Freedom in Metal AM Develompent & Production

Rhenium: Unlocking Extreme High-Temperature Performance

Rhenium: Unlocking Extreme High-Temperature Performance

With one of the highest melting points of all metals, outstanding strength, and excellent creep resistance, rhenium is indispensable in aerospace propulsion, energy, and catalytic applications.

RHENIUM ALLOYS

Rhenium Alloys: The Key to Stability at Ultra-High Temperatures

Introduction

Rhenium (Re) is a rare refractory metal with a melting point of 3180 °C, surpassed only by tungsten. It is unique in combining exceptional high-temperature strength with ductility, which makes it particularly valuable in environments where both resilience and toughness are required. Rhenium is primarily used in superalloys for turbine blades, where even small additions dramatically improve creep resistance and oxidation performance. It is also critical in rocket engines, electrical contacts, and catalysts for petroleum reforming.

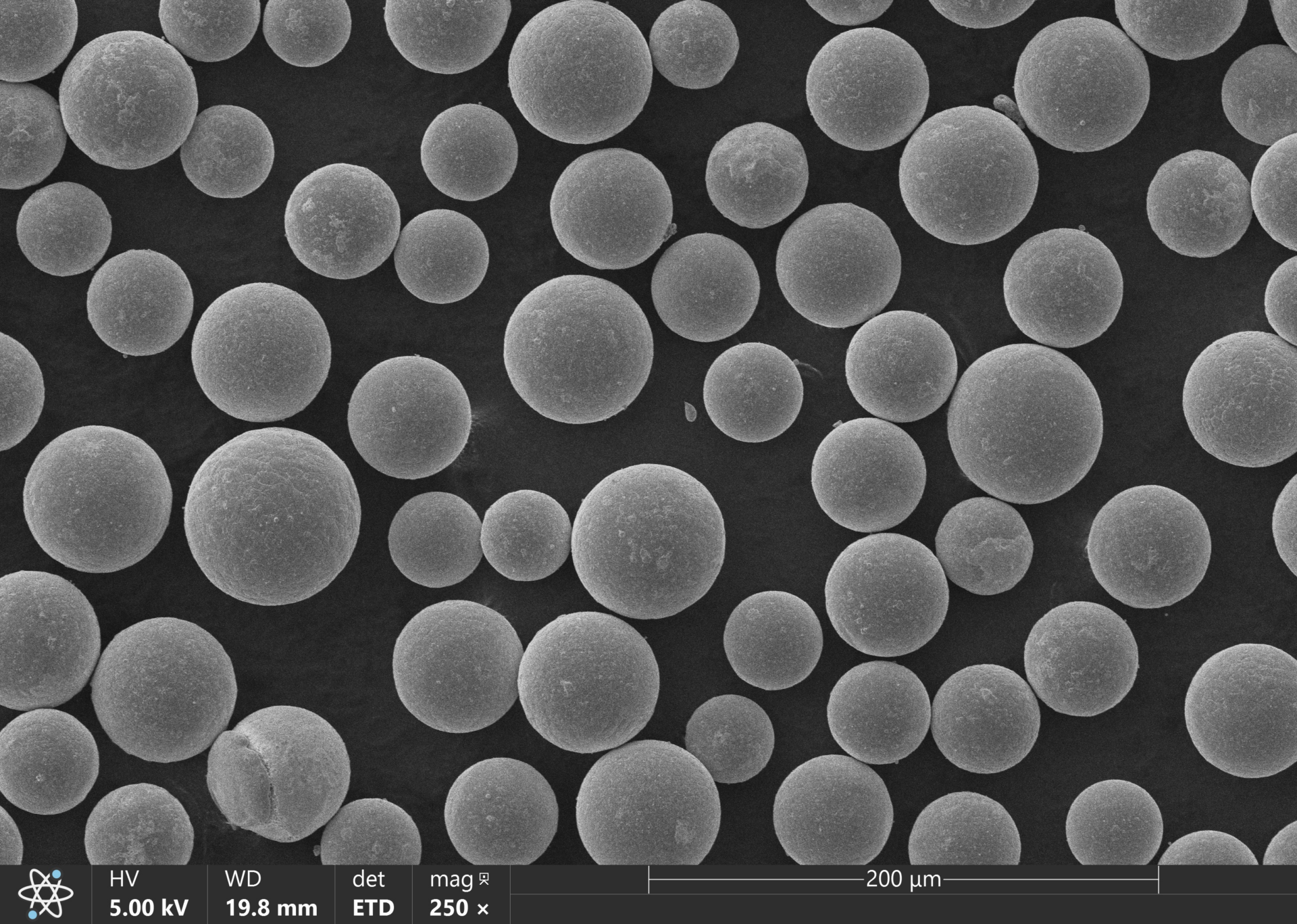

In powder form, rhenium enables advanced additive manufacturing (AM) and powder metallurgy routes, supporting the development of custom Re-based alloys and coatings for extreme conditions. Due to its cost and scarcity, access to rhenium in small, high-quality batches is vital for R&D teams, universities, and niche manufacturers developing next-generation aerospace and energy solutions.

