10 Advantages of Additive Manufacturing for Sustainable Metal Production

Powder waste is a costly problem in additive manufacturing. Discover how effective metal powder recycling with Powder2Powder can increase sustainability and save money.

10 Uses of Silicon: From Basic Research to Advanced Processes

Silicon's uses are vast, from electronics to metallurgy. Our blog explores these applications and how AMAZEMET supports innovation in silicon powder technology.

Heat Resistant Metals: Exploring the Strongest Materials for Extreme Temperatures

Whether it’s inside a jet engine, a nuclear reactor, or a manufacturing line working in extreme conditions, some environments are just too hot for ordinary materials to survive. In these high-stakes scenarios, heat resistant metals step in — built to withstand high temperatures that would melt or destroy conventional metals.

Precious Metals Atomization: Overcoming Challenges in Handling High-Value Materials

In this article, we explore precious metals atomization and how to overcome the challenges in handling high-value materials

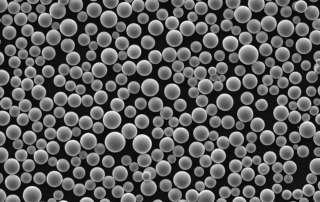

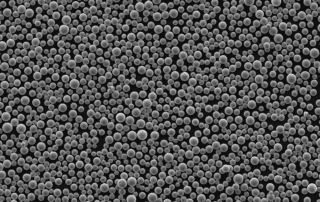

How to Make Metal Powder? What Metals Can Be Atomized Using Ultrasonic Technology?

Our latest blog post explores the essential methods of making metal powder, from industrial-scale gas atomization to advanced processes for research. Read the full guide to see how each technique compares and discover why ultrasonic atomization offers unmatched flexibility for developing nearly any alloy.