Freedom in Metal AM Develompent & Production

Refractory Alloys

Refractory metals are a group of metallic elements that exhibit extraordinary resistance to heat, wear, and corrosion, making them essential for high-temperature applications. These metals typically include tungsten (W), molybdenum (Mo), tantalum (Ta), niobium (Nb), and rhenium (Re). Known for their high melting points, refractory metals maintain their structural integrity even in extreme environments. With their unique combination of high melting points, strength, and resistance to oxidation, refractory metals play a critical role in producing parts for high-temperature processes and applications that demand superior durability.

HIGH-TEMPERATURE MATERIALS

Characterization & Properties

Characterization & Properties

Refractory metals stand out because of their impressive ability to withstand high temperatures and wear, making them indispensable in environments where other materials might fail. Common properties include:

Refractory metals stand out because of their impressive ability to withstand high temperatures and wear, making them indispensable in environments where other materials might fail. Common properties include:

High melting points

These metals can endure extreme heat, with melting points well above 2000°C. For instance, tungsten has the highest melting point of all metals at 3,422°C.

High density and strength

Refractory metals maintain their strength and hardness, even at elevated temperatures.

Wear and corrosion resistance

These metals are resistant to corrosion in aggressive chemical environments, making them ideal for use in harsh industrial conditions.

Thermal conductivity

They are good conductors of heat, allowing them to dissipate heat efficiently in high-temperature settings.

CHOOSE YOUR COMPOSITION

Example Refractory Metal Compositions

These compositions are highly valued in industries that demand materials with superior performance in extreme heat and stress conditions.

01

Tungsten (W)

