Freedom in Metal AM Develompent & Production

Magnetic Alloys and Powders for Next-Generation Applications

Magnetic Alloys and Powders for Next-Generation Applications

Magnetic alloys are at the core of next-generation technologies—from precision sensors and efficient transformers to actuators, spintronics, and advanced cooling systems. When processed into high-quality magnetic powders, these materials unlock new possibilities in additive manufacturing (AM) and materials research.

MAGNETIC ALLOYS

Magnetic Alloys for High-Performance Functional Devices

Introduction

Magnetic alloys encompass a diverse group of materials engineered for targeted electromagnetic behavior. Soft magnetic alloys, such as Permalloy (Fe-Ni) and FINEMET (Fe-Si-B-Nb-Cu nanocrystalline systems), are favored for their high permeability and low core losses. Hard magnetic alloys like Nd-Fe-B and SmCo exhibit strong coercivity and are widely used in permanent magnet applications.

Emerging materials like Gadolinium (Gd) and Gd-based systems show promise in magnetocaloric refrigeration, where temperature changes are induced by magnetic fields. Meanwhile, magnetoelastic alloys such as Terfenol-D (Tb-Dy-Fe) offer precise strain control for sensors and actuators through magnetically induced deformation.

Despite innovations, the industry still relies heavily on legacy Fe-Si (silicon steels)—soft magnetic materials introduced over a century ago. Although cost-effective and widely used, these materials fall short in high-frequency, high-efficiency, and miniaturized applications, underscoring the urgent need for more advanced magnetic powders and alloys.

Magnetic alloys encompass a diverse group of materials engineered for targeted electromagnetic behavior. Soft magnetic alloys, such as Permalloy (Fe-Ni) and FINEMET (Fe-Si-B-Nb-Cu nanocrystalline systems), are favored for their high permeability and low core losses. Hard magnetic alloys like Nd-Fe-B and SmCo exhibit strong coercivity and are widely used in permanent magnet applications.

Emerging materials like Gadolinium (Gd) and Gd-based systems show promise in magnetocaloric refrigeration, where temperature changes are induced by magnetic fields. Meanwhile, magnetoelastic alloys such as Terfenol-D (Tb-Dy-Fe) offer precise strain control for sensors and actuators through magnetically induced deformation.

Despite innovations, the industry still relies heavily on legacy Fe-Si (silicon steels)—soft magnetic materials introduced over a century ago. Although cost-effective and widely used, these materials fall short in high-frequency, high-efficiency, and miniaturized applications, underscoring the urgent need for more advanced magnetic powders and alloys.

METAL AM

The Limits of Commercial Magnetic Alloys

As innovation accelerates, many commercially available magnetic alloys fail to meet the performance, form factor, or powder specifications required by modern technologies.

Today’s researchers and engineers encounter numerous roadblocks:

