Tantalum is one of the lesser-known yet technologically critical metals that support modern innovation across a wide spectrum of industries. Valued for its high melting point, excellent corrosion resistance, and superior biocompatibility, tantalum plays a crucial role in sectors ranging from electronics to medicine and advanced manufacturing. This article explores the most important tantalum uses, including both well-established and emerging applications—highlighting how companies like AMAZEMET support cutting-edge research on this versatile metal.

Tantalum Properties That Define Its Applications

To understand where tantalum is used, it’s important to first consider its unique material properties:

- Melting point: ~3017°C (one of the highest among metals)

- Corrosion resistance: Extremely inert even in aggressive environments

- High density: 16.6 g/cm³

- Excellent biocompatibility

- Stable dielectric properties

These characteristics make it suitable for use in extreme environments, miniaturized electronics, and biomedical applications.

Common Uses of Tantalum in Industry

1. Electronics and Capacitors

The most common use of tantalum is in the electronics industry, where it is used to produce tantalum capacitors. These are favored for their:

- High capacitance per volume

- Long life span and reliability

- Resistance to high temperatures

Such capacitors are critical components in smartphones, medical devices, laptops, and automotive electronics.

2. Chemical and Process Industries

Tantalum’s resistance to chemical attack makes it a material of choice for:

- Heat exchangers

- Reactor linings

- Valve and pump components

These are often used in petrochemical plants, acid production, and other highly corrosive environments. Tantalum equipment can withstand hot acids where stainless steels or even nickel alloys would fail.

3. Aerospace and High-Temperature Components

Tantalum and its alloys are commonly used in high-temperature applications, especially in aerospace, defense, and space exploration. These include:

- Rocket engine parts

- Nuclear reactor components

- Thermal shielding

While more exotic than molybdenum or tungsten in these contexts, tantalum is chosen for its ability to retain mechanical integrity at extreme temperatures.

To learn more about such advanced refractory alloys, check out how we support material development for extreme environments.

Biomedical Applications of Tantalum

Due to its outstanding biocompatibility, tantalum is being studied and used in:

- Orthopedic implants

- Dental implants

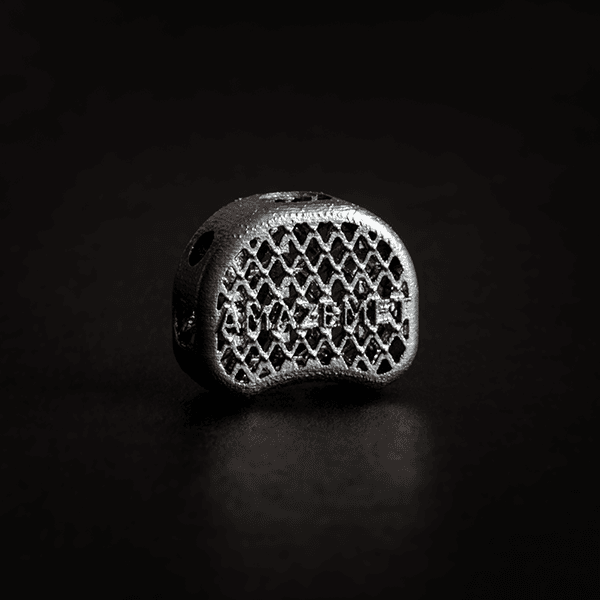

- 3D-printed porous scaffolds for bone in-growth

- Novel alloys such as TNTZ (Titanium-Niobium-Tantalum-Zirconium alloys)

Its resistance to bodily fluids and promotion of bone adhesion makes it a strong candidate for long-term implants. However, AMAZEMET does not currently provide medical-grade tantalum but supports research institutions developing novel biomaterials based on tantalum and other metals.

Tantalum Uses in Everyday Life

While some applications are highly specialized, tantalum does have roles in more familiar settings:

- Mobile phones – Tantalum capacitors help manage power regulation.

- Hearing aids and pacemakers – Benefit from tantalum’s biocompatibility.

- Lab equipment – Crucibles and tools made of tantalum are used for high-purity processes.

These tantalum uses in everyday life often go unnoticed but are critical for everyday life.