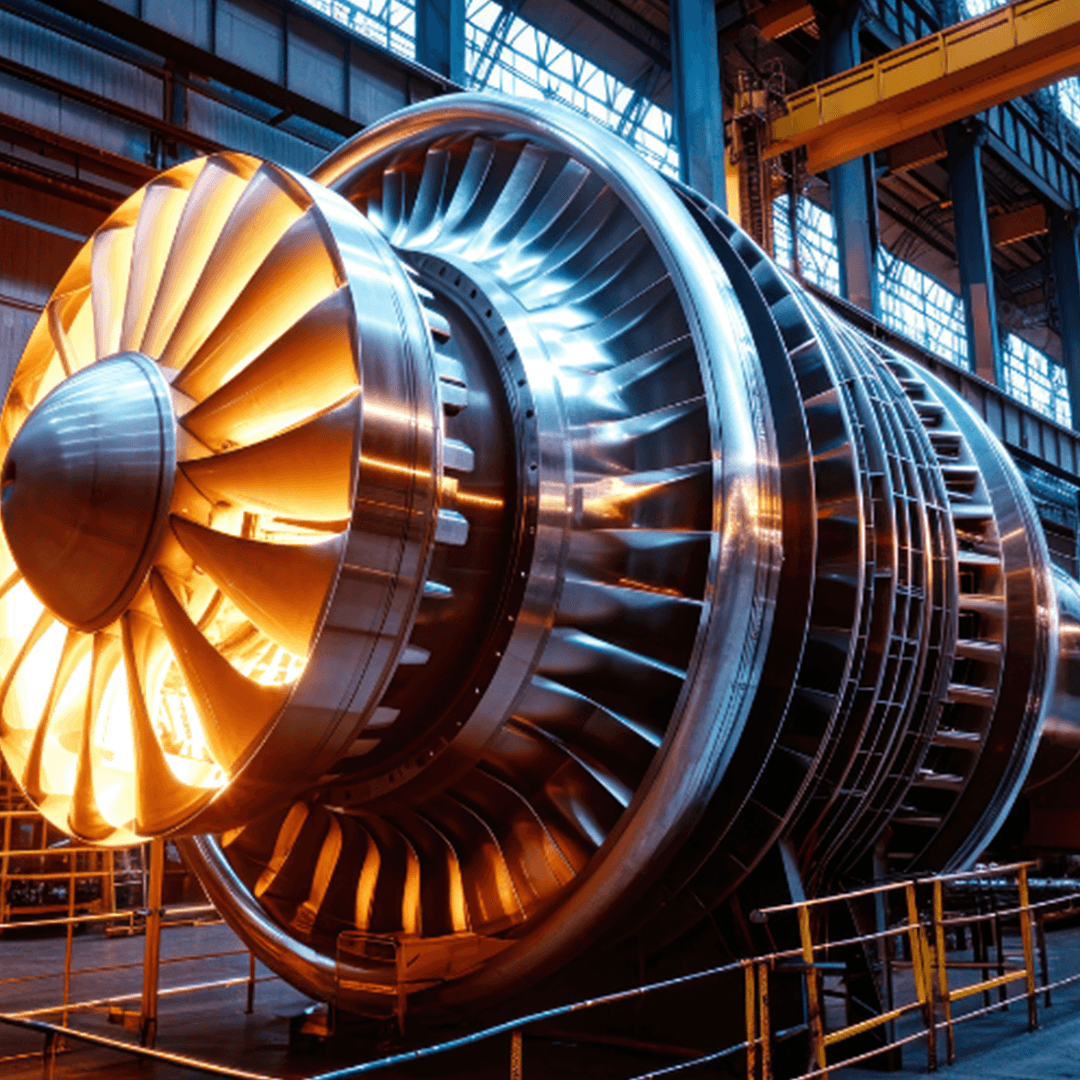

Known for its extremely high melting point and hardness, tungsten is used in applications such as rocket nozzles and high-temperature furnace components.

02

Molybdenum (Mo)

With excellent strength at high temperatures, molybdenum is frequently used in nuclear and aerospace components.

