Freedom in Metal AM Develompent & Production

Palladium Alloys for Advanced Powder Metallurgy

Palladium Alloys for Advanced Powder Metallurgy

Palladium, a core member of the platinum group metals (PGMs), is valued for its hydrogen absorption, electrical conductivity, and corrosion resistance—especially when alloyed for precise functionality. These characteristics make palladium alloys indispensable in electronics, catalysis, dentistry, and emerging clean energy applications.

PALLADIUM ALLOYS

Unlocking the Strategic Potential of Palladium Alloys

Introduction

As the global drive toward sustainability and miniaturization accelerates, palladium-based alloys are gaining renewed attention across industries. Their low density compared to other PGMs, excellent cold workability, and unique catalytic performance in hydrogenation and electrochemical systems distinguish them from other precious metals. Common alloying additions such as silver, gold, copper, ruthenium, and platinum are employed to modify mechanical strength, ductility, melting point, or electronic structure—tuning the alloy for specific applications.

In powder form, palladium alloys are key enablers for hydrogen storage research and fuel cell innovation. However, accessing these materials in research-ready quantities and tailored compositions remains a major challenge.

As the global drive toward sustainability and miniaturization accelerates, palladium-based alloys are gaining renewed attention across industries. Their low density compared to other PGMs, excellent cold workability, and unique catalytic performance in hydrogenation and electrochemical systems distinguish them from other precious metals. Common alloying additions such as silver, gold, copper, ruthenium, and platinum are employed to modify mechanical strength, ductility, melting point, or electronic structure—tuning the alloy for specific applications.

In powder form, palladium alloys are key enablers for hydrogen storage research and fuel cell innovation. However, accessing these materials in research-ready quantities and tailored compositions remains a major challenge.

METAL AM

Why Sourcing Palladium Alloy Powders Is So Difficult

Despite the increasing demand for palladium alloys in catalysis, electronics, hydrogen technologies, and medical devices, obtaining these materials in powder form is rarely straightforward. Key challenges include:

01

Limited Powder Availability

Palladium is one of the most volatile PGMs, with pricing and availability subject to mining output and geopolitical fluctuations.

02

Ultra-high Temperature Processing Requirements

Most suppliers focus on bulk solid alloys (e.g., Pd-Ag dental alloys or Pd-based brazing fillers), offering few powder options with spherical morphology.

03

Incompatibility with Traditional Powder Atomization

Powder producers typically serve large-volume customers, making it hard to acquire just 50 or 100 grams of a Pd-Ru or Pd-Cu experimental composition.

04

High Cots and Waste Risk

When special compositions are available, production and delivery often stretch over several months, delaying development timelines.

These obstacles can stall early-stage R&D, force compromises on alloy design, or even prevent feasibility testing altogether.

These obstacles can stall early-stage R&D, force compromises on alloy design, or even prevent feasibility testing altogether.

Common Palladium Alloys & Their Functional Roles:

| Alloy | Composition | Key Properties / Application |

|---|---|---|

| Pd-Ag | 70–90% Pd, balance Ag | High ductility and corrosion resistance; used in dentistry, electronics |

| Pd-Cu | 60–90% Pd, balance Cu | Improved mechanical strength; catalytic and hydrogen diffusion membranes |

| Pd-Ru | 95% Pd, 5% Ru (typical) | High hardness, enhanced oxidation resistance, catalytic converters |

| Alloy | Composition | Key Properties / Application |

|---|---|---|

| Pd-Ni | 80-90% Pd, balance Ni | Wear resisitance; used in electrical contacts and multilayer capacitors |

| Pd-Au | Various Pd/Au ratios | Excellent corrosion resistance; high-frequency connectors, biomedical uses |

| Pd-Co | Experimental | Magnetic functionality and sensor applications |

AMAZEMET

Flexible Options for Palladium Powder Development

Overcoming the limitations of traditional suppliers requires either collaboration with specialty powder producers or the ability to create palladium alloy powders in-house.

There are two strategic paths to develop palladium alloy powders tailored for research and innovation:

- Custom Powder Suppliers: These vendors produce small batches of palladium alloy powders, like Pd-Au for electrical contacts or Pd-Cu for hydrogen sensors, with precisely controlled particle size distribution and composition. This is ideal when material IP can be shared externally and time is flexible.

