Freedom in Metal AM Develompent & Production

Bronze Alloy Powders for Additive Manufacturing and Beyond

Bronze Alloy Powders for Additive Manufacturing and Beyond

Copper, one of the oldest metals utilized by humans, remains indispensable in modern engineering. Its exceptional electrical and thermal conductivity, combined with corrosion resistance and workability, make copper alloys foundational in advanced manufacturing. In powder form, copper powders are increasingly vital for additive manufacturing (AM), heat transfer systems, and high-performance functional components.

BRONZE ALLOYS

Engineering Tradition Reinvented: Bronze Alloys in Powder Form

Introduction

Bronze alloys—one of humanity’s earliest engineered materials—are now at the forefront of innovation in additive manufacturing, thermal systems, and high-wear components. The shift from cast parts to high-purity bronze powders opens new opportunities for design flexibility, microstructural control, and application-specific performance.

An alloy of bronze typically consists of copper combined with elements such as tin, aluminum, or silicon. This bronze alloy composition delivers outstanding wear resistance, thermal conductivity, and corrosion resistance—qualities that make it a top choice for bushings, gears, heat exchangers, and electrical contacts. In powder form, bronze alloy structure can be finely tuned to match the unique requirements of advanced manufacturing processes.

Among the most advanced bronze alloys are beryllium bronzes—high-performance materials containing 1.5–2.0% beryllium. These alloys exhibit exceptional mechanical properties, with yield strengths up to 1100 MPa and ultimate tensile strengths exceeding 1300 MPa. Their combination of high strength, fatigue resistance, and conductivity makes them ideal for aerospace, electronic connectors, injection mold tooling, and non-sparking safety tools.

Despite their technical promise, bronze powders with the required purity, morphology, and particle size are often unavailable from traditional bronze alloy suppliers. This creates a gap for engineers and researchers who demand tailored, consistent materials for high-precision applications.

Bronze alloys—one of humanity's earliest engineered materials—are now at the forefront of innovation in additive manufacturing, thermal systems, and high-wear components. The shift from cast parts to high-purity bronze powders opens new opportunities for design flexibility, microstructural control, and application-specific performance.

An alloy of bronze typically consists of copper combined with elements such as tin, aluminum, or silicon. This bronze alloy composition delivers outstanding wear resistance, thermal conductivity, and corrosion resistance—qualities that make it a top choice for bushings, gears, heat exchangers, and electrical contacts. In powder form, bronze alloy structure can be finely tuned to match the unique requirements of advanced manufacturing processes.

Among the most advanced bronze alloys are beryllium bronzes—high-performance materials containing 1.5–2.0% beryllium. These alloys exhibit exceptional mechanical properties, with yield strengths up to 1100 MPa and ultimate tensile strengths exceeding 1300 MPa. Their combination of high strength, fatigue resistance, and conductivity makes them ideal for aerospace, electronic connectors, injection mold tooling, and non-sparking safety tools.

Despite their technical promise, bronze powders with the required purity, morphology, and particle size are often unavailable from traditional bronze alloy suppliers. This creates a gap for engineers and researchers who demand tailored, consistent materials for high-precision applications.

METAL AM

Why Can’t You Get the Bronze Powder You Really Need?

Off-the-shelf bronze powders rarely meet the specifications required by modern manufacturing. As a result, innovation is often slowed by limited material access.

While bronze alloy is broadly available in bulk or semi-finished form, turning it into high-quality bronze powder suitable for powder metallurgy or additive manufacturing presents numerous challenges:

01

Poor Powder Flowability

Irregular particle morphology and surface oxidation lead to poor recoating behavior.

02

Oxidation Sensitivity

Even minimal oxide content can significantly reduce conductivity and sintering performance.

03

Limited Customization

Standard alloys of copper, like pure copper or CuSn10, often fall short in high-performance applications.

04

Laser Absorption Difficulties

Copper’s high reflectivity in the infrared spectrum hinders LPBF processing, requiring alloy modification for better laser absorptivity.

