The long-term value of research investments

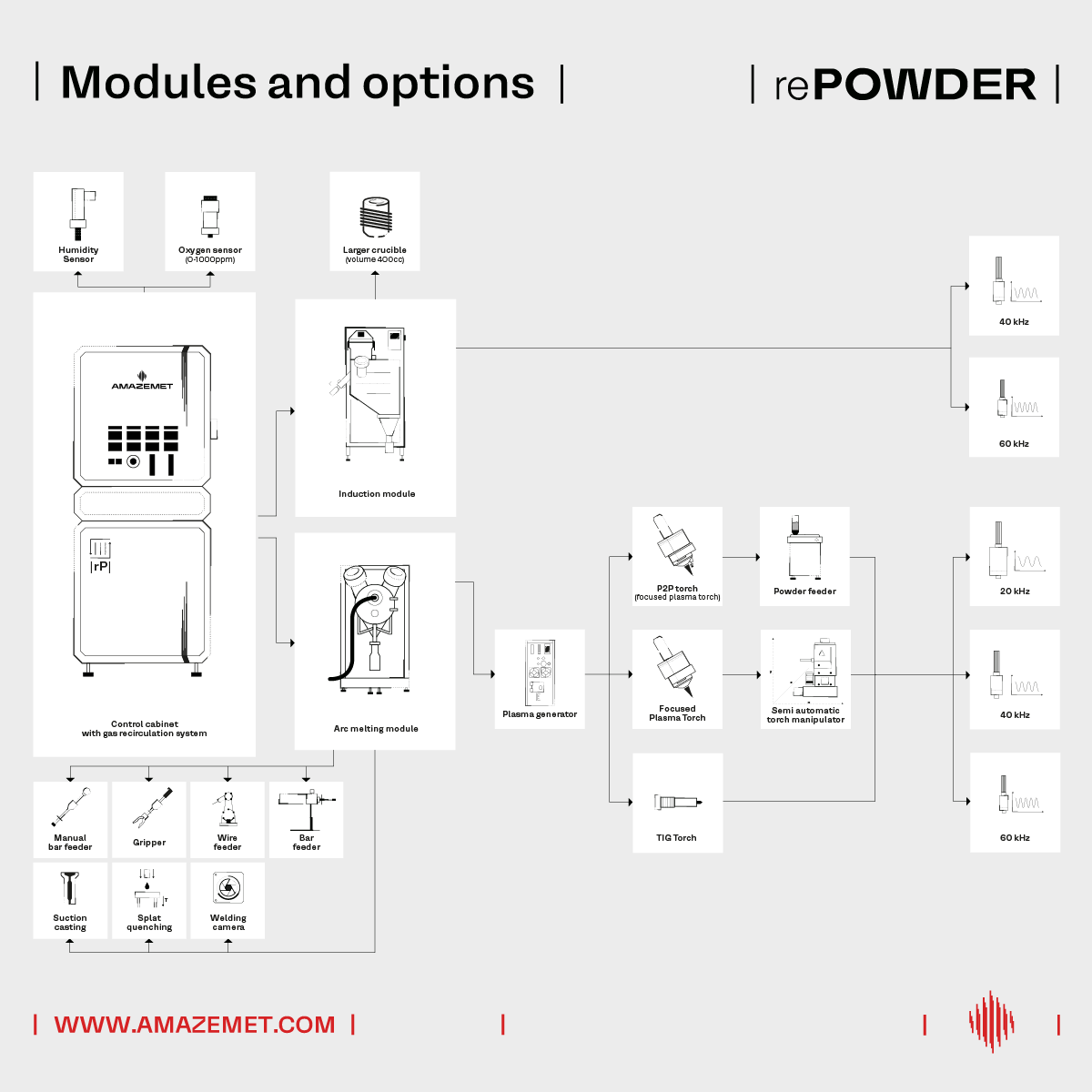

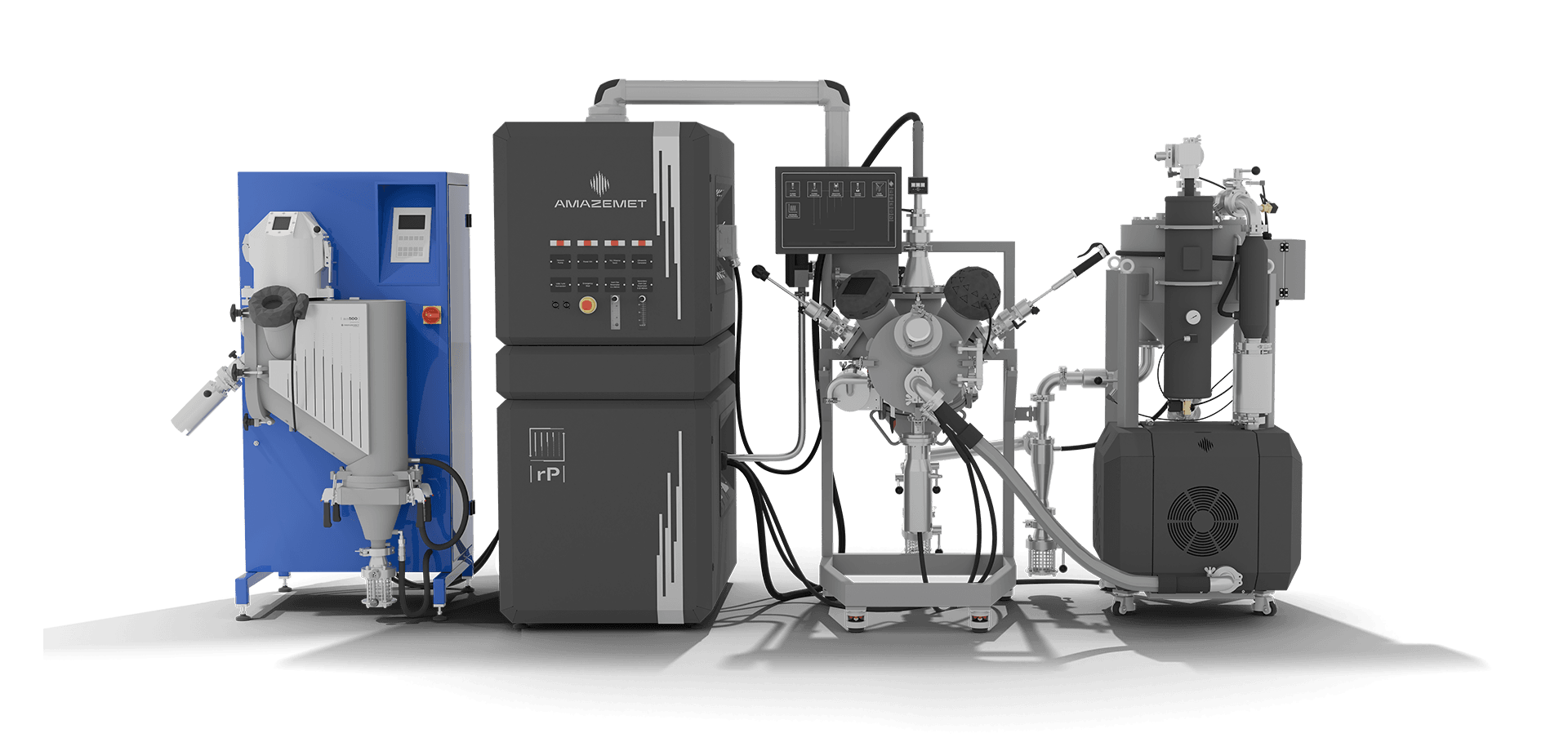

Universities and research institutes today face the challenge of quickly changing research directions and the need to adapt their equipment to new projects, often within tight budget constraints. AMAZEMET’s rePOWDER ultrasonic atomization system addresses this by providing an open platform designed for modular expansion. This allows institutions to start with a core system and expand their capabilities as research needs evolve and funding becomes available.

Łukasz Żrodowski, CEO of AMAZEMET, elaborates on this philosophy:

“Our core belief at AMAZEMET is that research equipment should support research, not hold it back. The rePOWDER platform was designed to be a very flexible system. Witnessing leading institutions like TUM use this modularity to advance their research confirms the value of our approach to system design and its long-term value.”

The journey of the Technical University of Munich (TUM) with rePOWDER is a prime example of this principle, showing how upgradability supports innovation and protects the long-term value of research investments.