03

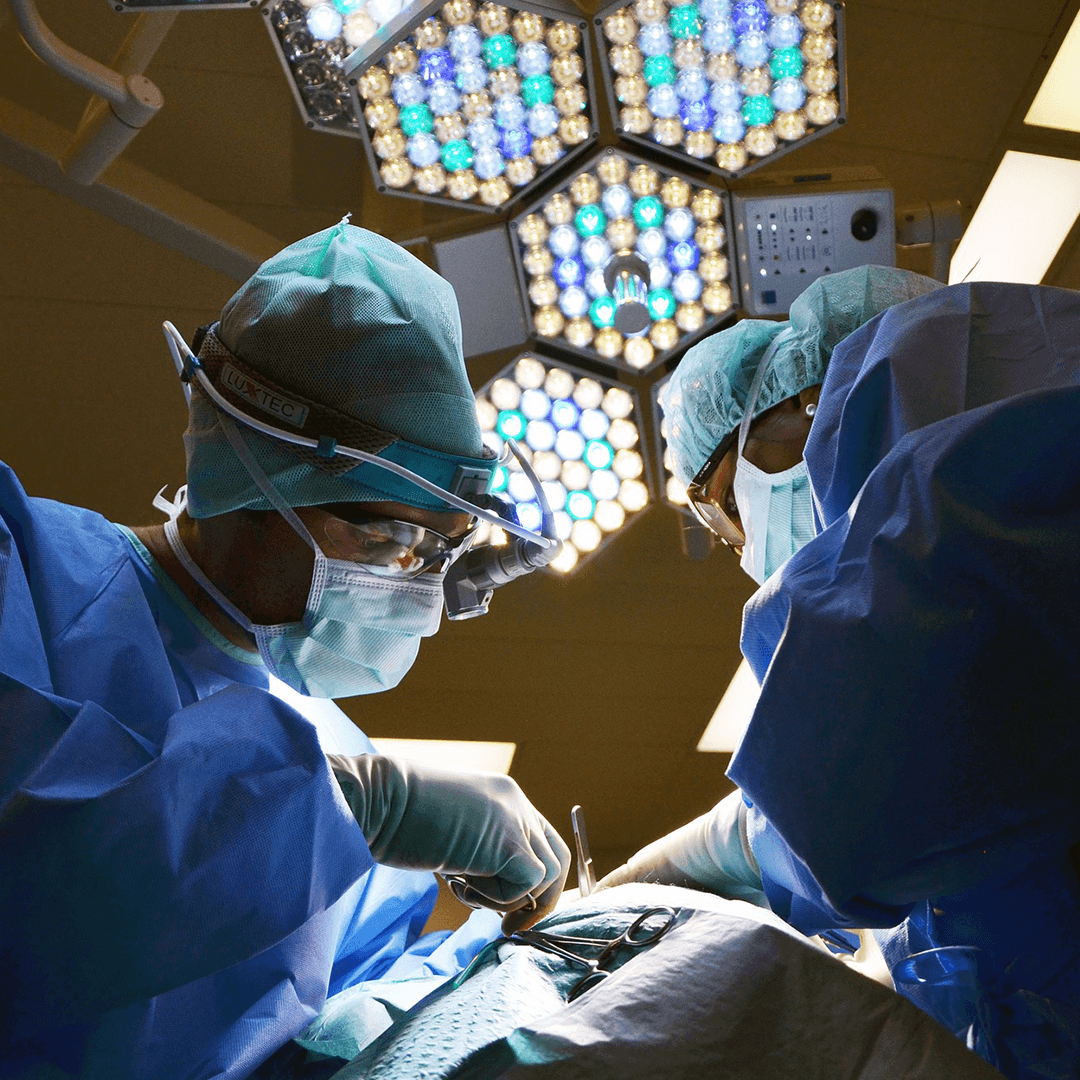

Tantalum (Ta)

Tantalum is highly resistant to corrosion and is often used in chemical processing equipment and medical devices.

04

Niobium (Nb)

This metal is prized for its superconducting properties, making it important in advanced electronics and scientific research.

05

Rhenium (Re)

