Freedom in Metal AM Develompent & Production

Aerospace: Advancing High-Performance Alloys for Extreme Environments

The aerospace industry demands materials with exceptional mechanical properties, thermal stability, and resistance to extreme environments. From propulsion systems to structural components, material solutions are essential for improving efficiency, reducing weight, and enhancing the capabilities. Advanced manufacturing processes such as ultrasonic atomization, additive manufacturing, and high-vacuum heat treatment enable the development of high-performance alloys tailored for aerospace applications.

AEROSPACE

How to make materials which can withstand extreme conditions?

How to make materials which can withstand extreme conditions?

Designing materials for extreme environments requires a deep balance between performance and practicality. Aerospace systems demand materials that not only endure high temperatures and mechanical stresses but also help reduce weight for improved efficiency.

Designing materials for extreme environments requires a deep balance between performance and practicality. Aerospace systems demand materials that not only endure high temperatures and mechanical stresses but also help reduce weight for improved efficiency.

High-Temperature Performance Challenges

Aerospace propulsion systems require materials that can withstand extreme temperatures and mechanical stresses. Conventional materials often struggle to maintain their integrity under such conditions, necessitating the development of advanced high-temperature alloys and coatings.

Weight Reduction for Improved Efficiency

Aircraft and spacecraft design relies on lightweight, high-strength materials to enhance fuel efficiency and overall performance. Traditional processing methods can limit the optimization of lightweight structural alloys without generative design approach.

CHOOSE YOUR COMPOSITION

The alloy you should choose!

Advanced aerospace applications rely on high-performance alloys and sustainable powder technologies to meet the extreme demands of temperature, strength, and efficiency in next-generation propulsion and structural systems.

01

Atomization of Niobium Alloy C103 for High-Temperature Applications

Niobium-based alloy C103 is widely used in aerospace propulsion systems due to its excellent oxidation resistance and high-temperature mechanical properties. C103 finds perfect usability in LPBF. Ultrasonic atomization enables the production of fine, spherical powders optimized for additive manufacturing for production of thrusters and nozzles.

02

Development of Nickel-Based Superalloys for Extreme Environments

High-performance nickel superalloys play a crucial role in turbine blades, heat exchangers, and other high-temperature components. Advanced processing techniques such as high-vacuum heat treatment ensure superior microstructural control and mechanical performance thanks to two step precipitation hardening heat treatment.

03

Lightweight Titanium and Aluminum Alloys for Structural Components

Aerospace structures demand lightweight yet durable materials. Titanium and aluminum alloys offer exceptional strength-to-weight ratios, making them ideal for airframe and space applications with optimized design.

