Freedom in Metal AM Develompent & Production

Iridium Alloys: Extreme Stability Meets Precision Powder Engineering

Iridium Alloys: Extreme Stability Meets Precision Powder Engineering

Ruthenium, one of the rarest platinum group metals, offers unparalleled catalytic activity, outstanding resistance to aggressive chemical environments, and exceptional thermal stability. These qualities make ruthenium powders indispensable for pioneering advancements in technology.

RUTHENIUM ALLOYS

Iridium Alloy Powders – Engineered for the Harshest Conditions on Earth (and Beyond)

Introduction

With one of the highest melting points of any element and exceptional corrosion resistance, iridium and its alloys are indispensable in applications where failure is not an option—from aerospace propulsion systems to biomedical implants and advanced crucibles. For engineers exploring the extremes of material performance, iridium is often the metal of last resort—and first choice.

Iridium's unique properties—extremely high-temperature stability (melting point 2446°C), exceptional resistance to oxidation, and outstanding mechanical strength—make it a critical material in hostile environments. When alloyed with other noble metals such as platinum, osmium, or rhenium, its capabilities expand even further, enabling precise control of creep resistance, hardness, and chemical durability.

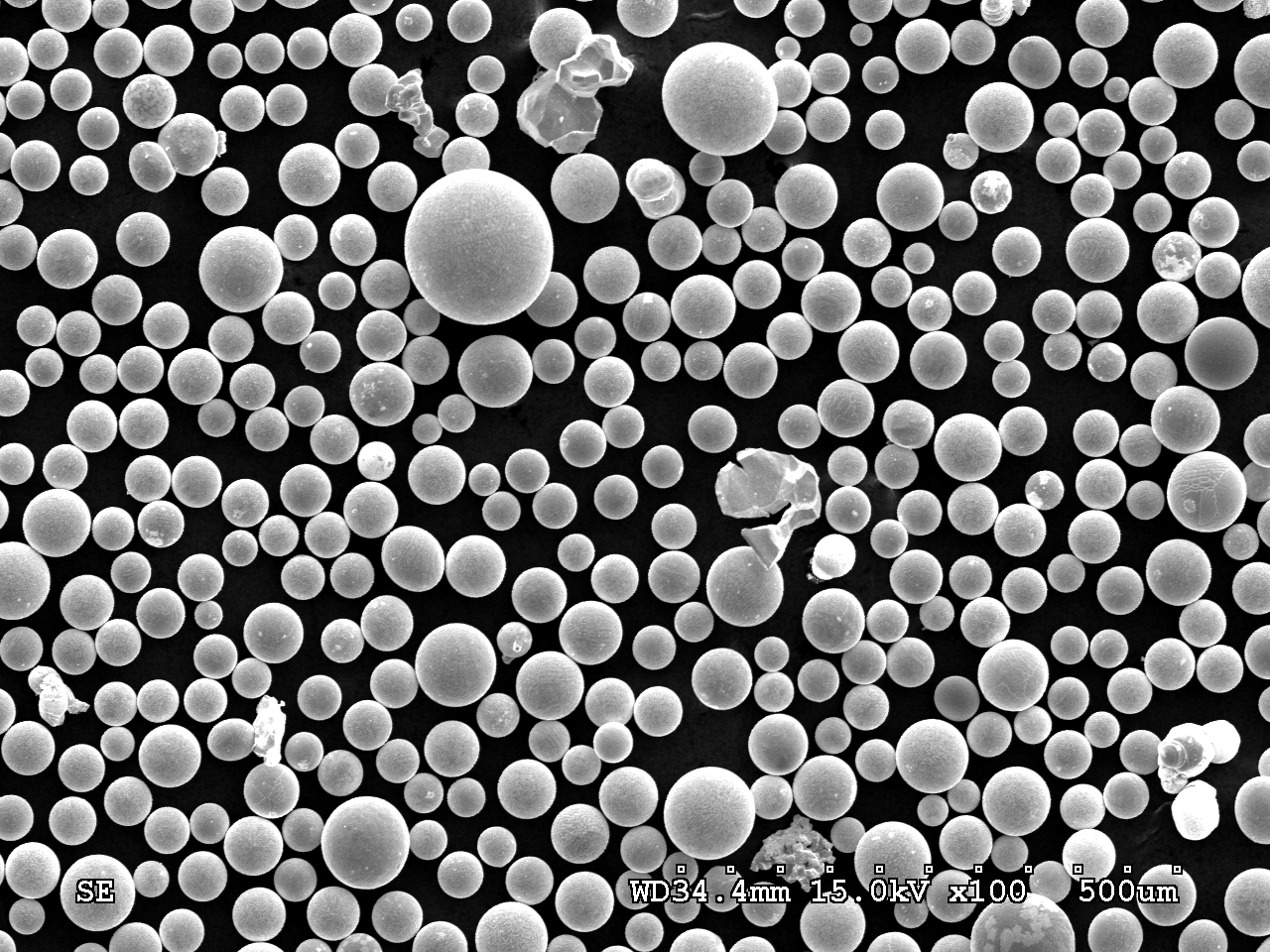

However, processing iridium remains notoriously challenging. Its brittleness in cast form, high density (~22.56 g/cm³), and extreme reactivity during melting call for specialized powder production methods, especially for spherical powders used in additive manufacturing (AM), advanced coatings, or near-net shape part fabrication. As demand grows for extreme-condition materials in aerospace, nuclear, and medical sectors, high-purity iridium alloy powders—suitable for powder bed fusion, binder jetting, or thermal spray—are becoming a vital resource.

