Freedom in Metal AM Develompent & Production

Gold Alloys in Additive Manufacturing

Gold Alloys in Additive Manufacturing

As additive manufacturing expands into high-performance applications, the demand for premium, application-specific materials is growing. Among them, gold alloys stand out—not just for their value, but for the unique properties they bring to the most demanding industries.

GOLD ALLOYS

Innovating with Gold Alloys

Introduction

Gold alloys are renowned for their exceptional electrical conductivity, corrosion resistance, and biocompatibility, making them invaluable in electronics, medical technologies, and advanced manufacturing. Precise gold powder production is now driving significant advancements in additive manufacturing (AM).

These alloys combine exceptional electrical conductivity (around 70% IACS), impressive corrosion resistance, and superior biocompatibility, making them highly sought-after in advanced technological applications. Additionally, gold's high density (around 19.32 g/cm³) further enhances its suitability for demanding applications. These characteristics make gold alloys indispensable in industries where powder quality significantly impacts final product integrity, particularly in AM.

Gold alloys are renowned for their exceptional electrical conductivity, corrosion resistance, and biocompatibility, making them invaluable in electronics, medical technologies, and advanced manufacturing. Precise gold powder production is now driving significant advancements in additive manufacturing (AM).

These alloys combine exceptional electrical conductivity (around 70% IACS), impressive corrosion resistance, and superior biocompatibility, making them highly sought-after in advanced technological applications. Additionally, gold's high density (around 19.32 g/cm³) further enhances its suitability for demanding applications. These characteristics make gold alloys indispensable in industries where powder quality significantly impacts final product integrity, particularly in AM.

TYPES

Carat Classifications and Alloy Properties

Gold alloys are classified by their carat rating, reflecting their gold content by weight. Common carats include:

01

14k Gold

Contains 58.3% gold, alloyed primarily with copper and silver. It offers increased hardness and durability, ideal for mechanical and structural applications.

02

18k Gold

Composed of 75% gold, often alloyed with copper, silver, or palladium. It balances purity and mechanical strength, suitable for precision electronics and medical implants.

03

22k Gold

Approximately 91.7% gold, commonly alloyed with silver or copper. It provides superior malleability and a rich color, ideal for detailed, delicate applications.

04

24k Gold

Pure gold (99.9%+), exceptionally soft, reserved for specialized applications requiring maximum chemical inertness and highest electrical conductivity, such as electrical contacts.

AMAZEMET

Complexities in Gold Powder Procurement

Securing custom gold alloy powders for specialized applications presents numerous challenges

- Diverse Regulatory Requirements: Varying international regulations regarding purity, import-export procedures, and compliance create logistical hurdles.

- Laser Powder Bed Fusion (LPBF) Issues: Gold's high reflectivity (especially to standard 1070 nm infrared lasers) poses significant challenges for LPBF processing. Inefficient energy absorption often leads to incomplete melting, porosity, and poor mechanical properties, necessitating specialized alloys with adjusted optical characteristics.

- Market Volatility: Over the past five years, pure gold prices have varied significantly, ranging from approximately $40,000 to $95,000 per kilogram, complicating procurement strategies and budgeting.

- Quality Control: Maintaining consistent powder quality—including particle size distribution, purity, and morphology—is essential yet challenging.

Applications of gold alloys across several sectors:

Electronics

Essential for high-performance connectors, contact points, and precision circuitry.

Medical Devices

Vital for implants, sensors, and surgical instruments due to their biocompatibility and corrosion resistance.

Jewelry and Luxury Items

Valued for their corrosion resistance, hypoallergenic properties, exceptional malleability, excellent castability, resistance to tarnishing, and superior reflectivity. These properties make gold ideal for intricate, detailed designs achievable through additive manufacturing.

METAL POWDERS PRODUCTION

Precision and Innovation in Gold Powder Solutions

AMAZEMET provides specialized, precision material solutions tailored to researchers, academic institutions, and innovative industries. Supported by extensive scientific collaborations and staffed by a dedicated team of materials scientists—including PhD holders and doctoral candidates—AMAZEMET enables tailored gold powder production to meet complex research and application demands.

Our commitment to innovation and collaboration ensures:

Custom-formulated gold alloys tailored specifically to project requirements.

