Precious metals, such as silver (Ag), gold (Au), and the platinum group metals (PGMs), including platinum (Pt), iridium (Ir), ruthenium (Ru), and palladium (Pd), play a central role in many advanced industries. Their rarity, high economic value, and unique properties make them indispensable in electronics, brazing, catalysis, laboratory equipment, and jewelry. However, processing these materials into a usable powder form presents unique challenges. Precious metals atomization is a crucial step in enabling modern manufacturing methods, such as additive manufacturing and precision casting.

While several atomization techniques exist, ultrasonic atomization is gaining ground as a flexible, cost-efficient method, especially for high-value, high-quality, or small-batch materials

Why Atomize Precious Metals?

Turning precious metals into powder form allows manufacturers to use advanced production methods such as additive manufacturing (AM), coating, brazing and powder metallurgy. Powder-based processes help reduce material waste, enable design innovation, and ensure tighter process control, all especially important when working with expensive materials.

Key Applications of Atomized Precious Metals

- Jewelry and High-End Watchmaking

Atomized gold, silver, platinum, and iridium alloys enable precise casting and even direct 3D printing of intricate, customized designs. - Catalysis

Platinum, palladium, and ruthenium are widely used in fuel cells, emissions systems, and chemical reactors due to their catalytic activity. - Glass Manufacturing

Platinum-rhodium and platinum-iridium alloys are essential in bushings and feed-throughs for glass fiber production, operating at extreme temperatures and in corrosive environments. - Brazing Alloys

Silver-based and gold-palladium alloys are widely used in brazing, a joining method for components in aerospace, electronics, and medical tooling. Powder-form brazing alloys ensure consistent flow, precise dosing, and strong, corrosion-resistant joints. Atomized powders are especially useful for paste formulations and AM-based brazing preforms. - Laboratory and Analytical Equipment

Platinum and iridium crucibles and electrodes are valued for their chemical inertness and thermal stability, crucial for high-purity applications. - Electronics and Sensors

Palladium, ruthenium, and gold are used in connectors, resistors, and microchips, where corrosion resistance and conductivity are critical.

Challenges in Precious Metals Atomization

Handling and atomizing precious metals involves several technical and economic obstacles:

- High Melting Points

Especially for Pt, Ir, Ru, which require specialized heating methods like plasma or induction systems. - Evaporation and Loss of Alloying Elements

Particularly in Ag and Au at high temperatures, where volatilization can alter composition and increase gold or silver content in the alloy. - Reactivity

Some precious metals react with air or crucible materials at molten states, risking contamination or oxidation. - High Material Cost

Even small losses during processing (e.g., via splatter, sticking, or spatter) can lead to significant financial waste.

Comparison of Atomization Techniques

Several methods exist for atomizing metals into powders, each with trade-offs in cost, quality, and scalability:

- Gas Atomization

Common in large-scale production, but can lead to broad particle size distributions and usually a large scale that might be too big and costly for certain applications. - Water Atomization

Incompatible with precious metals due to high contamination risk and irregular powder particles. - Plasma Atomization

