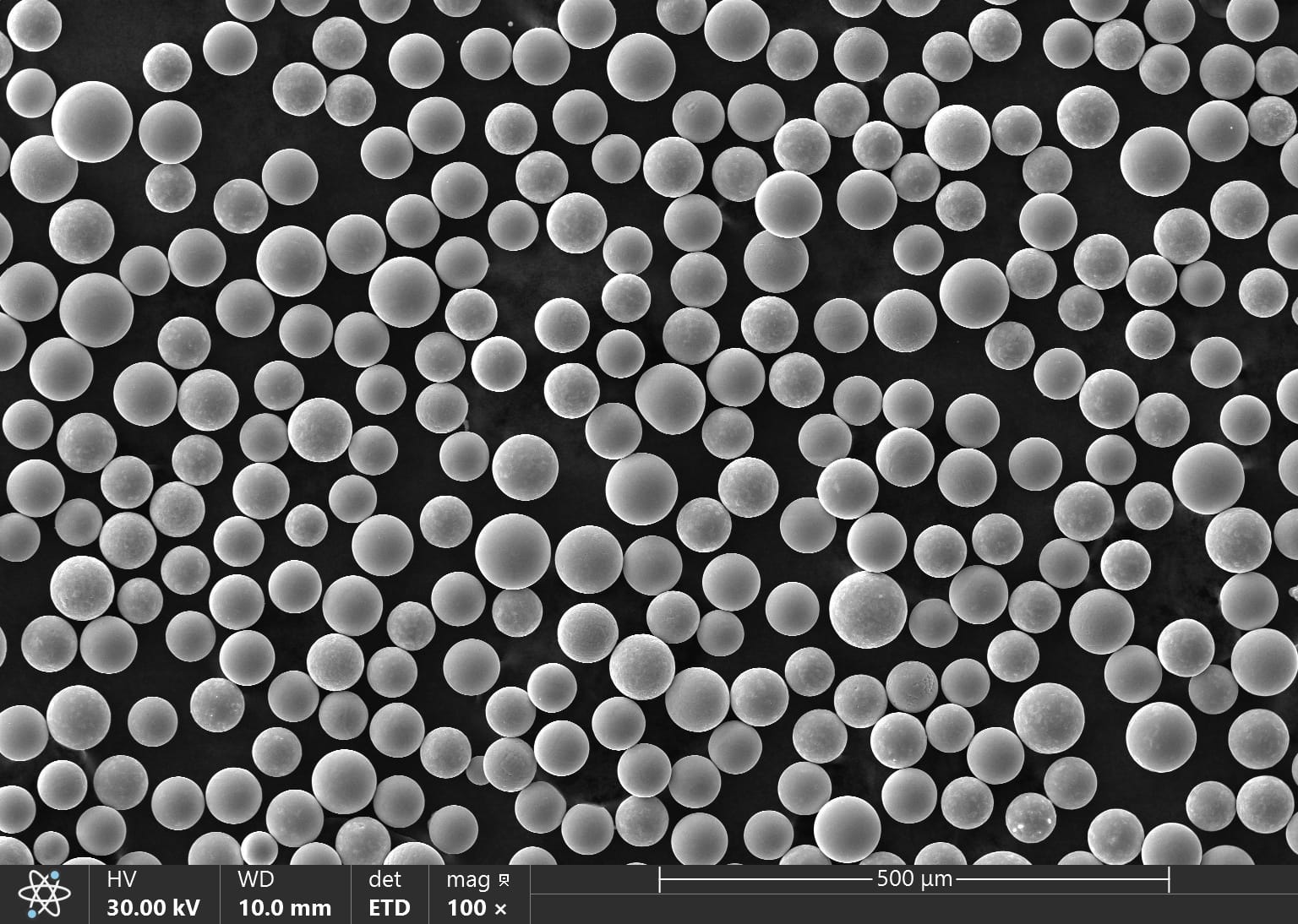

AMAZEMET specializes in delivering small-batch, custom titanium aluminide powders—designed to meet the unique demands of cutting-edge research and specialized manufacturing.

Custom Alloy Support

At AMAZEMET, we understand that next-generation applications require more than just standard alloys. Our focus is on enabling innovation by providing flexible solutions for creating custom titanium aluminide alloys.

Tailored Powder Development

Whether you need to adjust the composition to optimize phase distribution or require a novel TiAl powder formulation for R&D purposes, our team works closely with you to develop the precise material you need.

Flexible Powder Supply

We support projects of all sizes—offering minimal quantities for academic research or small batch production while ensuring high purity and consistent particle size. With a keen emphasis on quality and flexibility, we bridge the gap between mass-market solutions and the specialized requirements of modern engineering.

AMAZEMET SERVICES & REPOWDER

AMAZEMET Services & rePOWDER: Empowering Titanium Aluminide R&D

From custom powder production to in-house atomization, AMAZEMET’s offerings let you push the limits of titanium aluminide performance.

By combining our custom powder services with the rePOWDER system, AMAZEMET offers a comprehensive solution that empowers you to develop the next generation of titanium aluminide materials, whether for aerospace, automotive, or high-performance energy applications.

1. Custom Powder Production

- Specialized Formulations: Work with our experts to produce custom titanium aluminide powder tailored to your specific alloy requirements.

- Optimized Quantities: Order just the amount you need for prototyping or targeted research, reducing waste and overhead.

- Rapid Turnaround: Benefit from agile production cycles that accelerate your R&D efforts

2. rePOWDER Atomizer for In-House Research

- Advanced Plasma Module: Specifically engineered for challenging materials like titanium aluminide alloys, ensuring fine control over melt dynamics and particle formation.

- Iterative Experimentation: Produce multiple small batches to refine your alloy’s composition and microstructure, achieving the ideal balance of performance characteristics.

- Enhanced IP Security: Maintain confidentiality and protect proprietary formulations by handling production internally.

BOOST YOUR PROJECT WITH AMAZEMET

Connect with AMAZEMET to explore custom titanium aluminide powder solutions or to bring in-house atomization to your lab—unlocking new potentials in high-temperature, high-performance alloys.