The Start of a Successful Collaboration

The collaboration with the Technical University of Munich, a world-renowned research institution, began not in a lab, but during lively discussions at the 2022 “Alloys for Additive Manufacturing Symposium” in Munich. As AMAZEMET presented its solutions for producing small, tailored powder batches, we connected with Professor Peter Mayr. This sparked strong interest within TUM’s leading AM research group in a system that offered more than just powder production. It offered a new way to develop materials. Although the procurement process and securing funding extended into 2024, this initial meeting built a strong foundation for our future partnership.

Figure 1 AMAZEMET booth at the 2022 “Alloys for Additive Manufacturing Symposium” in Munich

Focusing on Aluminum Recycling and Powder Production for DED

TUM’s initial work with rePOWDER focused on two key goals: research into aluminum-based alloys and recycling aluminum from chip feedstock, a crucial step towards a circular economy. For this, the rePOWDER system with its induction ultrasonic atomization setup was the ideal choice. The main task was to produce high-quality aluminum scrap powders tailored for Directed Energy Deposition (DED) technology. This required operating at a lower ultrasonic frequency (around 20 kHz) to achieve the desired 50-200 micron particle size.

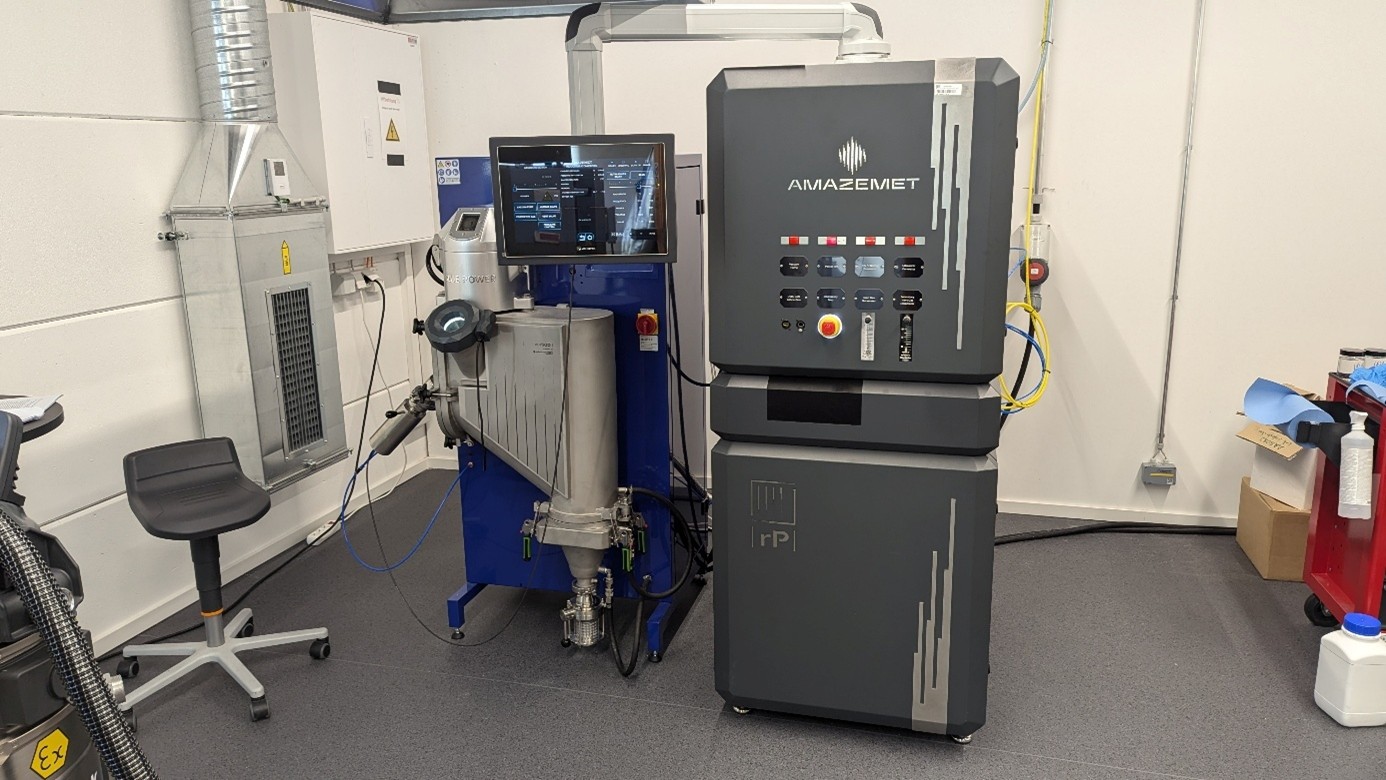

The system, commissioned in early February 2024, came with interchangeable 225 ml and 400 ml crucible volumes, offering immediate flexibility. Yet, even as the induction unit began its work, discussions between TUM and AMAZEMET were already exploring future upgrade possibilities.

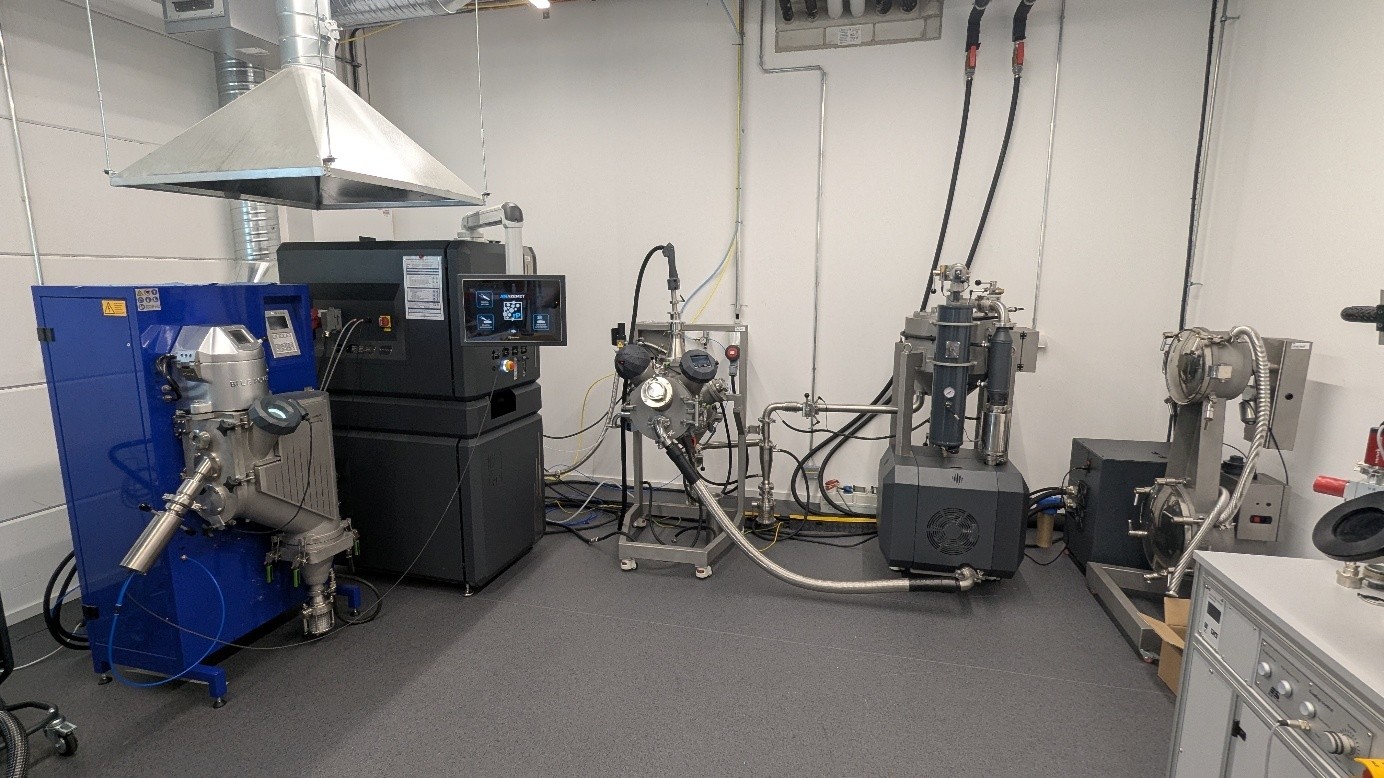

Figure 2 Photo of the initial rePOWDER setup at TUM

Daniel Vieweger, a key researcher on the project, commented on the system’s impact:

“The ultrasonic atomization system from AMAZEMET is a key component for our research project on sustainable aluminum processing with AM. It enables the fast and efficient transformation of aluminum scrap into highly spherical powder with a tailored fraction range, ideal for our plasma-based DED system. AMAZEMET empowers us to turn scraps and waste material back into value – a true milestone on the path toward a circular economy in metal additive manufacturing.”

