Solutions for Demanding Industries

Your projects require the highest precision and advanced solutions?

AMAZEMET offers a wide range of engineering services, including TIG welding, CNC machining, and access to advanced technologies such as metal 3D printing, hot isostatic pressing (HIP), and ultrasonic atomization. This enables us to deliver even the most challenging projects.

AMAZEMET offers a wide range of engineering services, including TIG welding, CNC machining, and access to advanced technologies such as metal 3D printing, hot isostatic pressing (HIP), and ultrasonic atomization. This enables us to deliver even the most challenging projects.

Collaborate with AMAZEMET

WE WANT TO MEET YOUR EXPECTATIONS

There are many reasons to choose AMAZEMET as your partner. What are your needs? If you answer “yes” to any of the following questions, we are here to help solve your challenges.

WHO WE ARE LOOKING FOR

WHO DO WE WANT TO COLLABORATE WITH?

We understand that successful collaboration relies on a clear understanding of mutual needs. We work with companies that have specific expectations:

Small / Medium Production Runs

We are seeking clients with small to medium-scale production needs, particularly in welding and CNC machining services.

Demanding Projects

We are looking for projects involving complex components that require vacuum technology or compliance with high standards in the food, pharmaceutical, and industrial sectors.

Focus on Quality

We want to collaborate with clients who prioritize quality and reliability in production and are searching for a partner to execute complex, demanding engineering projects.

Process Integration

We are interested in projects requiring precision and advanced technology, where the integration of multiple engineering processes—such as welding, CNC machining, and metal 3D printing—is essential.

Comprehensive Solutions

We are open to working with companies that need end-to-end solutions—from mechanical and electronic design to full production execution, complete with technical documentation.

Integrated Approach

We prefer projects that allow close collaboration, involving material research and production process optimization, to deliver ready-to-use, integrated technological solutions.

OUR OFFER

DISCOVER OUR CAPABILITIES

With years of experience, we provide a unique combination of expertise and cutting-edge technologies. Collaborating with international partners and utilizing our state-of-the-art research facilities, we ensure your projects are executed using the latest innovations. Our in-house machinery park and full control over production processes give us a dependable advantage you can trust.

TIG Welding

We specialize in high-precision TIG welding, crucial for complex structures and materials with demanding requirements.