01

Restricted Powder Access

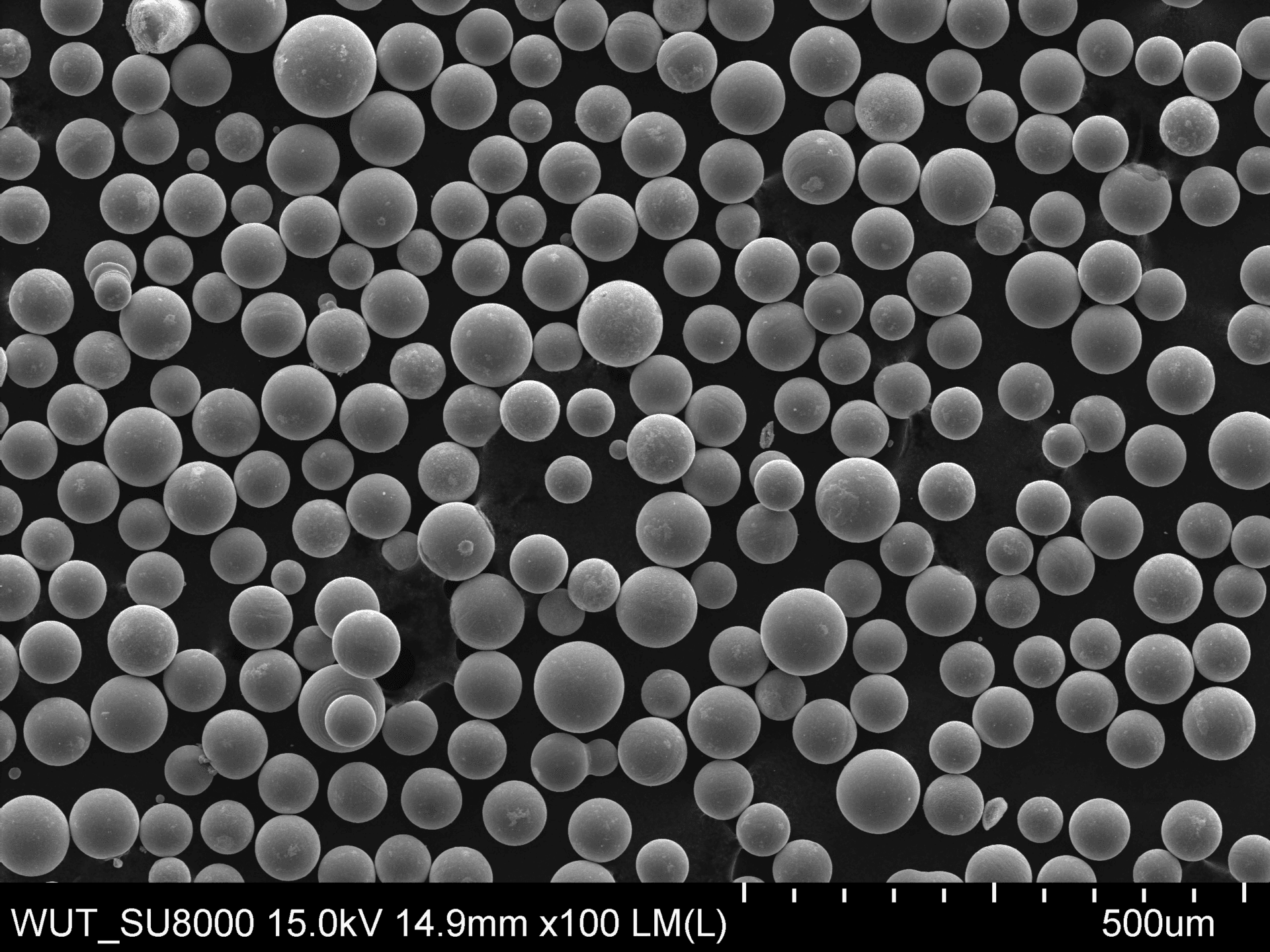

While soft magnetic alloys like Fe-Ni (Permalloy), Fe-Si (grain– and non-grain–oriented), and Fe-Co (Hiperco) are commercially available in bulk, high-quality spherical magnetic powders remain rare or insufficiently optimized for AM.

02

Obsolete Industry Standards

Despite widespread use, silicon steels struggle to keep pace with the requirements of higher frequency operation, reduced eddy currents, and thermal stability.

03

Oxidation and Microstructure Challenges

Magnetic alloys are sensitive to oxidation and phase instability during powder production, making control over process conditions critical.

04

Cost and Time Barriers

Custom orders for magnetic powders often involve long lead times, high minimum order quantities, and elevated prices, limiting their availability to smaller research labs and pilot-scale operations

AMAZEMET

New Paths for Magnetic Powder Innovation

The future of magnetic materials lies in smarter production strategies—tailored powder services and in-house atomization—enabling rapid, precise, and scalable innovation.

To address modern design and research demands, two main strategies are transforming how magnetic alloys are developed:

- Custom Magnetic Powder Production: Specialized providers can deliver advanced powders including FINEMET-type nanocrystalline alloys, magnetocaloric Gd-based materials, and Terfenol-D for magnetostrictive performance. However, emerging systems described only in recent scientific literature—such as Fe-Co-Hf-B amorphous alloys, La(Fe,Si)₁₃-type magnetocaloric compounds, and Fe-Al-Ga magnetostrictive hybrids—highlight the need for flexible production techniques that enable rapid prototyping with precise control over composition, particle size, and morphology.

- In-House Ultrasonic Atomization: AMAZEMET's rePOWDER system allows labs to alloy and atomize magnetic materials onsite, eliminating delays and enabling the fast, iterative development of novel soft magnetic, magnetoelastic, and magnetocaloric systems.

Together, these approaches empower engineers to move beyond the limits of Fe-Si steels and develop next-generation magnetic components for additive manufacturing and functional applications.

METAL POWDERS PRODUCTION

Empowering the Future of Magnetic Materials

AMAZEMET provides critical support for pioneering magnetic alloy research—offering small-scale, high-precision powder production and enabling full control through internal atomization capabilities.

From scientific exploration to industrial prototyping, we support the full journey of magnetic alloy development.

Our team specializes in enabling breakthrough discoveries in magnetics. Whether you're optimizing electromagnetic behavior, developing complex geometries for AM, or replacing outdated materials, AMAZEMET offers:

Custom Magnetic Powders for R&D

Research-scale batches of magnetic powders tailored to your needs.

Powder Quality Optimized for AM Processes

Spherical morphology and tight PSD control for compatibility with LPBF, binder jetting, or cold spray.

Expert Support for Application-Driven Solutions

Consultation and collaboration with materials scientists who understand your application challenges.

AMAZEMET SERVICES & REPOWDER

Experimental Magnetic Powders and In-House Production with rePOWDER

With rePOWDER, you're equipped to transform novel alloy concepts into processable magnetic powders without leaving your lab.

1. Custom Powder Production

- Development of next-generation magnetic alloys including:

- Fe-Co-Nb-B nanocrystalline soft magnetic systems

- Gd-Tb magnetocaloric alloys with enhanced temperature response

- Fe-Ga (Galfenol) magnetostrictive alloys with tunable magnetoelastic performance

- R&D-ready batches starting from 10 grams

- Engineered for precision AM and functional testing

2. In-house Powder Production with rePOWDER

- Create your own library of experimental magnetic powders

- Full control over alloy design, melting, and atomization

- Compatible with reactive or high-melting-point materials

- High atomization efficiency (up to 80%) due to narrow particle size distribution

BOOST YOUR PROJECT WITH AMAZEMET

Whether you’re advancing soft magnetic alloys, exploring magnetocaloric cooling, or developing magnetoelastic devices—AMAZEMET offers the materials, technology, and expertise to support your success.