PRECIOUS METALS

Characterization & Properties

Characterization & Properties

Precious metals and their alloys offer distinct characteristics that make them indispensable in several specialized industries. These attributes make precious materials ideal for use in high-tech industries, luxury goods, and advanced manufacturing processes that require both functional and aesthetic qualities. Key properties include:

Precious metals and their alloys offer distinct characteristics that make them indispensable in several specialized industries. These attributes make precious materials ideal for use in high-tech industries, luxury goods, and advanced manufacturing processes that require both functional and aesthetic qualities. Key properties include:

Corrosion resistance

Platinum group metals and gold alloys are highly resistant to oxidation and corrosion, even in harsh environments.

Electrical conductivity

These metals exhibit excellent conductivity, crucial for electronic components.

Catalytic properties

Platinum group metals, particularly, are widely used in catalytic converters due to their ability to facilitate chemical reactions.

Ductility and malleability

Precious materials like gold are highly malleable, allowing them to be shaped into thin wires or sheets without breaking.

High melting points

Especially for platinum group metals, the high melting points make them suitable for high-temperature applications.

CHOOSE YOUR COMPOSITION

Example High-Temperature Metal Compositions

These alloys provide optimal performance in high-stress, high-temperature environments where conventional materials would fail.

01

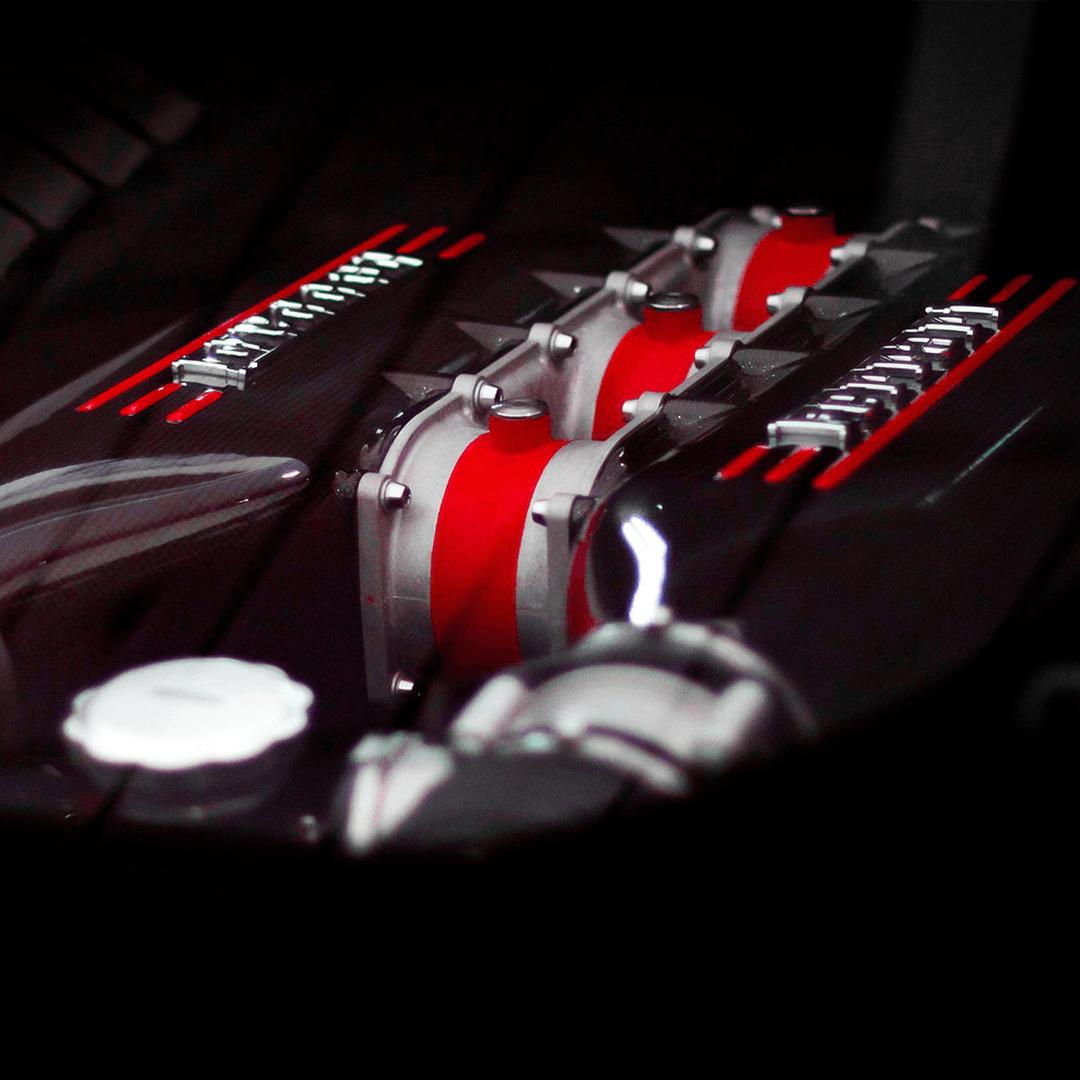

Nickel-based Superalloys (e.g., Inconel, Hastelloy)

These superalloys are designed to maintain mechanical strength at high temperatures. They are often used in jet engines, gas turbines, and power plants.