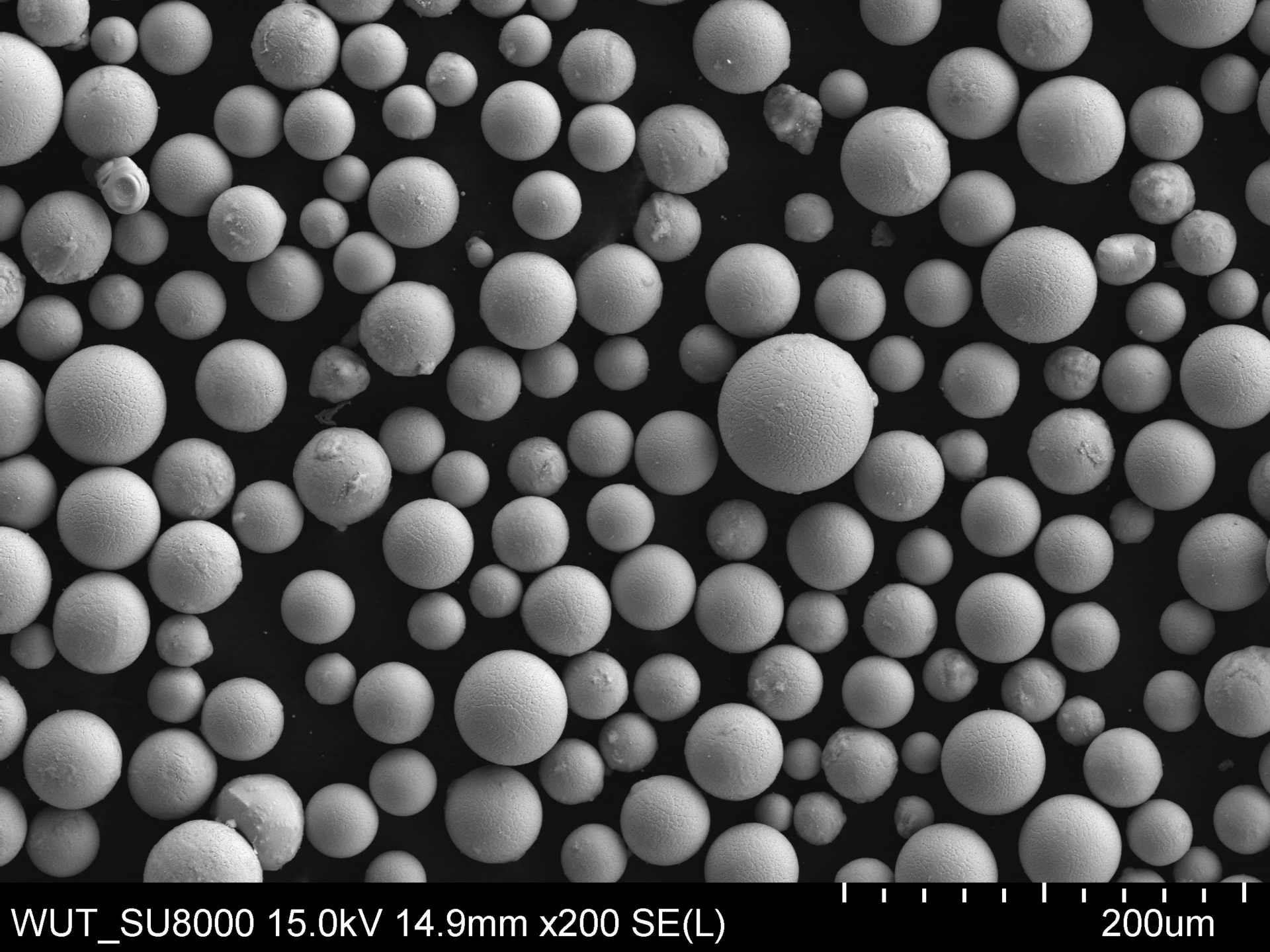

Superior gold powder quality through advanced ultrasonic atomization, ensuring precise particle characteristics.

Flexible production methods ideal for laboratories, specialized markets, and high-tech industrial applications.

AMAZEMET SERVICES & REPOWDER

AMAZEMET’s Custom Gold Powders and rePOWDER Atomizer

Whether sourcing tailored gold powders or setting up an in-house production line, AMAZEMET provides adaptable, high-performance solutions:

1. Customized Gold Alloy Powders

- Specialized alloy compositions.

- Controlled particle size and exceptional purity.

- Flexible production suited for targeted research and prototyping.

2. rePOWDER Atomizer

- Enables internal production of customized gold powders.

- High atomization efficiency, achieving material yields up to 90%, significantly surpassing traditional methods. This efficiency reduces material waste, lowers production costs, and accelerates research and development cycles, directly benefiting end-users and researchers.

- Facilitates material recovery, particularly beneficial for smaller systems, reaching recovery rates up to 99.9%, greatly reducing material waste.

- Secures proprietary alloy formulations through internal production management.

BOOST YOUR PROJECT WITH AMAZEMET

Partner with AMAZEMET to procure specialized gold alloy powders or establish your own efficient atomization capabilities, advancing your innovative projects effectively.