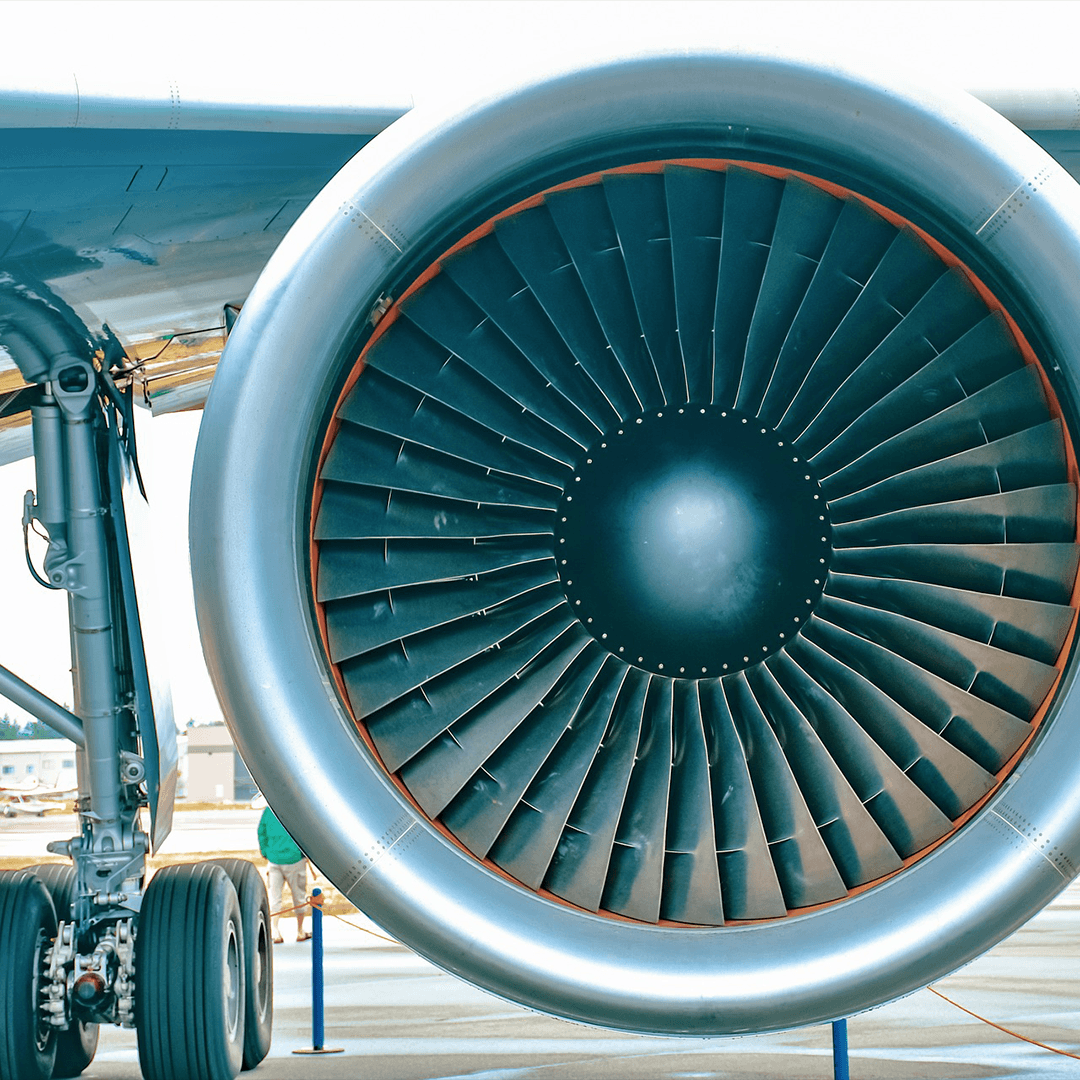

Rhenium is used in jet engines and gas turbine blades due to its ability to retain strength at high temperatures.

REFRACTORY METALS

Applications

Refractory metals have become indispensable across many industries due to their unique properties. These applications demonstrate the critical role of refractory metals in creating reliable, long-lasting components that perform under extreme stress and temperatures.

METAL POWDES PRODUCTION

Where to Buy Refractory Metal Powders?