Rhenium (Re) is a rare refractory metal with a melting point of 3180 °C, surpassed only by tungsten. It is unique in combining exceptional high-temperature strength with ductility, which makes it particularly valuable in environments where both resilience and toughness are required. Rhenium is primarily used in superalloys for turbine blades, where even small additions dramatically improve creep resistance and oxidation performance. It is also critical in rocket engines, electrical contacts, and catalysts for petroleum reforming.

In powder form, rhenium enables advanced additive manufacturing (AM) and powder metallurgy routes, supporting the development of custom Re-based alloys and coatings for extreme conditions. Due to its cost and scarcity, access to rhenium in small, high-quality batches is vital for R&D teams, universities, and niche manufacturers developing next-generation aerospace and energy solutions.

METAL AM

Barriers to Accessing Specialized Rhenium Powders

Despite its unique properties, rhenium’s rarity and high cost make it one of the most challenging metals to source in powder form.

Rhenium supply chains are constrained by both economic and practical challenges:

01

High Cost and Scarcity

Rhenium is one of the rarest elements in Earth’s crust, with limited global production primarily as a by-product of copper mining. Bulk pricing and availability limit access for smaller research projects.

02

Bulk-Oriented Supply

Most rhenium is consumed by the aerospace industry in superalloy production, leaving little flexibility for small-batch orders.

03

Limited Alloy Options

While Re-containing superalloys are essential in turbines, researchers often require powders tailored for experimental alloys, coatings, or AM applications, which are rarely available off the shelf.

04

Extended Lead Times

Unlike nickel superalloys, RHEAs do not yet have established grades or widely accepted reference compositions, complicating collaboration and scaling.

These obstacles restrict innovation in aerospace propulsion, energy systems, and advanced manufacturing, where rhenium’s unique role cannot be substituted.

These obstacles restrict innovation in aerospace propulsion, energy systems, and advanced manufacturing, where rhenium’s unique role cannot be substituted.

AMAZEMET

Expanding Access to Rhenium and Re-Based Alloys

With the right strategies, researchers and engineers can secure tailored rhenium powders that meet their specific technical needs.

Two main approaches help overcome rhenium’s supply limitations:

- Specialty Powder Providers: Certain advanced materials suppliers can deliver small-batch rhenium and rhenium-alloy powders, ensuring controlled purity, particle morphology, and composition tailored to R&D objectives.

- In-House Production: By adopting atomization systems such as rePOWDER, research teams can produce rhenium powders directly in their facilities. This approach minimizes reliance on external supply chains, reduces waste by producing exactly the needed quantity, and enables rapid iteration for alloy development.

Both solutions provide flexibility and enable progress in superalloy research, propulsion systems, and novel Re-containing materials for aerospace and energy applications.

METAL POWDERS PRODUCTION

AMAZEMET: Delivering Tailored Rhenium Powder Solutions

AMAZEMET supports advanced projects by enabling small-batch rhenium powder production and in-house alloy development.

At AMAZEMET, we recognize the unique role of rhenium in next-generation aerospace and energy technologies. Our approach is designed to address the key barriers of cost, availability, and flexibility by:

Producing

custom rhenium and Re-alloy powders optimized for aerospace superalloys, coatings, or AM applications.

Offering

research-scale volumes ranging from grams to kilograms.

Guaranteeing

high purity and uniform morphology, essential for high-stress, high-temperature environments.

Enabling

confidential, in-house production through rePOWDER, giving teams direct control over rhenium powder development.

AMAZEMET SERVICES & REPOWDER

AMAZEMET Services & rePOWDER: Your Rhenium Partner

From bespoke powder batches to in-house atomization, AMAZEMET provides the tools to explore rhenium’s full potential.

1. Custom Powder Production (Small Batches):

- Tailored formulations including rhenium superalloys and experimental compositions.

- Precise order volumes suited to R&D and prototyping.

- Shorter lead times compared to traditional large-scale suppliers.

2. rePOWDER Atomizer for In-House Production

- Adapted for refractory metals such as rhenium.

- Full control over parameters, including alloying additions, and particle size.

- Enhanced IP protection by producing powders internally.

BOOST YOUR PROJECT WITH AMAZEMET

Whether you need small-batch rhenium alloy powders or in-house production capabilities, AMAZEMET provides the tools to explore refractory alloys at the highest level.