Tantalum in Powder Metallurgy and Additive Manufacturing

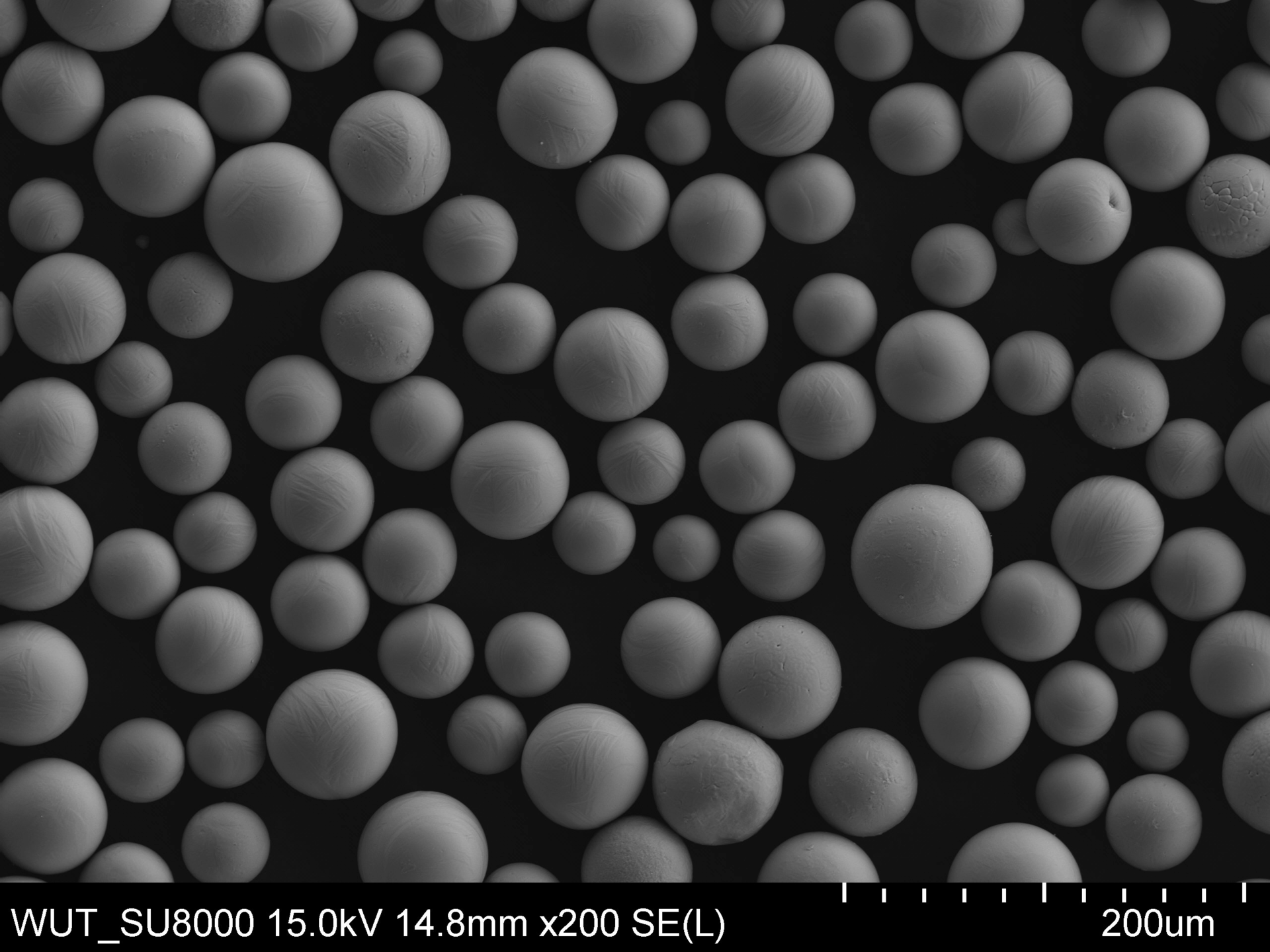

The rise of powder metallurgy and additive manufacturing has opened new avenues for using tantalum.