04

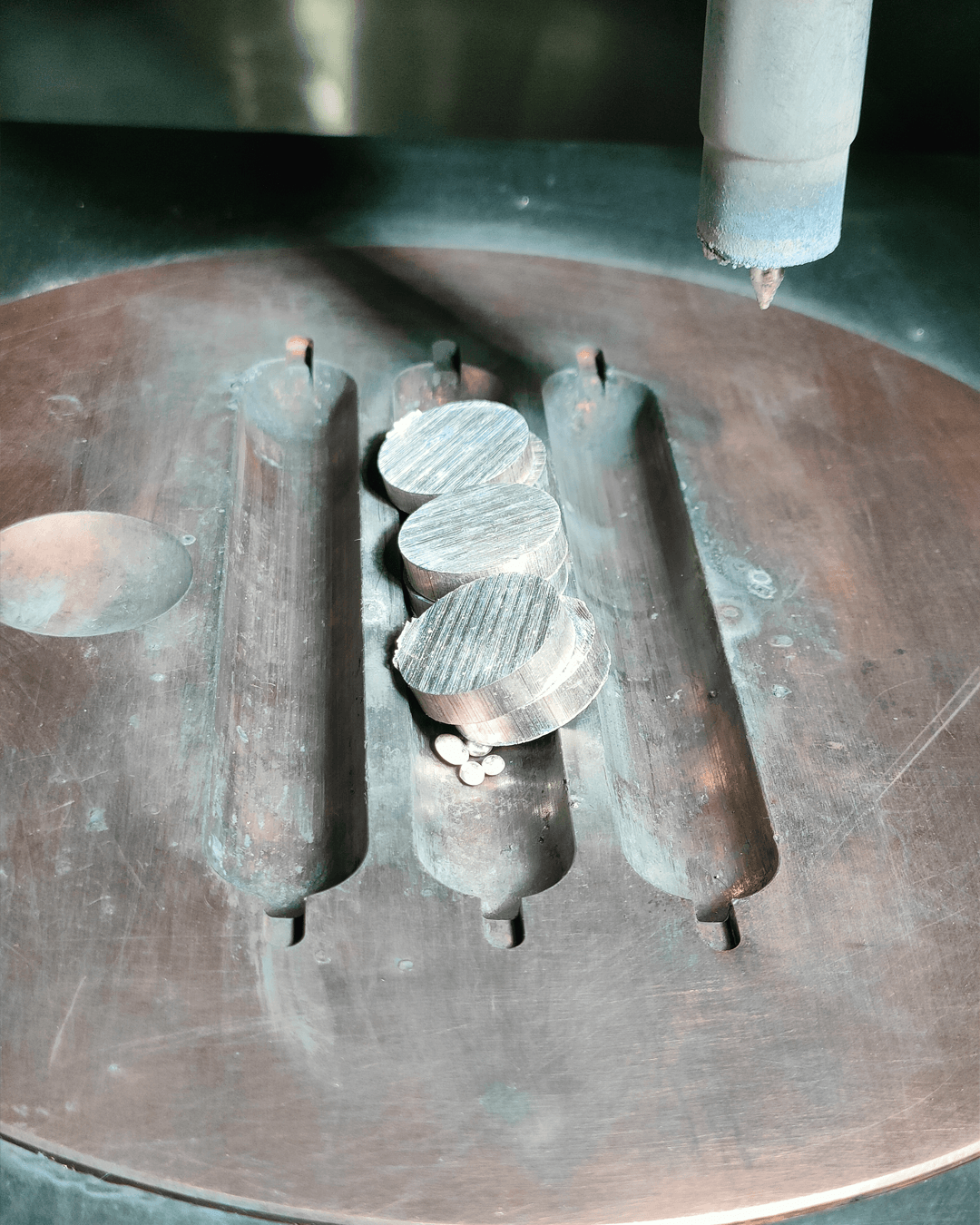

Recycling and Re-Atomization of Aerospace Powders

Such strategic materials are just asking for sustainable materials processing by re-atomization technologies, allowing for the recovery and refinement of out-of-spec powders, reducing waste, and optimizing material efficiency.

AMAZEMET

Driving Innovation in Aerospace Materials

As a leading provider of high-performance materials processing solutions, AMAZEMET delivers technologies such as ultrasonic atomization, high-vacuum heat treatment, and powder recycling. Our expertise in high-performance alloys supports the aerospace industry’s need for lightweight, high-temperature, and structurally optimized materials.

WHY AMAZEMET

AMAZEMET Solutions for Aerospace Material Development

At AMAZEMET, we provide key solutions for material development dedicated for aerospace. Discover range of our products:

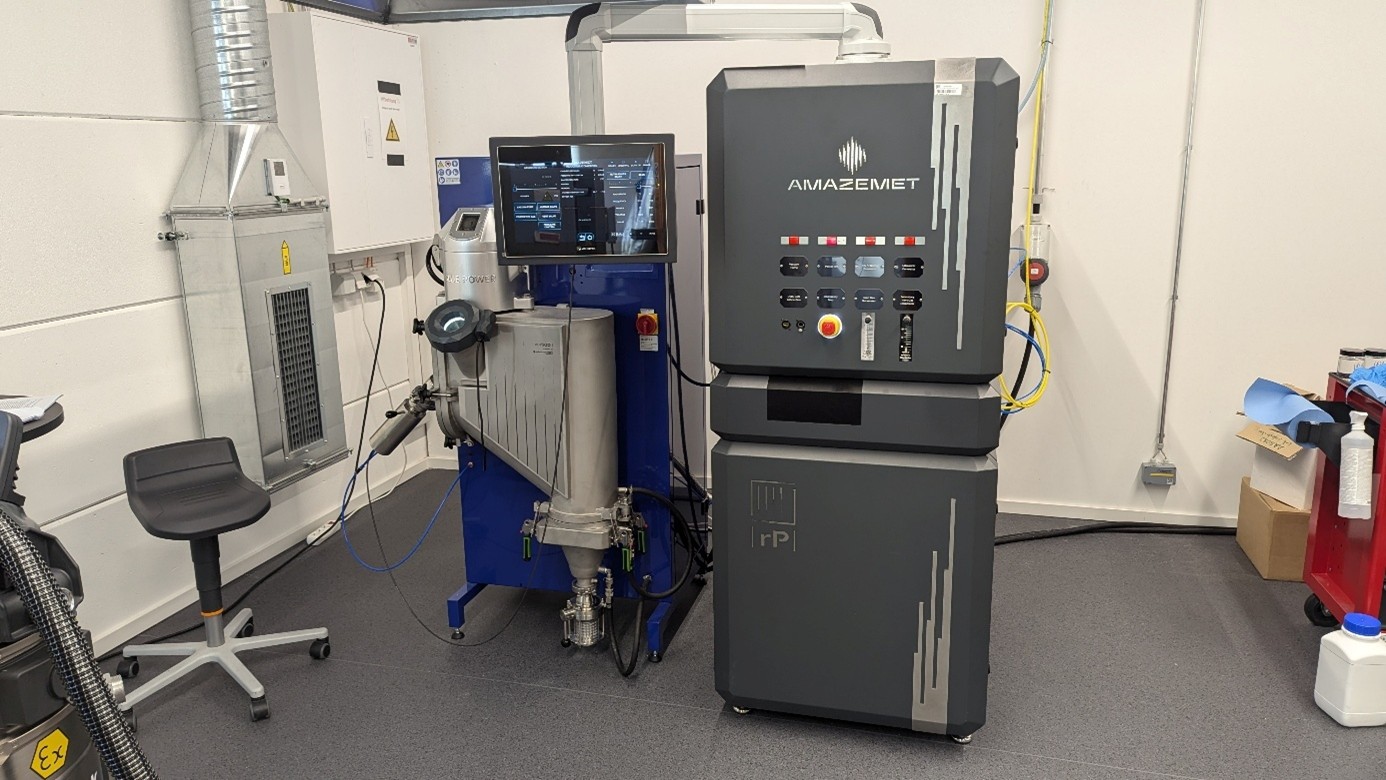

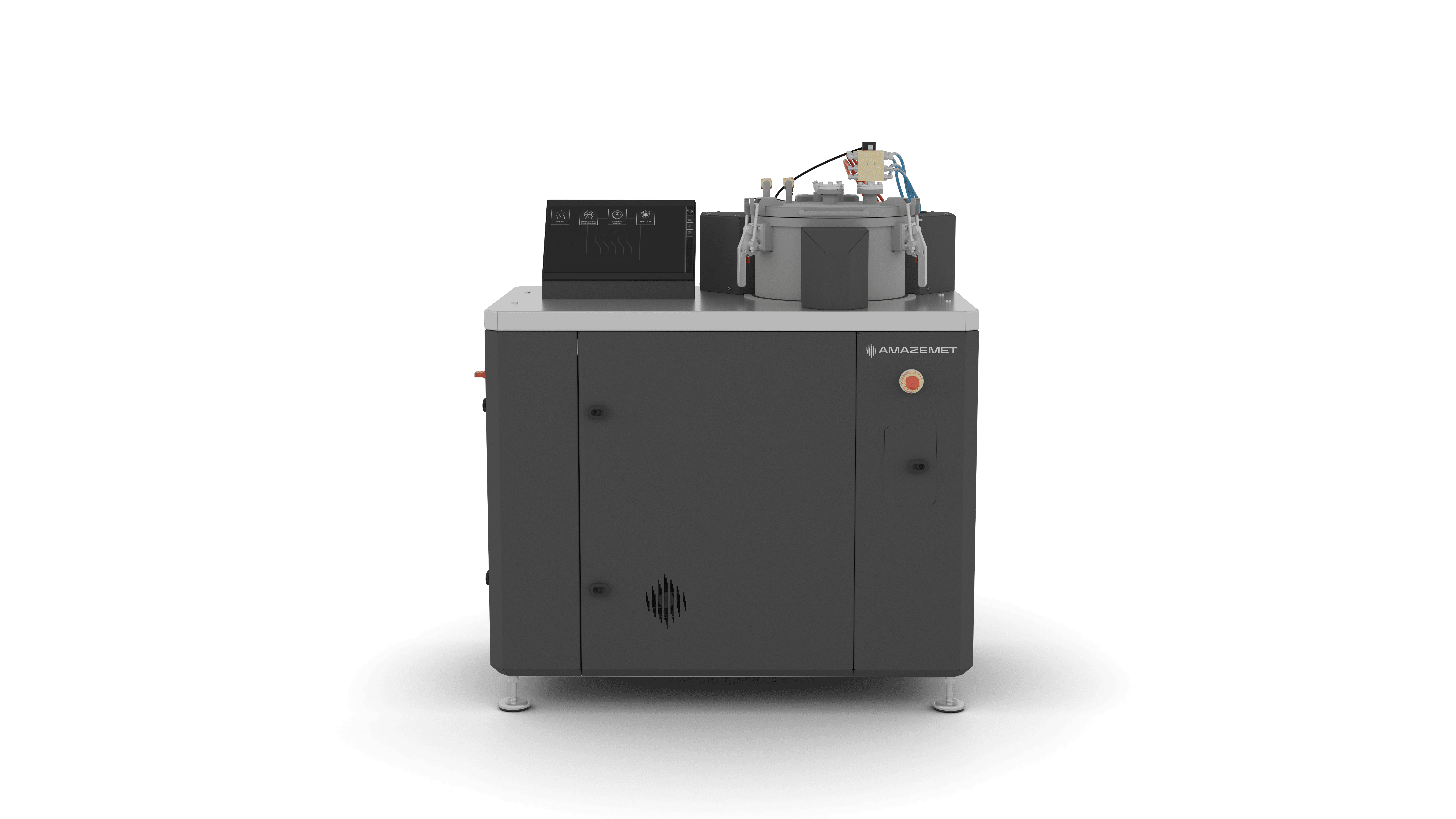

rePOWDER

As a leading provider of high-performance materials processing solutions, AMAZEMET delivers technologies such as ultrasonic atomization, high-vacuum heat treatment, and powder recycling. Our expertise in high-performance alloys supports the aerospace industry’s need for lightweight, high-temperature, and structurally optimized materials.

inFURNER

A high-vacuum furnace ensuring precise heat treatment of aerospace materials, enhancing their mechanical properties and phase stability.