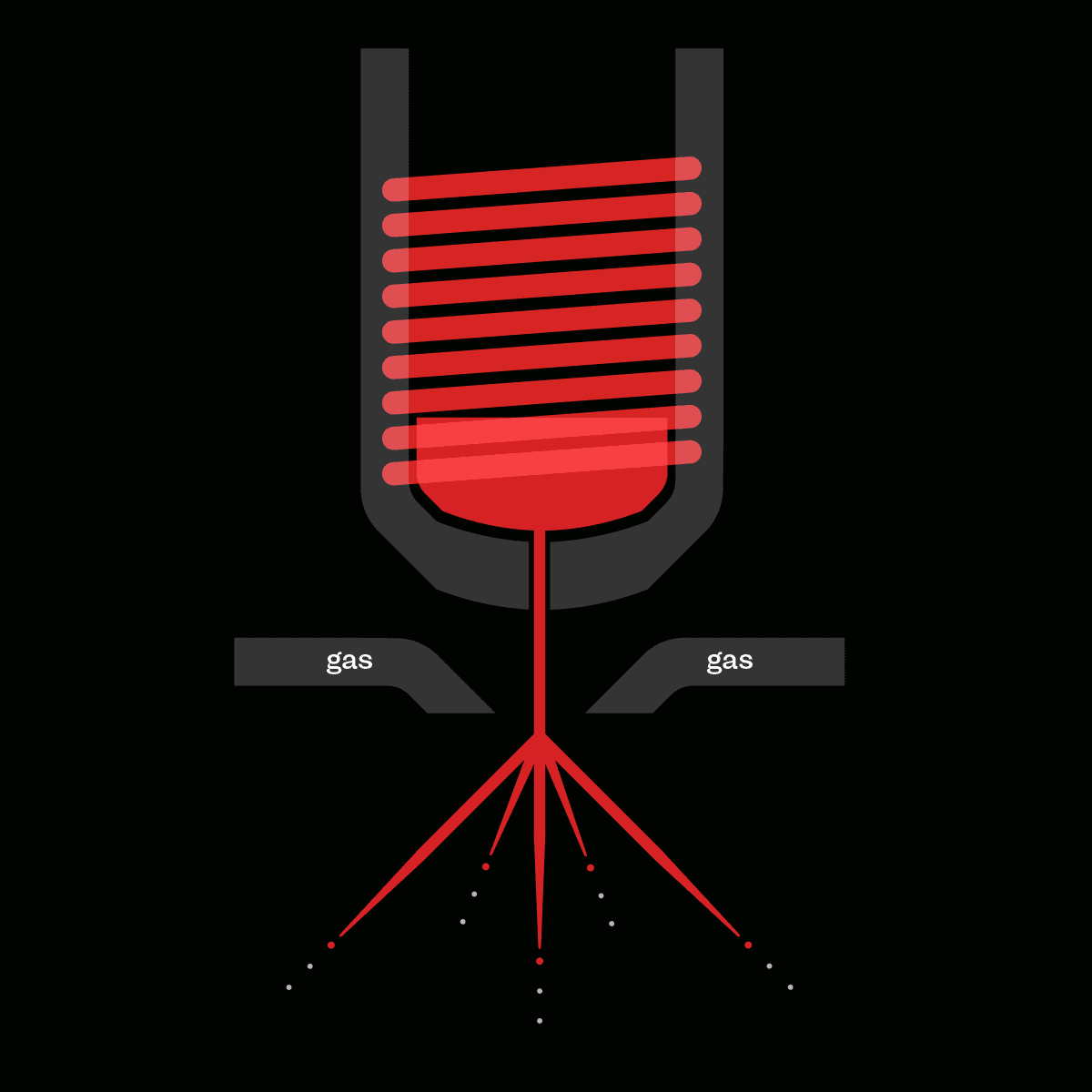

Provides high purity and control but is costly and energy-intensive, often overkill for smaller batches or causes evaporations of alloying elements, e.g., in gold or silver alloys. - Ultrasonic Atomization