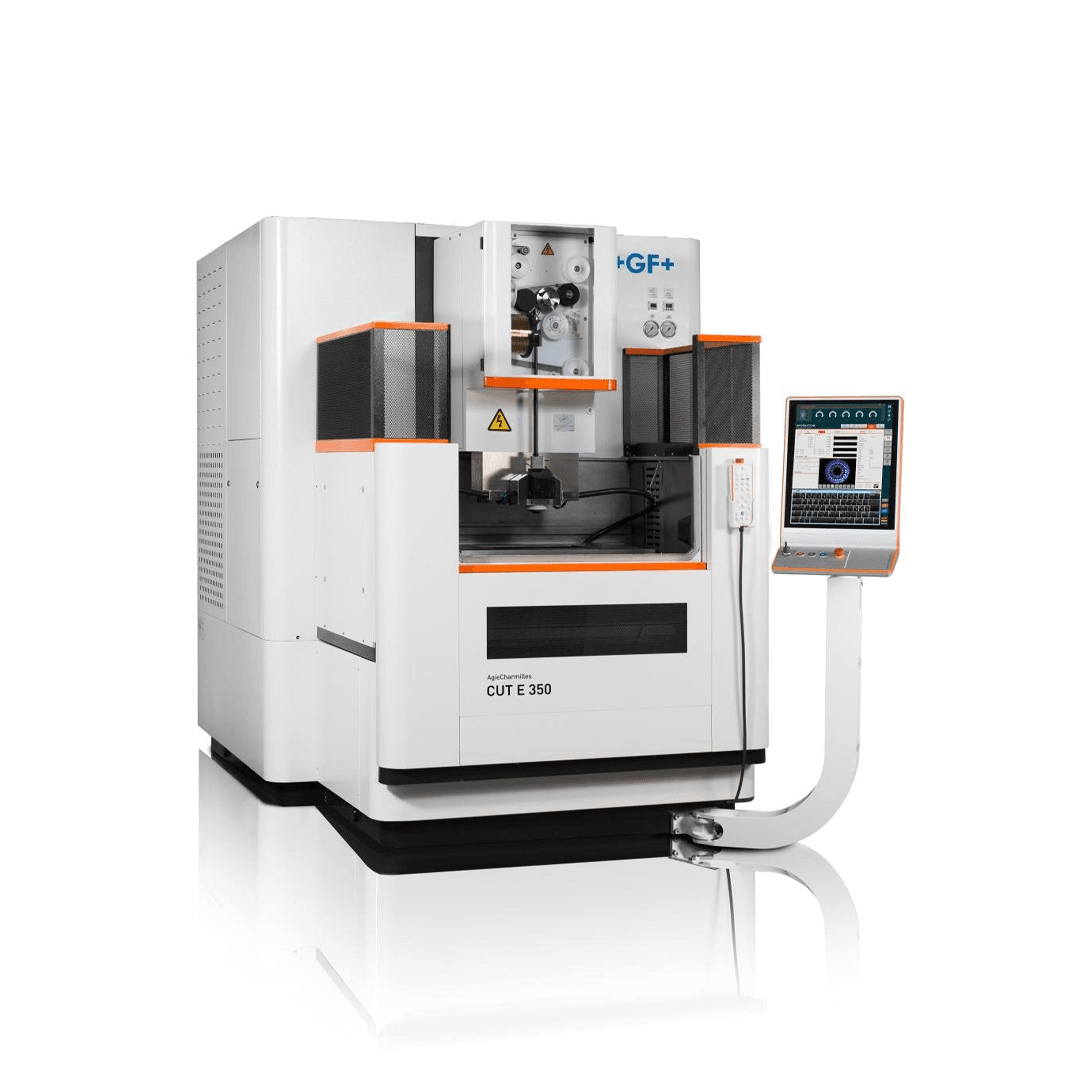

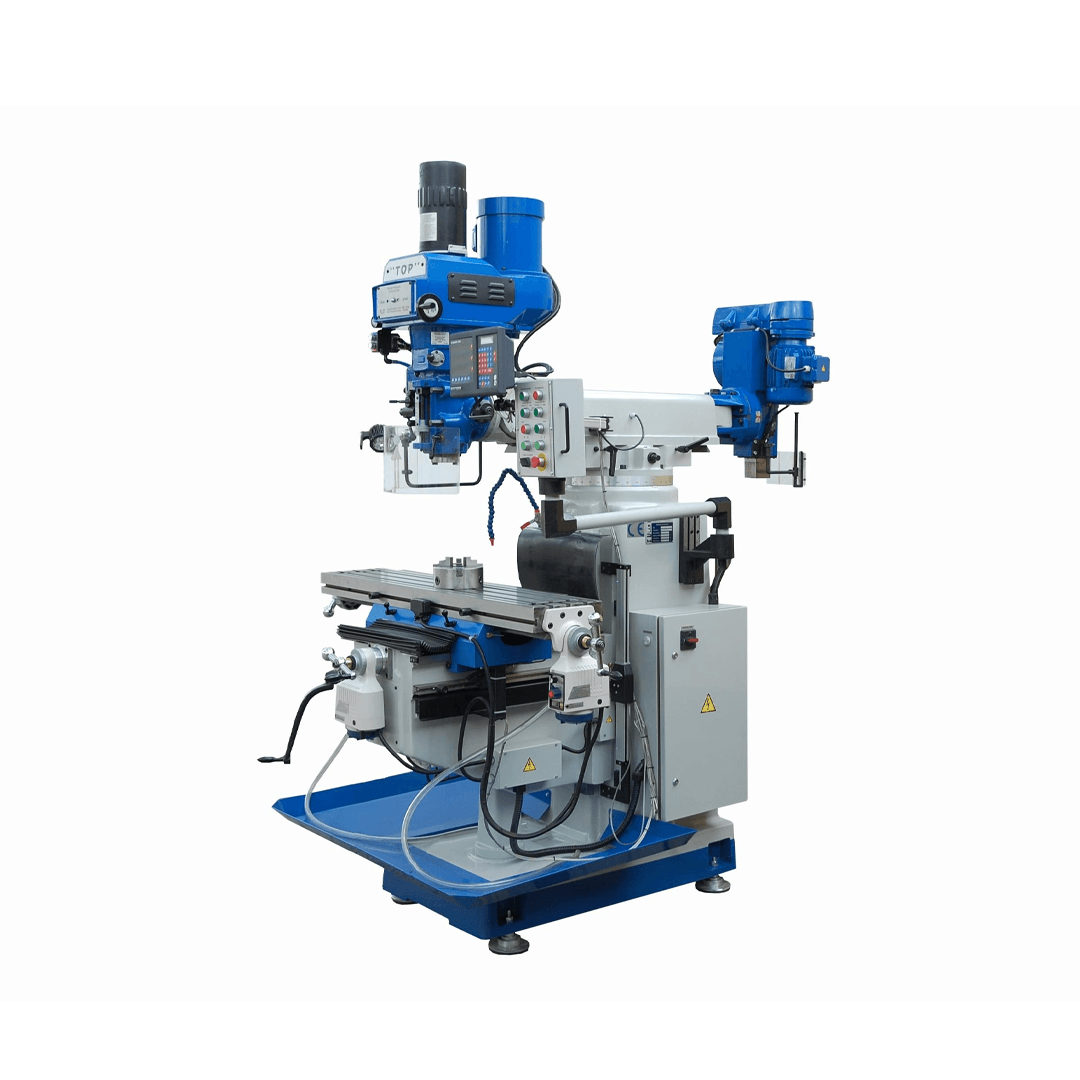

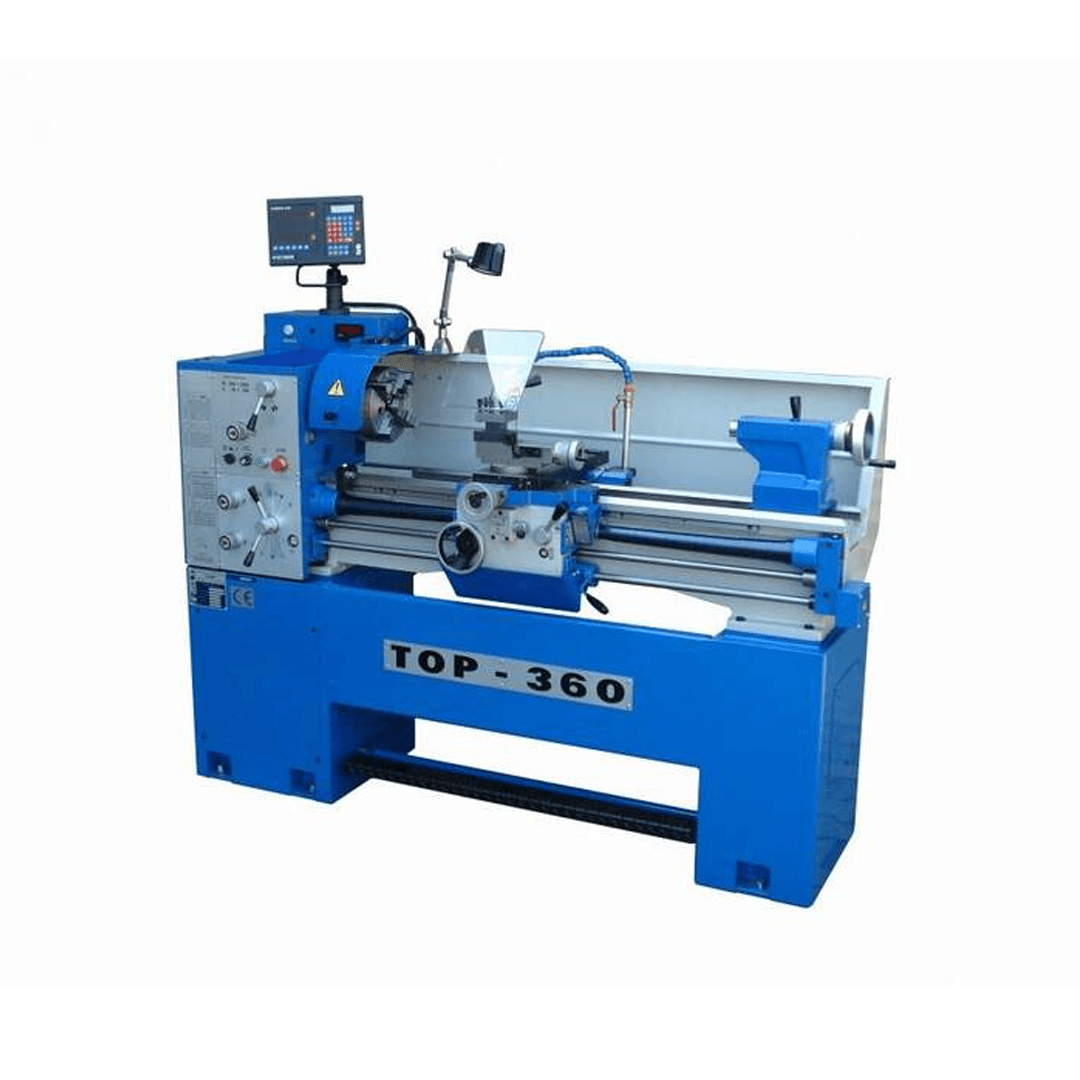

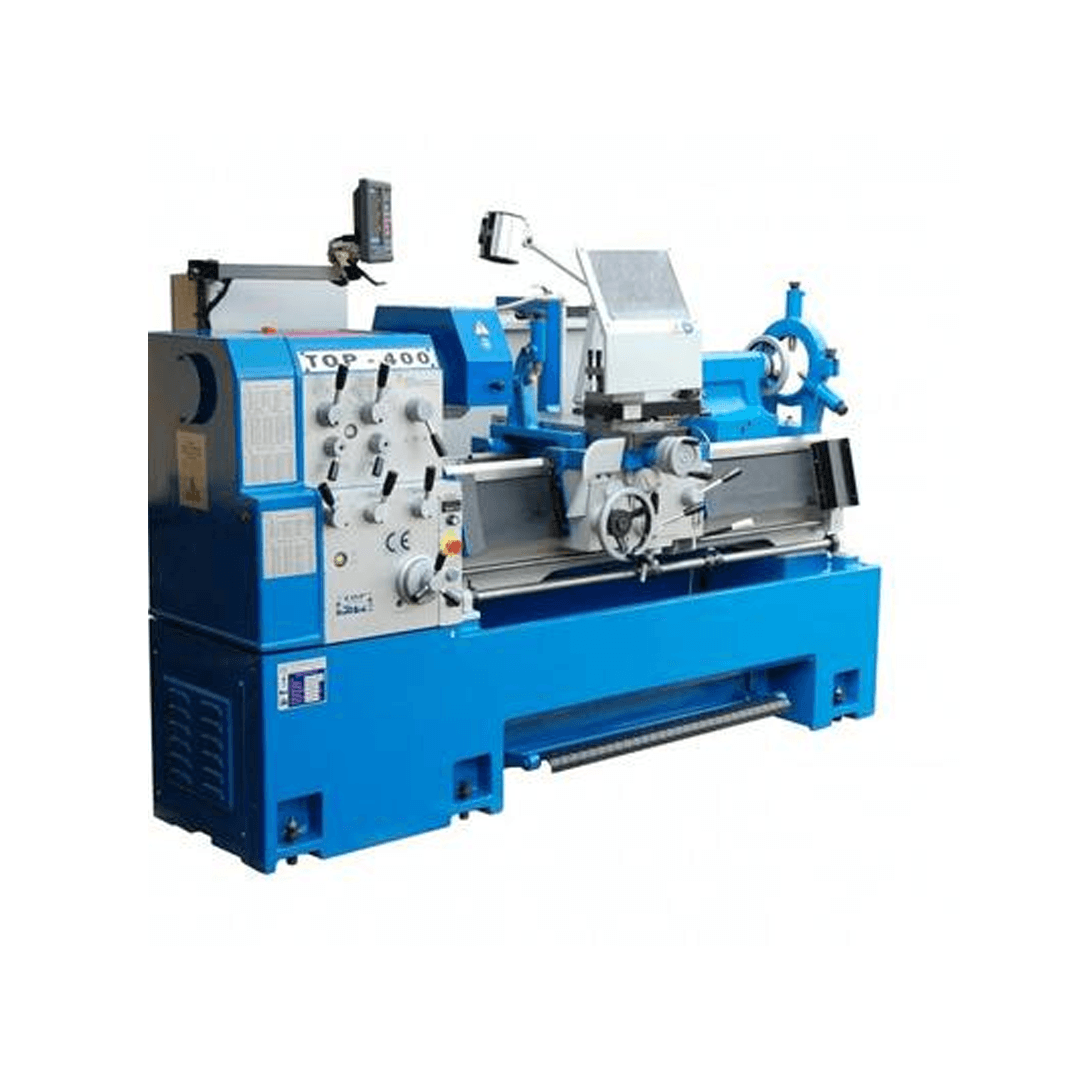