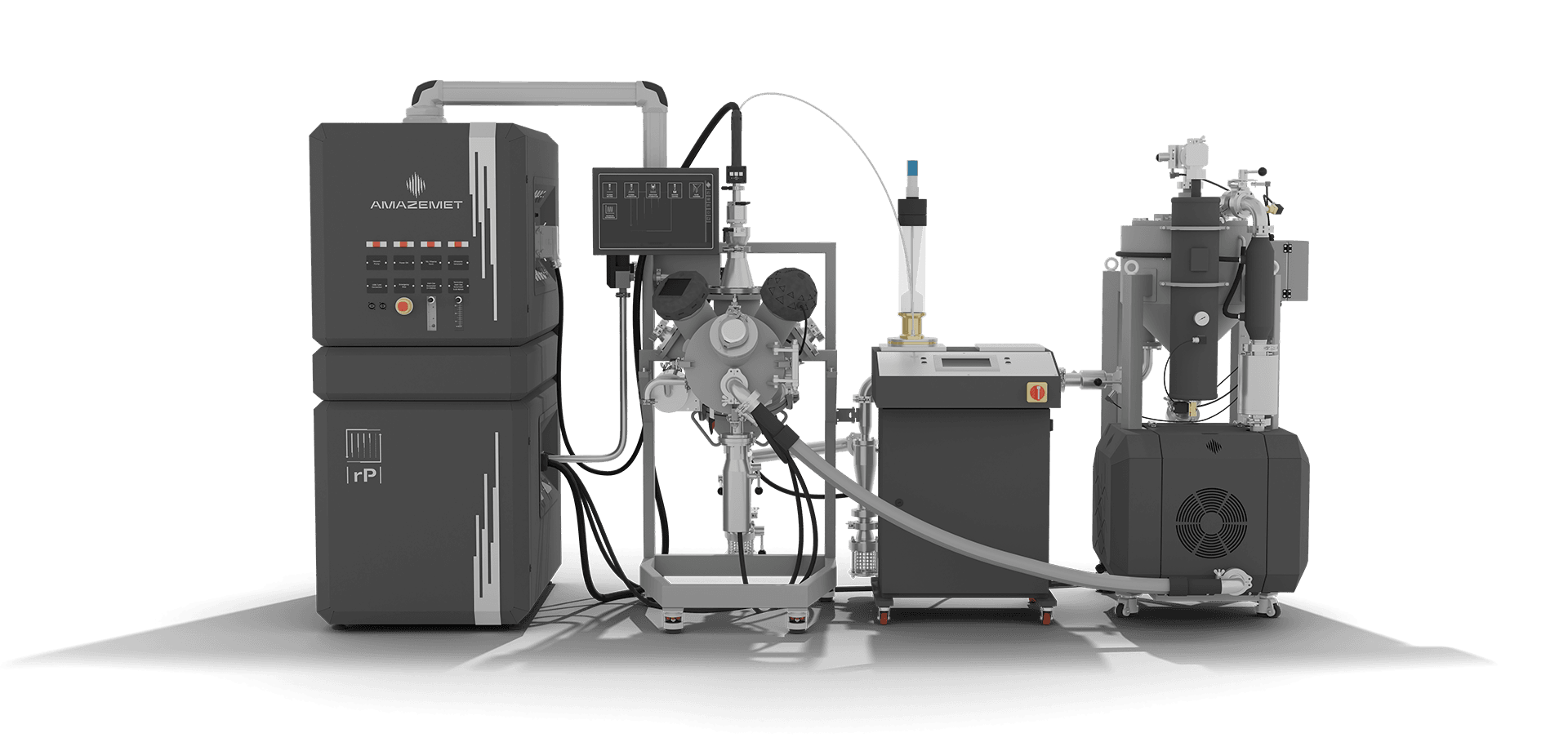

Powder2Powder

A sustainable re-atomization technology that enables the recycling of aerospace powders, minimizing waste and maximizing material utilization.

