Freedom in Metal AM Develompent & Production

Ruthenium Powders: Unleashing the Potential of a Rare Element

Ruthenium Powders: Unleashing the Potential of a Rare Element

Ruthenium, one of the rarest platinum group metals, offers unparalleled catalytic activity, outstanding resistance to aggressive chemical environments, and exceptional thermal stability. These qualities make ruthenium powders indispensable for pioneering advancements in technology.

RUTHENIUM ALLOYS

Exceptional Properties of a Scarce Metal

Introduction

Ruthenium is highly prized for its extraordinary hardness, corrosion resistance, and unmatched catalytic efficiency. Such distinctive properties make ruthenium powders crucial for cutting-edge applications in aerospace, electronics, fuel cells, and catalytic converters. Given its rarity and highly specialized nature, obtaining ruthenium in precisely tailored powder forms poses considerable logistical challenges, particularly for researchers and engineers pushing the boundaries of innovation.

Ruthenium is highly prized for its extraordinary hardness, corrosion resistance, and unmatched catalytic efficiency. Such distinctive properties make ruthenium powders crucial for cutting-edge applications in aerospace, electronics, fuel cells, and catalytic converters. Given its rarity and highly specialized nature, obtaining ruthenium in precisely tailored powder forms poses considerable logistical challenges, particularly for researchers and engineers pushing the boundaries of innovation.

METAL AM

Is Limited Access to Custom Ruthenium Powders Holding Back Your Research?

Advanced applications of ruthenium powders, especially in catalysis, electronics, and additive manufacturing, demand exceptionally pure and customized materials. Researchers and developers commonly encounter obstacles such as:

01

Extreme Scarcity

Ruthenium's natural rarity severely limits availability, complicating access to specialized powders.

02

Inflexible Specifications

Off-the-shelf powders often fail to meet precise compositional requirements critical for optimized catalytic or electronic performance.

03

Extended Lead Times and Elevated Costs

Custom orders usually involve prolonged waiting periods and higher expenses, significantly impeding agility and innovation in research environments.

These challenges hinder project progress, disrupt timelines, and restrict the scope of innovative exploration.

These challenges hinder project progress, disrupt timelines, and restrict the scope of innovative exploration.

AMAZEMET

Advanced Solutions for Custom Ruthenium Powder Production

To transcend traditional supply chain limitations, specialized powder production and advanced in-house atomization technologies emerge as essential solutions.

- Specialized Powder Providers: Niche suppliers offer ruthenium powders with customized purity levels, precise particle sizing, and exact compositional adjustments, catering directly to stringent application demands, though typically at premium prices.

- In-House Atomization Technology: Establishing your atomization capabilities provides unmatched flexibility, enabling rapid iteration of powder compositions, immediate quality control, and robust intellectual property security.

Both approaches deliver exceptional control and precision, empowering researchers and innovators to fully leverage ruthenium's unique capabilities.

METAL POWDERS PRODUCTION

Your Expert in Rare Ruthenium Powders

AMAZEMET is dedicated to advancing niche research and sophisticated manufacturing by supplying high-purity, custom-formulated ruthenium powders supported by cutting-edge atomization technology. We enable unparalleled access to ruthenium’s rare properties, supporting groundbreaking innovations and technical excellence.

AMAZEMET recognizes the crucial role ruthenium plays in modern engineering and scientific breakthroughs. We specialize in:

Custom Silver Alloy Powders

Collaborate directly with our metallurgical specialists to create precisely formulated, high-purity ruthenium powders.

R&D-Ready Quantities

Easily obtain research-friendly quantities, perfect for initial testing and rapid prototyping.