02

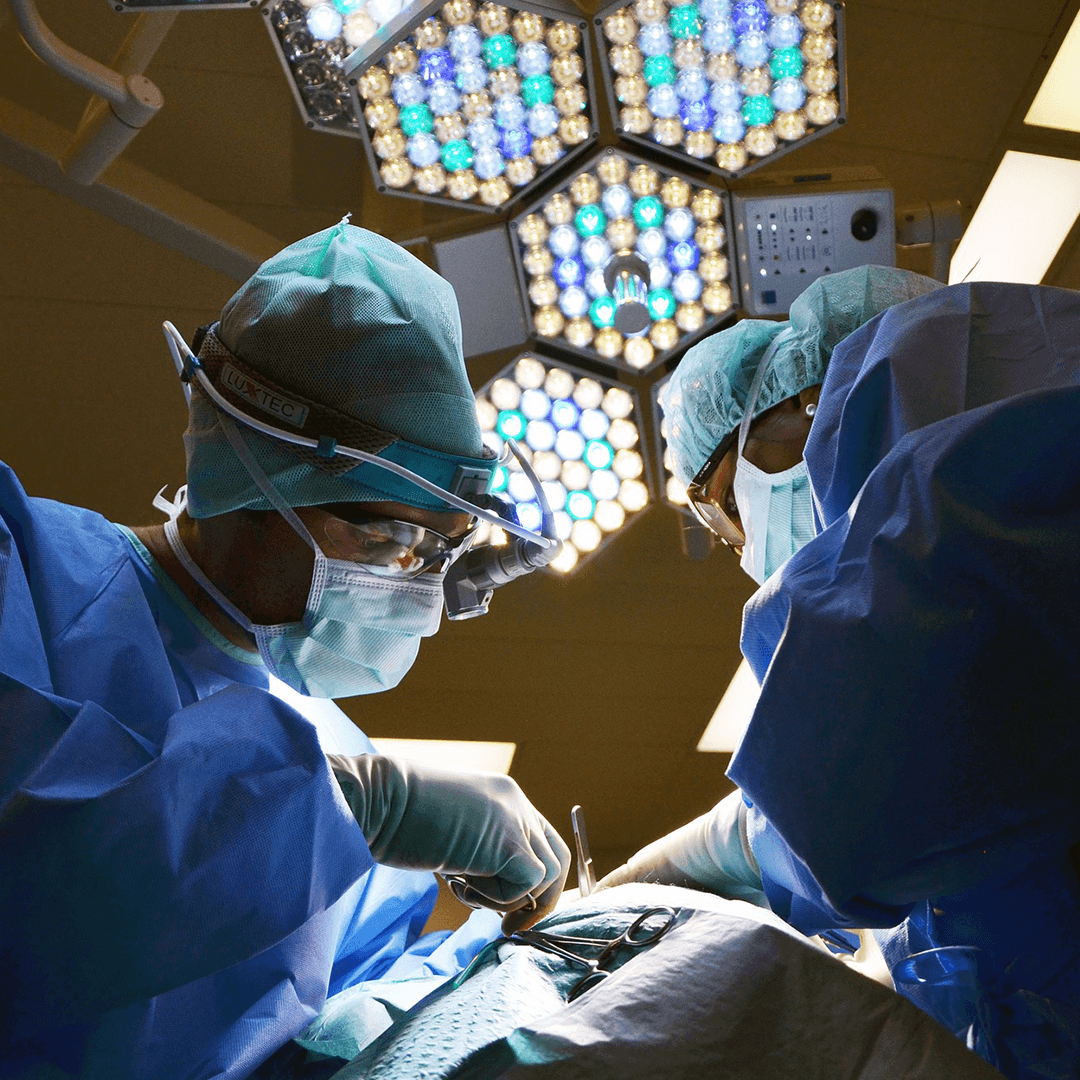

Cobalt-based Alloys (e.g., Haynes, Stellite)

Known for their excellent thermal and oxidation resistance, cobalt alloys are used in critical components like turbine blades and medical implants where high temperature and wear resistance are essential.

03

Titanium Alloys (e.g., Ti-6Al-4V)

Titanium alloys offer an excellent balance of strength, low weight, and high-temperature resistance. They are frequently used in aerospace applications such as airframes, jet engines, and exhaust systems.

PRECIOUS METALS

Applications

Precious materials are essential in various industries due to their unique properties. Some notable applications include:

METAL POWDES PRODUCTION

Where to Buy Precious Metal Powders?

