Freedom in Metal AM Develompent & Production

CHROME ALLOYS FOR DEMANDING POWDER APPLICATIONS

CHROME ALLOYS FOR DEMANDING POWDER APPLICATIONS

Chromium-containing alloys have long been at the heart of materials engineering, offering corrosion resistance, hardness, and high-temperature strength. Today, as these materials transition into powder form, they unlock a new frontier in additive manufacturing and functional metallurgy.

CHROMIUM ALLOYS

Chromium Alloys in the Age of Precision Engineering

Introduction

From wear-resistant steels to superalloys and high-entropy compositions, chromium is an essential building block in engineering metallic systems. Chromium alloys, often referred to as Cr alloys or Cr-alloy systems, offer exceptional oxidation resistance, structural stability at elevated temperatures, and the formation of protective surface oxides—critical traits for aerospace, energy, and tooling sectors.

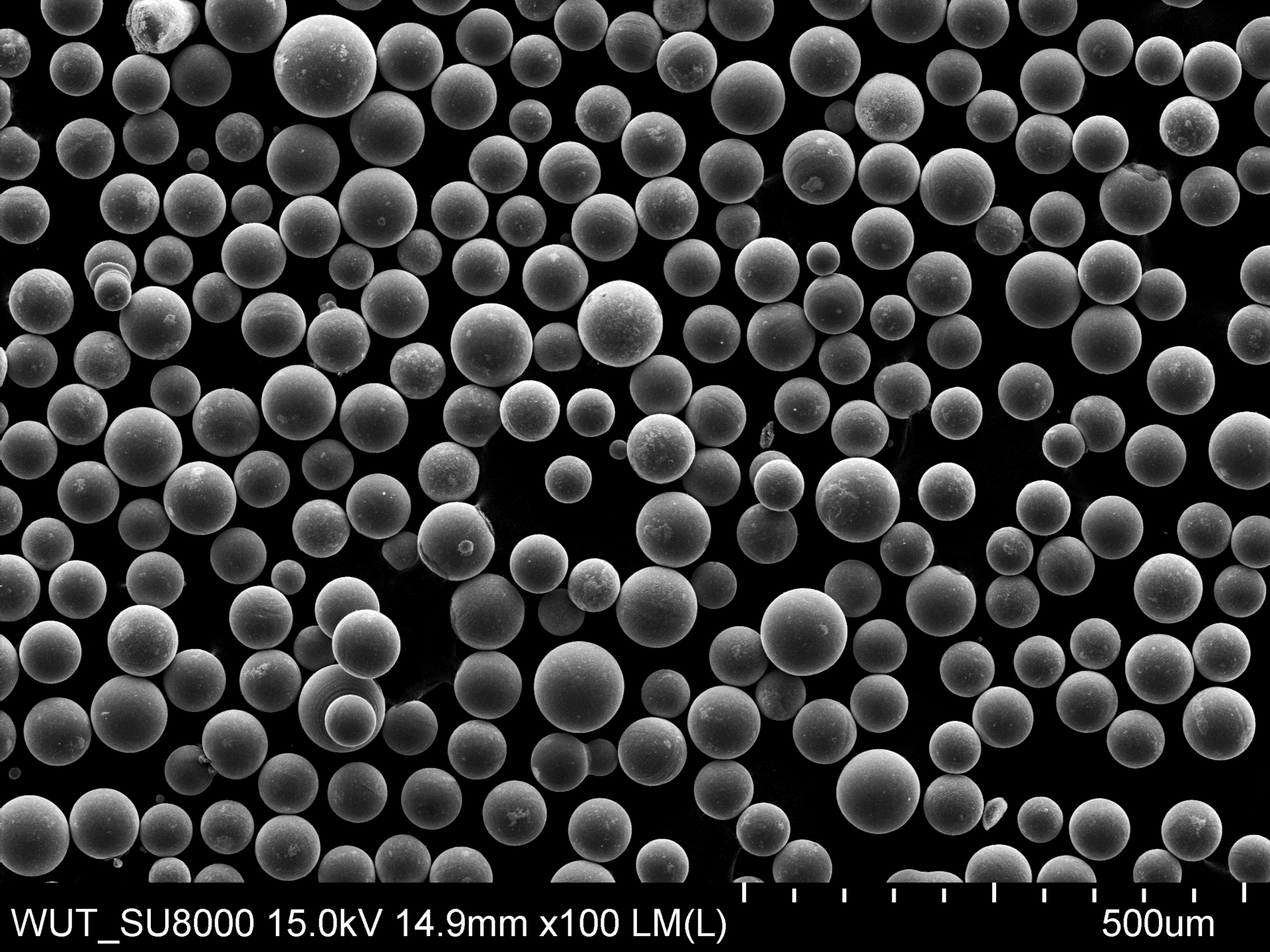

In powder form, alloys of chromium expand their utility: enabling net-shape fabrication, enhancing microstructural control, and supporting the development of gradient materials. They are increasingly applied in laser powder bed fusion (LPBF), binder jetting, and direct energy deposition (DED), where fine-tuned flowability and precise control of chemical composition directly influence part quality. Researchers exploring high-strength or corrosion-resistant components benefit from cr alloy powder's ability to deliver performance with flexibility.

However, due to chromium's high reactivity at elevated temperatures and sensitivity to oxygen pickup during atomization, producing spherical chromium powder with tight PSD (particle size distribution) and consistent morphology remains a significant technical challenge. Reliable chromium powder suppliers must mitigate these complexities through advanced atomization environments and strict process control.