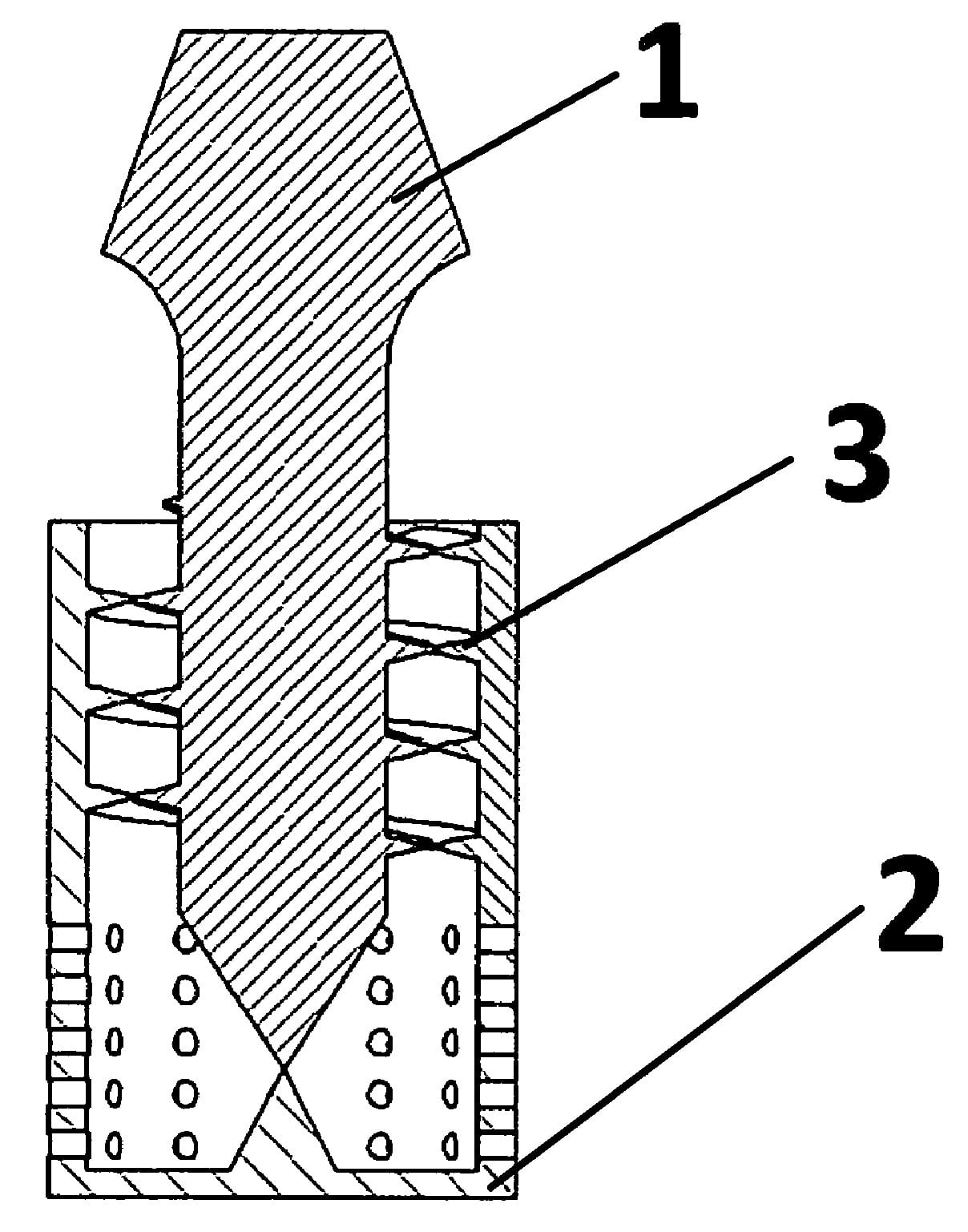

Powder Metallurgy Applications

Tantalum powders are used to fabricate complex components via sintering, including:

- Biomedical scaffolds with controlled porosity

- High-performance parts for energy and defense industries

- Corrosion-resistant components for analytical equipment

Such applications demand control over powder purity and morphology.

