Freedom in Metal AM Develompent & Production

Rediscovering Silver Alloys for Advanced Engineering

Rediscovering Silver Alloys for Advanced Engineering

Known for centuries as a decorative and electrical material, silver is experiencing a resurgence in high-performance applications—especially when processed as alloyed powder for additive manufacturing and advanced metallurgy.

SILVER ALLOYS

Engineering Silver Alloys for Modern Performance

Introduction

While pure silver is prized for its conductivity and reflectivity, its mechanical softness limits its structural applications. By alloying silver with elements like copper, indium, tin, palladium, or zinc, engineers can significantly enhance properties such as strength, creep resistance, and oxidation behavior.

Silver alloys now find relevance not only in electronics and brazing but also in functional components across aerospace, energy, and medical industries. Various silver grades—including sterling silver, coin silver, Argentium® silver, fine silver (99.9%), Britannia silver, and Mexican silver—highlight the breadth of metallurgical possibilities when designing for specific performance targets.—especially when applied via additive manufacturing. As demand grows for materials with specialized combinations of electrical conductivity, thermal performance, and formability, access to high-quality silver alloy powders becomes more critical than ever.

Yet, the challenges lie in sourcing small quantities or non-standard compositions tailored to the specific needs of research teams, prototyping labs, and precision manufacturing setups.

While pure silver is prized for its conductivity and reflectivity, its mechanical softness limits its structural applications. By alloying silver with elements like copper, indium, tin, palladium, or zinc, engineers can significantly enhance properties such as strength, creep resistance, and oxidation behavior.

Silver alloys now find relevance not only in electronics and brazing but also in functional components across aerospace, energy, and medical industries. Various silver grades—including sterling silver, coin silver, Argentium® silver, fine silver (99.9%), Britannia silver, and Mexican silver—highlight the breadth of metallurgical possibilities when designing for specific performance targets.—especially when applied via additive manufacturing. As demand grows for materials with specialized combinations of electrical conductivity, thermal performance, and formability, access to high-quality silver alloy powders becomes more critical than ever.

Yet, the challenges lie in sourcing small quantities or non-standard compositions tailored to the specific needs of research teams, prototyping labs, and precision manufacturing setups.

METAL AM

When Standard Silver Alloys Fall Short

While commercial silver alloys exist for brazing and electronics, they rarely meet the performance needs of cutting-edge applications—or come in powder form with the right specs.

Despite silver's excellent base properties, adapting it to demanding environments often requires custom alloying strategies. Traditional grades such as Fine Silver (Ag 99.9%) for ultra-high purity applications, sterling silver (92.5% Ag), coin silver (90% Ag), or Britannia silver (95.8% Ag) are well-known in jewelry and industrial use but may fall short in powder metallurgy or additive manufacturing without compositional adjustment.. Engineers may need silver-based compositions that:

- Improve mechanical strength while retaining thermal conductivity

- Resist tarnishing and oxidation during high-temperature operation

- Maintain ductility in thin-walled AM parts or micro-components

Unfortunately, sourcing silver alloys in powder form—especially in non-standard formulations—is a major hurdle. Common issues include:

01

Low Availability of Custom Grades

Most silver alloy powders available commercially are designed for narrow industrial use (e.g., Ag-Cu-In for brazing), with few options for modification.

02

Large-Scale Focus

Manufacturers prioritize bulk sales for jewelry, electronics, or brazing rods—not R&D-grade powder batches.

03

Limited Adaptability for Additive Manufacturing

Some standard alloys do not flow well or solidify optimally under LPBF or binder jetting conditions, making reoptimization necessary.

04

Challenging Laser Processing

Due to silver's high reflectivity in the infrared spectrum, it requires process parameter tuning or alternate wavelengths in LPBF systems.