From wear-resistant steels to superalloys and high-entropy compositions, chromium is an essential building block in engineering metallic systems. Chromium alloys, often referred to as Cr alloys or Cr-alloy systems, offer exceptional oxidation resistance, structural stability at elevated temperatures, and the formation of protective surface oxides—critical traits for aerospace, energy, and tooling sectors.

In powder form, alloys of chromium expand their utility: enabling net-shape fabrication, enhancing microstructural control, and supporting the development of gradient materials. They are increasingly applied in laser powder bed fusion (LPBF), binder jetting, and direct energy deposition (DED), where fine-tuned flowability and precise control of chemical composition directly influence part quality. Researchers exploring high-strength or corrosion-resistant components benefit from cr alloy powder's ability to deliver performance with flexibility.

However, due to chromium's high reactivity at elevated temperatures and sensitivity to oxygen pickup during atomization, producing spherical chromium powder with tight PSD (particle size distribution) and consistent morphology remains a significant technical challenge. Reliable chromium powder suppliers must mitigate these complexities through advanced atomization environments and strict process control.

METAL AM

Struggling to Source Chromium Alloy Powders That Actually Perform?

The properties that make chromium attractive—its oxidation resistance and hardness—also make it exceptionally difficult to process into usable powder for additive manufacturing or sintering.

Engineers and researchers working with chromium-containing alloys encounter persistent problems that stall innovation and complicate component qualification:

01

Oxygen Sensitivity

Irregular particle morphology and surface oxidation lead to poor recoating behavior.

02

Poor Sphericity

Even minimal oxide content can significantly reduce conductivity and sintering performance.

03

Scarce Custom Grades

Standard alloys of copper, like pure copper or CuSn10, often fall short in high-performance applications.

04

Excessive MOQ and Lead Time

Copper’s high reflectivity in the infrared spectrum hinders LPBF processing, requiring alloy modification for better laser absorptivity.

05

Unpredictable Chromium Powder Price

Global demand and resource constraints can drive price volatility, complicating planning for both prototyping and production runs.

These limitations restrict the use of chromium alloys in advanced manufacturing, despite their immense potential. Even when chromium powder is technically available, its morphology, purity, or price point often makes it unsuitable for next-generation applications.

AMAZEMET

Two Routes to the Powder You Need: Tailored Supply or In-House Production

To work with high-performance chromium alloys in powder form, you can either partner with custom powder specialists or control the process internally with lab-scale atomization tools.

Modern research and prototyping workflows demand fast access to non-standard cr alloy compositions. Two complementary pathways allow for optimized material development:

- Custom Powder Providers: Specialty vendors can deliver engineered powders such as Cr-Fe-Mo for corrosion resistance or Cr-Co-Ni systems for wear-critical surfaces. These powders are typically processed using inert gas or vacuum-assisted atomization to minimize oxide content and ensure high sphericity—although cost and availability remain limiting factors.

- In-House Ultrasonic Atomization: With technologies like the rePOWDER system, research labs can melt and atomize their own cr alloys from bars or compacted feedstock. Full control over process parameters means rapid iteration of chromium alloy compositions, especially useful when working on wear-resistant Cr-CrB composites or exploring carbide-stabilized systems.

Whether validating a Cr-V high-strength formulation or tailoring chromium-based coatings for reactive environments, these options provide flexibility and speed. In-house atomization also ensures confidentiality—an essential factor for proprietary alloy development.

METAL POWDERS PRODUCTION

AMAZEMET: Enabling Chromium-Based Powder Innovation

AMAZEMET helps researchers and developers overcome the barriers to working with complex, reactive alloys like chromium-based systems.

At AMAZEMET, we understand the challenges of processing reactive, oxygen-sensitive metals into high-performance powders. We specialize in delivering flexible solutions to meet cutting-edge research demands:

Custom Chromium Alloy Powders

From high-chromium tool steels and wear-resistant Cr-Mo systems to experimental Cr-Ni-V compositions, our team works collaboratively to develop materials that match your mechanical, thermal, and environmental specifications.

Small Batch Production

Whether you need 20 g for alloy screening or 500 g for process validation, we provide scalable solutions that reduce cost and eliminate waste.

Expertise in Reactive Atomization

Our proprietary ultrasonic systems are designed to operate under controlled atmospheres (argon or vacuum), limiting oxygen pickup and ensuring morphology suitable for AM.

AMAZEMET SERVICES & REPOWDER

Tailored Chromium Alloy Powders or In-House Control with rePOWDER

Whether you’re searching for custom chromium powder batches or a compact device to produce your own, AMAZEMET delivers precise solutions for chromium-based materials.

1. Custom Powder Services

- Chromium alloy compositions for AM, sintering, and wear-resistant applications.

- Controlled morphology and PSD for optimized flowability and process repeatability.

- Ideal for Cr-Ni, Cr-V, Cr-Fe-C, and Cr-Co-B systems, as well as complex high-entropy designs involving chromium as a base element.

- Access flexible quantities without sacrificing precision or purity.

2. rePOWDER In-House Atomizer

- Designed for processing reactive and refractory metals, including Cr alloys and experimental compositions.

- Atomization of bar, casting, or compacted feedstock under inert or vacuum conditions.

- Enables high-yield, low-loss production

- Full control of your cr powder development cycle—from alloy design to AM-ready particles—while protecting your intellectual property.

BOOST YOUR PROJECT WITH AMAZEMET

Contact AMAZEMET to discuss custom cr alloy powder needs or integrate rePOWDER into your research environment for full control of your chromium powder development