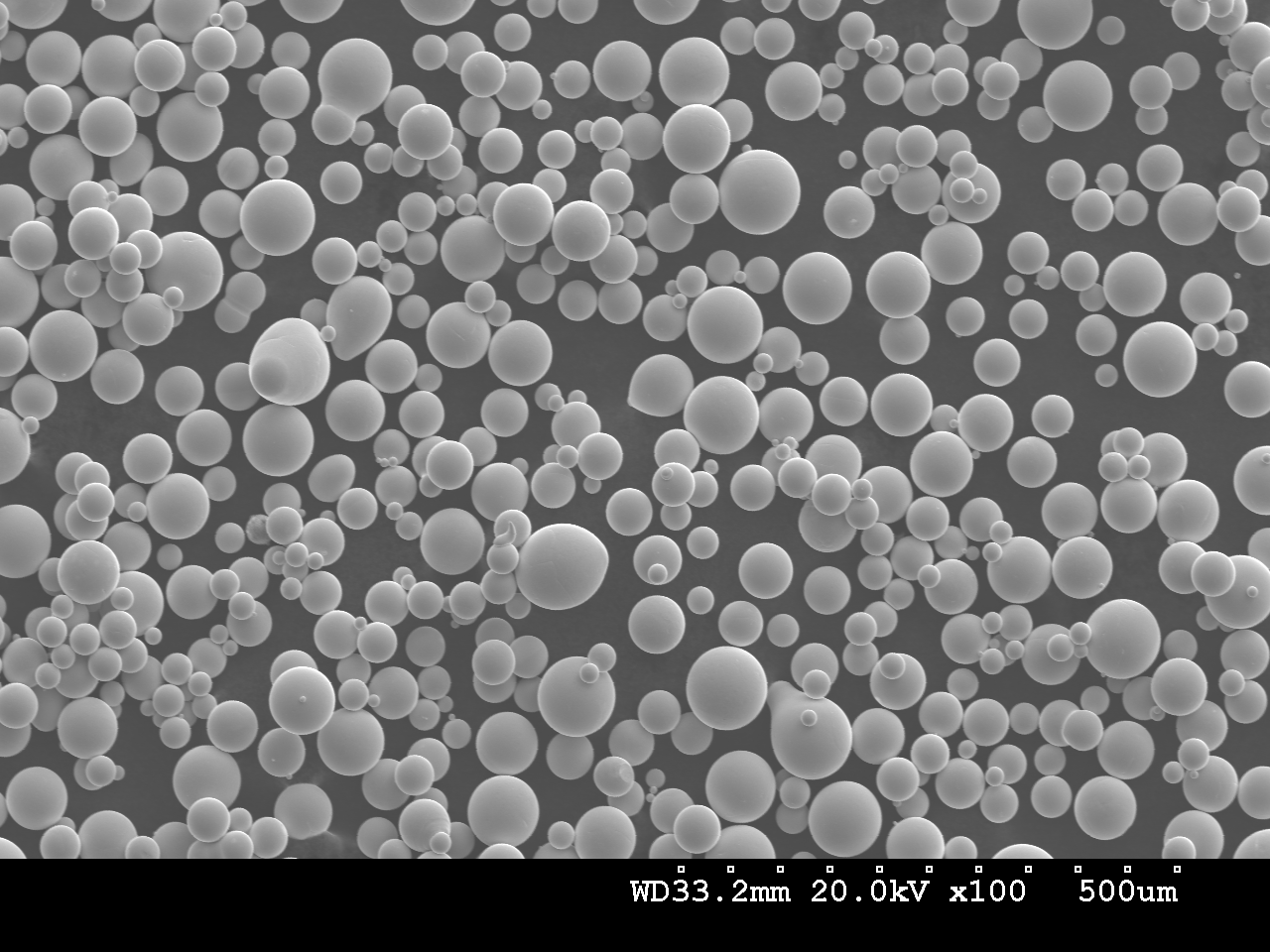

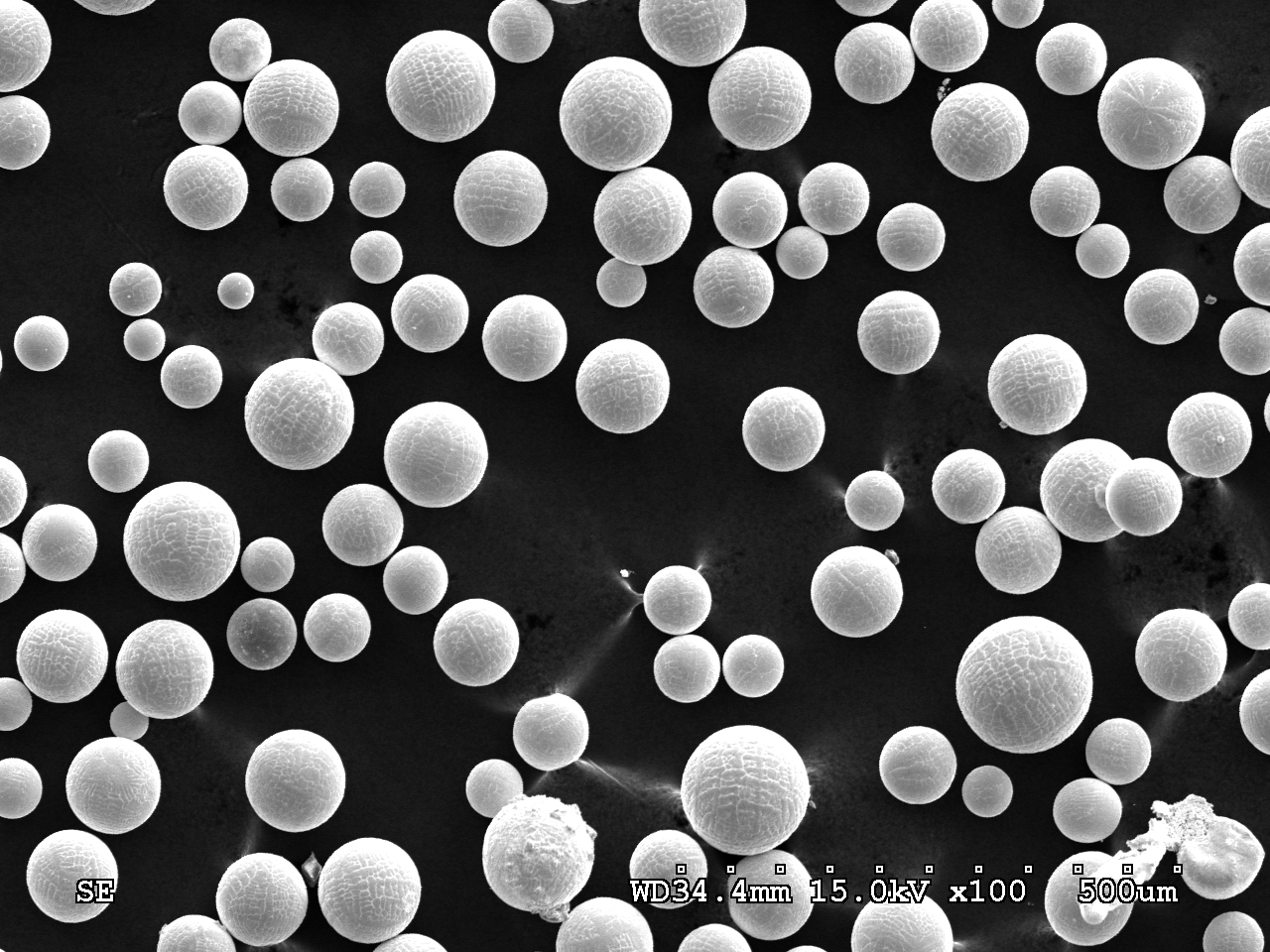

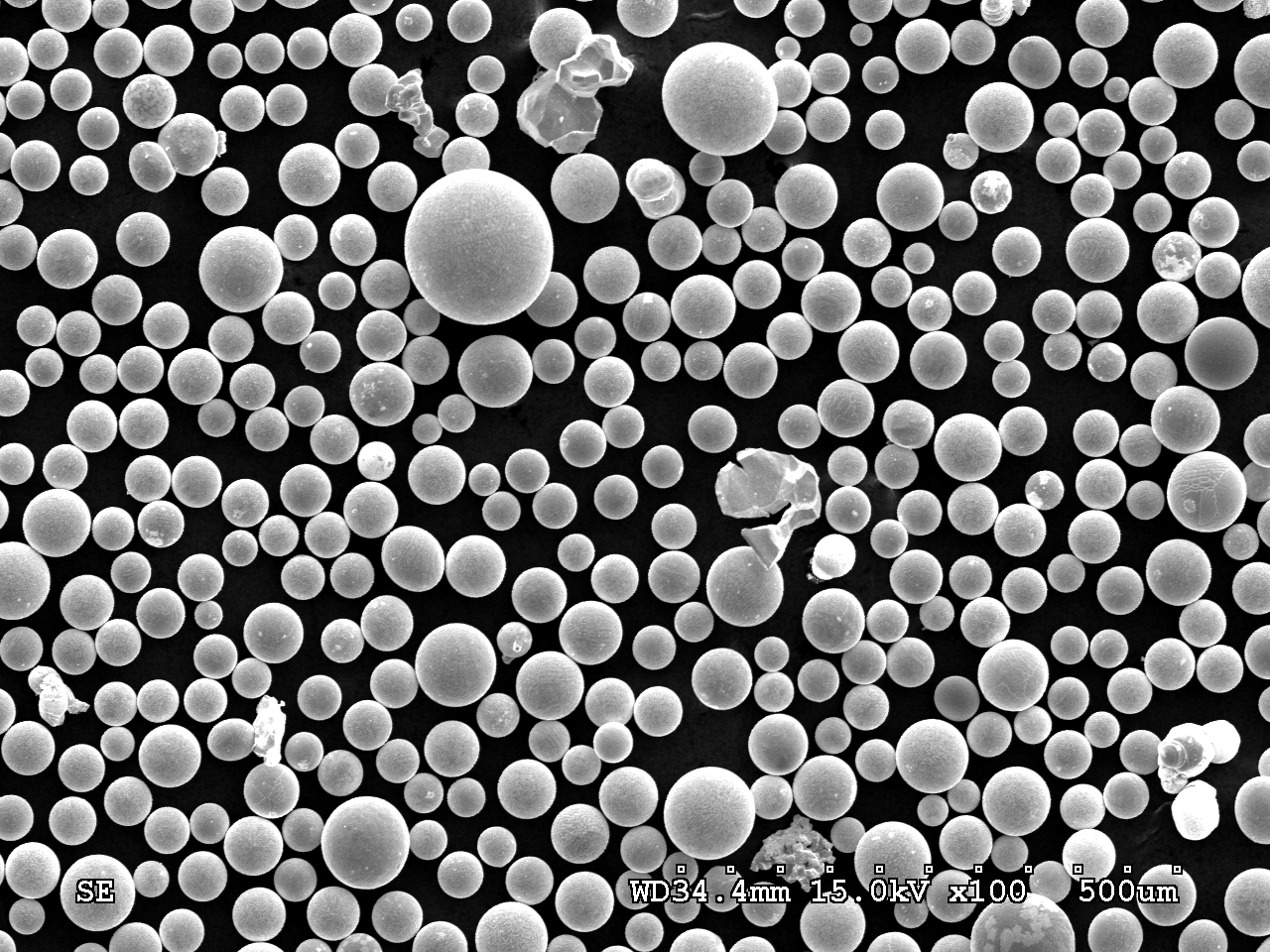

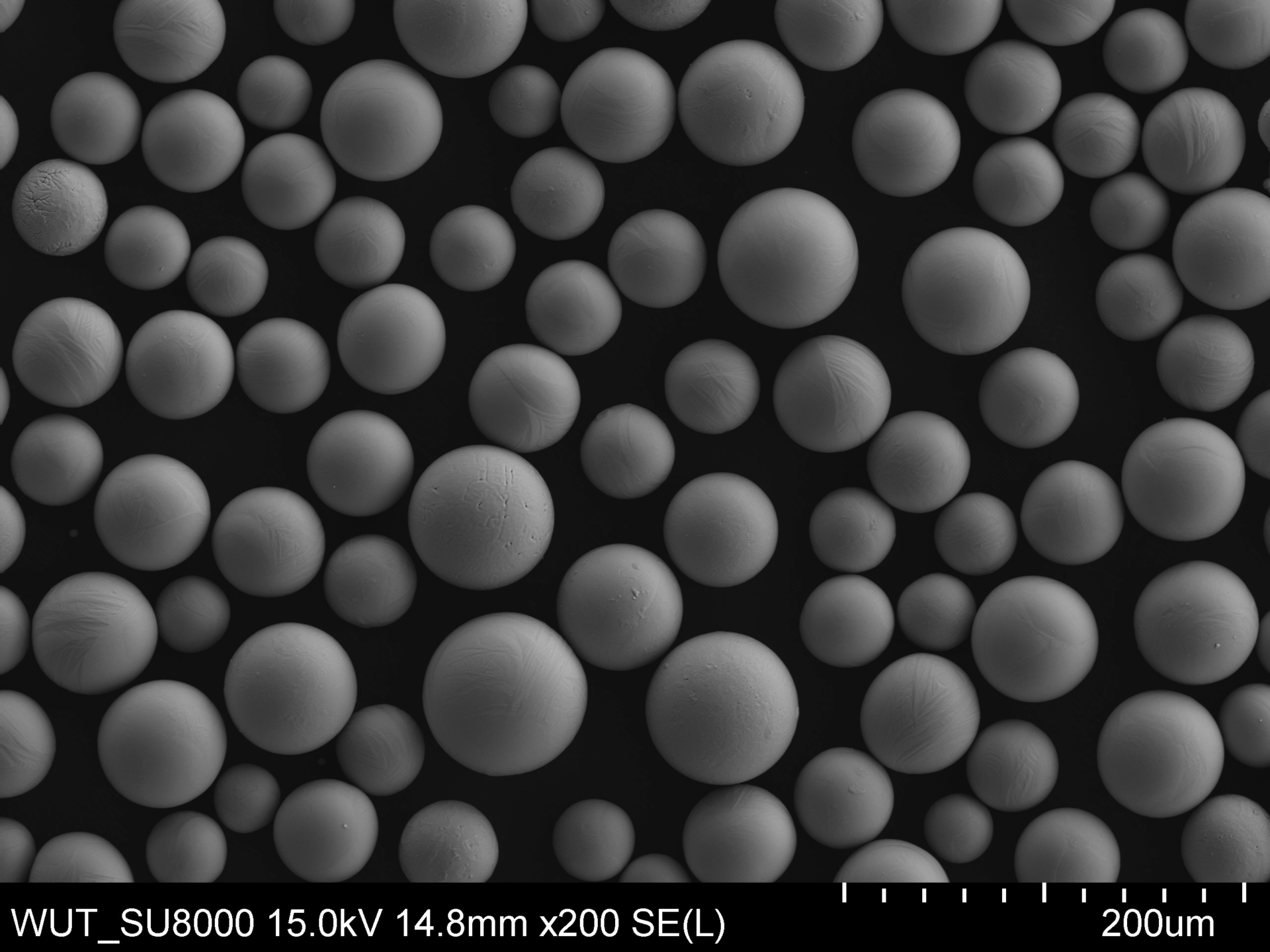

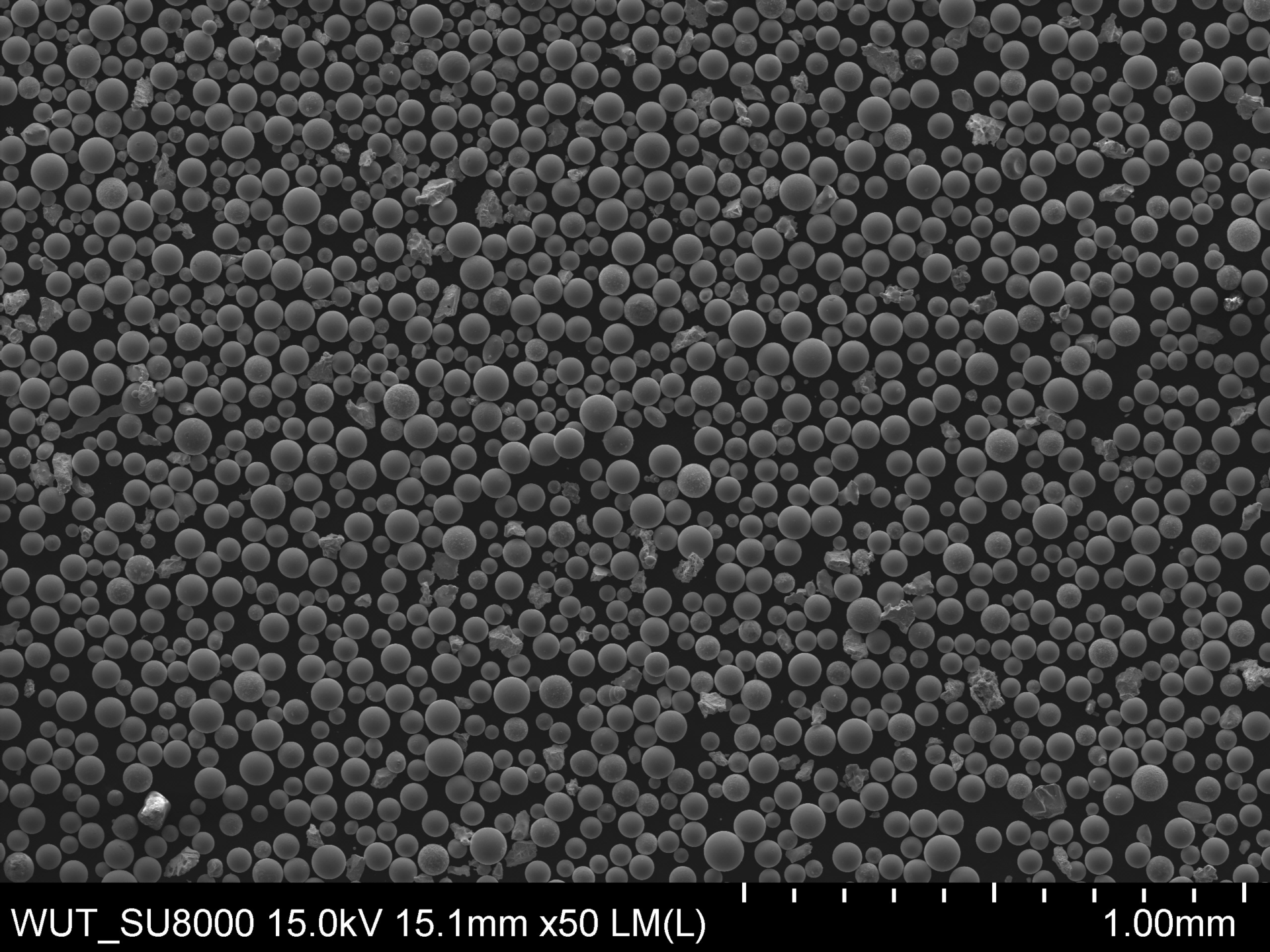