05

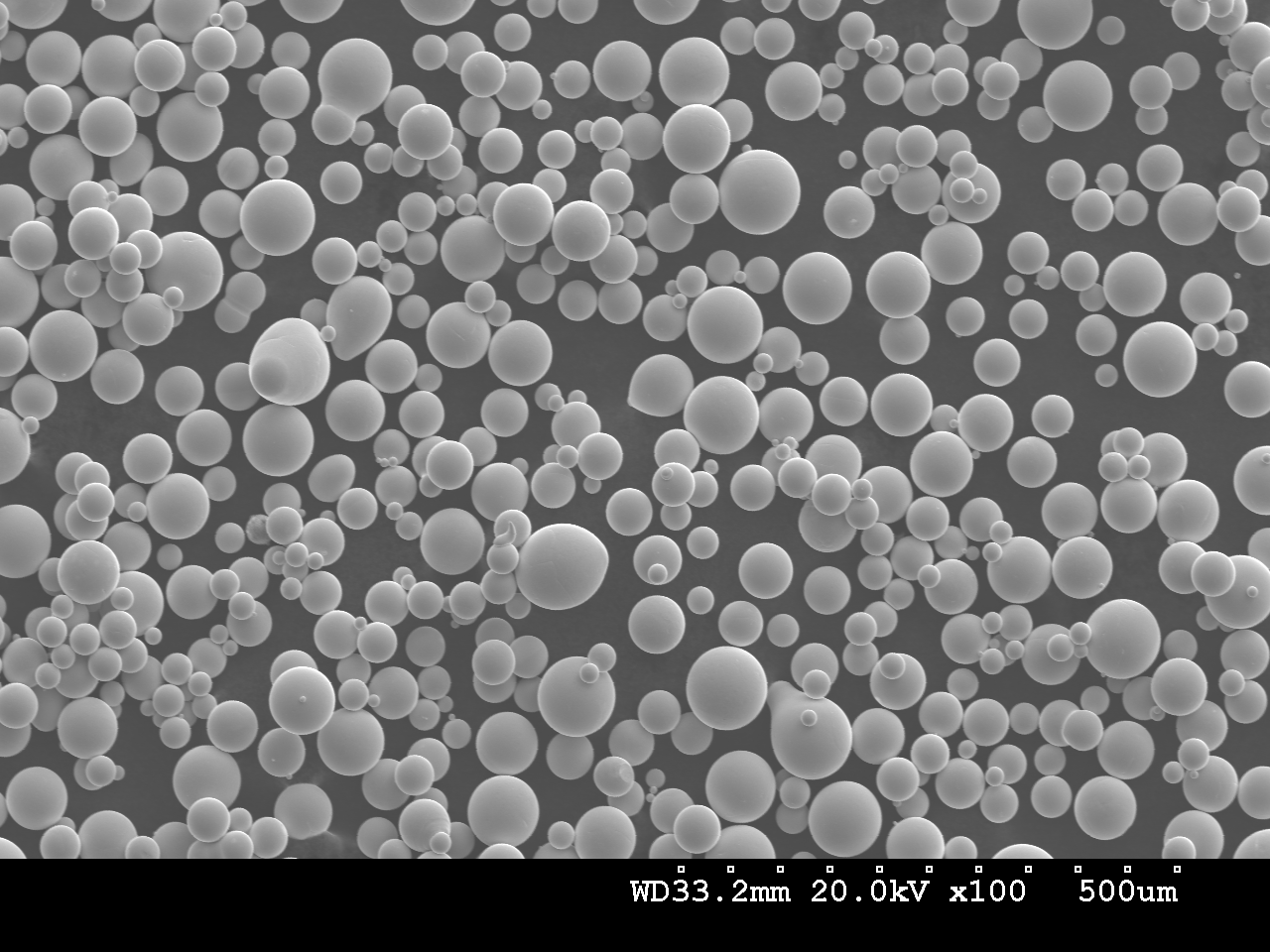

Low Yield of Usable Fraction

Many large-scale powder production processes generate a broad particle size distribution (PSD), resulting in only a limited amount of powder falling within the optimal size range for additive manufacturing. Additionally, the morphology can be inconsistent, affecting powder flowability and packing density.

Without easy access to tailored silver alloy powders, promising designs in advanced electronics, micro-AM, or thermally conductive structures may remain on the drawing board.