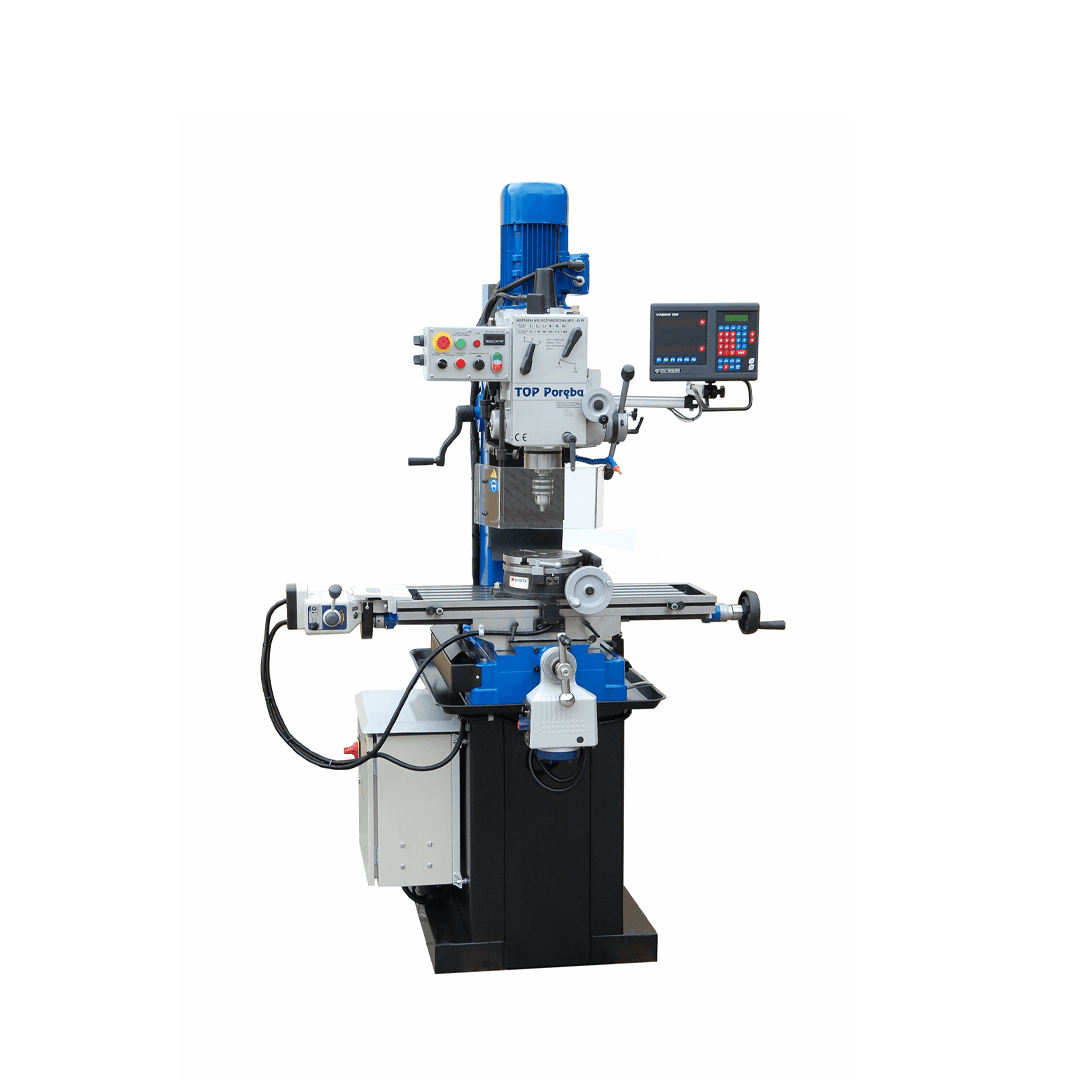

Precision CNC Machining

Our advanced CNC machining services deliver exceptional quality and consistency, even for the most challenging projects.