Changing Research Needs Demands a System Upgrade

As TUM’s research progressed, particularly within the Future Sustainable Car Materials (FSCM) project, new challenges emerged. The team identified a critical need to work with materials beyond aluminum. Future projects included recycling titanium support structures from their EBM unit and designing novel alloys tailored for additive manufacturing.

This goal to explore advanced steels, resilient titanium alloys, high-performance nickel alloys, and novel materials like High-Entropy Alloys (HEAs) and refractories, prompted the next step in their rePOWDER story: a major system upgrade.

Prof. Peter Mayr, TUM Representative, on their evolving needs:

”AMAZEMET’s rePOWDER system is the dream of each materials scientist. The enormous versatility enables on one hand to produce standard metal powders on demand for subsequent additive manufacturing processes. On the other hand, the system also allows us to bring ideas in alloy design into reality in unprecedented speed. The rePOWDER system at TUM closes the gap between computational alloy design and advanced manufacturing and allows us to investigate the full process chain from an idea to the final product.”

Broadening Capabilities: Integrating Plasma Technology

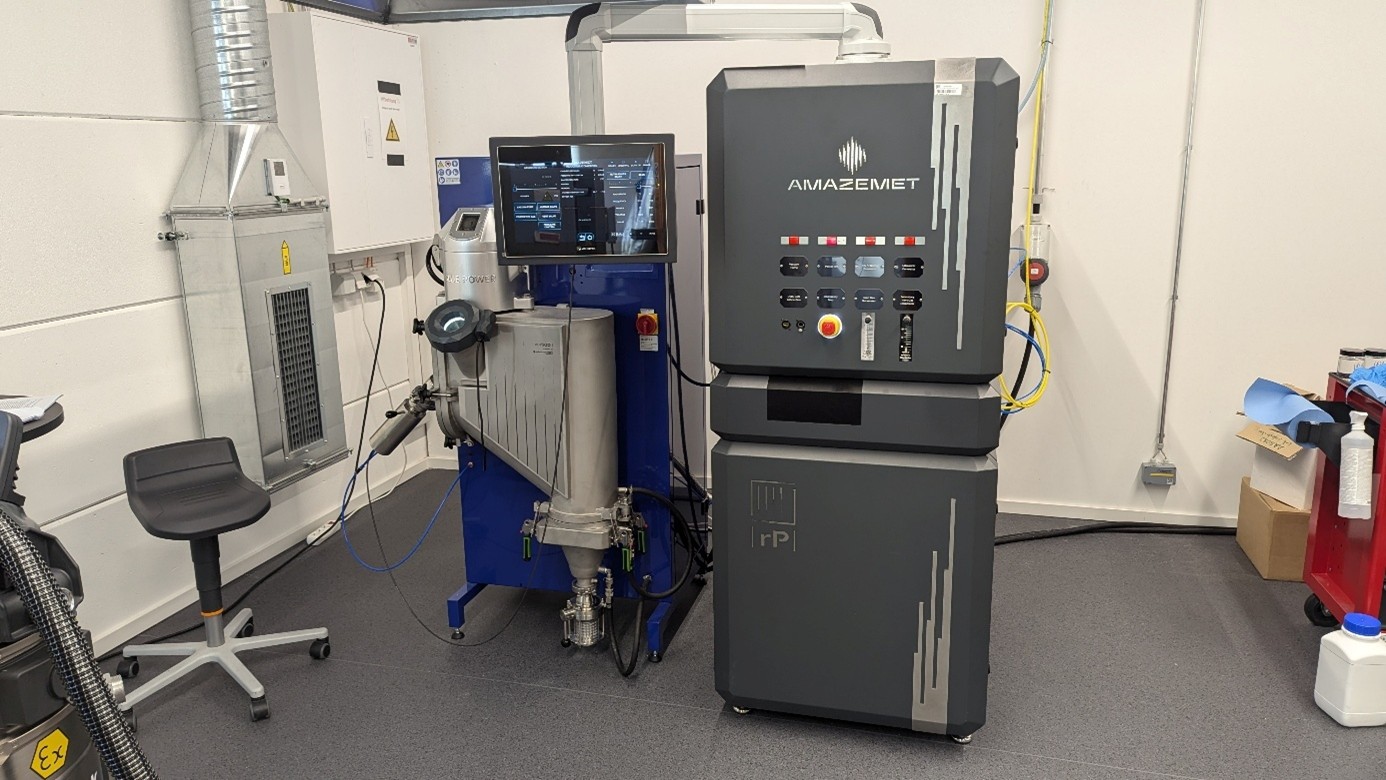

In December 2024, the rePOWDER system at TUM was upgraded. The AMAZEMET team arrived to integrate a state-of-the-art plasma ultrasonic atomization module and an automatic wire feeder into the existing unit. The original ultrasonic generator and transducer were reused to power the new plasma features. AMAZEMET team provided the necessary mounting parts, plasma-specific sonotrodes, and the recirculation system. The integration was, as planned, seamless.