Special Focus on Addtive Manufacturing

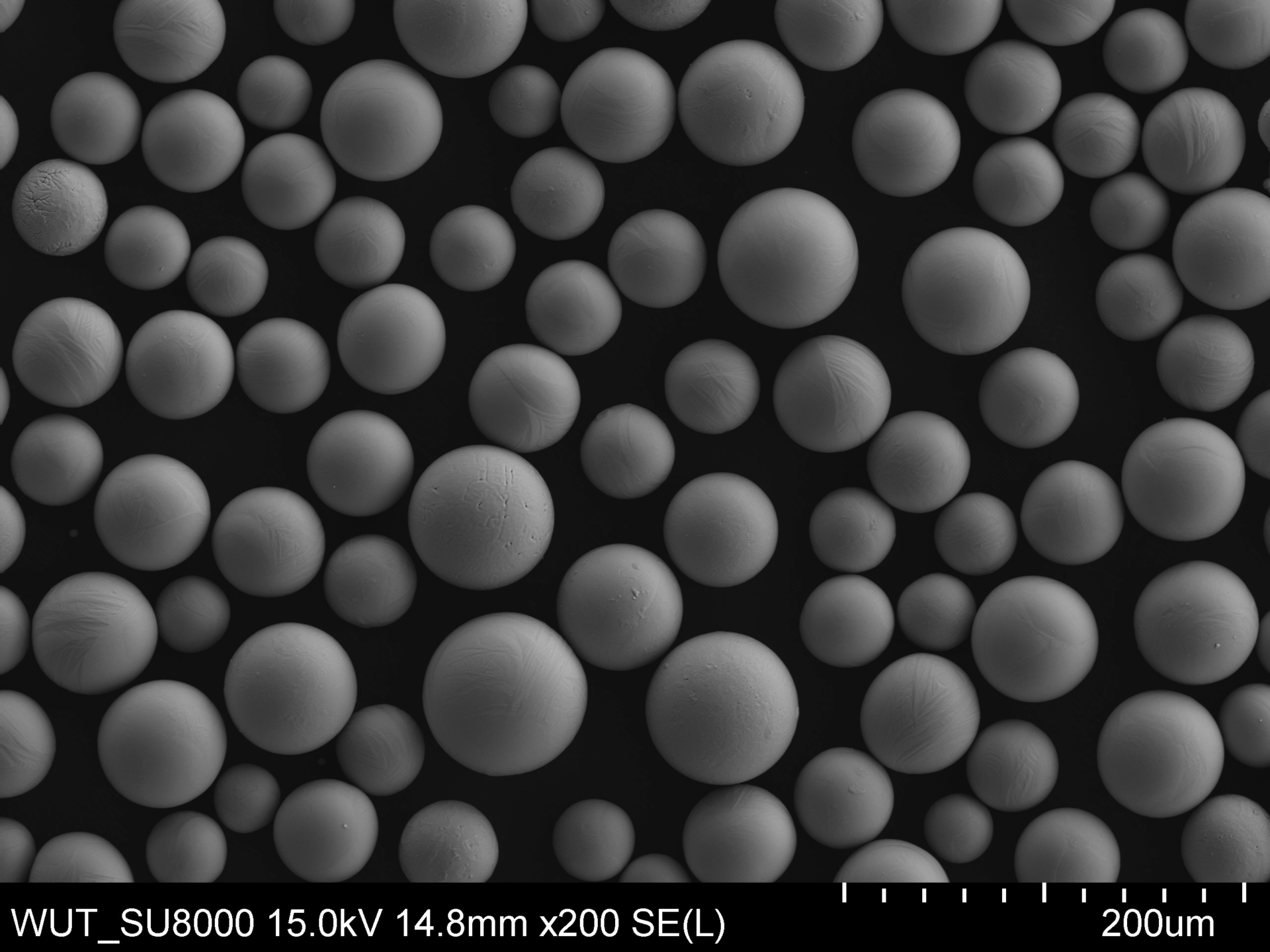

Our advanced ultrasonic atomization processes yield consistently uniform, contaminant-free powders specifically tailored to your project’s exact requirements.

AMAZEMET SERVICES & REPOWDER

Custom Ruthenium Powder Solutions & rePOWDER Atomizer

AMAZEMET’s specialized powder services and innovative rePOWDER atomizer open new pathways for advanced ruthenium powder development.

Our comprehensive solutions strategically position your research at the forefront of ruthenium technology

1. Tailored Powder Services

- Precision Formulation: Craft ruthenium powders precisely customized to your specific application needs in catalysis, electronics, or additive manufacturing.

- Scalable Production: Order precisely the quantities you need, minimizing waste and controlling costs effectively.

- Rapid Turnaround: Achieve faster project timelines with expedited delivery of specialized powder orders.

2. rePOWDER In-House Atomization

- Advanced Plasma Atomization: Specifically engineered to handle rare, high-temperature materials like ruthenium, optimizing particle morphology and purity.

- Rapid Development Cycle: Quickly experiment, refine, and validate multiple powder compositions to accelerate your research and development.

- Secure Intellectual Property: Protect sensitive, proprietary powder formulations by maintaining production within your own facility.

BOOST YOUR PROJECT WITH AMAZEMET

Whether your research requires specialized ruthenium powder formulations or advanced in-house atomization capabilities, AMAZEMET provides the essential solutions to achieve exceptional results.