Prototype and Small-Scale Production

We offer fast and efficient prototyping and small-batch production, enabling rapid implementation and testing of innovative solutions.

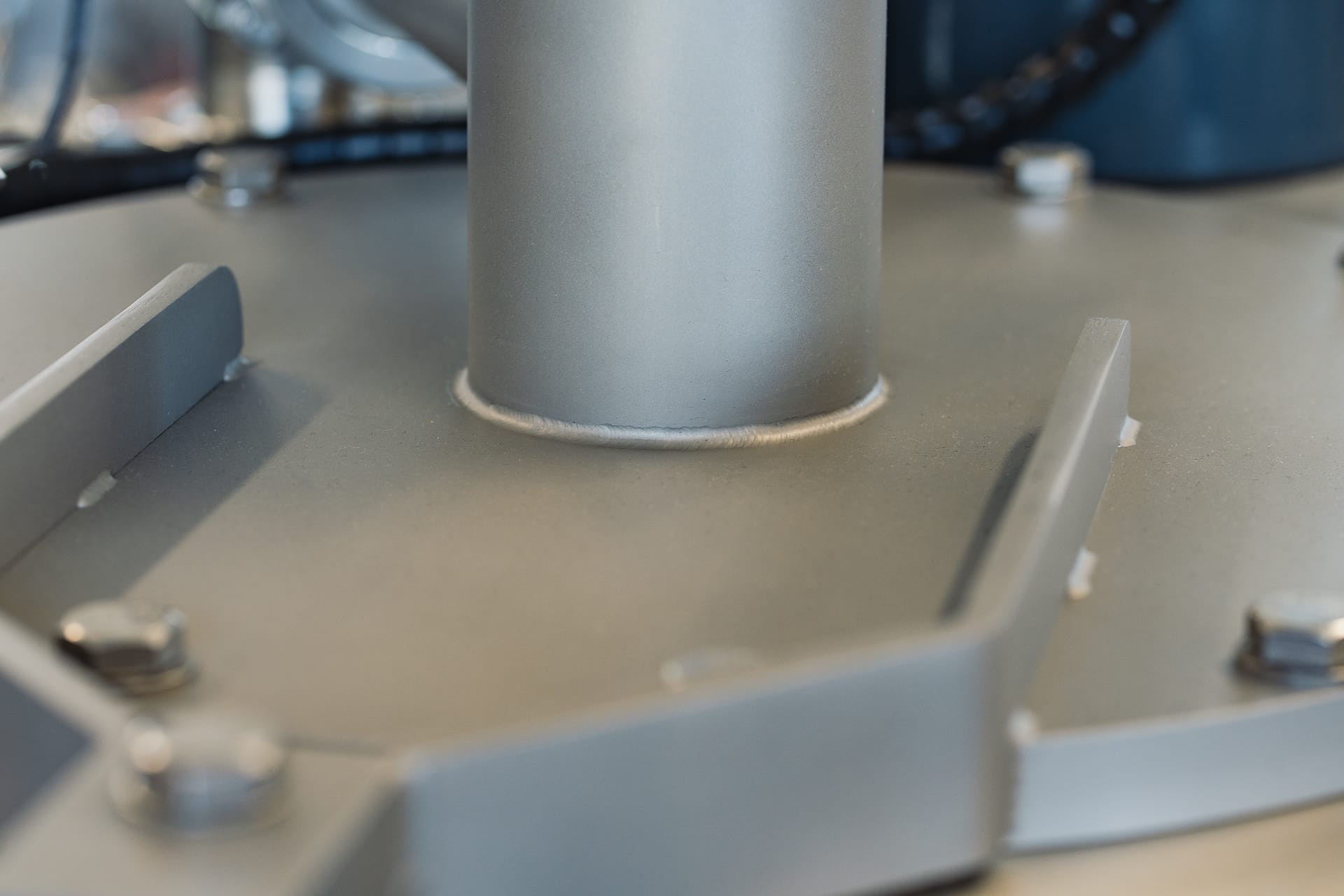

Metal 3D Printing

Using additive manufacturing technologies, we create complex, multilayer components with exceptional precision and minimal material waste.