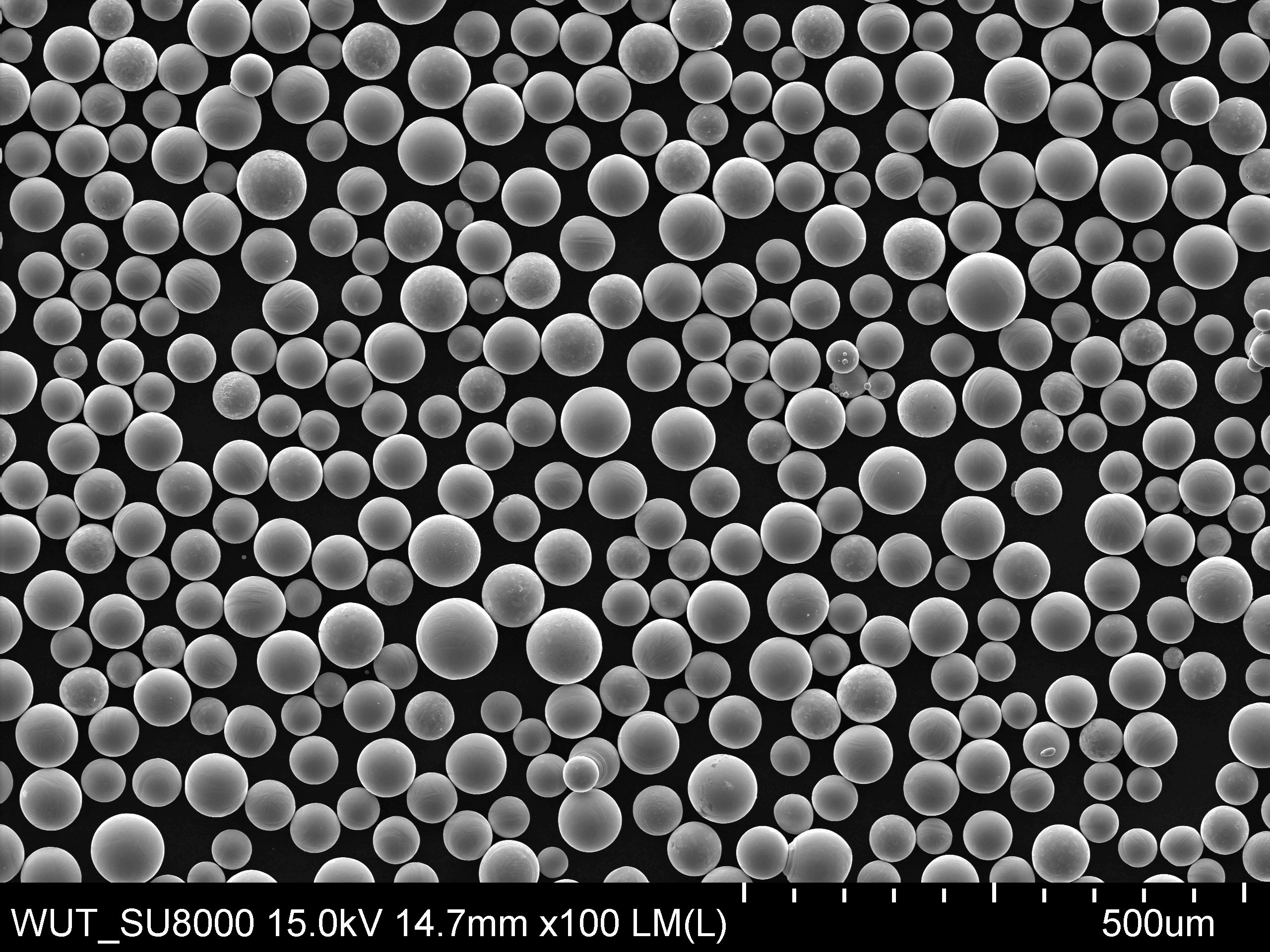

Refractory metal powders are available from specialized suppliers who focus on producing high-quality powders for advanced applications. At AMAZEMET, we offer a service to manufacture refractory metal powders produced using plasma ultrasonic atomization, ensuring consistent quality and particle size for applications such as 3D printing and high-temperature manufacturing.

WHY AMAZEMET

Why Choose AMAZEMET Refractory Metal Powders?

AMAZEMET is committed to delivering high-quality refractory metal powders for a variety of advanced applications. Our refractory metal powders are trusted by industries requiring materials that can withstand extreme heat and stress while maintaining their structural integrity. Here are the key benefits of choosing our powders:

High purity

Ensures consistent performance and mechanical properties in demanding environments.

Uniform particle size

Plasma ultrasonic atomization ensures that the powders are fine and spherical, which is essential for applications like additive manufacturing.

Excellent flowability

Our powders are easy to handle, ensuring precise and reliable use in industrial processes.

Custom solutions

We can create custom powders and compositions to meet your specific needs.

ORDER POWDERS

Refractory Metal Powders for Sale

AMAZEMET provides a service to manufacture refractory metal powders, produced through plasma ultrasonic atomization. Our powders are carefully engineered to meet the demanding specifications required in high-performance applications, ensuring uniform particle size and high purity. Our refractory metal powders are designed to provide consistent performance in the most demanding conditions. Some of the refractory metal powders we offer include:

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

HIGH QUALITY METAL POWDERS

How to Make High-Temperature Metal Powders?

Refractory metal powders are created using specialized atomization techniques to ensure high quality and uniformity. At AMAZEMET, we use plasma ultrasonic atomization to produce these powders. Plasma ultrasonic atomization allows us to produce powders that are consistent, reliable, and suitable for a range of demanding applications. The process involves:

Custom Powders In-House

For customers who want to create their own refractory metal powders, AMAZEMET offers the rePOWDER metal powder atomizer. This system allows you to atomize small batches of metal powders in-house, giving you full control over material composition and quality.

Benefits of the rePOWDER atomizer include:

- Customizability: Produce refractory metal powders with specific compositions for your needs.

- Efficiency: Create powders on-demand, reducing the need for external suppliers.

- Flexibility: The rePOWDER system can handle a variety of refractory metals, including tungsten, molybdenum, tantalum, and niobium.

- Ease of use: Compact and user-friendly, ideal for research institutions or small-scale production environments.

With the rePOWDER system, you can create custom refractory metal powders, allowing for faster prototyping and more control over your materials.