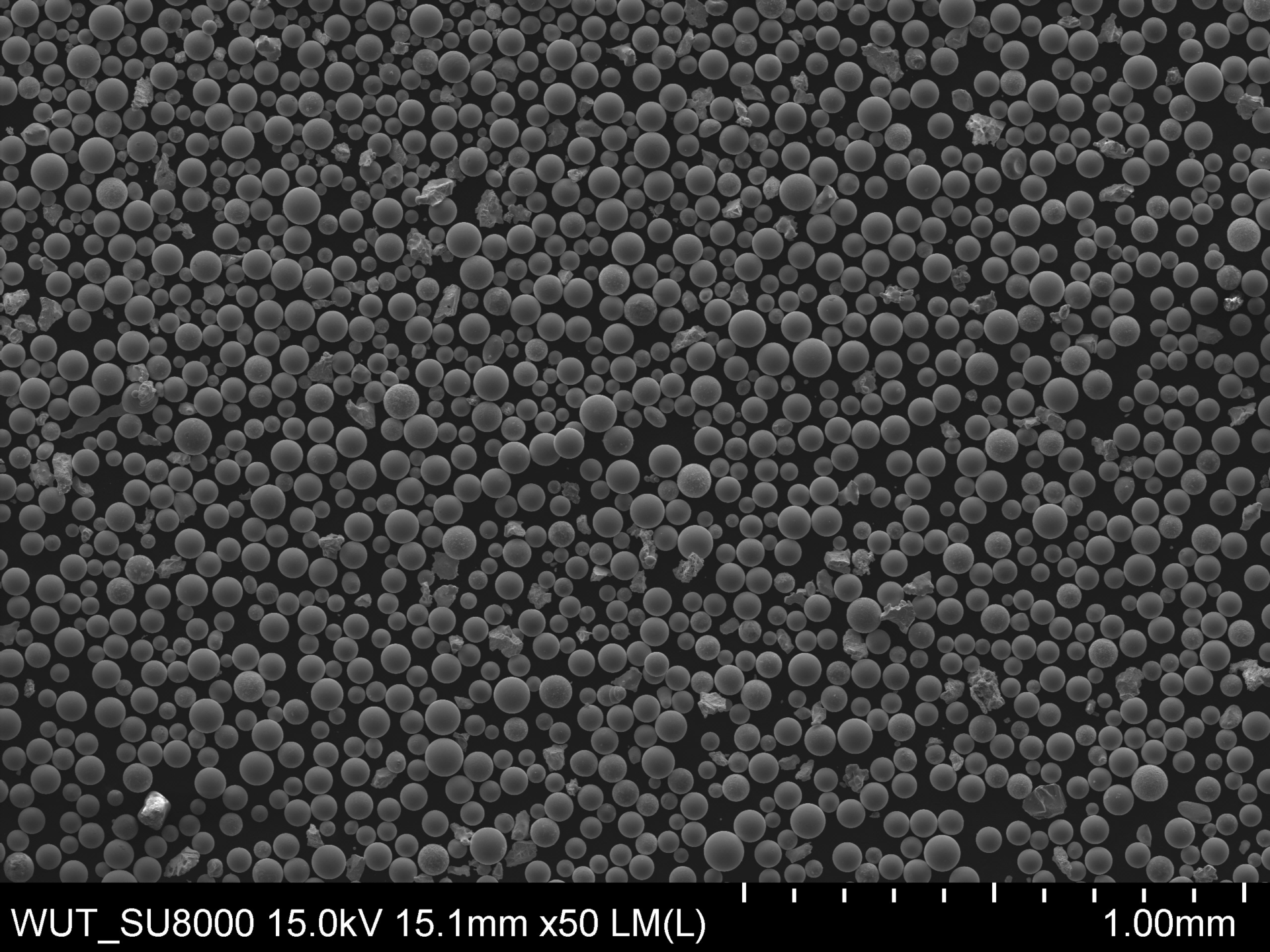

- In-House Ultrasonic Atomization: With lab-scale tools like AMAZEMET's rePOWDER system, researchers can rapidly produce Pd-alloy powders using ultrasonic atomization. Pd-Ru, Pd-Ag, or Pd-based high entropy alloys can be designed, melted, and atomized on-site—perfect for securing proprietary alloy compositions and accelerating development timelines.

Both approaches provide access to high-purity palladium alloy powders with the morphology and particle size required for AM, thin film deposition, or catalyst layer formation.

METAL POWDERS PRODUCTION

Enabling Custom Palladium Alloy Powders

At AMAZEMET, we support innovators exploring palladium-based materials by offering advanced ultrasonic atomization services and tools tailored for research-grade powder production.

Whether your project involves hydrogen separation membranes, low-voltage contact materials, or catalytic layers, AMAZEMET is your partner in unlocking palladium's full potential.

Our technology and services are designed for customers working with strategic, high-value materials. Palladium alloy powders are no exception. AMAZEMET enables:

Custom Formulations

Design Pd-based alloys with silver, gold, ruthenium, or copper, precisely adjusted to match your mechanical, catalytic, or thermal targets.

R&D-Compatible Batches

Order as little as 50–100 g of palladium alloy powder for initial tests, minimizing cost and waste.

AM-Optimized Powders

Achieve high sphericity, flowability, and narrow PSD with our proprietary ultrasonic atomization platform—ideal for binder jetting, LPBF, or cold spray.

AMAZEMET SERVICES & REPOWDER

Custom Pd Alloy Powders & In-House Production with rePOWDER

AMAZEMET offers both tailored powder manufacturing services and the tools to produce palladium alloys on demand within your own facility.

This dual offering empowers both rapid prototyping and scalable material development—key for early-stage hydrogen technologies, MEMS devices, and catalyst research.

1. Tailored Powder Services

- Pd-Ag, Pd-Ru, Pd-Cu and other experimental alloy systems.

- Minimal order quantity as low as 20 grams

- Controlled narrow Particle Size Distribution

- Research-scale orders with quick turnaround.

2. rePOWDER Ultrasonic Atomizer

- Compact ultrasonic system designed for PGMs and reactive alloys.

- Enables quick alloying and atomization from bar, casting, or compact.

- Particle size and sphericity optimized for AM workflows.

- Full protection of intellectual property by keeping production internal.

BOOST YOUR PROJECT WITH AMAZEMET

Access specialized palladium alloy powders or take control of your own powder development process with our rePOWDER system.