Freedom in Metal AM Develompent & Production

Copper Alloy Powders for Advanced Manufacturing

Copper Alloy Powders for Advanced Manufacturing

Copper, one of the oldest metals utilized by humans, remains indispensable in modern engineering. Its exceptional electrical and thermal conductivity, combined with corrosion resistance and workability, make copper alloys foundational in advanced manufacturing. In powder form, copper powders are increasingly vital for additive manufacturing (AM), heat transfer systems, and high-performance functional components.

COPPER ALLOYS

Reinvigorating a Classic Material for Cutting-Edge Applications

Introduction

From electric motors and electronic connectors to rocket engine liners and heat exchangers, copper-based alloys address a wide spectrum of industrial needs. But as designs become more complex and performance demands rise, traditional processing routes often fall short. Copper alloy powders enable the production of parts with optimized thermal conductivity, fine-feature geometries, and intricate internal structures.

Advanced copper alloys such as CuCrZr, CuNiSi, CuAg, and dispersion-strengthened systems like GlidCop® offer outstanding combinations of conductivity, mechanical strength, and high-temperature resilience. However, sourcing these powders with precise composition, controlled particle size, and low oxide levels remains a challenge. Copper powder suppliers often struggle to meet the stringent requirements of AM workflows, especially for novel alloy systems.

From electric motors and electronic connectors to rocket engine liners and heat exchangers, copper-based alloys address a wide spectrum of industrial needs. But as designs become more complex and performance demands rise, traditional processing routes often fall short. Copper alloy powders enable the production of parts with optimized thermal conductivity, fine-feature geometries, and intricate internal structures.

Advanced copper alloys such as CuCrZr, CuNiSi, CuAg, and dispersion-strengthened systems like GlidCop® offer outstanding combinations of conductivity, mechanical strength, and high-temperature resilience. However, sourcing these powders with precise composition, controlled particle size, and low oxide levels remains a challenge. Copper powder suppliers often struggle to meet the stringent requirements of AM workflows, especially for novel alloy systems.

METAL AM

Why Copper Alloy Powders Are So Difficult to Get Right

Atomizing copper alloys is technically demanding due to their high thermal conductivity and reflectivity, making it difficult to obtain powders that meet the stringent demands of additive manufacturing and high-performance engineering.

Despite their widespread use, copper and its alloys present unique challenges when converted into powder form suitable for AM processes. Engineers and researchers routinely face issues such as:

01

Poor Powder Flowability

Irregular particle morphology and surface oxidation lead to poor recoating behavior.

02

Oxidation Sensitivity

Even minimal oxide content can significantly reduce conductivity and sintering performance.

03

Limited Customization

Standard alloys of copper, like pure copper or CuSn10, often fall short in high-performance applications.

04

Laser Absorption Difficulties

Copper’s high reflectivity in the infrared spectrum hinders LPBF processing, requiring alloy modification for better laser absorptivity.

Recent breakthroughs, such as NASA’s GRX-810 (a copper-nickel-silicon alloy with oxide dispersion strengthening) and GRCop-42 (a Cu-Cr-Nb alloy for rocket engines), underscore the need for custom-designed copper alloys tailored for AM. These materials demonstrate exceptional strength retention and creep resistance at elevated temperatures but remain largely unavailable in powder form to most researchers and manufacturers. This gap significantly delays adoption and experimentation.

Such limitations restrict R&D progress, diminish material performance, and hinder the integration of copper alloys into next-generation systems across aerospace, electronics, and energy sectors.

AMAZEMET

Customizable Paths to High-Quality Copper Powders

Achieving reliable performance with copper alloys in powder form requires specialized strategies—either through advanced suppliers or in-house atomization systems.

Two effective pathways have emerged to overcome the barriers in producing advanced copper alloy powders:

- Specialty Powder Suppliers:

Focused vendors offer additive-grade copper powders such as CuCr1Zr and CuNi2Si with tailored particle size distribution and enhanced absorptivity. These powders are engineered for LPBF, binder jetting, or cold spray. If you're seeking copper powder for sale in research-ready quantities or exploring copper powder uses in high-efficiency components, these suppliers offer practical options. - In-House Atomization:

Systems like AMAZEMET's rePOWDER allow you to produce copper alloy powders on-site using solid bars or compacted feedstock. This solution provides full control over atmosphere, morphology, and composition, enabling development of next-generation alloys while protecting proprietary formulations.

Both approaches empower users to meet precise application requirements in conductivity, strength, and printability.

METAL POWDERS PRODUCTION

Precision Copper Alloy Powders for AM and R&D

At AMAZEMET, we understand the challenges of developing copper alloys and offer both tailored powder services and atomization tools to support your material innovation.

For teams looking to act as their own copper alloy supplier or reduce dependency on external copper powder suppliers, our technology offers full autonomy and flexibility.

We help researchers and manufacturers overcome limitations in copper alloy powder development by offering:

Custom Alloys

Formulations such as CuCrZr, CuAg, and copper-aluminum bronzes, tailored for strength, conductivity, and laser absorption.