Hot Isostatic Pressing (HIP)

Our HIP technology eliminates porosity and enhances material strength, significantly improving the durability and quality of finished products.

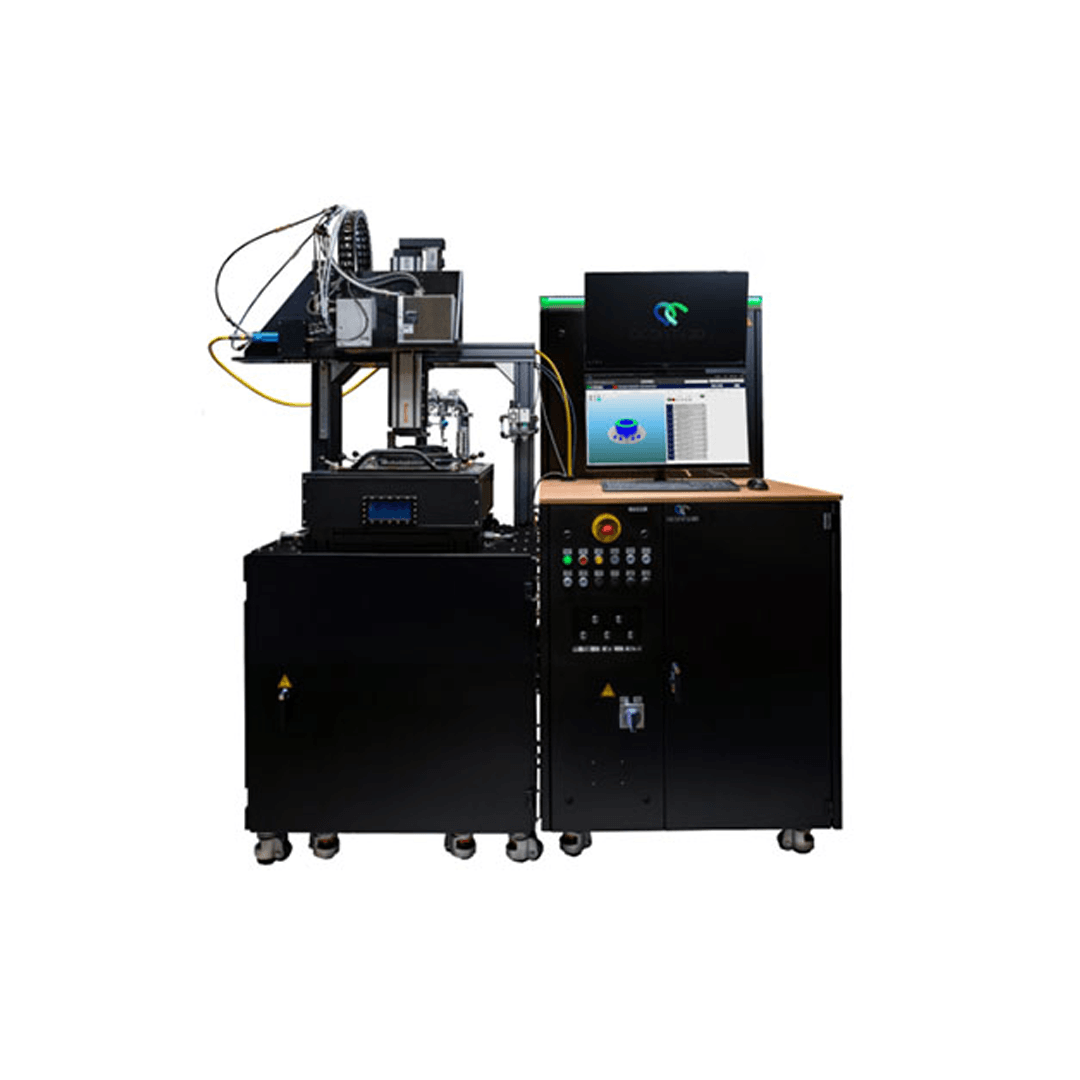

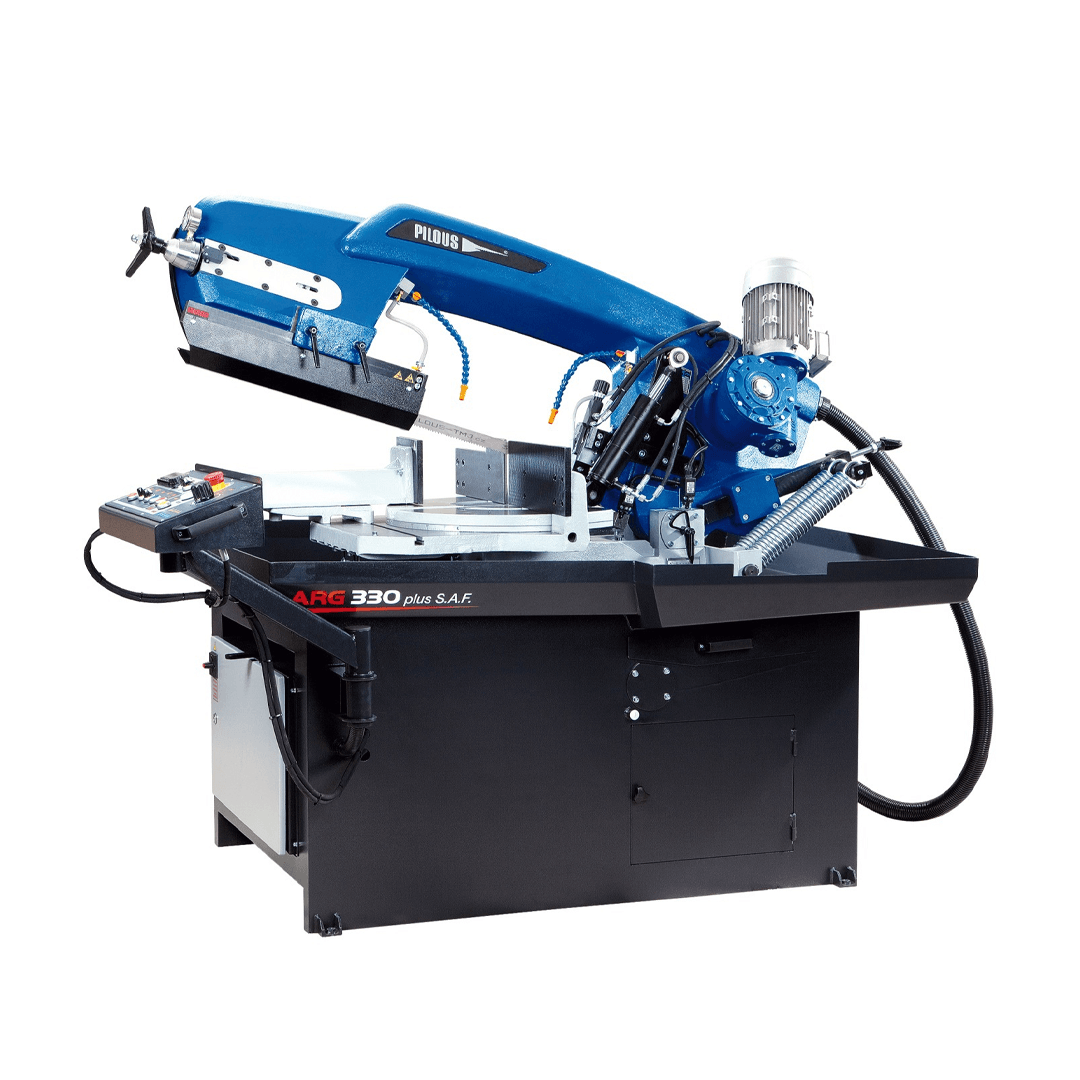

In-House Machinery Park

Our advanced facilities include cutting-edge equipment, enabling us to handle complex and custom projects from start to finish.

In-House Equipment Design

We design all our machines internally, ensuring full control over every stage of the production process.