Without easy access to tailored silver alloy powders, promising designs in advanced electronics, micro-AM, or thermally conductive structures may remain on the drawing board.

AMAZEMET

Flexible Silver Alloy Development Paths for Research and Prototyping

To meet modern performance criteria, silver alloys must evolve—and that means exploring new formulations and new ways to produce them in powder form.

When commercial offerings are insufficient, two flexible paths emerge:

- Collaborate with Custom Powder Providers: Specialized vendors can create silver alloys tuned to your performance goals, from high-strength Ag-Cu-Pd blends to ductile Ag-In or biocompatible Ag-Zn systems. This is ideal for short-run research or unique functional applications.

- Produce In-House with Atomization Tools: With modern ultrasonic atomization systems, you can create your own silver alloy powders. This approach lets you adjust the composition, optimize particle size distribution, and maintain full control—all in your lab or pilot facility.

Both strategies offer a high degree of flexibility in controlling microstructure, composition, and particle morphology—factors essential for consistent performance in additive manufacturing, especially in demanding applications.

To complement these approaches, engineers and researchers can draw upon a range of silver alloy formulations that reflect both established industrial practice and the frontiers of material science. Together, these alloys demonstrate the versatility of silver as a base material for tailored compositions—ready to be adapted and optimized using AMAZEMET's production methods:

Examples of currently available silver alloys include:

Common Commercial Grades

Ag-Cu (commonly used in brazing and joining), Ag-Zn (conductive structural alloy for connectors), Ag-Pd (noted for high tarnish resistance and chemical stability), Sterling Silver (Ag 92.5% + Cu), Coin Silver (Ag 90% + Cu), Britannia Silver (Ag 95.8%)

Advanced R&D Alloys

Ag-In-Sn (ideal for low-temperature bonding applications), Ag-Cu-Pt (engineered for high-temperature conductivity and thermal stability), Ag-Ni-Zn (explored for magnetically tunable and multifunctional properties), Argentium® Silver (germanium-doped for improved tarnish resistance).

METAL POWDERS PRODUCTION

Supporting Advanced Silver Alloy Powder Needs

Whether you're modifying classic Ag-Cu systems or inventing new silver-based alloys, AMAZEMET provides the tools and services to bring your ideas to life.

AMAZEMET supports engineering and scientific teams working with precious metals by delivering:

Custom Silver Alloy Powders

Tailored to specific conductivity, hardness, or processing requirements. From trace-element doping to binary and ternary blends, we enable experimentation and short-run validation.

R&D-Ready Quantities

Receive only the material you need, with high purity and tight particle size control. Perfect for sintering trials, microfabrication, or AM benchmarking.

Special Focus on Addtive Manufacturing

Our powders are optimized for flowability, morphology, and composition stability—key for PBF, binder jetting, or cold spray.

AMAZEMET SERVICES & REPOWDER

Custom Silver Alloy Powders and In-House Production with rePOWDER

AMAZEMET enables your silver alloy research with both custom powder services and tools to generate unique powders on demand.

From material science to micro-manufacturing, AMAZEMET offers complete support for your silver alloy goals.

1. Custom Powder Production

- Non-Standard Silver Alloys: Work with us to develop Ag-based alloys tailored to conductivity, hardness, or thermal behavior.

- Flexible Batches: Order from as little as 100 grams for early-stage projects, minimizing waste and cost.

- High Purity, Controlled Morphology: Our atomization ensures uniform particles with excellent repeatability and flow.

2. In-House Powder Production with rePOWDER

- Ultrasonic Atomization Optimized for Silver: High atomization efficiency with a narrow particle size distribution.

- Iterative Alloy Development: Create and refine new Ag-X compositions for functional testing.

- Compact Chamber Design: Enables quick material changeovers and easy recovery of remaining powder, with yields of up to 99.9%.

- Protect Your IP: Keep sensitive alloy development in-house—no external labs, no compromise.

BOOST YOUR PROJECT WITH AMAZEMET

Contact AMAZEMET to explore customized silver alloy powder production or install a rePOWDER system to control your silver-based R&D from start to finish.