Year 2020 checklist: successful atomization of gold

New year comes with new opportunities and energy for further development. Our recent work with rePowder provided us with very promising results – we developed a solution that is able to atomize various alloys.

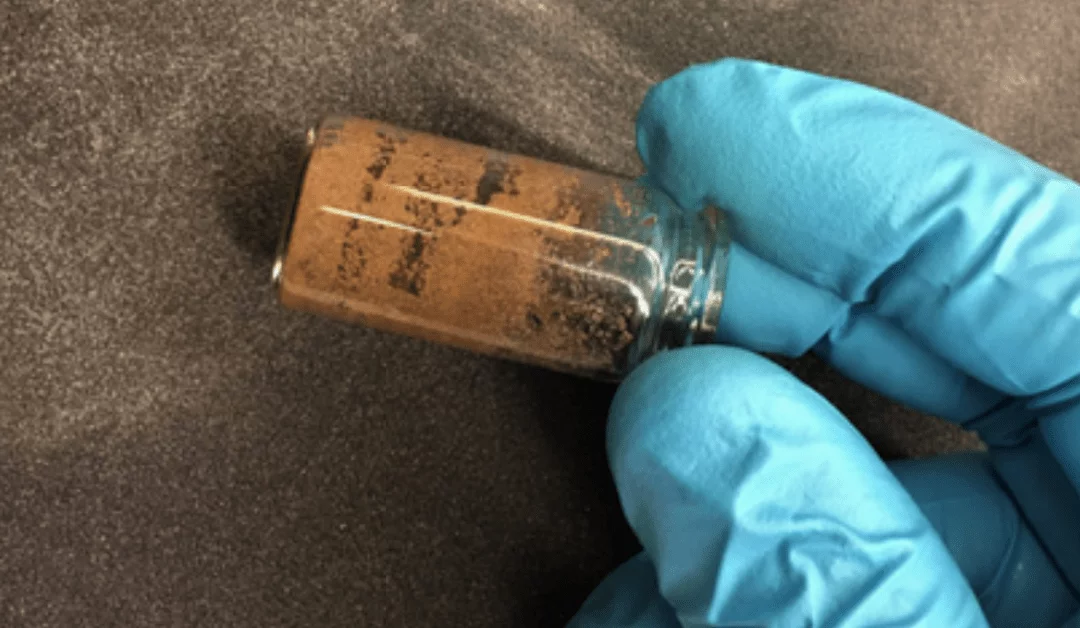

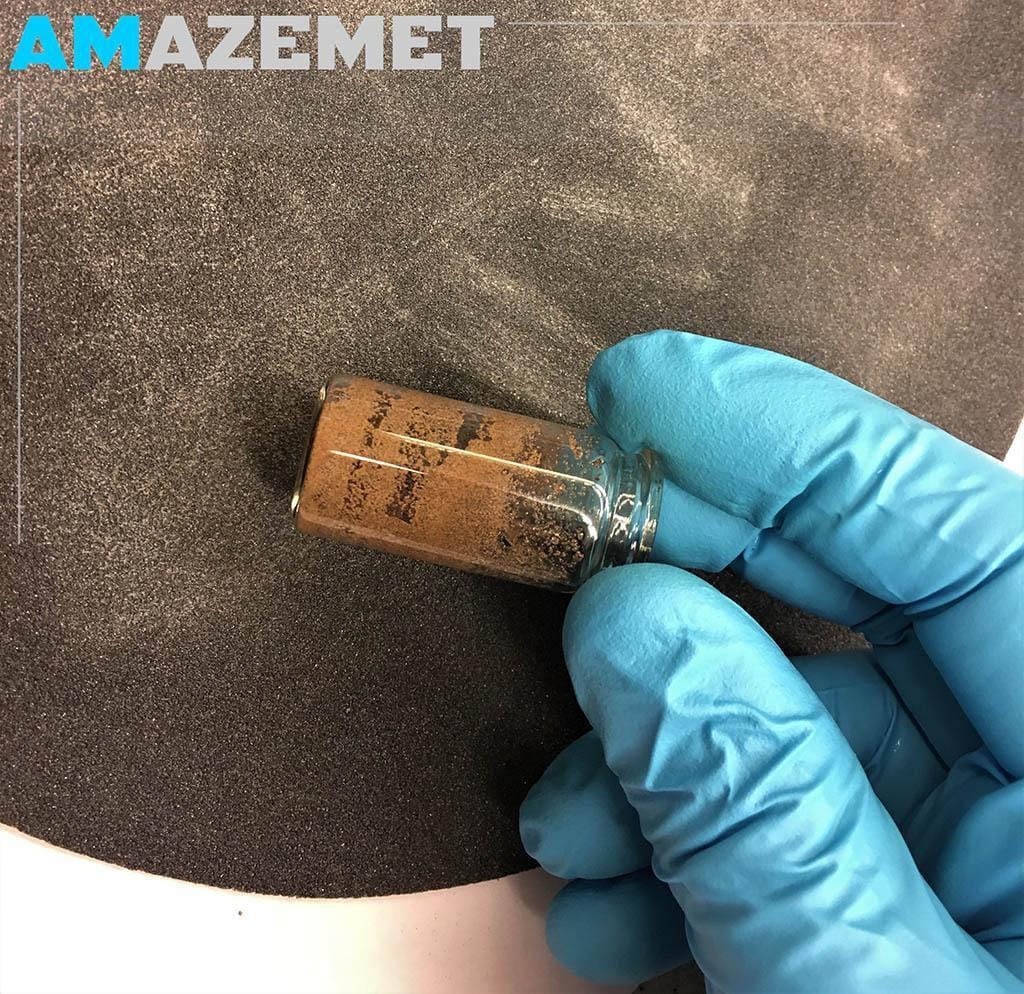

We started the new decade with another small success — rare 15k alloy gold atomization. Our team managed to atomize the small jewellery material in order to obtain the sample of powder, which you can see in the picture.

What would you like to print out of it?

This is why I need to hide my jewellery. Otherwise, I will receive it back as a gold powder. ~ Anna

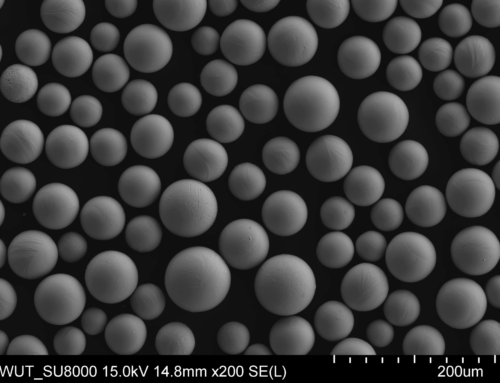

We checked also the particle size distribution and chemical composition of the alloy. Over 60% yield was less than 100 µm and no contamination was visible in the atomized powder. Fine particles can be used for metal 3D-printing as well as for other powder metallurgy applications, while higher chemical purity makes rePowder tool perfect for R&D in precious metal field.

We checked also the particle size distribution and chemical composition of the alloy. Over 60% yield was less than 100 µm and no contamination was visible in the atomized powder. Fine particles can be used for metal 3D-printing as well as for other powder metallurgy applications, while higher chemical purity makes rePowder tool perfect for R&D in precious metal field.

Graphics — before & after