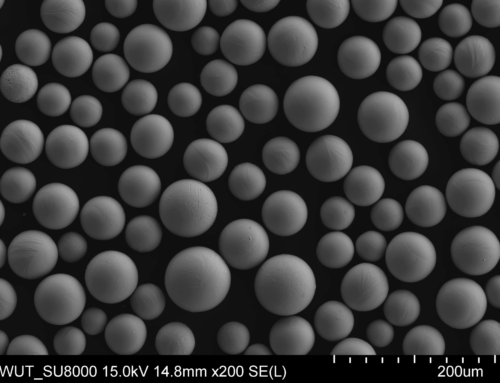

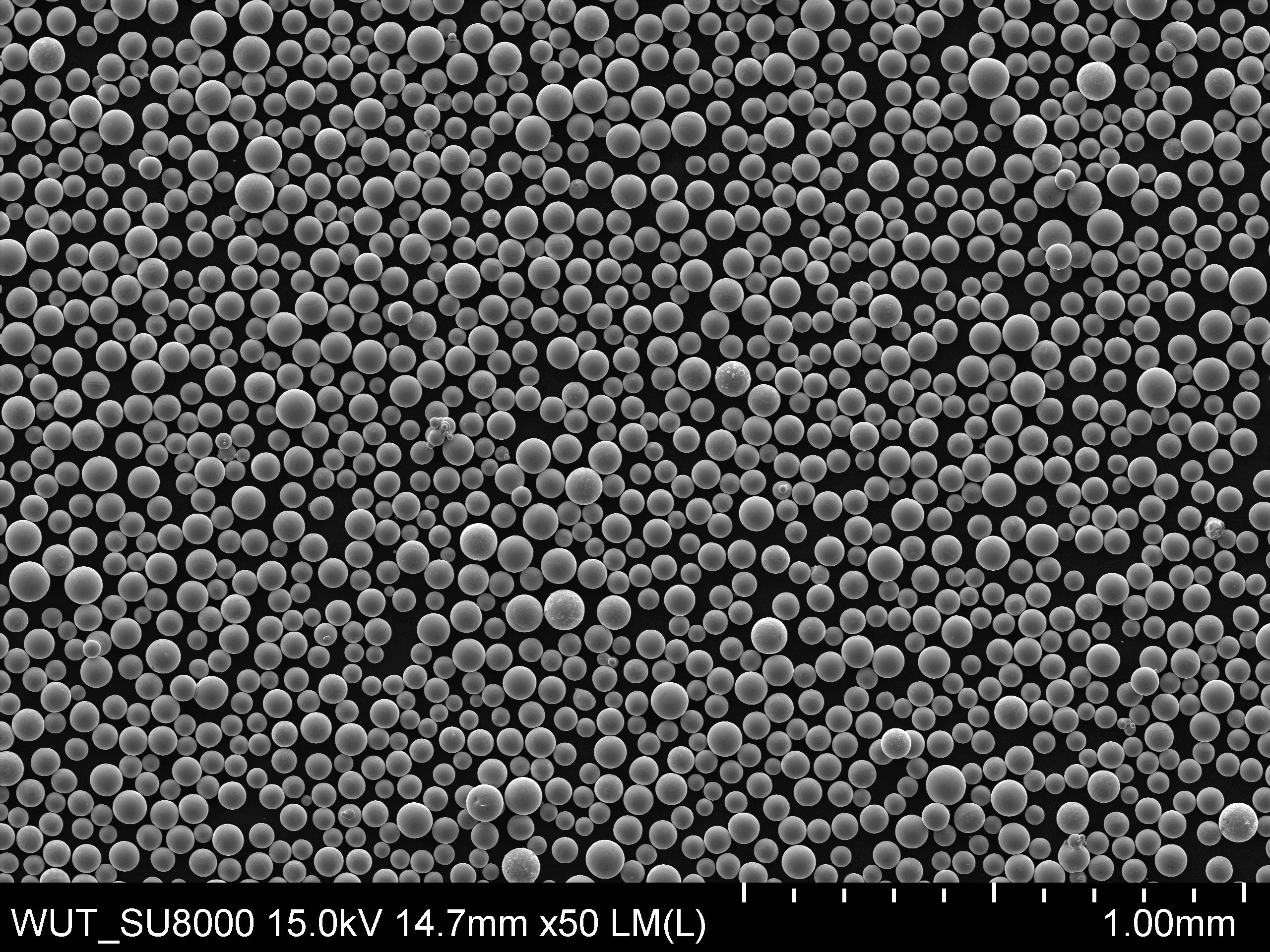

Offers precise droplet size control, excellent sphericity, and minimal material loss. Ideal for R&D, recycling, and low-volume production. Learn more about ultrasonic atomization.

For an overview of available metal powders, including those based on precious metals, visit our catalog.

Tailored Approaches for Each Metal Group

Silver (Ag) and Gold (Au)

These metals, though relatively low-melting, are susceptible to evaporation and contamination. To avoid losses and preserve alloy composition:

- Induction-based ultrasonic atomization is preferred.

- It enables precise temperature control.

- A crucible-based system is ideal for recycling scrap, closed-loop production, and experimental alloy development.