Tomasz Choma, Application Engineer at AMAZEMET, comments on the upgrade process:

“It’s satisfying for us as professionals to see our rePOWDER system support the changing research directions of our clients. The integration of the plasma module at TUM went smoothly and quickly, as our way of designing focuses on making upgrades easy. We focus on ensuring that we plan for future expansions from the initial installation, which reduces downtime and allows research teams to quickly use new system features.”

This seamless upgrade ensured TUM could continue its research without significant delays. Beyond the physical installation, AMAZEMET provided comprehensive commissioning and advanced training to ensure the team could fully utilize their rePOWDER’s expanded capabilities.

Figure 3 Upgraded Induction + Plasma setup at TUM

A Major Improvement in Research Capabilities

The plasma atomization module was more than an upgrade; it unlocked entirely new research areas for TUM:

- Working with High-Melting Point Materials: The plasma torch, capable of reaching temperatures far exceeding the induction coil’s limits (which is ideal up to approx. 1300°C and for materials non-reactive with graphite crucibles), made it possible to process steels, titanium, nickel, HEAs, and refractory materials.

- Developing Alloys On-Site: The upgraded system gained the functionality of an arc melter, allowing TUM researchers to create new alloys from pure elements or carefully change existing ones directly within the rePOWDER.

- Improved Efficiency & Automation: The automatic wire feeder made the atomization process more efficient, enabling semi-automatic operation. This not only boosted efficiency but also reduced the manual labor involved, saving valuable researcher’s time.