Even simple design tests or alloy variations can be delayed or abandoned entirely due to the combination of sourcing constraints and high bronze powder price volatility.

AMAZEMET

Tailored Bronze Powders for Advanced Applications

New strategies for producing bronze powders—either through external specialists or in-house systems—enable fast, flexible material development.

Two practical approaches help engineers meet the demands of advanced bronze alloy applications:

- Custom Powder Suppliers: Specialized vendors can deliver bronze powders formulated for high strength, corrosion resistance, or conductivity. This includes non-standard grades that are rarely available through mainstream bronze alloy suppliers.

- In-House Powder Production: With tools like the rePOWDER system by AMAZEMET, engineers can atomize bronze alloys from rods, bars, or compacted feedstock. This enables real-time development of new compositions and immediate process optimization.

These approaches give full control over bronze alloy structure, reduce dependency on external sourcing, and help mitigate long lead times or unstable bronze powder price trends.

METAL POWDERS PRODUCTION

Precision Bronze Powder Solutions for R&D and Industry

Whether optimizing a classic alloy of bronze for sintering or developing a high-strength grade for AM, AMAZEMET offers expertise and flexibility for demanding projects.

Our team supports your innovation efforts with responsive production and expert material guidance, no matter the stage of your research or product development.

We specialize in enabling breakthrough materials research and production through:

Custom Bronze Alloy Powders

Tailored compositions including Cu-Al-Si-Zr, Cu-Sn-Ni, and beryllium bronze for specialized performance goals.

Small Batch Flexibility

Order from just 200 grams—ideal for iterative testing, microstructure evaluation, and prototyping.

High-Quality Powders

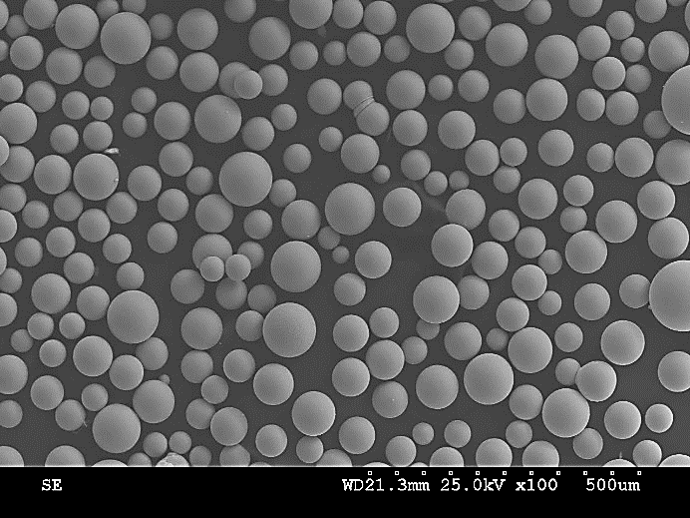

Produced via ultrasonic atomization for excellent flowability, narrow particle size distribution, and minimal oxide content.

AMAZEMET SERVICES & REPOWDER

Bronze Powder Services and the rePOWDER Atomizer

Whether you need custom-engineered bronze powders or a reliable in-house production setup, AMAZEMET provides a complete solution.

This integrated approach supports everything from the restoration of historic alloys to the creation of next-generation high-performance bronze alloy structures.

1. Custom Powder Production

- Develop specialized bronze alloy compositions for AM, thermal spraying, or sintering.

- Tailor particle size distribution and morphology for LPBF, binder jetting, or press-and-sinter applications.

- Access high-performance variants, including beryllium bronzes, for strength-critical designs.

2. rePOWDER In-House Atomizer

- Equipped with an induction melting module optimized for copper-based systems.

- Allows quick alloy switching and supports short production cycles without retooling.

- Enables rapid development of new compositions, reducing reliance on external bronze alloy suppliers.

- Helps stabilize project budgets by mitigating bronze powder price fluctuations.

BOOST YOUR PROJECT WITH AMAZEMET

Reach out to discuss how AMAZEMET can support your bronze alloy development—whether through custom bronze powder supply or rePOWDER in-house production.