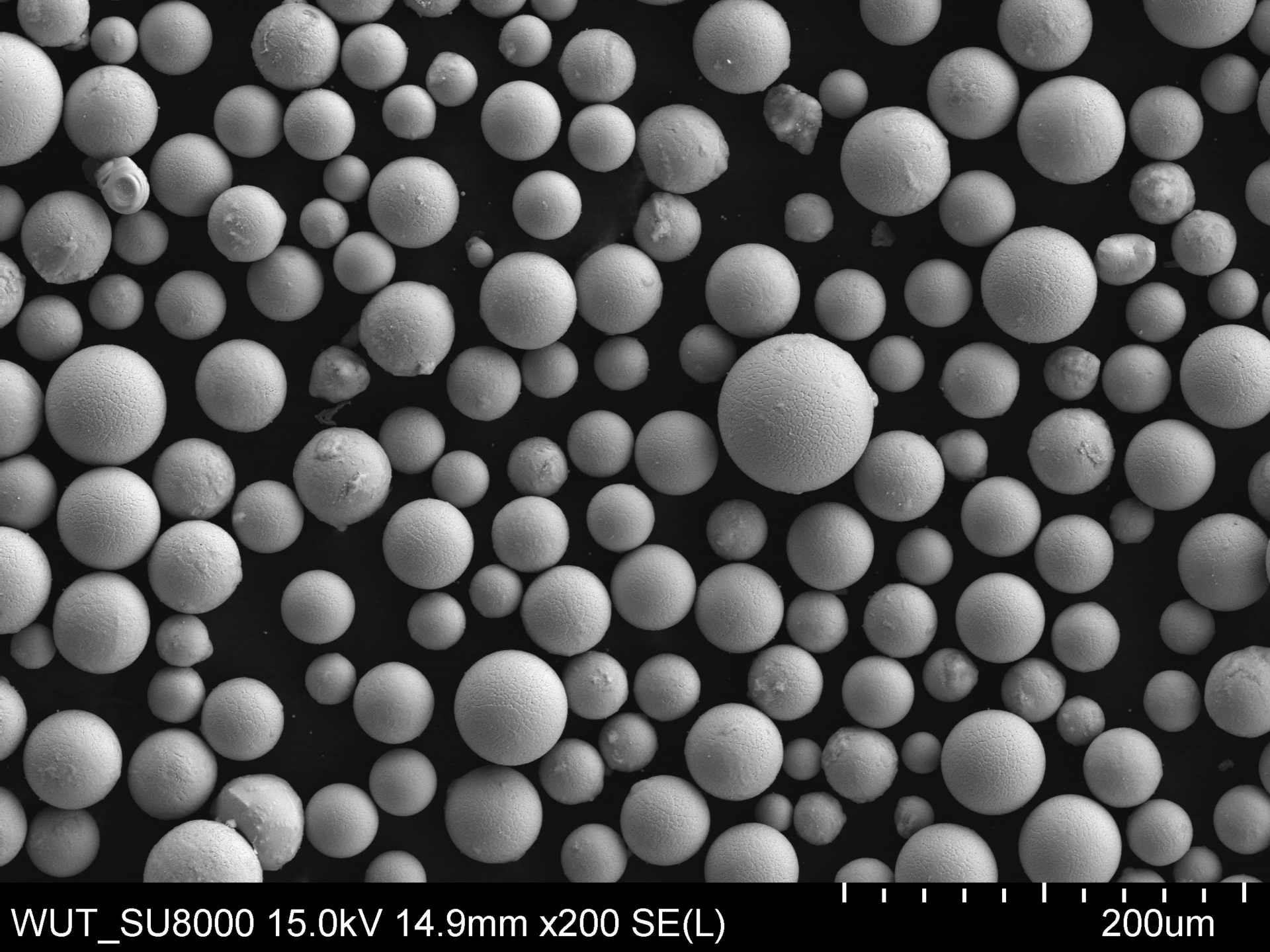

Platinum Group Metals (Pt, Ir, Ru, Pd)

Due to their extremely high melting points, more robust systems are required:

- Plasma-assisted ultrasonic atomization combines thermal plasma for melting and ultrasonic energy for dispersion.

- This allows controlled atomization of even the most demanding materials.

- Narrow particle size distributions and high powder purity can be achieved by selecting optimal process tooling, crucial for laboratory, catalytic, and high-temperature industrial uses.

For a full overview, visit our page dedicated to precious metals.

The Role of Ultrasonic Atomizers

Modern ultrasonic atomizers, such as AMAZEMET’s modular systems, are ideal for R&D, recycling, and processing of high-value materials. They offer:

- Flexible scalability, from grams to hundreds of grams.

- Minimal material losses due to precise droplet control, non-contact heating and recirculation system equipped with HEPA filters.

You can learn more about AMAZEMET’s ultrasonic atomizer and how it supports advanced powder production.

AMAZEMET’s Approach

At AMAZEMET, we focus on enabling innovation in metal powder processing through ultrasonic technologies. Our solutions are tailored for:

- Low-batch production of precious metal powders.

- Recycling of overused or experimental materials from production processes or additive manufacturing.

- R&D applications requiring purity, custom composition, or alloy modification.

We don’t manufacture commodity-scale powders but instead support clients who require flexibility, modularity, and process control in their precious metal workflows.

Conclusion

Atomizing precious metals comes with unique challenges: high melting points, volatility, and cost sensitivity. Choosing the right technique is essential, and for many advanced and reactive use cases, ultrasonic atomization stands out as the most precise, flexible, and economical option.

Interested in developing or recycling precious metal powders?

Let’s collaborate, AMAZEMET’s ultrasonic systems can help you process high-value materials efficiently and safely.