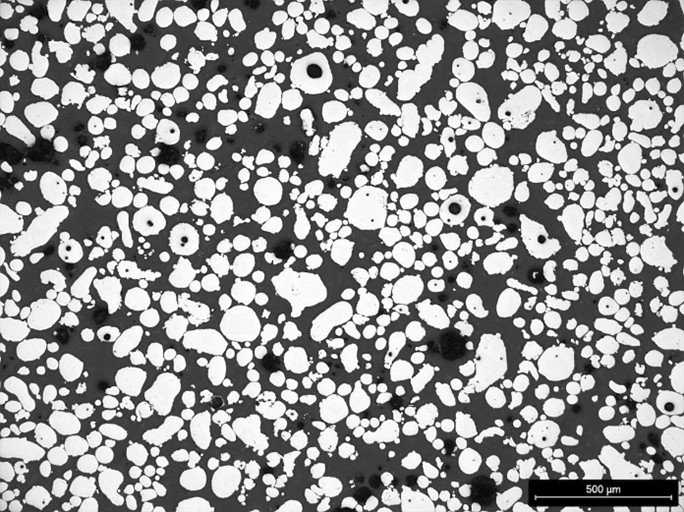

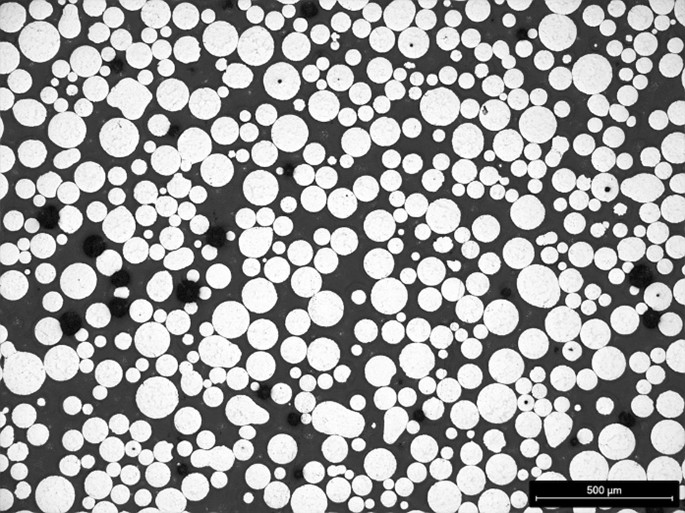

Figure 4 Comparison of gas atomized vs ultrasonic atomized powder (AA5083)

Modularity: A Smart Investment for Future Growth

Modularity is a key factor for research institutions when considering the long-term value of equipment. The rePOWDER system is designed to be a sustainable investment that can adapt to the evolving landscape of scientific inquiry. This flexibility allows research groups to start with a configuration tailored to their immediate needs and expand its capabilities as new projects emerge and research directions shift. As a result, rePOWDER can grow alongside the ambitions of the research team, ensuring the initial investment remains relevant and productive for years to come without the need for frequent replacement.

Figure 5 Modules and options of rePOWDER Ultrasonic Atomization Platform

Platform for Continued Innovation: Valuable Feedback from TUM

TUM’s experience shows that rePOWDER’s modularity is not just for current needs but also prepares for future discoveries. The team in Munich is already looking to the future and is interested in adding more to their system. With all available heat sources now at their disposal, future improvements can focus on greater automation, advanced process instrumentation, like high-speed cameras for melt pool monitoring, or new modules like Powder2Powder.

Reflecting on their hands-on experience, the TUM team noted its ease of use and speed after a few trials. It enables them to reuse cut substrate plates and old DED structures that would otherwise be discarded. They also highlighted the unmatched quality of the powder compared to gas atomization, noting it is “extremely spherical” with “way less internal porosity,” and appreciated the reliable customer support that typically provides a response within a day.

A key part of the user experience highlighted by the team is the new AMAZEMET ACADEMY. They noted this online platform as a customer-centric feature that makes daily work with the machine and the training of new personnel significantly easier. By providing a centralized resource for documentation, support, and knowledge sharing, the platform further strengthens the partnership and ensures users can maximize the value of their system.

The team also provided valuable feedback for future enhancements, showcasing the kind of collaborative input that helps drive AMAZEMET’s product development. Suggestions included a higher level of automation, where heating, gas washing, and pressure control could be programmed as a single sequence to prevent steps from being missed. Another area for improvement was centralizing all parameter controls within the HMI to avoid the need to also use the induction system panel, streamlining the user experience.

Figure 5 Hybrid rePOWDER Ultrasonic Atomization Platform

Key Benefits of rePOWDER’s Modularity: The TUM Experience Summarized

TUM’s journey with the rePOWDER system clearly shows the major advantages of a truly modular approach:

- Future-Proof and Adaptable Investment: Protecting the initial investment by allowing the system to be expanded with new modules over time, aligning its capabilities with evolving research goals.

- Easy Upgrades Without Interruptions: Well-designed modules and early planning ensure that adding new capabilities is a straightforward process.

- Easily Adapting to Changes in Research: Easily moving from aluminum studies to new work with high-melting-point alloys and novel material development.

- Good Value for Money Over Time: Making the most of investment over time by improving current equipment instead of making unnecessary new purchases.

- Research Platform Ready for the Future: Trust that the system can change to include new technologies and meet future research challenges.

The Technical University of Munich’s experience clearly shows that the AMAZEMET rePOWDER system is far more than a standard atomizer. It works as a flexible research multitool. Its open design and modularity are the keys to its long-term value, helping institutions by allowing them to keep upgrading the device, add new standard or even custom modules, and adjust the system to their changing research needs over time. This makes sure that rePOWDER stays a leading tool, improving its abilities along with the important research projects it helps.