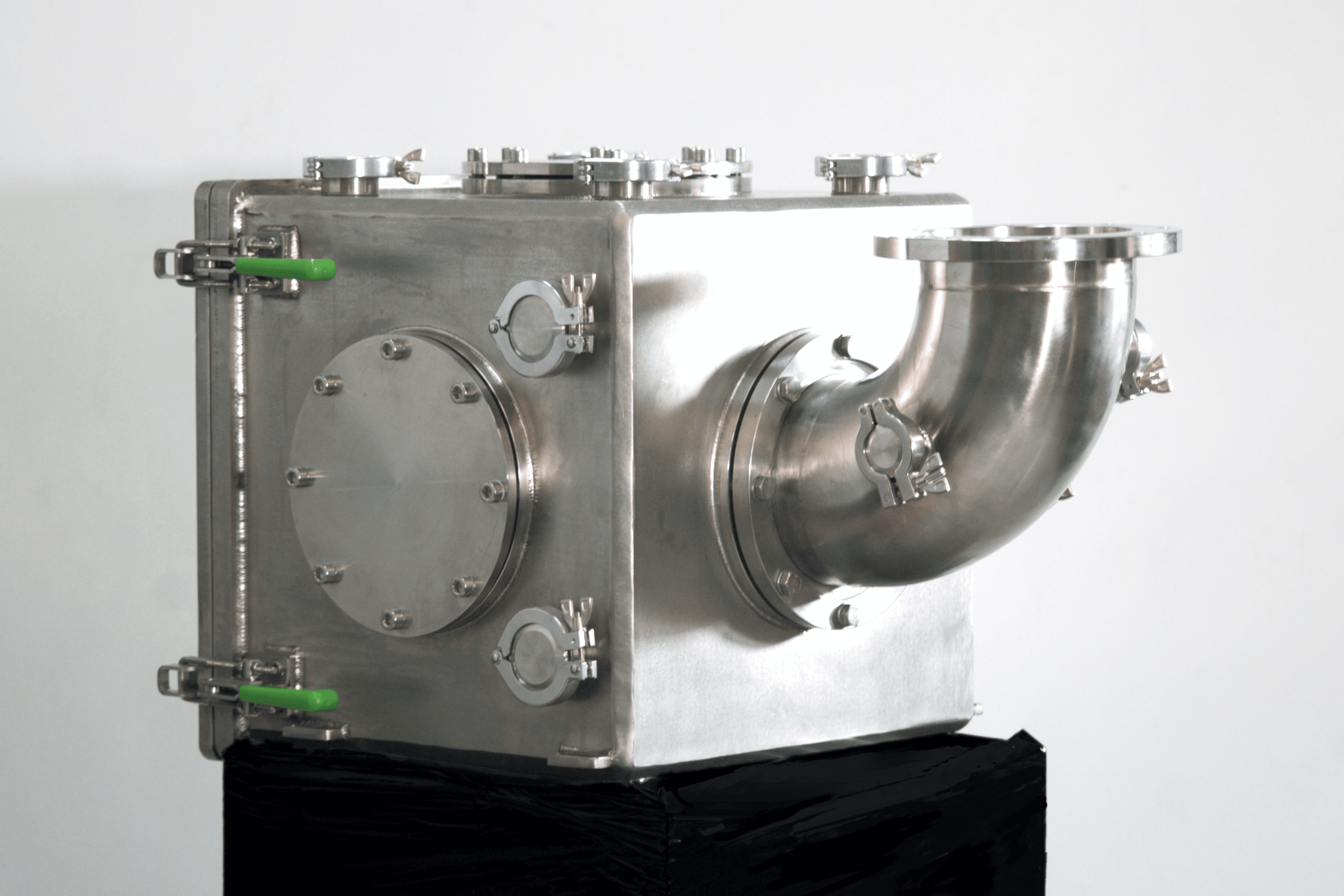

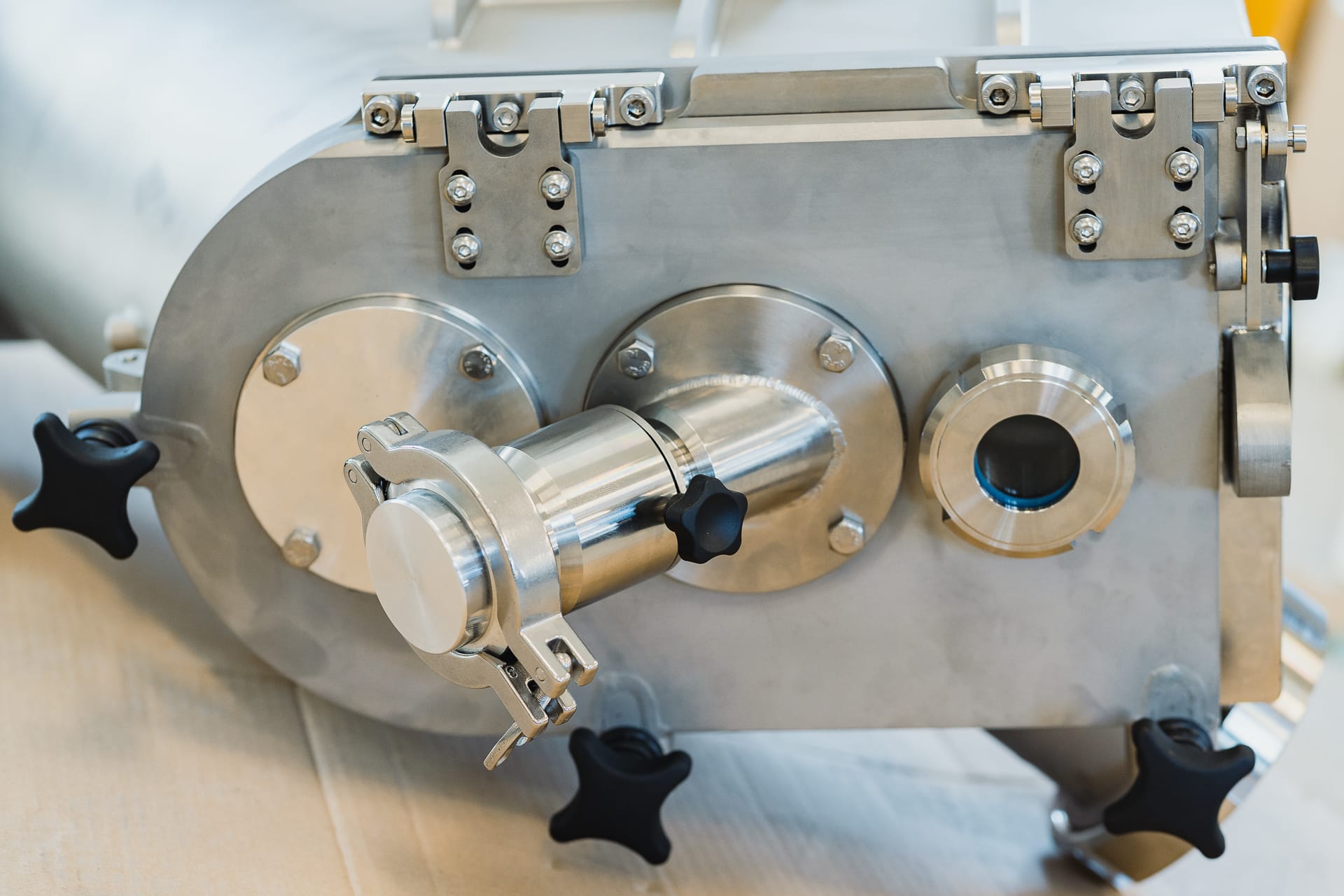

Vacuum Technology

We use advanced vacuum systems to process materials under controlled atmospheric conditions, essential for high-precision operations.

Material Research

Our team conducts advanced material property analyses, enabling process optimization and enhanced product quality.

OUR MACHINES SPECIFICATION

OUR MACHINERY PARK

Our comprehensive machinery park features not only standard equipment for machining and welding but also cutting-edge technologies that provide our clients with a competitive advantage. These include metal 3D printers, ultrasonic atomizers, and a variety of laboratory devices specialized in metallography.

OUR PROJECTS

SEE THE RESULTS OF OUR WORK

We are dedicated to ensuring our clients are fully satisfied with the outcomes of our collaboration. Browse through photos of our completed projects and discover why working with us is the right choice.

ABOUT US

Amazemet is a Polish company rooted in the Warsaw University of Technology, specializing in advanced engineering technologies, including design, construction, and CNC machining. With extensive experience, we excel in producing precision components, including TIG-welded structures, for demanding technological industries.

We are experts in independently designing and manufacturing vacuum technology devices, allowing us to control and optimize production processes under complex conditions. Our metal 3D printing services enable the creation of intricate, high-quality components with minimal waste. Through hot isostatic pressing (HIP), we improve the mechanical properties of parts by eliminating structural defects such as porosity.

Our state-of-the-art research facilities and partnerships with international companies and scientific institutions ensure that our technologies meet the highest global standards. We also specialize in prototyping and small-scale production runs, offering our clients the ability to quickly implement innovative solutions. With our in-house machinery, we maintain full control over production quality.

Comprehensive Engineering Services

WHAT MAKES US DIFFERENT

01

Innovative Machinery Park

Our advanced facilities feature state-of-the-art equipment, enabling us to execute complex and custom projects throughout the entire production cycle.

02

Expertise in Complex Projects

We specialize in tackling challenging, unconventional projects that demand advanced technological solutions and the integration of multiple engineering disciplines.

03

Precision Welding for Demanding Industries

We deliver high-precision welding services for industries with strict requirements, including vacuum, food, and pharmaceutical applications, where hygiene and airtightness are critical.

04

Custom Software and Technical Documentation

Our in-house programming team develops tailored software and provides complete technical documentation for every project.

05

Complete Control Over Production

All work is carried out in our facility using our own machinery, ensuring full control over the production process. We do not outsource tasks.