METAL AM

Why Iridium Alloy Powder Atomization Remains a Bottleneck in Advanced Materials R&D

Despite their strategic importance, iridium alloy powders remain elusive—difficult to source, challenging to produce, and prohibitively expensive in small quantities.

Developing with iridium is not for the faint-hearted. For all its beneficial properties, iridium’s extreme melting point and reactive nature pose significant obstacles to metal powder production. Key issues include:

01

Limited Powder Availability

Most iridium materials are only commercially available as rods, foils, or wires. Additive manufacturing-ready iridium powders—especially spherical ones with flowable particle size distributions—are nearly absent from typical supplier catalogs.

02

Ultra-high Temperature Processing Requirements

Atomizing iridium requires advanced melting systems capable of reaching >2500°C without contamination. Most commercial gas atomization services are not equipped for this.

03

Incompatibility with Traditional Powder Atomization

Gas and centrifugal atomization methods suffer from low yields, poor powder morphology, and excessive oxidation when applied to iridium alloys.

04

High Cots and Waste Risk

With iridium prices exceeding $130,000/kg, material conservation during atomization is essential. Conventional systems often generate unusable fractions, making small-batch prototyping costly and inefficient.

These limitations prevent many research groups from exploring iridium-based alloy systems in powder metallurgy, thermal spray coatings, or laser powder bed fusion (LPBF) applications.

These limitations prevent many research groups from exploring iridium-based alloy systems in powder metallurgy, thermal spray coatings, or laser powder bed fusion (LPBF) applications.

AMAZEMET

Powder Atomization Services and In-House Tools for Iridium Alloys

To overcome sourcing and processing barriers, research teams now turn to advanced powder atomization service providers or deploy compact in-house systems designed specifically for iridium and other refractory metals.

Accessing high-performance iridium alloy powders is possible through two main approaches:

- Custom Powder Atomization Services: Specialized providers like AMAZEMET offer iridium powder atomization using ultrasonic or plasma-assisted systems. These services deliver small-batch, high-purity powders tailored for AM, coatings, or sintering. Ideal for Ir-Pt, Ir-Ta, or Ir-Re compositions.

- In-House Powder Production Systems: Lab-scale ultrasonic atomizers such as the rePOWDER platform give R&D labs the ability to melt and atomize iridium-based alloys directly on-site. With integrated metal recovery and contamination prevention, this route supports fast iteration and high material efficiency.

Both methods enable precise control over composition, particle size distribution (PSD), and powder morphology—key for producing iridium alloy powders optimized for additive manufacturing, thermal spraying, or compacted sintering.

METAL POWDERS PRODUCTION

Experts in Ultrasonic Atomization of Iridium Alloy Powders

AMAZEMET specializes in powder atomization services for ultra-high–temperature metals and provides compact in-house systems for iridium powder production.

Whether your project calls for powder atomization services or an internal iridium powder production workflow, AMAZEMET delivers the solution

At AMAZEMET, we make iridium powder atomization feasible for researchers and small-batch producers. Our platform supports:

Custom Powder Development

From Ir-Pt and Ir-Re to advanced systems like Ir-Hf or Ir-Ta, we help formulate and atomize alloy powders tailored for specific engineering properties.

Small-Batch Iridium Powder Service

Order as little as 20 g of high-purity iridium powder—perfect for feasibility studies, sintering tests, or AM validation runs.

Atomization for AM Applications

Our ultrasonic systems deliver spherical, flowable powders with minimal oxide content—ideal for LPBF, binder jetting, or cold spray.

Scientific Collaboration

We regularly support academic and industrial R&D projects requiring precision atomized powders of high-value, rare metals.

AMAZEMET SERVICES & REPOWDER

Custom Iridium Alloy Powder Services and rePOWDER Atomization Technology

Whether you’re sourcing iridium powder for additive manufacturing or looking to produce it in-house, AMAZEMET offers complete control over the atomization process

1. Iridium Powder Atomization Services

- High-purity iridium alloy powders with tailored PSD and spherical morphology.

- R&D-scale orders from 20 g to 500+ g.

- Optimized for LPBF, cold spray, and coating applications.

2. rePOWDER Ultrasonic Atomizer

- Designed for refractory metals and PGMs like iridium.

- Efficient powder recovery (up to 99.9%), essential for ultra-precious materials.

- Flexible batch processing for iterative alloy development.

- Enables in-house control of alloy formulation, melting, and atomization

BOOST YOUR PROJECT WITH AMAZEMET

Access premium iridium powder atomization services or explore in-house ultrasonic atomization systems tailored for R&D and high-value materials.