FREEDOM IN METAL AM

DEVELOPMENT & PRODUCTION

RESEARCH PARTNERSHIP

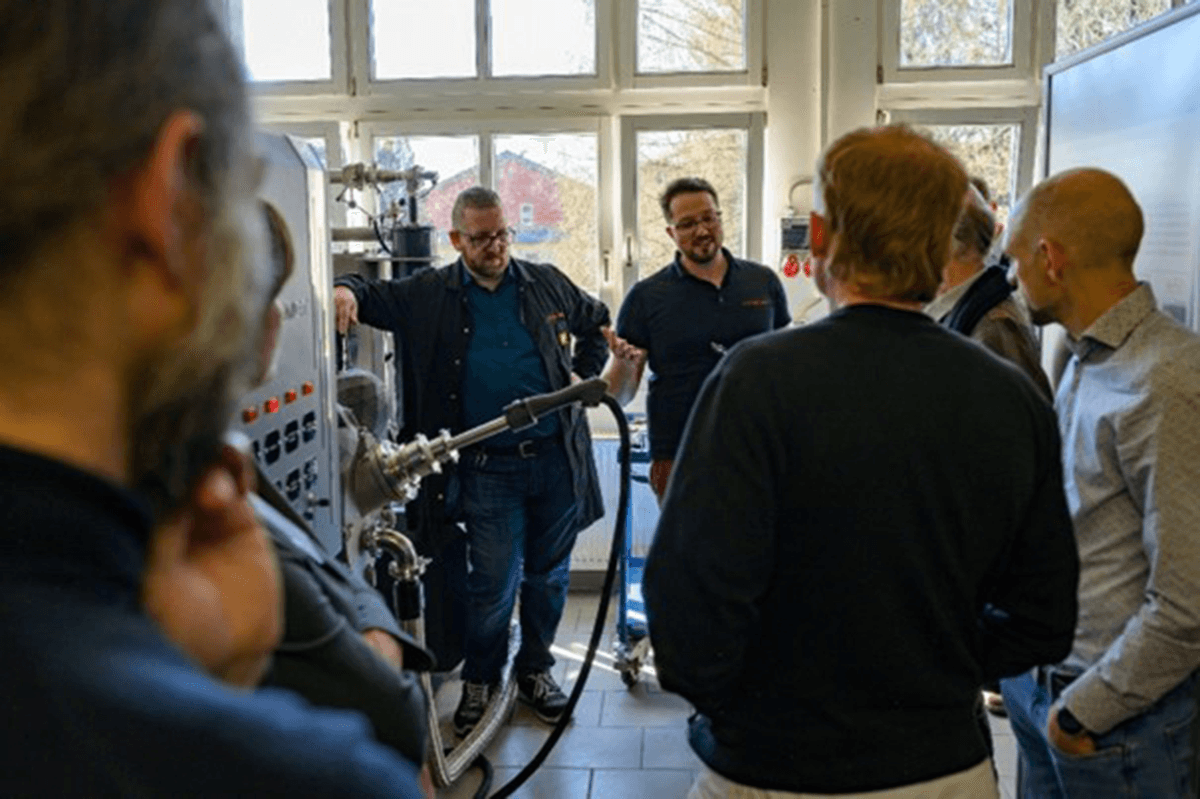

Partnering with Aerospace Researchers for Advanced Materials Innovation

At AMAZEMET, we support aerospace research with cutting-edge tools and deep materials expertise to accelerate innovation in extreme-condition applications.

We offer research institutes flexible, modular platforms like rePOWDER for alloy prototyping, powder development, and sustainable material processing tailored to aerospace needs. Our technology enables rapid iteration of new high-temperature alloys, lightweight structural materials, and fine-tuned powder characteristics for additive manufacturing. With capabilities like ultrasonic atomization, arc melting, and high-vacuum heat treatment, researchers can explore novel compositions and optimize processing routes within a single system. AMAZEMET’s team of engineers and scientists collaborates closely to adapt setups for experimental goals, helping push the boundaries of aerospace material science. Whether you’re developing propulsion components, structural alloys, or sustainable powder recycling methods, we’re ready to support your research from concept to data.

a

ENABLING MATERIALS FOR CUTTING-EDGE APPLICATIONS

Explore Our Work in Action

Discover how AMAZEMET supports research and innovation through real-world collaborations and deep technical insights

Case Studies

Our case studies showcase how we’ve supported partners across industries with tailored solutions—from alloy development to process optimization. They focus on real challenges and how our technology helped turn ideas into results.

Application Notes

Application notes provide a deeper look into the technical aspects of our systems, methods, and materials. They’re ideal for researchers and engineers seeking detailed knowledge and insights to guide their own experiments and development work.

LET’S TALK

Advance Aerospace Material Innovation with AMAZEMET

Discover how ultrasonic atomization and high-vacuum heat treatment can enhance your aerospace manufacturing capabilities.

Order high-quality powders tailored for aerospace—ready for your next project.