Small Batch Quantities

Minimum orders starting at 100 grams—ideal for feasibility studies and prototype builds.

High-Quality Powders

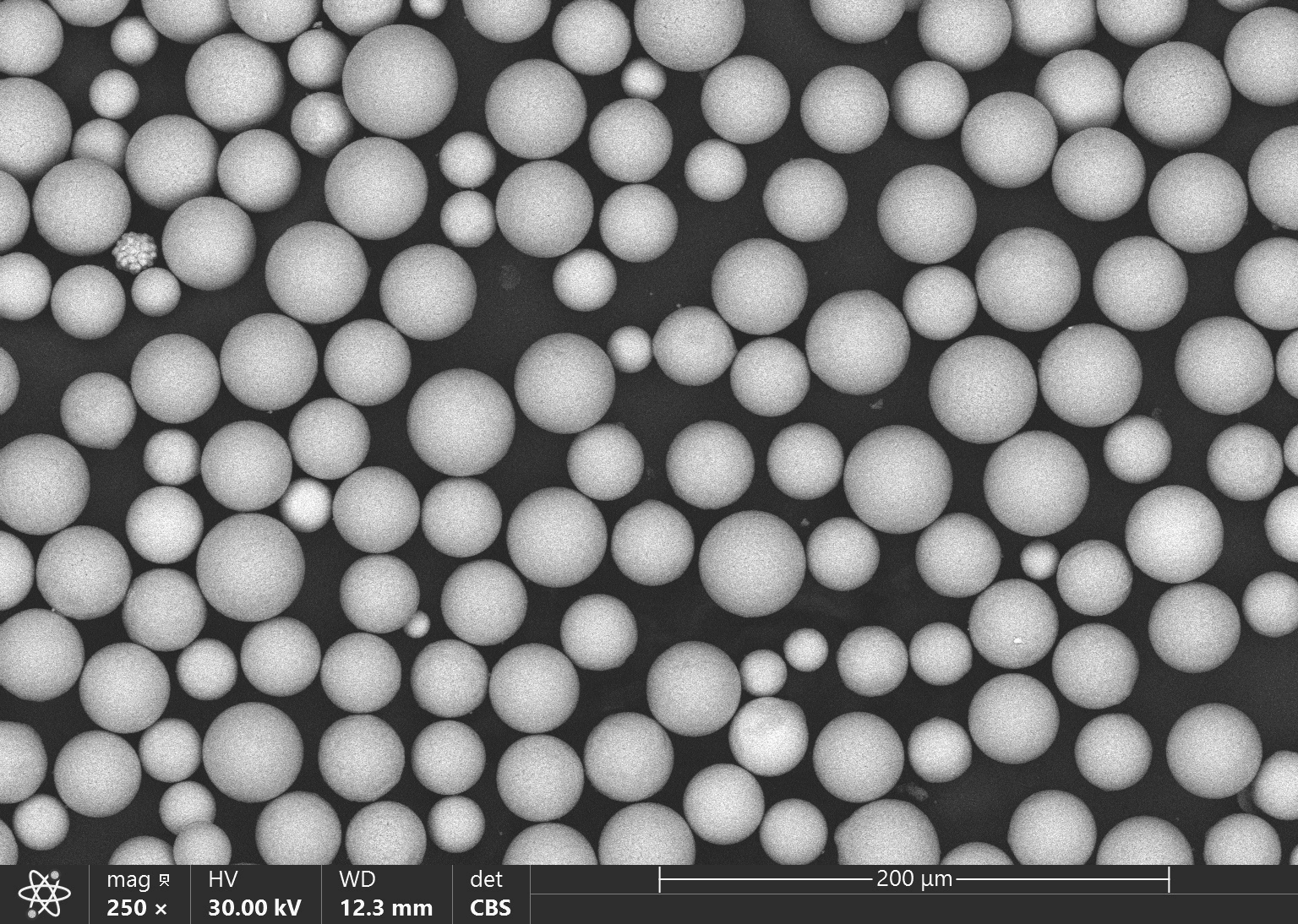

Spherical, flowable copper powders produced through ultrasonic atomization, ensuring high packing density and consistency.

AMAZEMET SERVICES & REPOWDER

Copper Alloy Powder Services and In-House Production with rePOWDER

Whether developing a thermally conductive lattice or a high-precision AM part, AMAZEMET provides the tools and powders to make it possible.

1. Custom Copper Alloy Powder Services

- Tailor-made copper powders including novel and experimental copper alloys such as research-grade systems like Cu-Ce, Cu-Ti, and Cu-Zr-Y alloys under evaluation for improved creep resistance, laser absorptivity, and high-temperature strength.

- Controlled particle morphology and PSD for optimal AM performance.

- Available in research-ready or scale-up quantities.

2. rePOWDER Atomization Platform

- Compact ultrasonic system with induction melting, optimized for oxygen-sensitive copper-based alloys.

- Enables fast alloy development and in-house powder production.

- High atomization efficiency with yields of up to 90%.

- Full control over composition, process atmosphere, and batch size.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you’re launching high-performance components or developing novel copper alloy formulations, AMAZEMET is ready to support your innovation journey.