Bioresorbability Dependence on Microstructure of Additivelly- Manufactured and Conventionally-Produced Fe-Mn Alloys

Authors: Matjaž Godec, Jakob Kraner, Danijela Skobir Balantič, Irena Paulin, Damjana Drobne, Veno Kononenko c, Aleksandra Kocijan, Paul McGuiness, Črtomir Donik

Hypereutectic Al-Ce-X (X=Mn, Cr, V, Mo, W) alloys fabricated by laser powder-bed fusion

Authors: Clement N. Ekaputra, Jovid U. Rakhmonov, Christian Leinenbach, David C. Dunand

AMAZEMET to Unveil Powder2Powder Atomization System at Formnext 2024

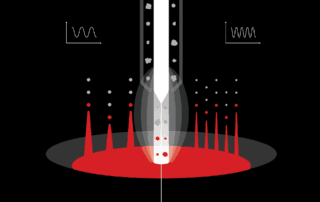

Powder2Powder World Premiere AMAZEMET, based in Warsaw, Poland, is set to introduce its new Powder2Powder (P2P) atomization system at Formnext 2024. The P2P system presents a versatile solution for recycling metal powders and manufacturing custom pre-alloy powders directly from powder feedstock. This unique technology (Figure 1) combines plasma processing and ultrasonic atomization to transform irregular or oversized particles into highly spherical, satellite-free powders optimized for additive manufacturing (AM). Unlike plasma spheroidization, the P2P technology allows powder size to be independent of the initial feedstock, making it the only technology capable of direct atomization of pulverized Ti-feedstock. Figure 1 Animation and [...]

Theory-guided design of high-strength, high-melting point, ductile, low-density, single-phase BCC high entropy alloys

Authors: Y. Rao, C. Baruffi, A. De Luca, C. Leinenbach, W.A. Curtin

Effect of oxidation temperature on the properties of niobium in view of its biomedical applications

Authors: Tomasz Borowski, Katarzyna Zielińska, Maciej Spychalski, Bogusława Adamczyk-Cieślak, Łukasz Żrodowski

In-situ alloy homogenization from raw elements | Application note

Create custom FeCrAlY alloys from raw elements as spherical powder for research or CSP. Discover in-situ alloy homogenization with rePOWDER.

Recycling of Ti alloy machining chips | Case study

Discover how arcMELTER efficiently transforms CNC machining chips into high-quality ingots for severe plastic deformation (SPD). This case study highlights the use of a getter for inert atmosphere purification before homogenization. Learn about this sustainable, cost-effective closed-loop approach to metal production and material valorization.

Alloy preparation from irregular powder | Case study

Learn how arcMELTER transformed poorly flowing irregular powder into spherical feedstock suitable for Direct Energy Deposition. This case study details how the process also enabled alloy homogenization with an additional element, improving thermal stability and precipitation hardening, unlocking new possibilities for advanced component manufacturing.

Custom master alloy preparation | Case study

Explore how arcMELTER facilitated the creation of a custom Mg-25%Ag master alloy, bypassing temperature limitations and evaporation issues of induction melting. This case study demonstrates a novel approach to precise alloying with pure elements, offering greater control and flexibility for material property tailoring without relying on commercially available master alloys. Discover the benefits for mechanical, corrosion, and thermal properties.

Metal matrix composites | Case study

Discover how we utilized arc melting (arcMELTER) for in-situ phase transformation in TiB2/Ti MMCs, achieving unique dendritic structures and avoiding additive manufacturing challenges. This case study highlights the potential of this technology for advanced materials in aerospace and automotive applications. Explore the property testing results and future research directions.