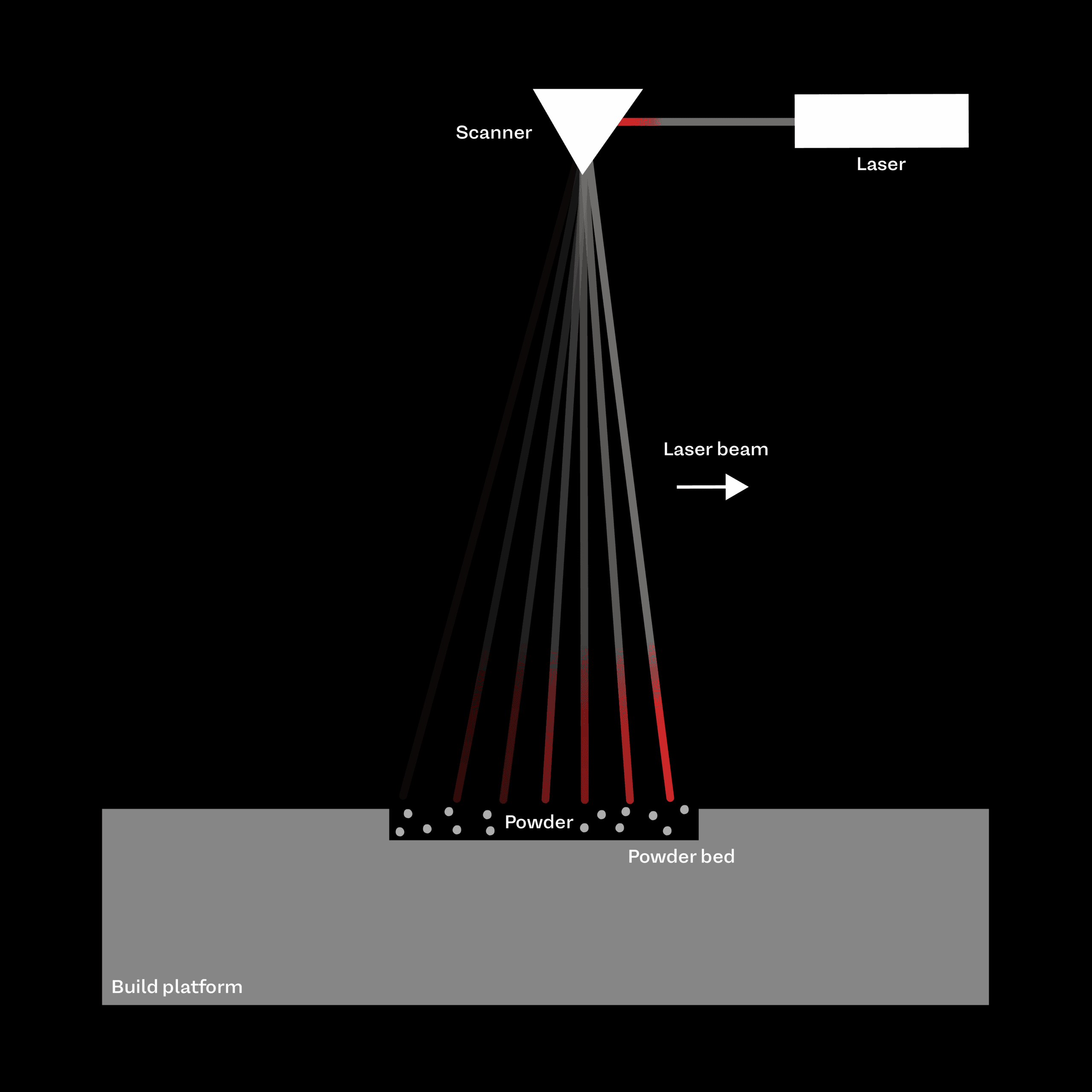

Additive Manufacturing Potential

Although still niche, tantalum is increasingly being tested in Laser Powder Bed Fusion (LPBF) and similar AM technologies. The challenges are non-trivial: tantalum’s high melting point and oxidation sensitivity require precise process control.

That’s where advanced atomization technologies come in. With tools like the ultrasonic metal atomizer, it becomes possible to produce high-quality, spherical tantalum powders with tailored properties for research and prototyping.

If you’re exploring advanced materials research, AMAZEMET provides support in:

- Powder development for refractory metals like tantalum

- Custom alloying strategies

- Research-scale production and consulting

A dedicated subpage for tantalum powder will soon be available for those interested in detailed specifications.

Summary: Is Tantalum the Right Fit for Your Project?

From common uses of tantalum in electronics to more niche roles in aerospace and medicine, this metal stands out as a high-performance material with diverse applications. However, its true value emerges when used in applications where corrosion resistance, biocompatibility, or thermal stability is critical.

At AMAZEMET, we support research and innovation in:

- Advanced metallurgy and alloy development

- Custom metal powder production, including tantalum alloys

- Small-scale additive manufacturing solutions

If your work involves exploring the frontiers of materials science, let’s discuss how we can help you prototype, develop, or test new tantalum-based solutions.

Explore our portfolio of metal powders and technologies designed to push materials research forward.