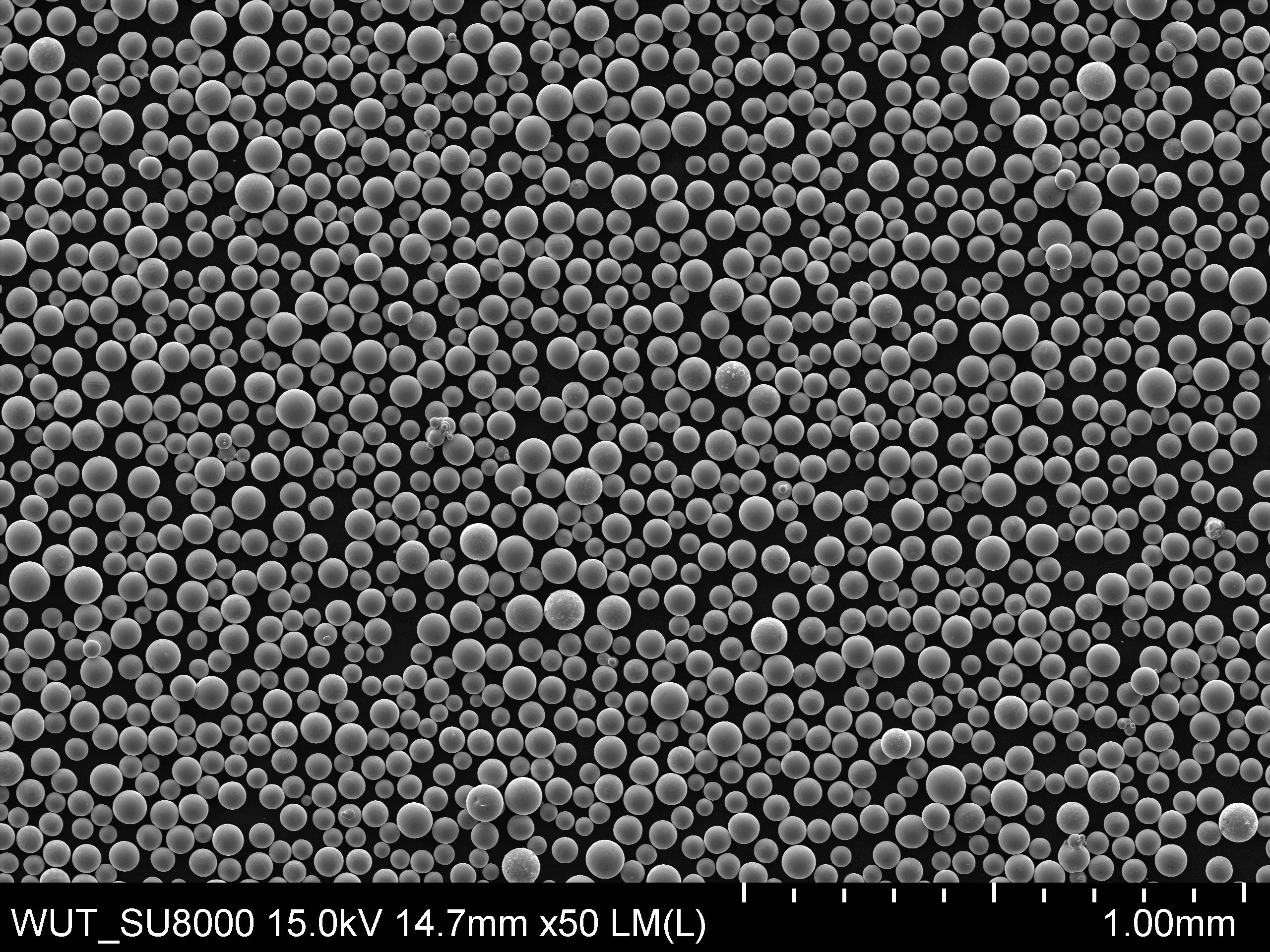

You can purchase precious metal powders from specialized suppliers that offer consistent, high-quality products for industries like electronics, jewelry manufacturing, and catalytic applications. AMAZEMET offers advanced solutions to produce platinum group metals and gold alloys using its rePOWDER system, providing superb particle sphericity, lack of satellites, and narrow particle size distribution – all ensuring exceptional flowability leading to consistent results in manufacturing and other processes.

WHY AMAZEMET

Why Choose our High-Temperature Metal Powders?

AMAZEMET’s precious metal powders are known for their purity and precision. Here’s why our powders stand out:

High purity

We ensure that our powders meet the strictest standards for quality in chemical composition.

Uniform particle

Our atomization process results in powders with consistent particle sizes and shapes with no satellites essential for precision manufacturing.

Minimal amount of waste

Desing of the system and process ensures maximal recovery of used precious materials.

Custom solutions

We offer the ability to create powders and systems that are customized to your project’s unique requirements.

ORDER POWDERS

Precious Metal Powders for Sale

AMAZEMET offers the ability to produce a variety of precious metal powders using the rePOWDER system. This technology ensures consistent particle size and high purity, making it suitable for industries that demand precision and reliability. Our capabilities in precious materials processing include:

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

HIGH QUALITY METAL POWDERS

How to Make Precious Metal Powders?

Producing precious metal powders involves melting the materials and atomization – turning metals into fine, uniform particles suitable for various applications. The rePOWDER system utilizes both plasma and induction melting together with ultrasonic vibrations. Both processes ensure that the powders produced are of high quality and uniform in size, making them suitable for specialized applications.

Custom Powders In-House

For companies or research institutions looking to produce their own precious metal powders, AMAZEMET offers the rePOWDER metal powder atomizer. This system allows the in-house production of powders, offering full control over material properties. The benefits of rePOWDER include:

- Flexibility: Create powders with specific compositions and properties.

- Precision: High-quality powders can be produced on a small scale with unmatched consistency.

- Cost-effectiveness: Reduce dependence on external suppliers by producing powders in-house.

- Simplicity: The rePOWDER system is user-friendly, making it ideal for research and small-scale production.

With rePOWDER, you can develop custom precious metal powders tailored to the exact needs of your project, ensuring precision and control at every stage.