06

Comprehensive Project Services

We offer fully integrated services, from designing mechanical and electronic systems to complete production and assembly.

07

Material Consultancy and Testing

We provide expert material consultancy and conduct testing to resolve material challenges and recommend the most effective solutions.

08

Material Flexibility

We work with both customer-supplied materials and materials we source ourselves, accommodating welding and CNC machining needs.

09

Highly Skilled Team

Our work is carried out by a qualified team, including certified welders and IWE engineers, ensuring excellence in every project.

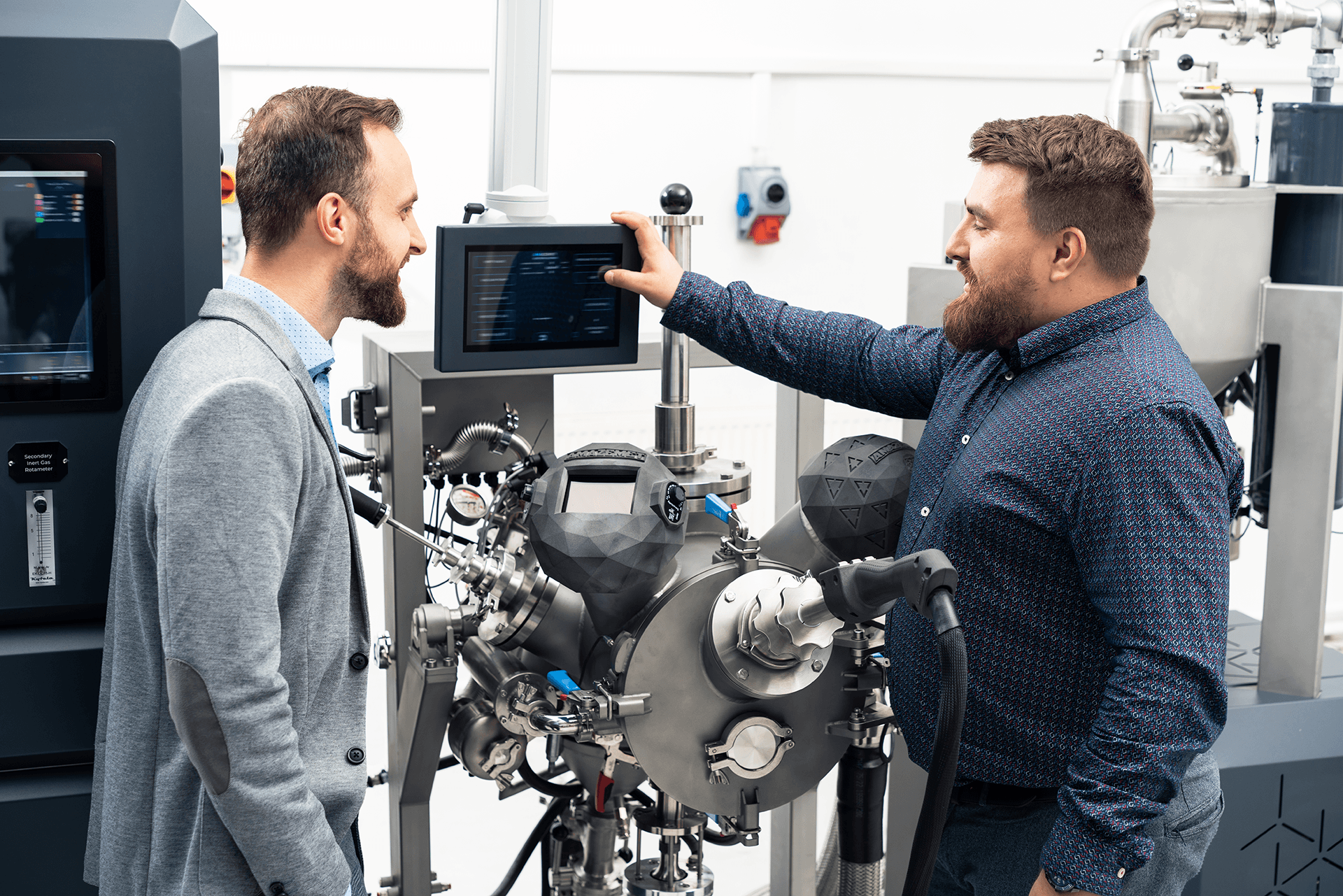

Meet Our Experts

Get to know the people behind AMAZEMET and explore their areas of expertise. The AMAZEMET team is a group of highly skilled specialists who combine extensive knowledge and experience in various engineering disciplines to deliver innovative technological solutions.

Krzysztof

Niedźwiecki

Production

Wojciech

Łacisz

Welding

Paweł

Czarnacki

Technology

Jakub

Ciftci

3D Printing, HIP

Adam

Mysiukiewicz

CNC

Assembly Team

Our assembly team, made up of expert assemblers and electromechanics, oversees the final assembly of devices, ensuring precision and the highest quality in every project.

Welding Team

AMAZEMET’s welding team specializes in TIG welding, using advanced equipment to deliver superior precision and quality. They meet the highest standards for applications in vacuum, food, and pharmaceutical industries.

Design Team

Our design team develops intricate mechanical and electronic systems using 3D design tools such as Siemens NX, SolidWorks, and AutoCAD. Their designs are tailored to meet customer requirements, from concept to the finished product.

Electronics and Software Team

The electronics and software team designs dedicated systems and controllers using programming languages like C++, Python, and VHDL. They integrate software with mechanical systems to ensure seamless compatibility and optimal performance.

CNC Machining Team

Our CNC machining team is equipped with state-of-the-art CNC machines and manual workstations. We specialize in precision milling, turning, and drilling operations, delivering high-quality and repeatable results for every project.

Request a Quote for Your Project

FREE QUOTE

If you are looking for a trusted partner to execute advanced engineering projects, feel free to reach out. Our team of experts is ready to support you at every stage of the process—from material consultancy and design to production and process optimization. AMAZEMET specializes in manufacturing small- to medium-sized production series and executing complex projects that require precise CNC machining, welding, or metal 3D printing. We welcome collaborations with companies that need technologically advanced solutions and a combination of multiple engineering processes. Our company is prepared to take on even the most challenging assignments.